Drum spring and insertion sleeve automatic assembling machine with rejecting function

A technology of automatic assembly machine and drum spring, which is applied to the assembly/disassembly of contact parts and the manufacture of contact parts, etc. It can solve the problems of low assembly efficiency, affecting the yield, and easy loss, so as to achieve uniform processing time, improve efficiency, and reduce The effect of time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

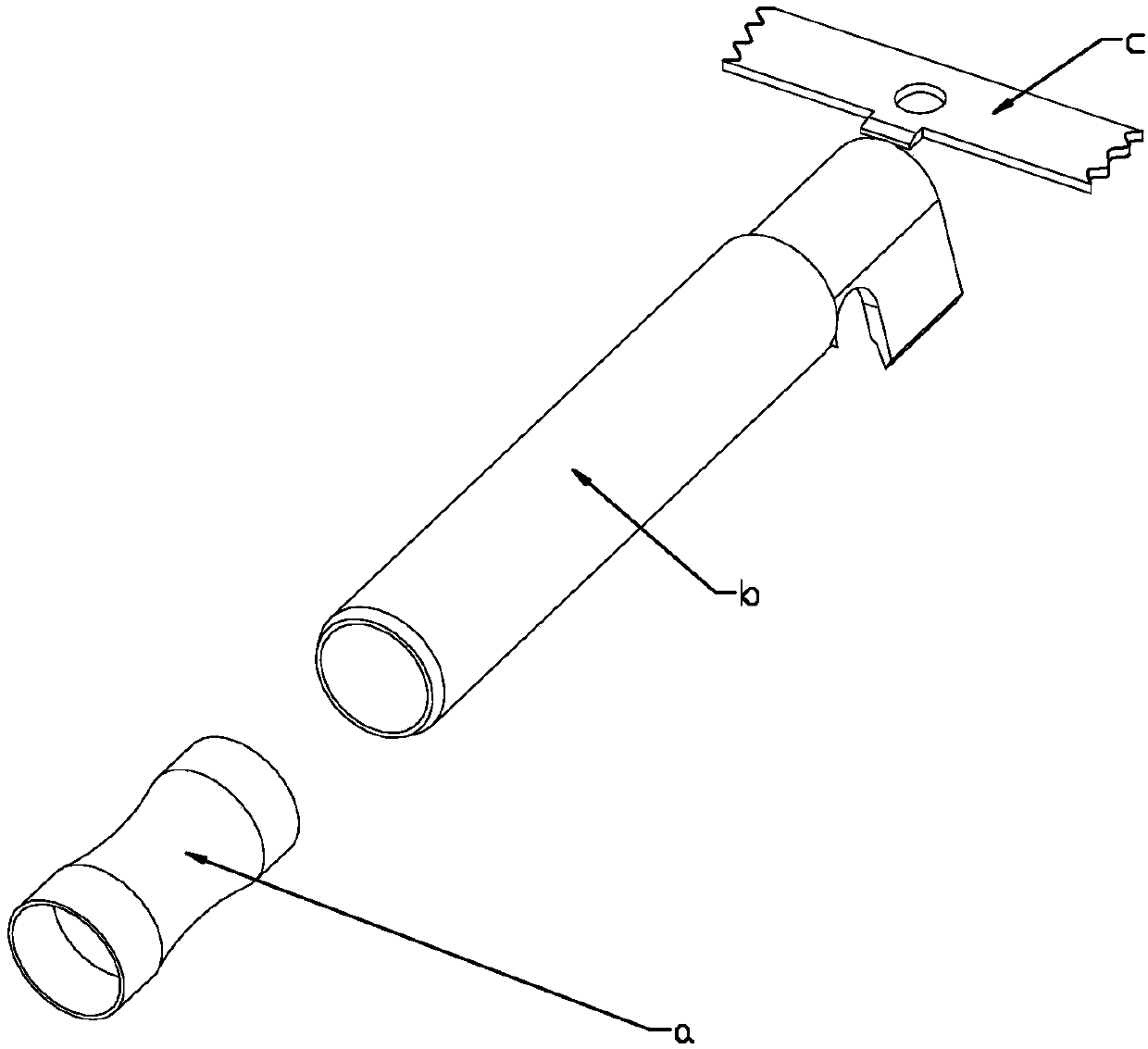

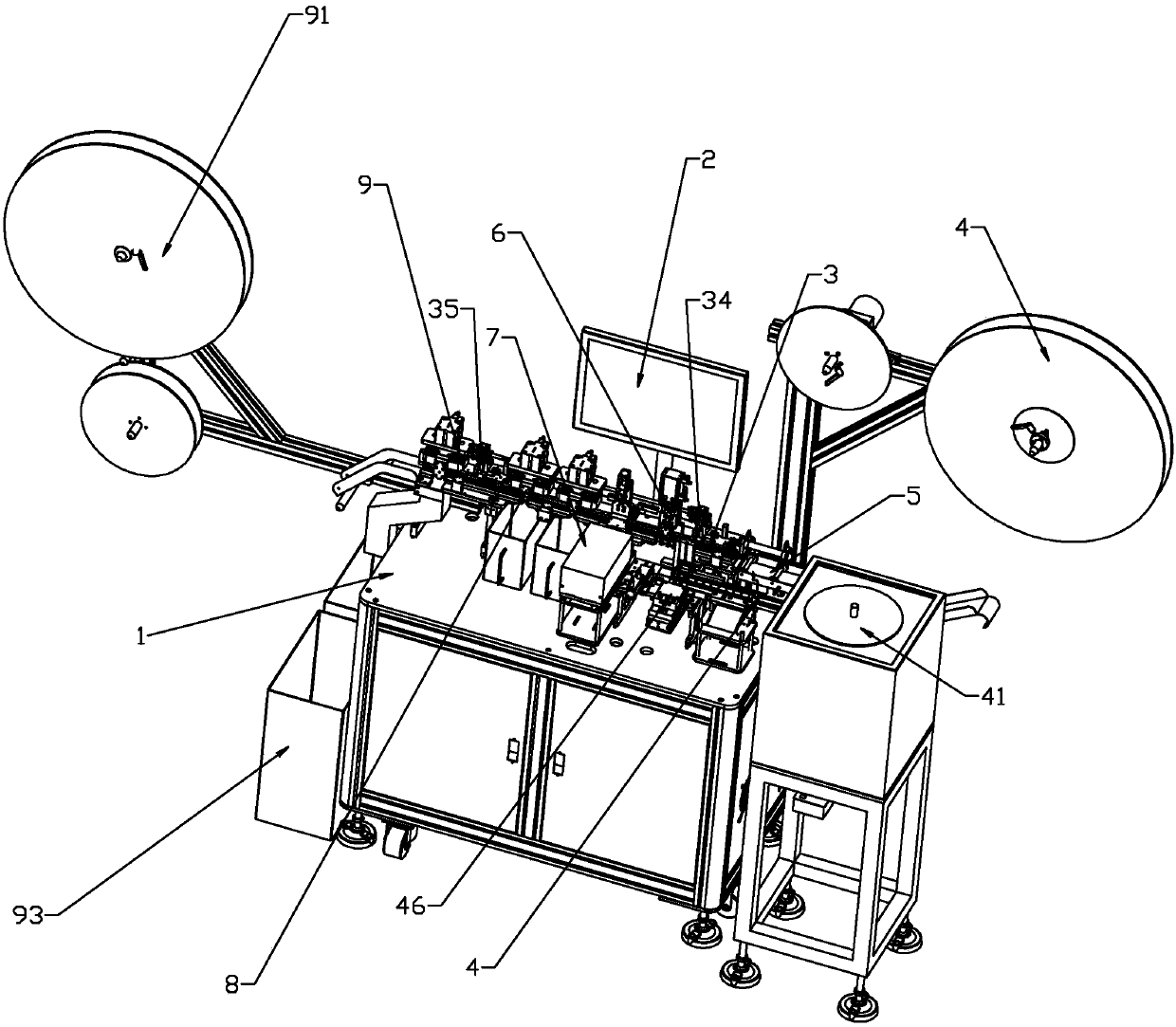

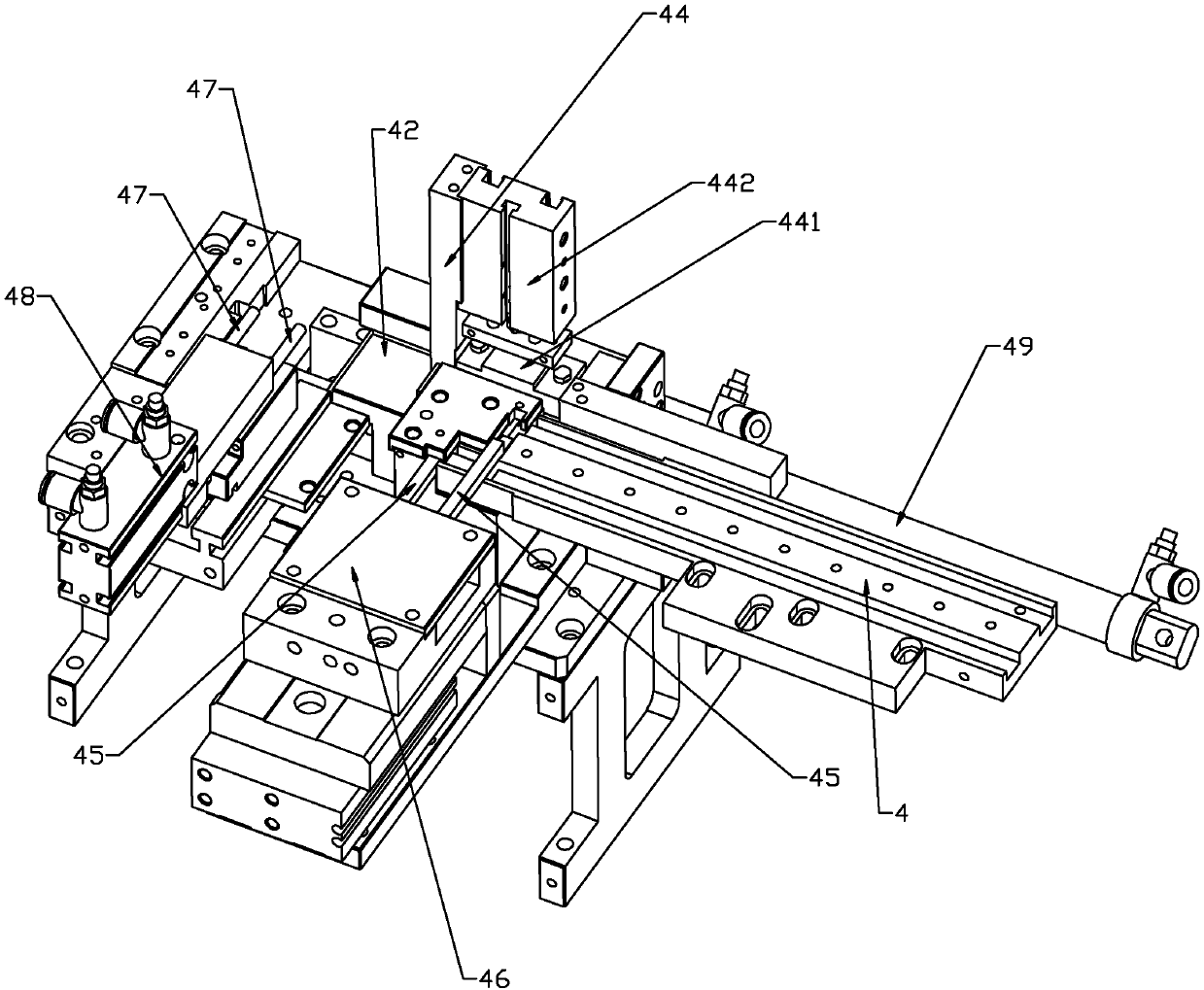

[0033] like figure 1 As shown, the explosion diagram of the drum spring a and the sleeve b is disclosed, and the sleeve b is arranged on the coil c, as shown in figure 2 — Figure 11 As shown, the present invention discloses an automatic drum spring socket assembly machine with a rejecting function, including a frame 1 and a control processor 2, the control processor 2 is an existing component, and is used to control the coordination of various devices and image comparison , the frame 1 is provided with the main transmission track 3 and the drum spring distribution track 4 in parallel, the main transmission track 3 is provided with a plug-in transmission device for transmitting the socket along the main transmission track 3, and the main transmission track 3 is arranged successively along the transmission direction. Coil unwinding device for unrolling coils with sockets arranged side by side, coil leveling device for leveling the unrolled coils 5, fixing device for fixing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com