Efficient blocking coal shoveling device

A coal shovel and agglomeration technology, which is applied in the directions of slitting machinery, propulsion, earthwork drilling, etc., can solve the problems of reducing productivity and block rate, difficulty in operation control, waste of resources, etc. The structure is simple and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

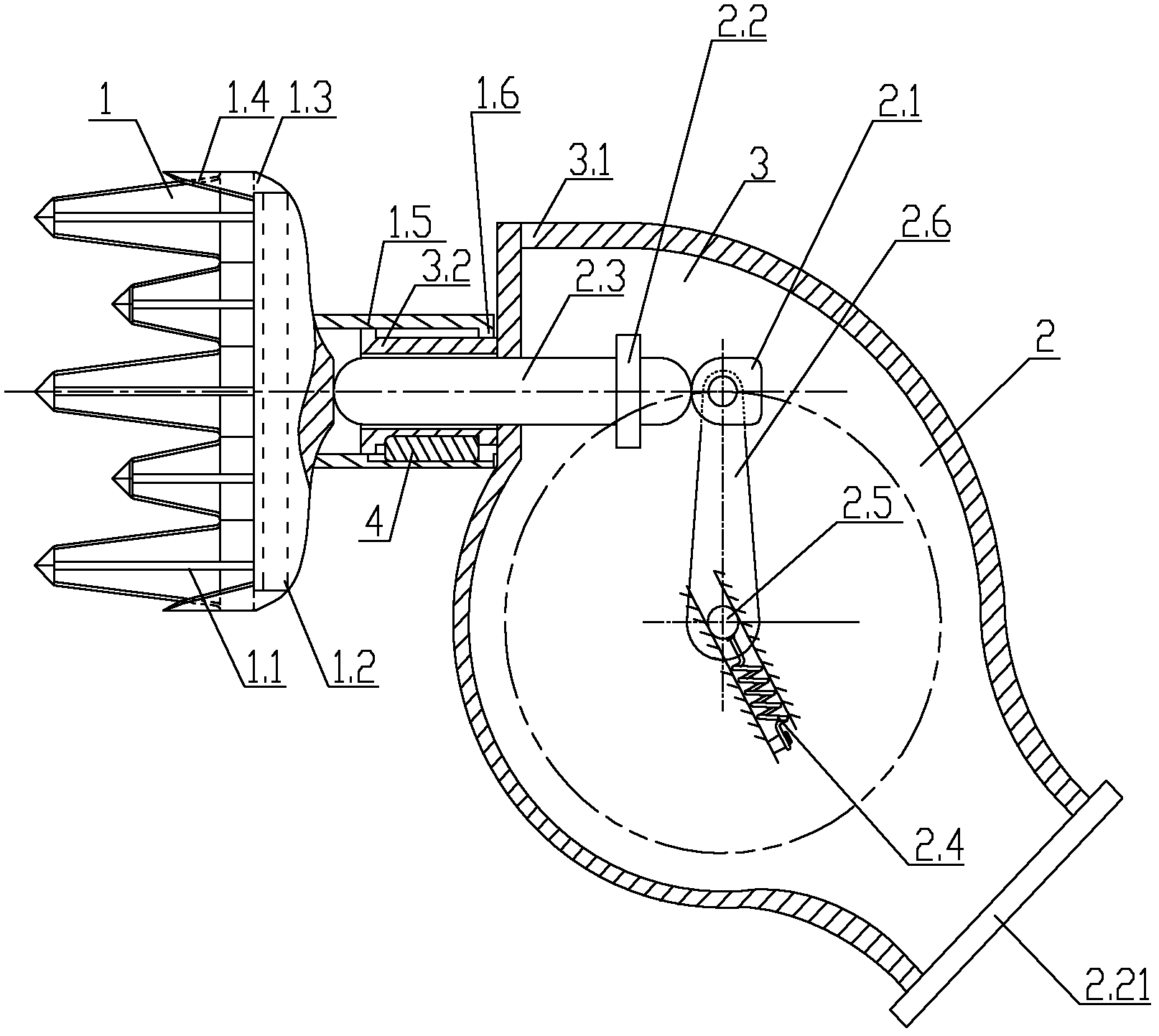

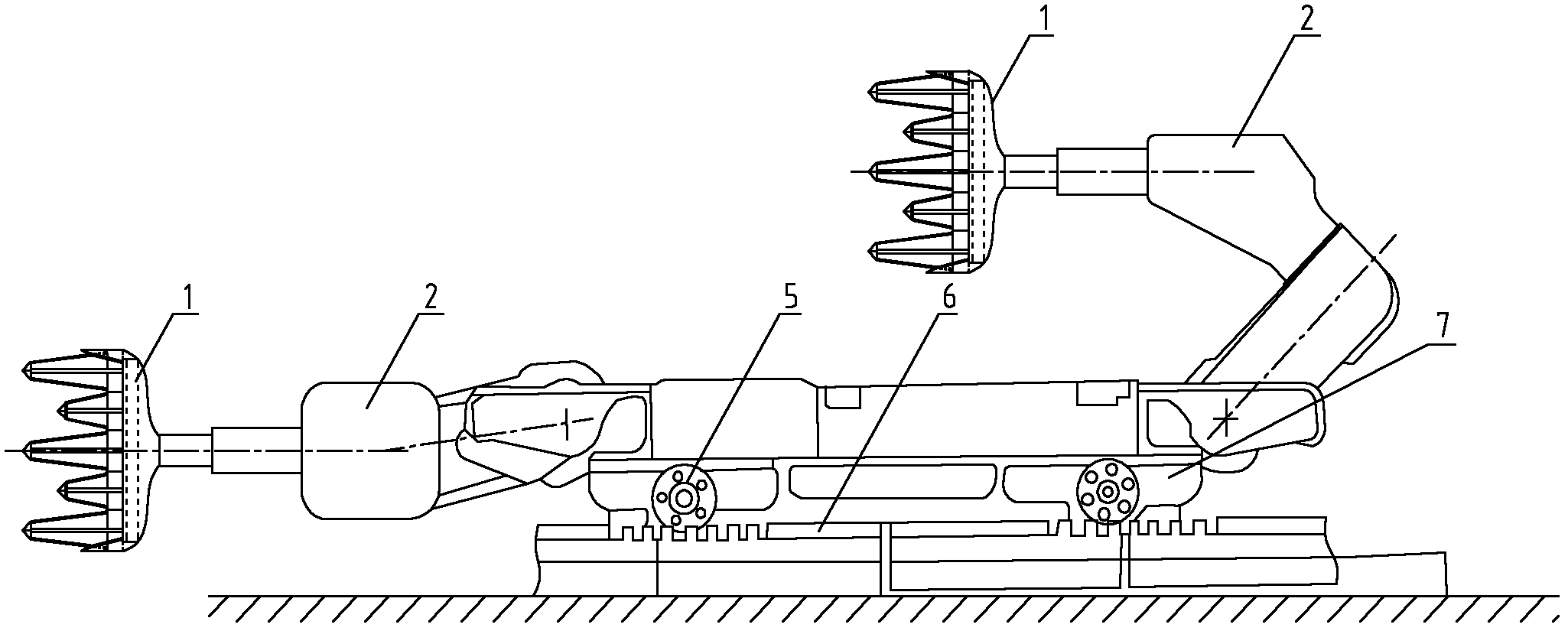

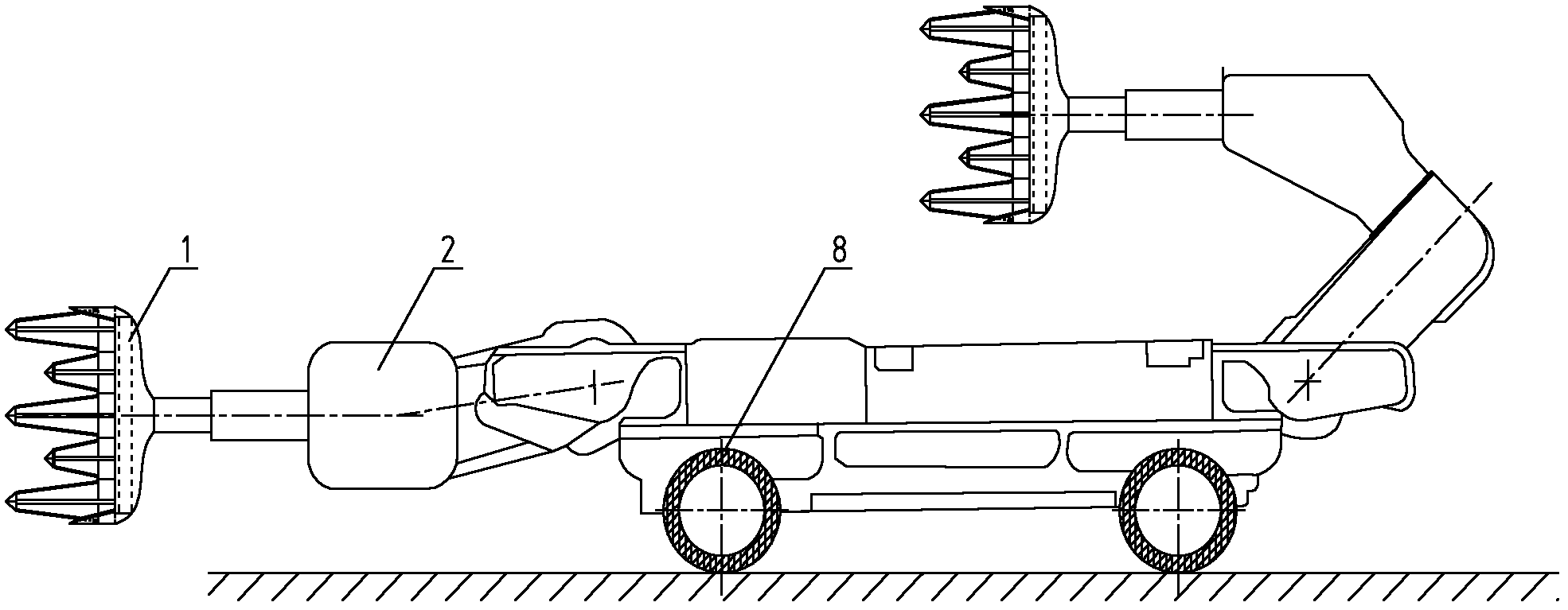

[0048] figure 1 and figure 2 It is the high-efficiency block coal scraper described in Embodiment 1. The equipment includes a shoveling mechanism, the shoveling mechanism includes a shovel head 1 and an impact device 2, the shovel head 1 includes shovel teeth 1.1 and a fixed part 1.2, the shovel teeth 1.1 are fixed on the fixed part 1.2, and the shovel teeth are arranged in a "|" shape, """ shape, "]" shape or a combination of the above shapes, the rear part of the fixed part 1.2 is provided with an impact stroke guide rod 1.5, the impact stroke guide rod 1.5 is slidingly connected with the guide sleeve, and the guide sleeve is arranged on the impact device and / or Or on the frame, the impact device includes a support frame and a driving mechanism. The impact device 2 is located behind the shovel head 1, and the shovel head 1 and the impact device 2 are two independent parts. The impact device and the impact stroke guide rod 1.5 are split Structure. The shovel teeth 1.1 may ...

Embodiment 2

[0054] Figure 5 It is the high-efficiency block coal shovel described in embodiment 2. The difference from Embodiment 1 is that no buffering component is arranged on the rotating shaft in the rotary hammer device.

[0055] Others are with embodiment 1.

Embodiment 3

[0057] Figure 6 It is the high-efficiency block coal shovel described in embodiment 3. The difference from Embodiment 1 is that the rotating shaft 2.5 in this device is connected with the driving part 2.18 through a transmission chain or a transmission belt, and there is a certain transmission ratio between the rotating shaft 2.5 and the driving part 2.18, thereby realizing the rotation of the rotating shaft 2.5. Acceleration and / or variable speed, so the rotary shaft 2.5 together with the drive components constitutes a variable speed transmission. The variable speed transmission device drives the hammer handle to rotate and impact the punch rod, and the punch rod impacts the shovel head to move forward, realizing the impact of the shovel head to drop coal and clean the surface. By arranging the variable speed transmission device, not only the rotation speed of the rotating shaft 2.5 can be increased, but also the reaction force produced by the hammer head in the process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com