Crawler-type T-shaped scraping plate machine coal collecting mechanism

A technology of crawler type and scraper machine, which is applied in the direction of slitting machinery, earth drilling and mining, etc. It can solve the problems affecting the forward movement of equipment, and achieve the effect of small dust, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

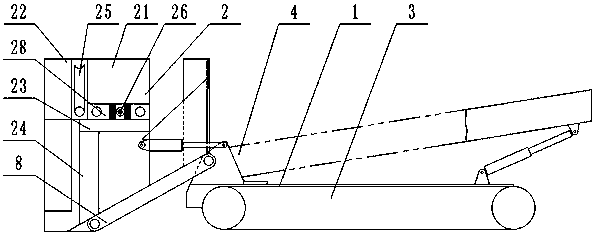

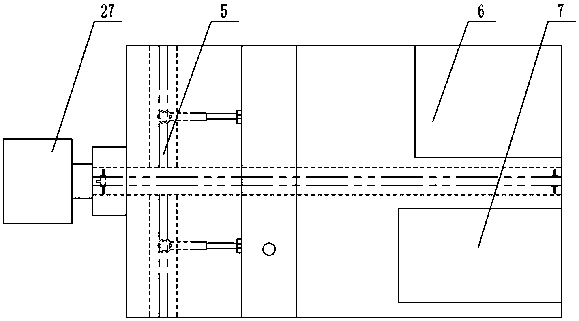

[0013] Such as figure 1 , figure 2 As shown, a crawler-type T-type scraper coal collection mechanism of the present invention includes a coal collection mechanism body 1, a coal collection part 2 and a crawler-type walking part 3, and the coal collection part 2 is located in front of the coal collection mechanism body 1. The crawler-type walking part 3 is set at the bottom of the coal collection mechanism body 1, and the top of the coal collection section 2 is provided with a coal shovel plate 8, and one end of the coal shovel plate 8 is set on the coal collection mechanism body 1 The bottom of the coal shoveling plate 8 is provided with a T-shaped scraper machine 5 for gathering coal, and the middle part of the coal collection mechanism body 1 is provided with a scraper conveyor 4, and the scraper conveyor 4 transports the coal collection part 2 The collected lump coal is transported away;

[0014] The structure of the coal collection part 2 is: comprising a motor 21, a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com