Efficient dust-prevention boiler feeding device

A feeding device, high-efficiency technology, applied in loading/unloading, transportation and packaging, conveyor objects, etc., can solve problems such as insufficient safety, labor consumption, low efficiency, dust splashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical solution of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

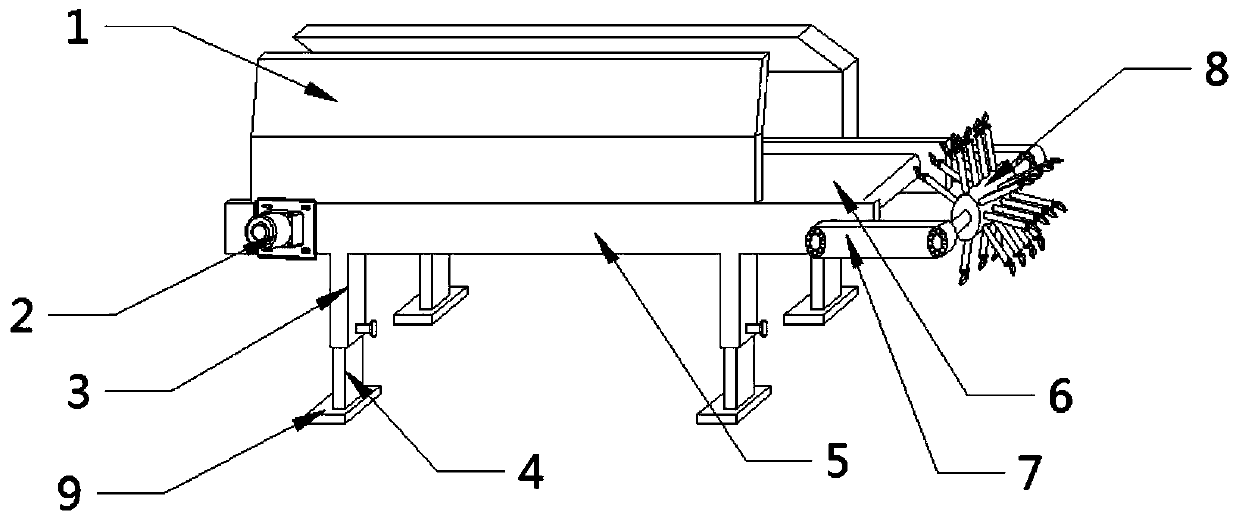

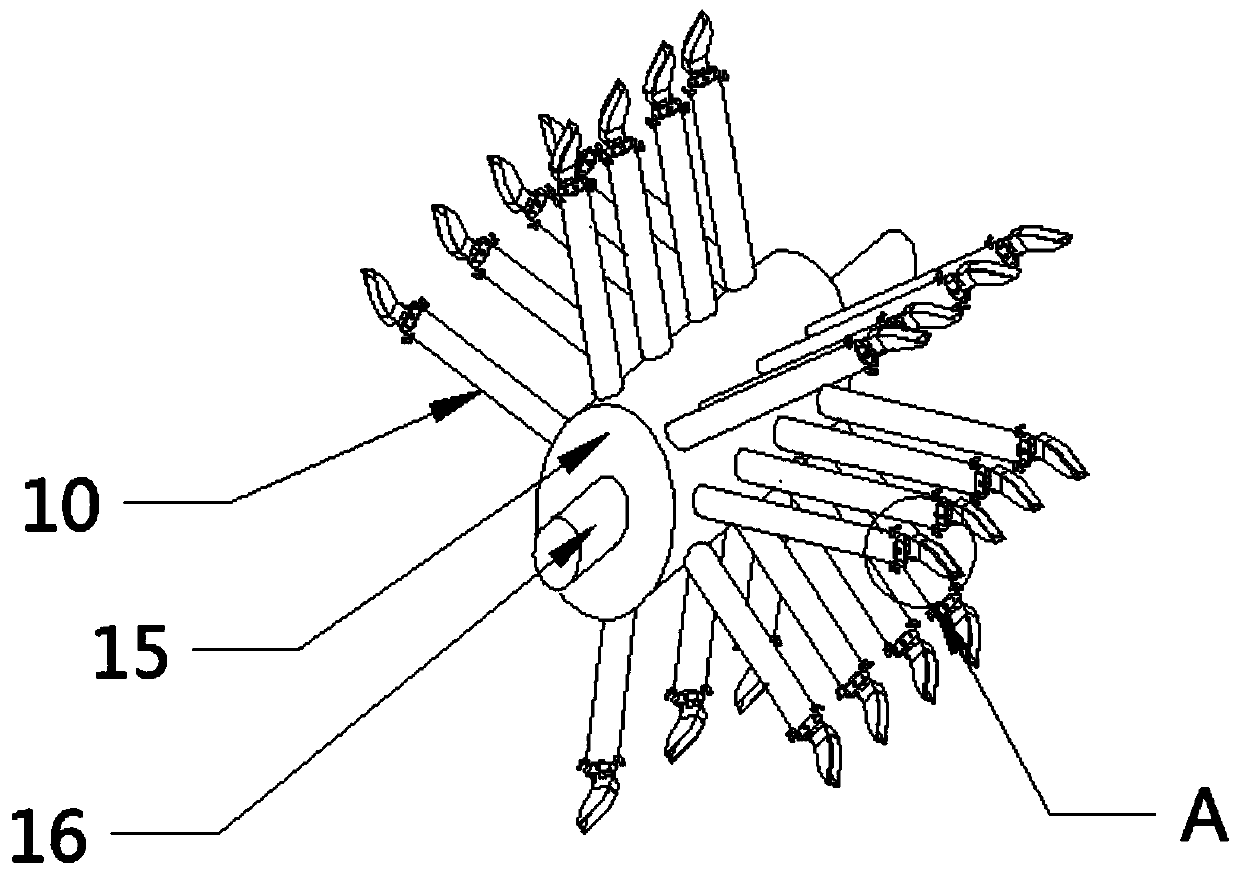

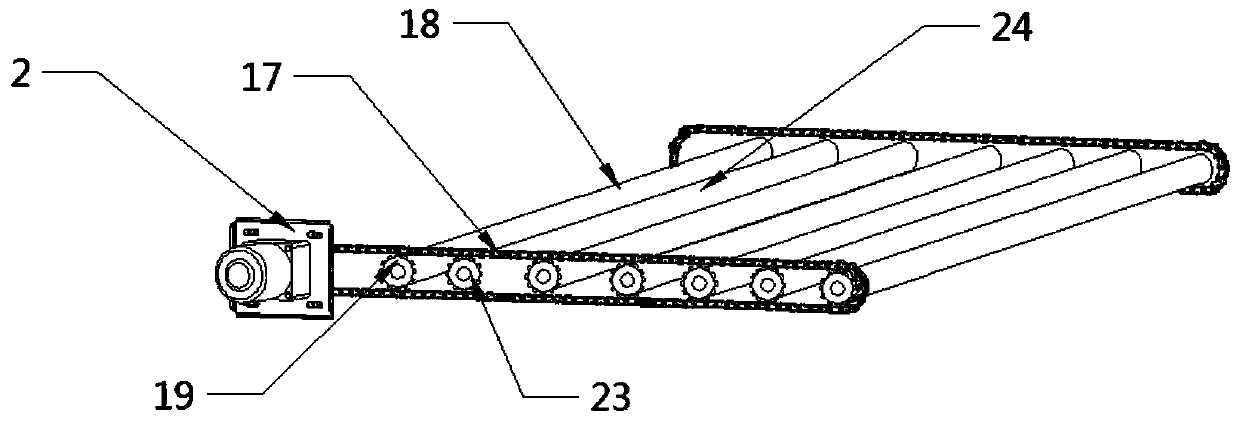

[0025] like Figure 1-Figure 5 As shown, a dust-proof and efficient boiler feeding device provided in this embodiment includes two sets of side fixing plates 5 and a drive motor 2 installed on the outer end of a set of side fixing plates 5. The output end of the drive motor 2 passes through The inner side of the side fixing plate 5 is installed with a main rolling roller 18, the outer ends of the main rolling roller 18 are provided with a main transmission gear 19, the outer side of the main transmission gear 19 is engaged with a transmission chain 17, and the inner side of the transmission chain 17 is along its axial direction. There are secondary transmission gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com