Mobile inspection type float coal cleaning system and working method thereof

A technology of sliding system and floating coal, which is applied in the direction of closed-circuit television system, earth drilling, cutting machinery, etc., can solve the problems affecting the moving efficiency of scraper conveyor, unfavorable coal mining face, and affecting coal mining efficiency, etc. Achieve the effect of stable detection effect, fast speed and convenient bucket unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

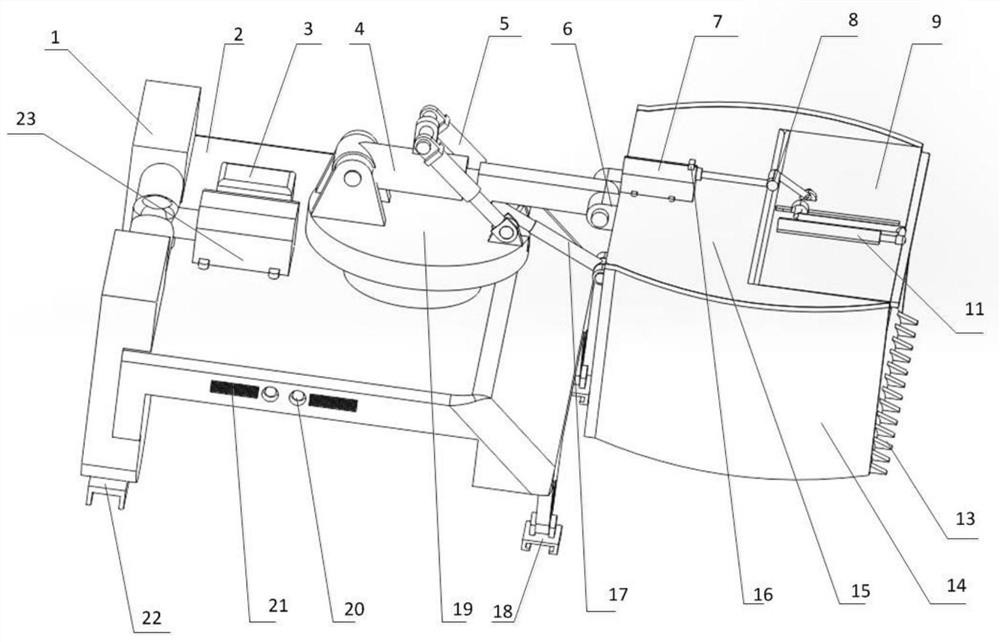

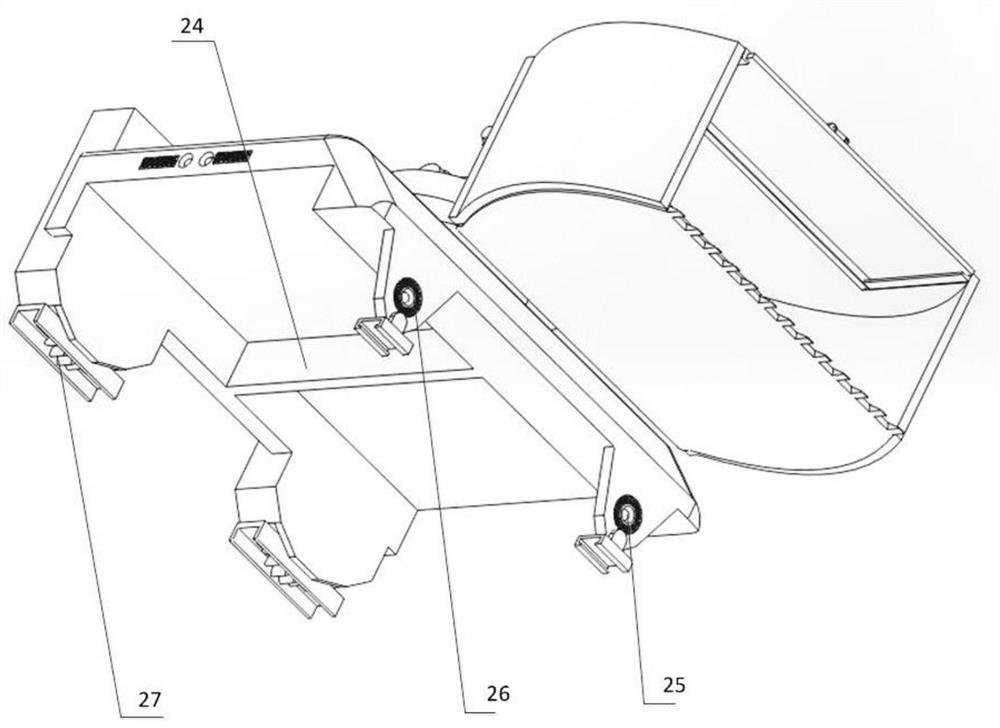

[0061] A mobile inspection floating coal cleaning system, such as Figure 1-5 As shown, the car body 2 is included, and the car body 2 is provided with a sliding system, a machine vision and control system 3, a rotating system 19 and a coal shoveling system;

[0062] The sliding system is arranged under the car body 2, and is used to cooperate with the scraper conveyor to realize the front and rear movement of the car body. The rotating system 19 can rotate back and forth relative to the car body 2. The coal shoveling system is arranged on one side of the car body 2, and is connected Rotary system 19 is connected for shoveling coal;

[0063] Machine vision and control system 3 includes interconnected PLC controller and machine vision system, which is protected by a protective shell outside. The machine vision system is used to continuously collect images to judge the timing of execution actions, and transmit signals to the PLC controller. PLC The controller is connected with ...

Embodiment 2

[0065] A mobile inspection type floating coal cleaning system, the structure is as shown in embodiment 1, the difference is that the machine vision system includes a visual sensor, a high-speed image acquisition system, a special graphics processing system and a computer, and the computer is connected to a PLC controller;

[0066] The visual sensor includes an image sensor and a light projector. The image sensor is used to collect the distance between the car body and the end of the coal shearer or scraper conveyor and the height of the floating coal seam in real time. The light projector is used to supplement light for the image sensor so that the image sensor The image can be received more clearly, the image sensor and the light projector are embedded in the interior of the car body 2, and the exterior is protected by toughened glass;

[0067]The analog video signal collected by the visual sensor is transmitted to the high-speed image acquisition system. The high-speed image ...

Embodiment 3

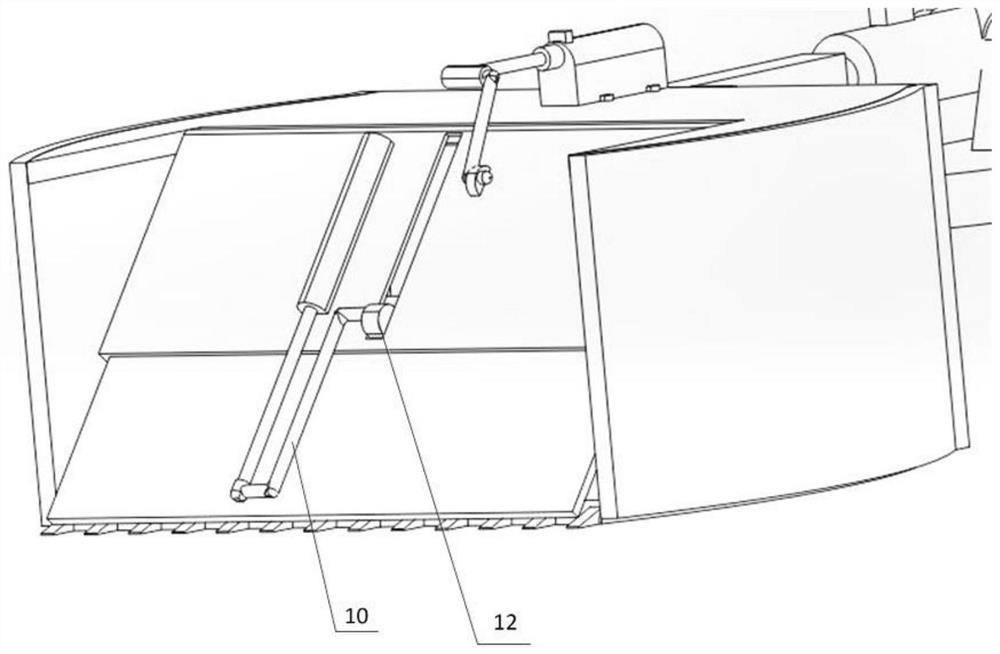

[0078] A mobile inspection type floating coal cleaning system, the structure of which is shown in Embodiment 2, the difference is that the visual sensor also includes a laser radar sensor 16, and the laser radar sensor 16 is located on the coal shoveling system for detecting coal mining face The distance from the bucket of the coal shoveling system to avoid collisions when shoveling coal.

[0079] Utilizing the detection distance of the laser radar sensor 16 is the prior art. When the bucket is moved forward to charge coal, the laser radar sensor constantly detects the distance between the laser radar sensor itself and the coal mining face, and then knows the distance between the bucket and the coal wall. The distance between buckets is compared with the set value in the PLC controller. When the distance decreases to the set value, the bucket stops advancing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com