Drill clamp universal for large high-speed printing roller

A high-speed printing and drilling jig technology, applied in the direction of clamping, clamping devices, manufacturing tools, etc., can solve the problems of long time-consuming connection holes, difficult roller assembly coaxiality requirements, etc., to achieve low manufacturing costs and ensure processing Quality, fast clamping results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

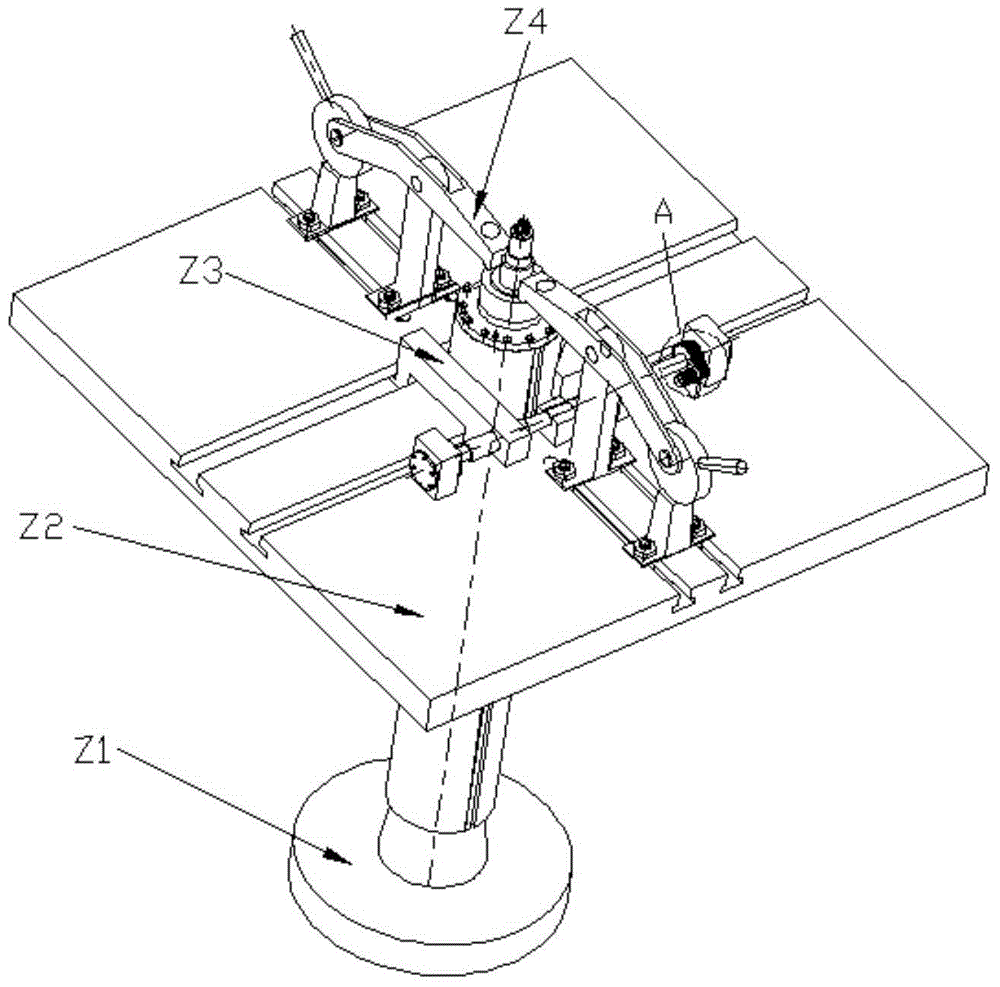

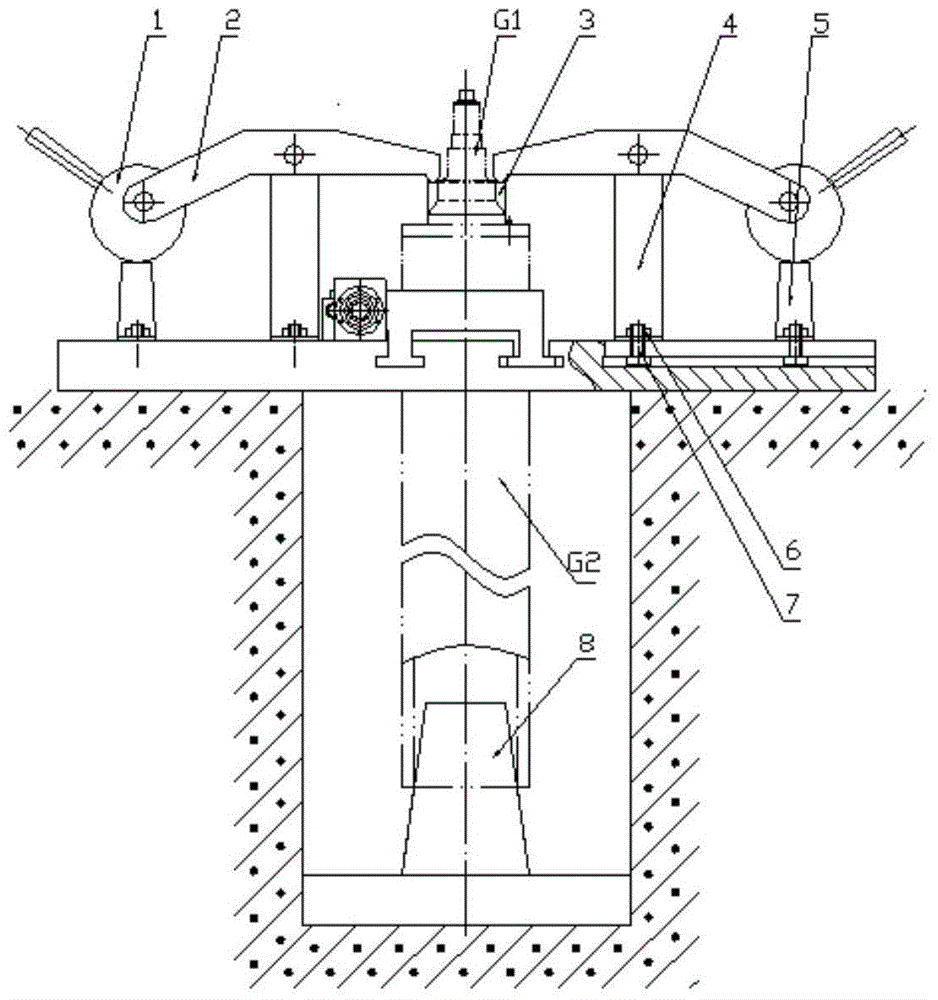

[0020] Such as Figure 1 to Figure 5 As shown, a series of large-scale high-speed printing roller assembly hole fixtures are invented, including an underground workbench Z1, a ground workbench Z2, a self-centering device Z3, and a radial cam clamping device Z4.

[0021] Such as figure 1 , 3 As shown, the underground workbench Z1 is provided with a flat top 8.

[0022] Such as figure 1 , 3 As shown in , a self-centering device Z3 and one to two sets of radial cam clamping devices Z4 for clamping the printing roller are installed on the ground workbench Z2.

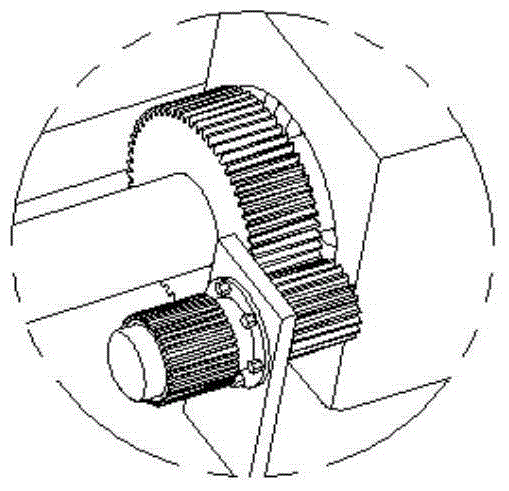

[0023] Such as figure 1 , 3 , 4, the self-centering device Z3 is composed of a coaxial double-helix linkage mechanism, left and right threaded sliders 10, 11, and a motor drive device. The motor drive device drives and connects the coaxial double-helix linkage mechanism. The double-helix scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com