Underground coal bunker cleaning robot

A technology for robots and warehouse clearance, applied in underground transportation, clockwork mechanisms, load hanging components, etc., to achieve the effect of mechanization and reduction of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

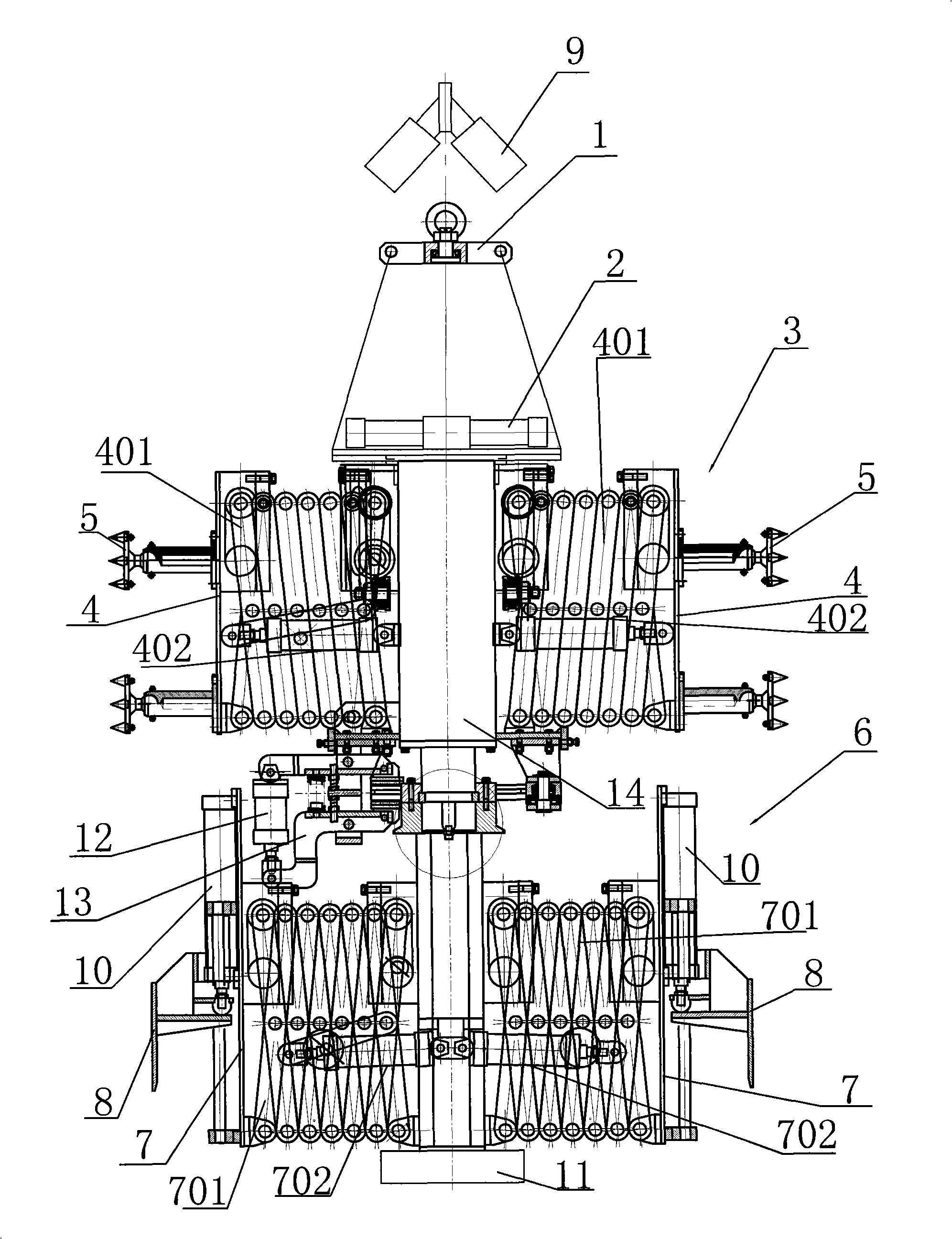

[0022] In conjunction with the accompanying drawings, an underground coal bunker clearing robot includes: a suspension mechanism 1 used to connect with the traction cable of the hoisting device outside the bunker; a drive mechanism 2 used to drive the following upper mechanism and lower mechanism to rotate and swing respectively; The upper mechanism 3 used to support the warehouse wall for positioning, the upper mechanism 3 is provided with three telescopic horizontal support arms 4, and the free end of the lateral support arms 4 is provided with a contact part 5 with a pointed object; it is used for eradicating the warehouse wall The lower mechanism 6 of the condensate, the lower mechanism is provided with two telescopic horizontal working arms 7, and the free end of the horizontal working arms is provided with a coal shovel 8 that can reciprocate up and down; The last camera 9, the camera 9 is connected with the monitor outside the warehouse. The specific instructions are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com