Lock stitch metal roof board system

A metal roof and roof panel technology, which is applied to roofs, roof cladding, and roofs using flat/curved panels, etc., can solve problems such as roof leakage, crooked, and roof cracking, and achieve enhanced wind resistance, improved airtight performance, The effect of enhancing waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

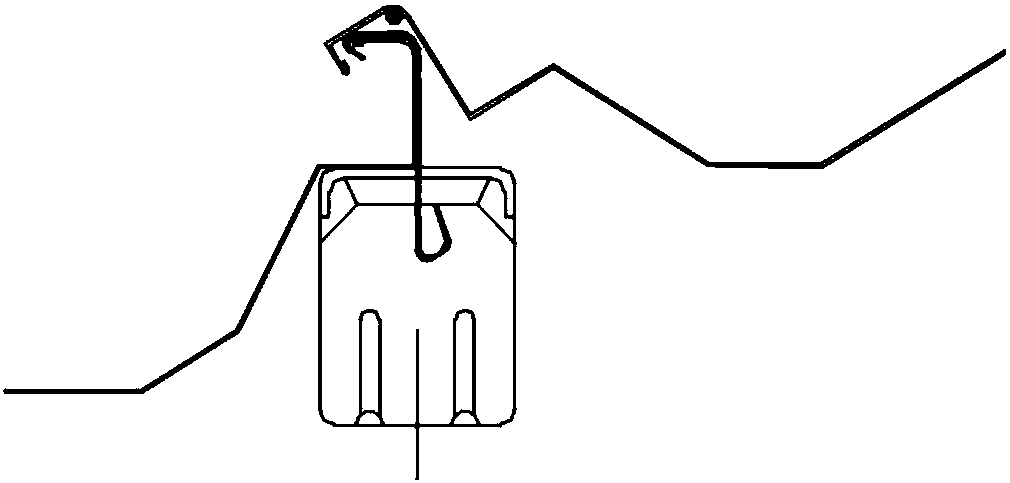

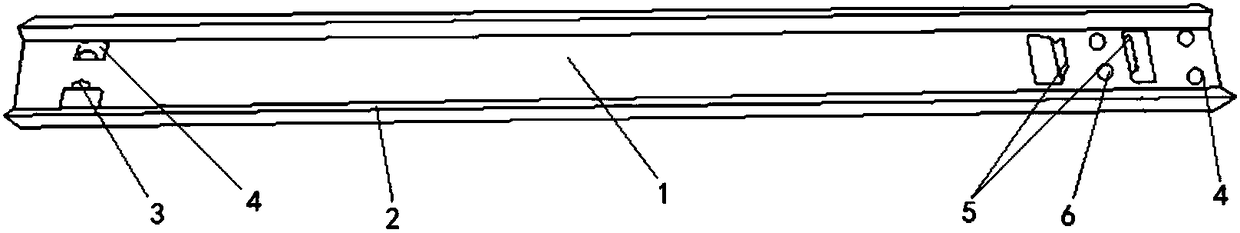

[0046] A lock seam metal roof panel system constructed asfigure 1 Shown, comprise roof panel, modular ruler and the connection bracket 7 that roof panel is fixedly connected on the modular ruler.

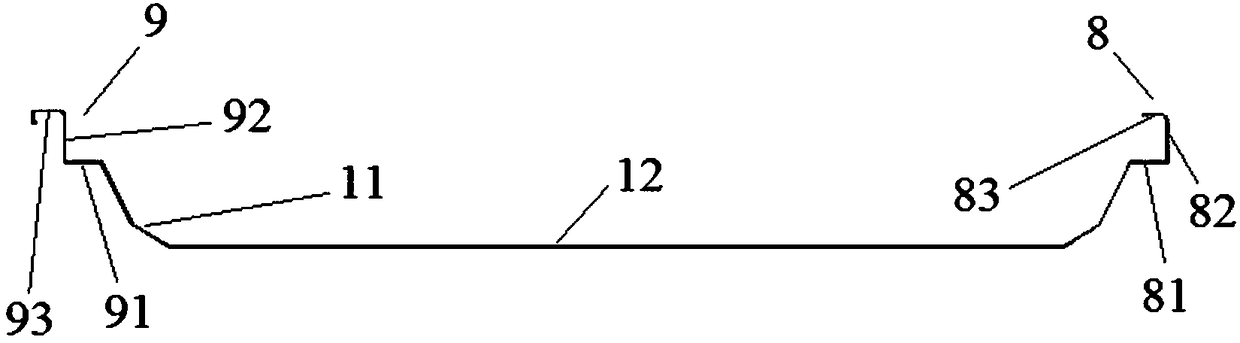

[0047] The structure of the roof panel is as figure 2 As shown, it includes a flat bottom plate 12 and a male rib 8 and a female rib 9 arranged at both ends of the flat bottom plate 12 , the male rib 8 and the female rib 9 are connected to the flat bottom plate 12 through a bent plate 11 . The male rib 8 comprises a horizontal lower plate 81, a vertical plate 82 and a male rib hook plate 83 connected in sequence, the horizontal lower plate 81 and the vertical plate 82 are perpendicular to each other, and the horizontal lower plate 81 passes through the curved plate 11 and the flat bottom plate 12. side connection.

[0048] The female rib 9 comprises a horizontal bottom plate 91, a long vertical plate 92 and a female rib hook plate 93 connected in sequence. The horizontal bottom pl...

Embodiment 2

[0057] A lock seam metal roof panel system, its structure is basically the same as that of Example 1, the difference is that in this example, the method of forming and fixing the roof panel is different from that of Example 1, and its process is as follows Figure 5 As shown, the following steps are taken:

[0058] (1) The roof panel is pre-bent when forming, pre-bending 0-70°, wrapping the female rib 9 of the roof panel on the male rib 8 of the adjacent roof panel to form a seam, and then the vertical seam of the seam The straight section is toward the end of the male rib 8. In this embodiment, in order to obtain the best effect, the middle part of the vertical section is pre-bent 30° toward the end of the male rib;

[0059] (2) bending and compressing the front end of the female rib 9 on the outer side of the male rib 8;

[0060] (3) Use the undercutting machine to occlude the male rib 8 and the female rib 9 and press the bending section to form a 360° locking seam to fix t...

Embodiment 3

[0063] A lock seam metal roof panel system, the structure of which is basically the same as that of Embodiment 1, the difference is that the front end of the male rib hook plate 83 used in this embodiment also has a male rib that is bent inward to form a hook-shaped structure. Rib reinforcing edge 84 also has inwardly bending at the front end of female rib hook plate 93 equally, forms the female rib reinforcing edge 94 of crotch structure, as Figure 7 , 8 shown. Through the design of the above-mentioned reinforced edge, the mechanical strength of the roof panel itself can be further improved during use due to the use of the edge-wrapping design, and on the other hand, it can also protect the end of the roof panel from wear and tear. The service life is reduced, and the third can also improve the sealing performance and safety performance. Adding the reinforced small side can not only solve the problem of the edge wave of the board, but also solve the overall strength of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com