High-strength aluminum alloy embedded channel module and embedded channel forming process

A pre-embedded channel and molding technology technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problems of uneven thickness around the inner riveting head, damage to the surface anti-corrosion layer, and shorten the service life, etc., to achieve guaranteed Product quality and appearance quality, improved strength and load capacity, and the effect of high load bearing level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation modes and specific operation processes, but the protection scope of the present invention is not limited to the following described embodiment.

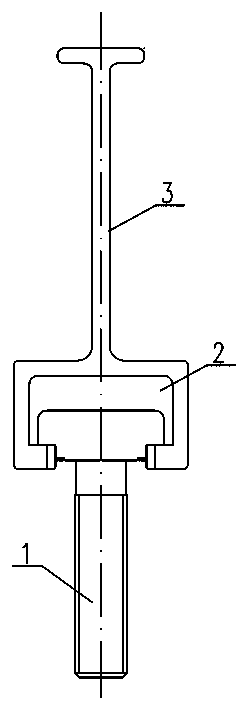

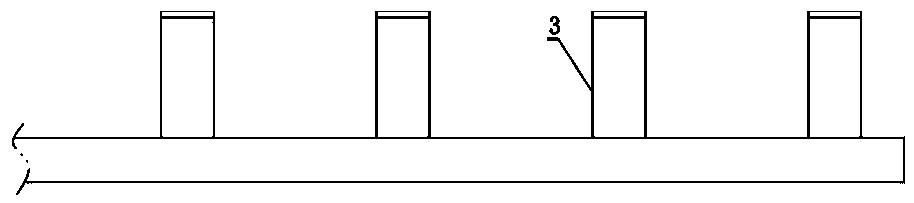

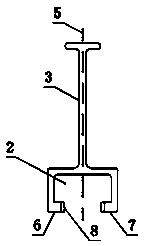

[0038] like Figure 1-7 As shown, the high-strength aluminum alloy pre-embedded channel assembly of the present invention includes a pre-embedded channel and a T-shaped bolt 1 arranged in the pre-embedded channel groove; The groove 2 is formed by a plurality of anchor rods 3 that are fixedly connected to the back of the groove bottom at an axial interval, and a process hole 4 is opened on the groove bottom of the C-shaped groove 2 between the adjacent two anchor rods 3; the anchor rods 3 and C The groove 2 is extruded into an integral structure by an aluminum extrusion machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com