Material leveling and compacting device of compartment

A technology of leveling and carriage, which is applied in the field of leveling and compacting devices for bulk materials, which can solve the problems of potential safety hazards, damage to railway facilities, and no self-locking function, and achieve the effect of eliminating potential safety hazards and reducing running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

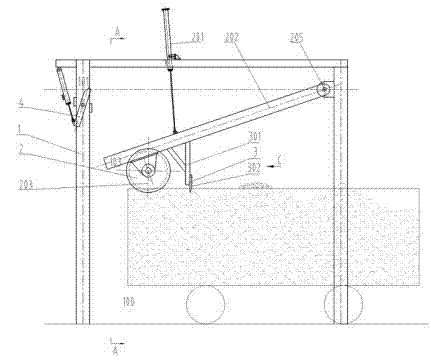

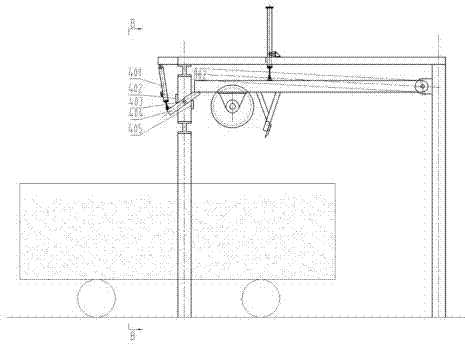

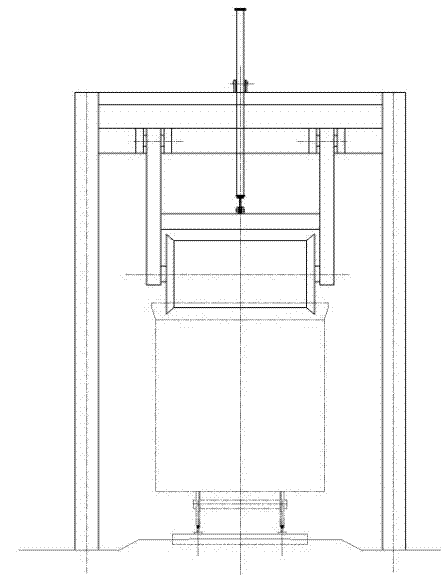

[0029] exist figure 1 , figure 2 The preferred embodiments of the working state and the non-working state of the present invention are respectively shown in the figure, including a frame body 1 arranged above the compartment and a leveling and compacting mechanism 2 and a self-locking mechanism 4 installed on the frame body 1. One end of the landing gear 202 of the leveling and compacting mechanism 2 is hinged on the frame body 1 through the rotary shaft 205, and the free end of the landing gear 202 is suspended on the frame body 1 through the oil cylinder 201. The elongation of the 201 adjusts the position of the flat pressure roller 203 when it is working, and the pressure of the oil cylinder 201 is adjusted to adjust the pressure of the flat pressure roller 203 on the material.

[0030] When the flat pressing roller 203 is not working, the undercarriage 202 of the leveling and compacting mechanism 2 is brought to a horizontal position, and the free end of the undercarriag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com