Directional corn seeding machine

A seeder and corn technology, applied to seeder parts, spaced quantitative sowing machinery, etc., can solve problems affecting crop harvest, reducing photosynthesis time, cross-interference, etc., to ensure directional seed fall and directional growth, The effect of simple and reliable structure and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

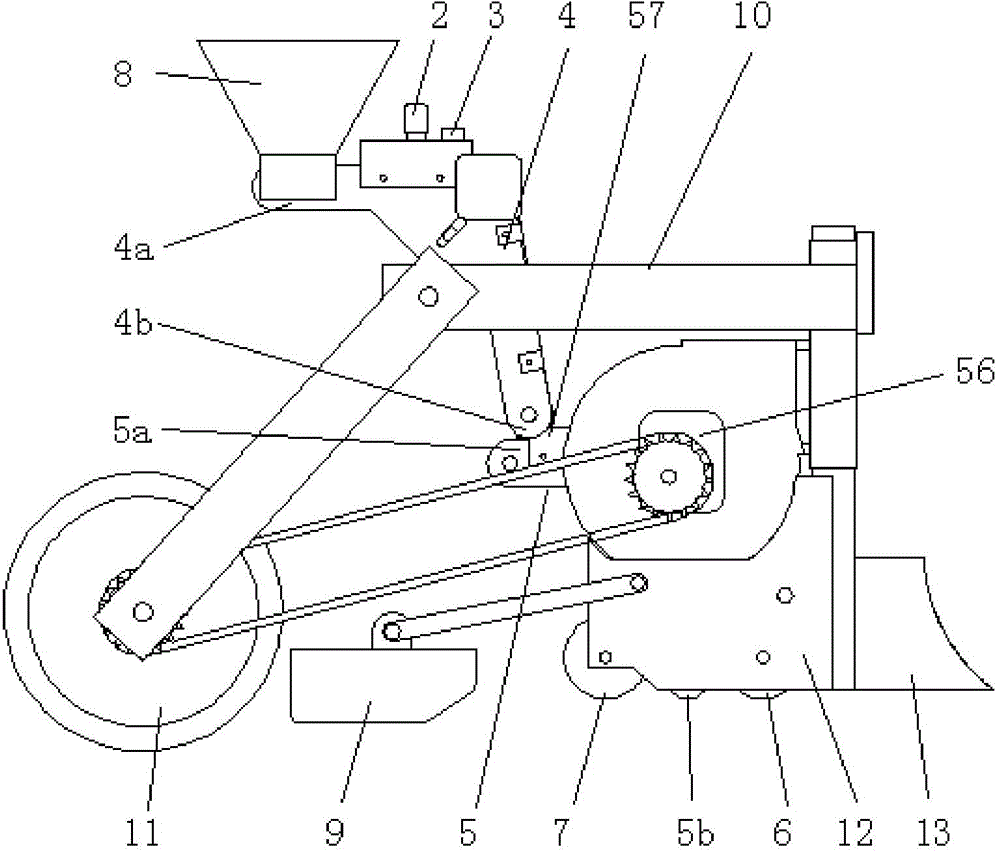

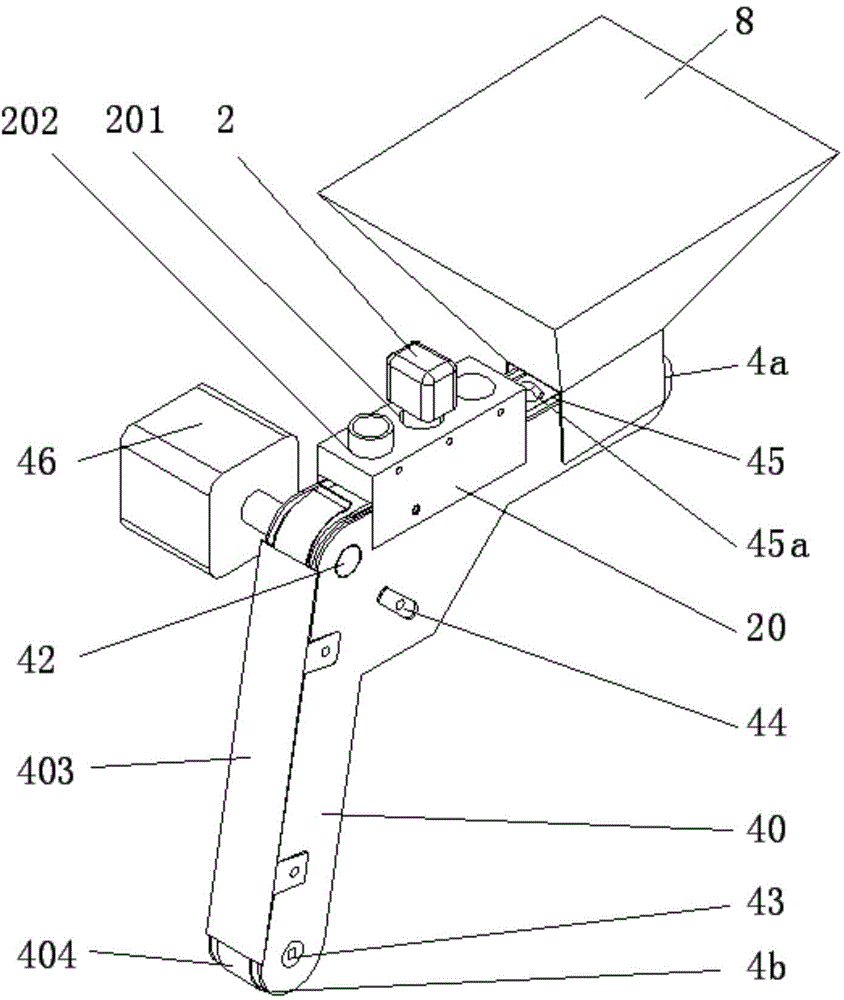

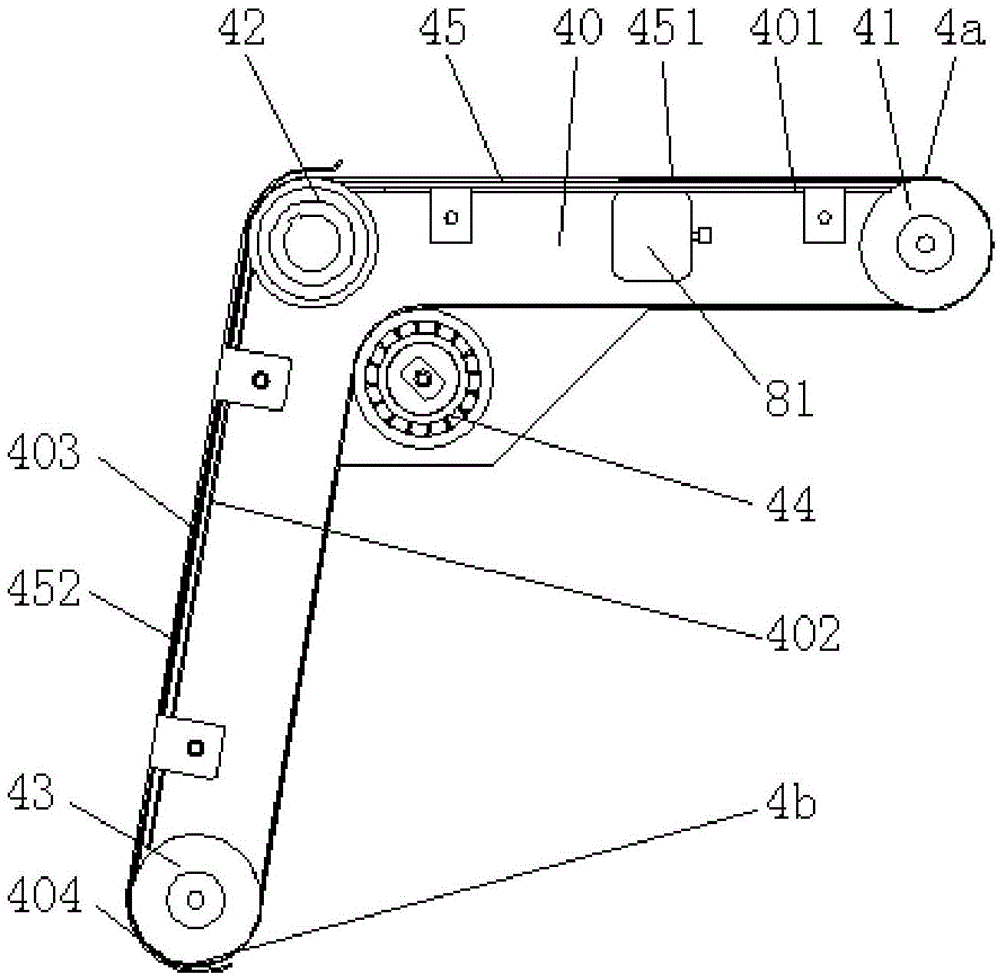

[0033] figure 1 It is the front view of the planter of the present invention. Such as figure 1 Shown, sower of the present invention comprises: sowing frame 10, and its bottom is provided with traveling wheel 11; The buffer hopper 8 that is used to hold corn grain that is installed on the sowing frame 10, its bottom has discharge port 8a ( Such as Figure 11 Shown); the grain alignment mechanism installed on the seeding frame 10 has a first feed end 4a and a first discharge end 4b, the first feed end 4a corresponds to the discharge port 8a, and is used to receive the buffer hopper 8. After the corn kernels are discharged, the first feeding end 4a receives the corn kernels, and the kernel alignment mechanism arranges the corn kernels according to a predetermined direction and transmits them to the first discharging end 4b; The mechanism 5 has a second feed end 5a and a second discharge end 5b, the second feed end 5a corresponds to the first discharge end 4b, and is used to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com