Patents

Literature

84results about How to "Prevent rolling out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

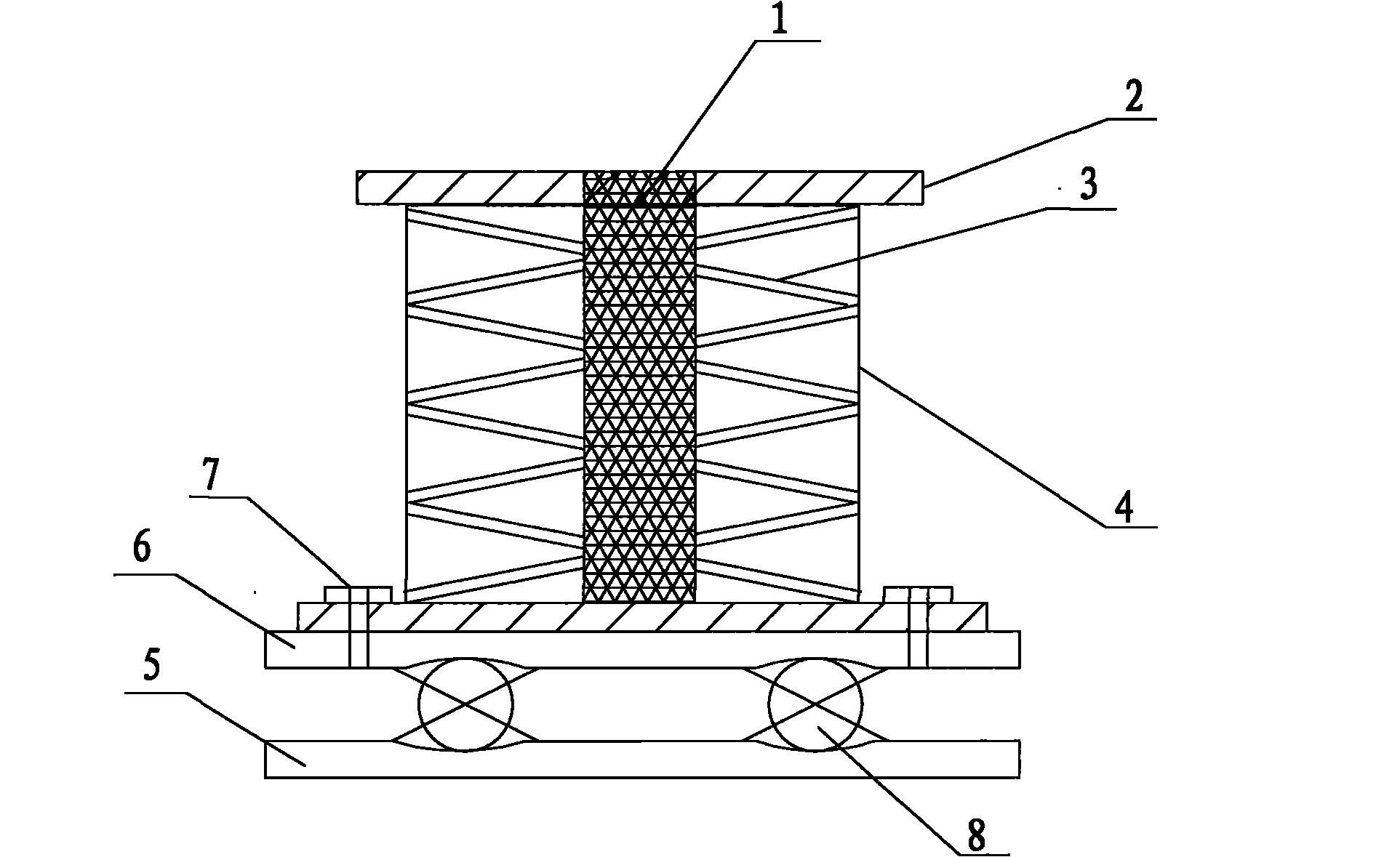

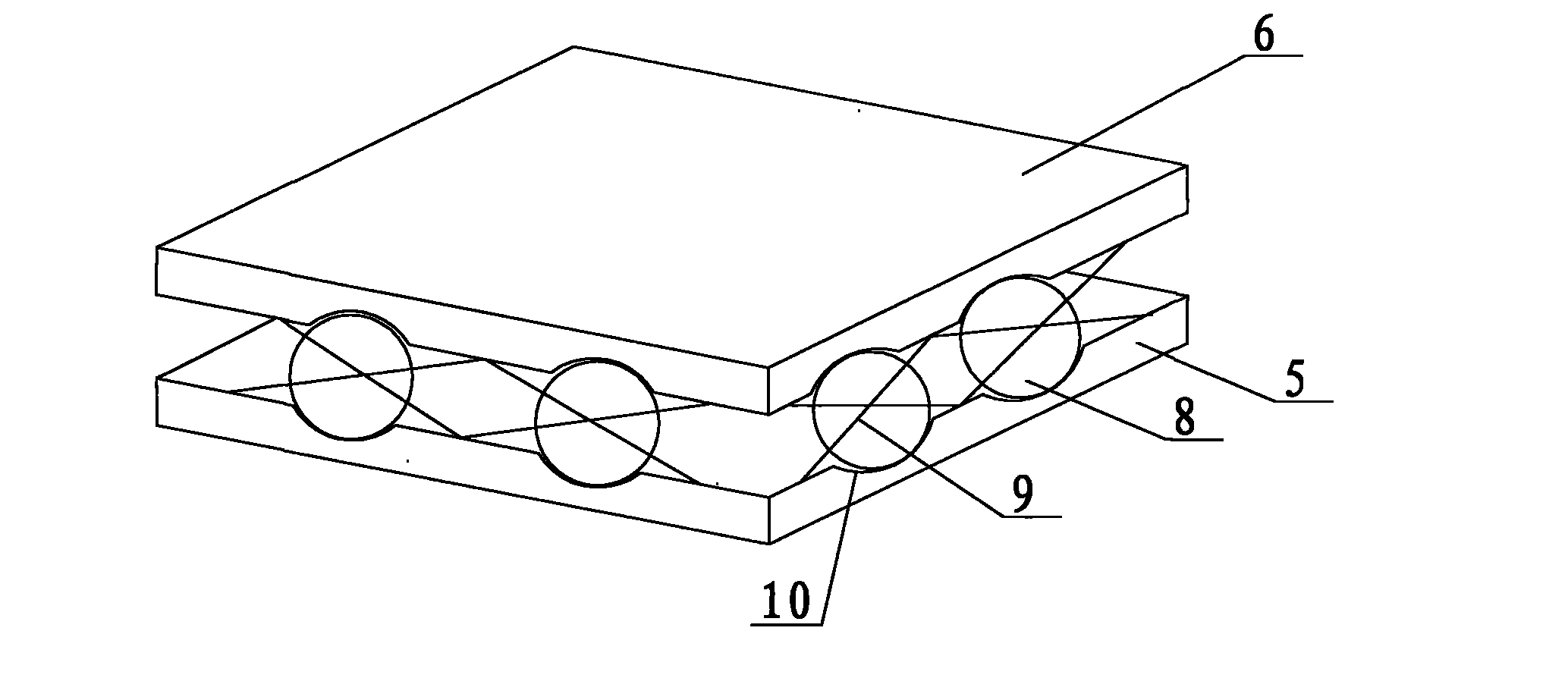

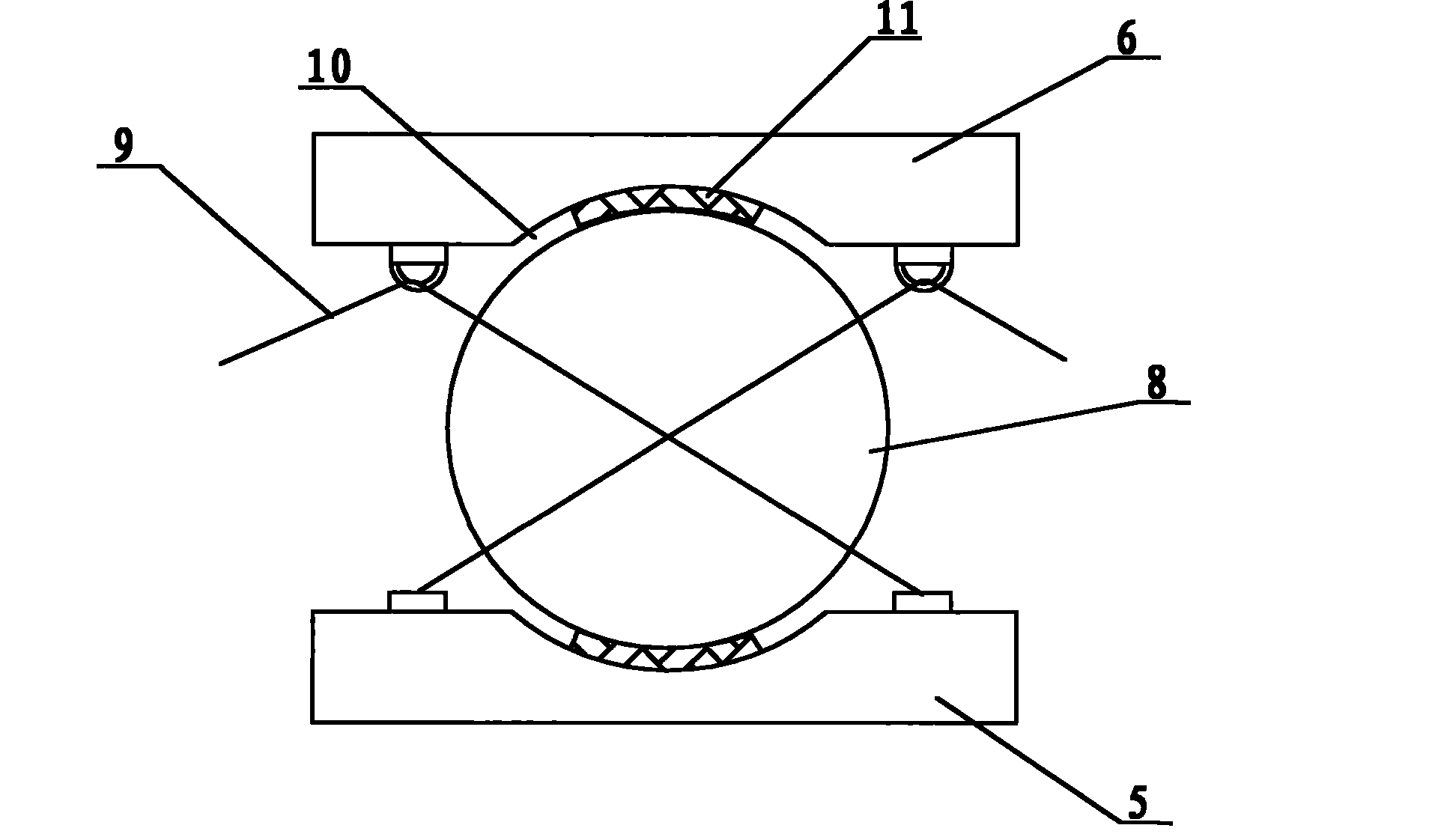

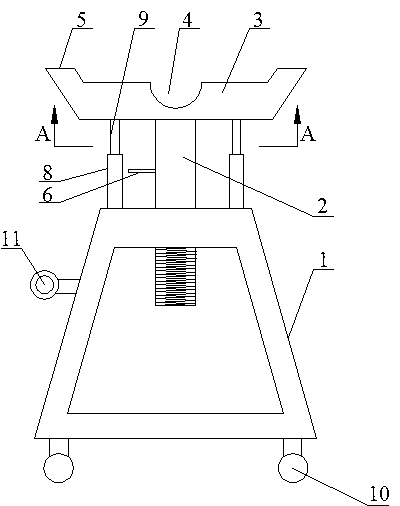

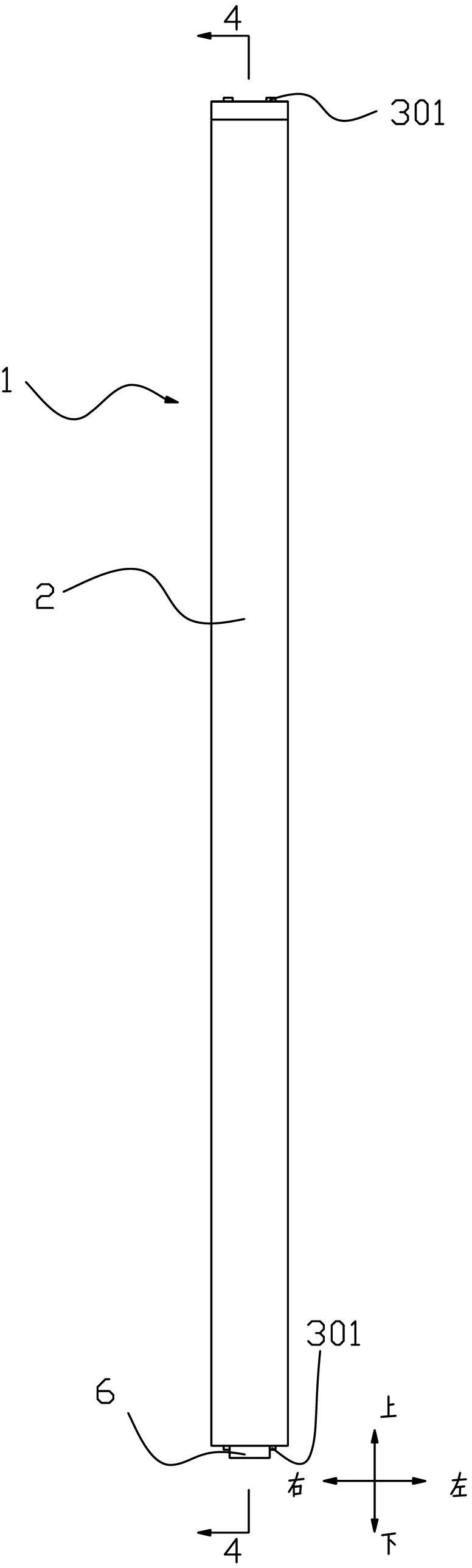

Ball/disc spring vibration-isolating device

InactiveCN102337761AImprove securityDesign freedomBridge structural detailsShock proofingVibration isolationInstrumentation

The invention relates to a vibration-isolating device, in particular to a combined vibration-isolating device. A ball / disc spring vibration-isolating device comprises a vibration-isolating support, and the upper end of the vibration-isolating support is connected with a damper. The device is not only suitable for a newly-built structure, but also suitable for anti-seismic reinforcement and post-earthquake repair of an original structure. Moreover, the device is applicable to ordinary civilian housings, civil engineering such as structures, bridges and the like, as well as storey-increased buildings and shifting buildings. The device can also be applied in vibration isolation and reduction of instruments and equipment and has low manufacturing cost and broad application prospects.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

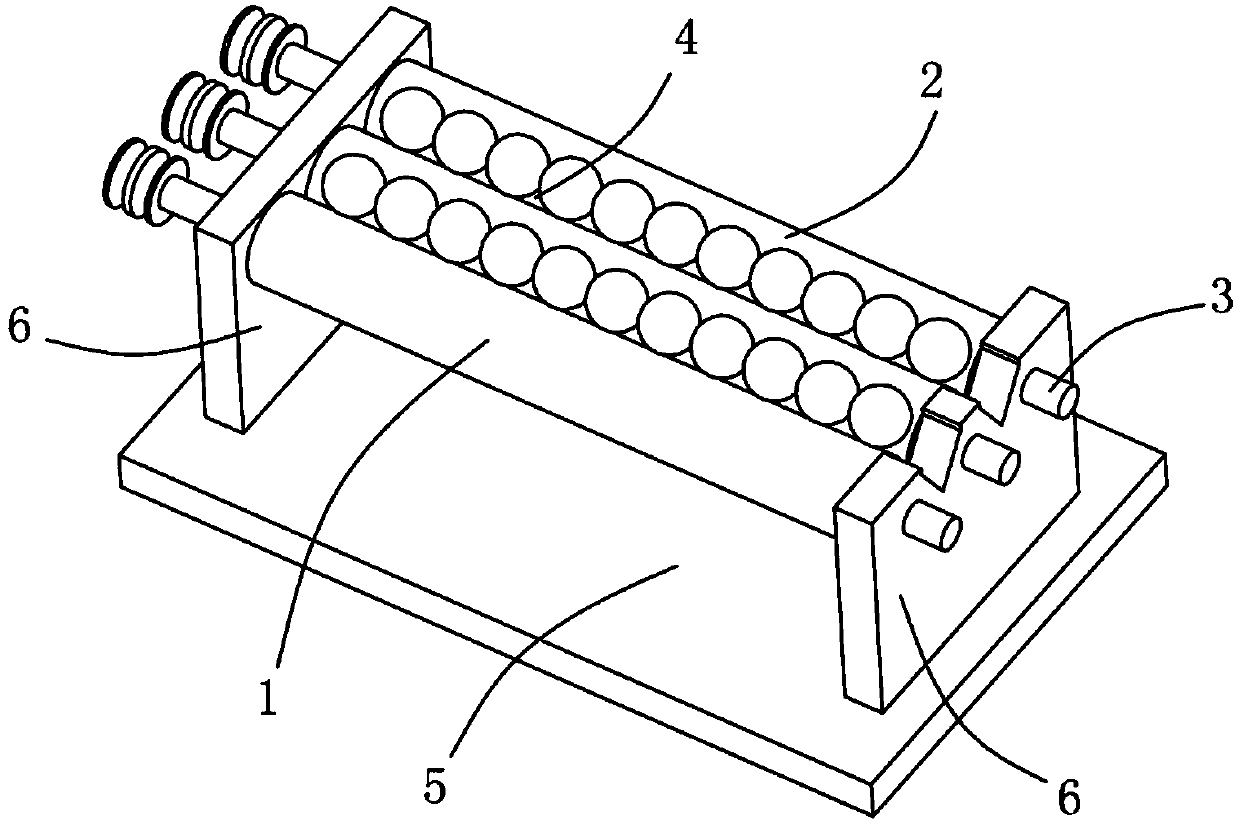

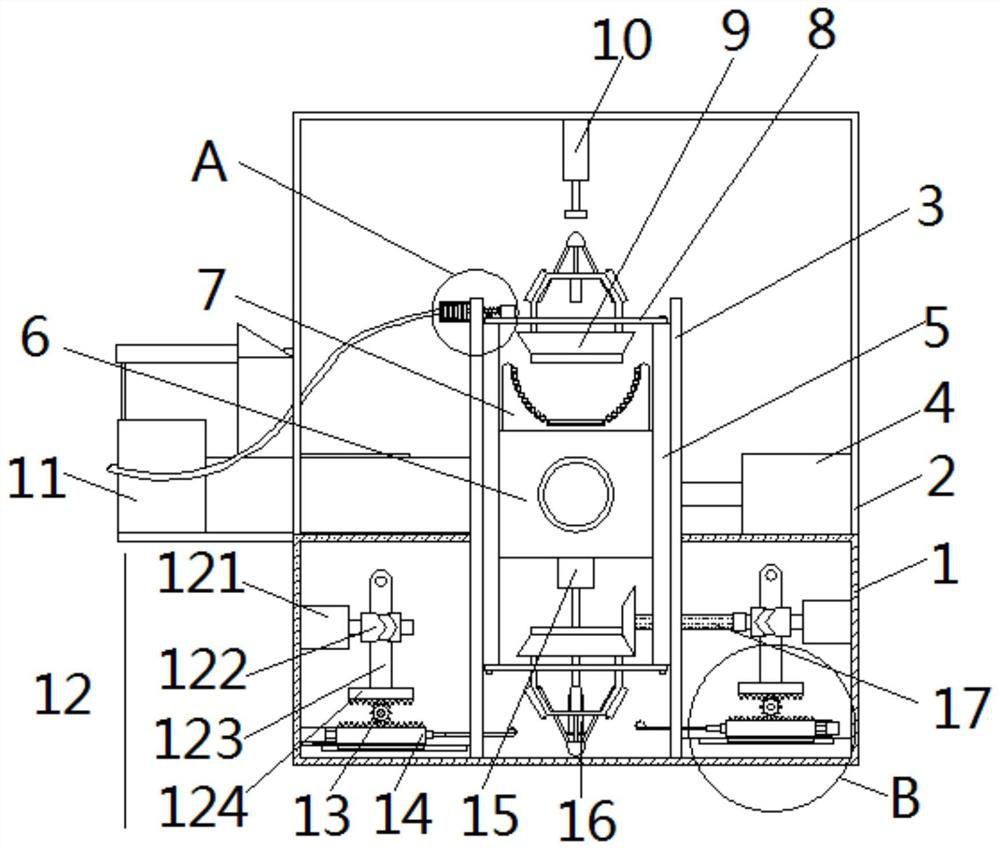

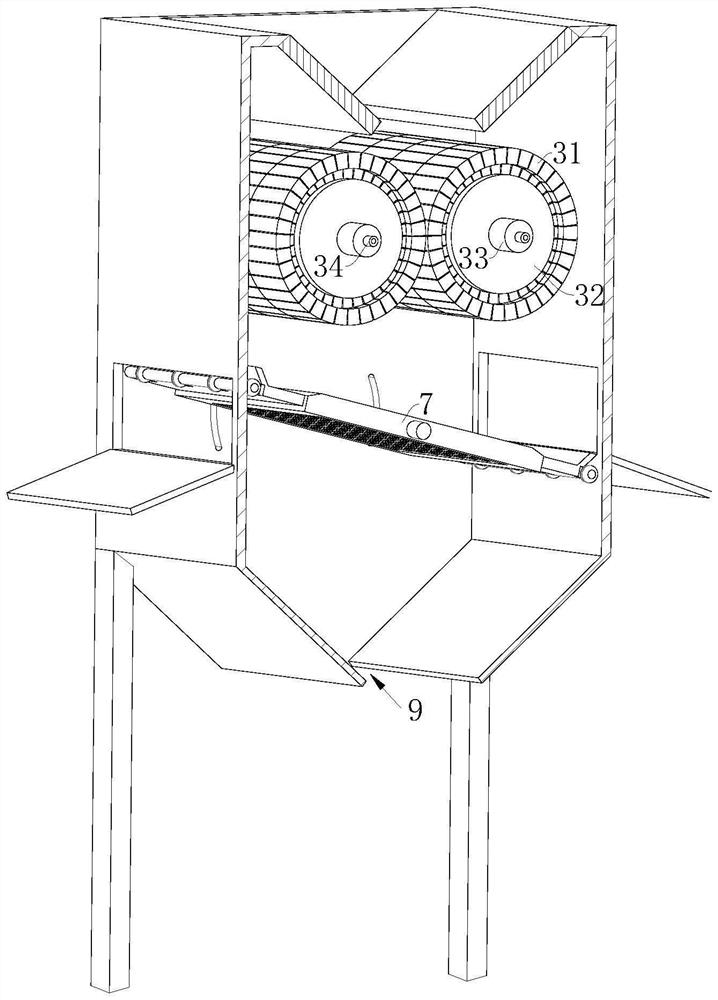

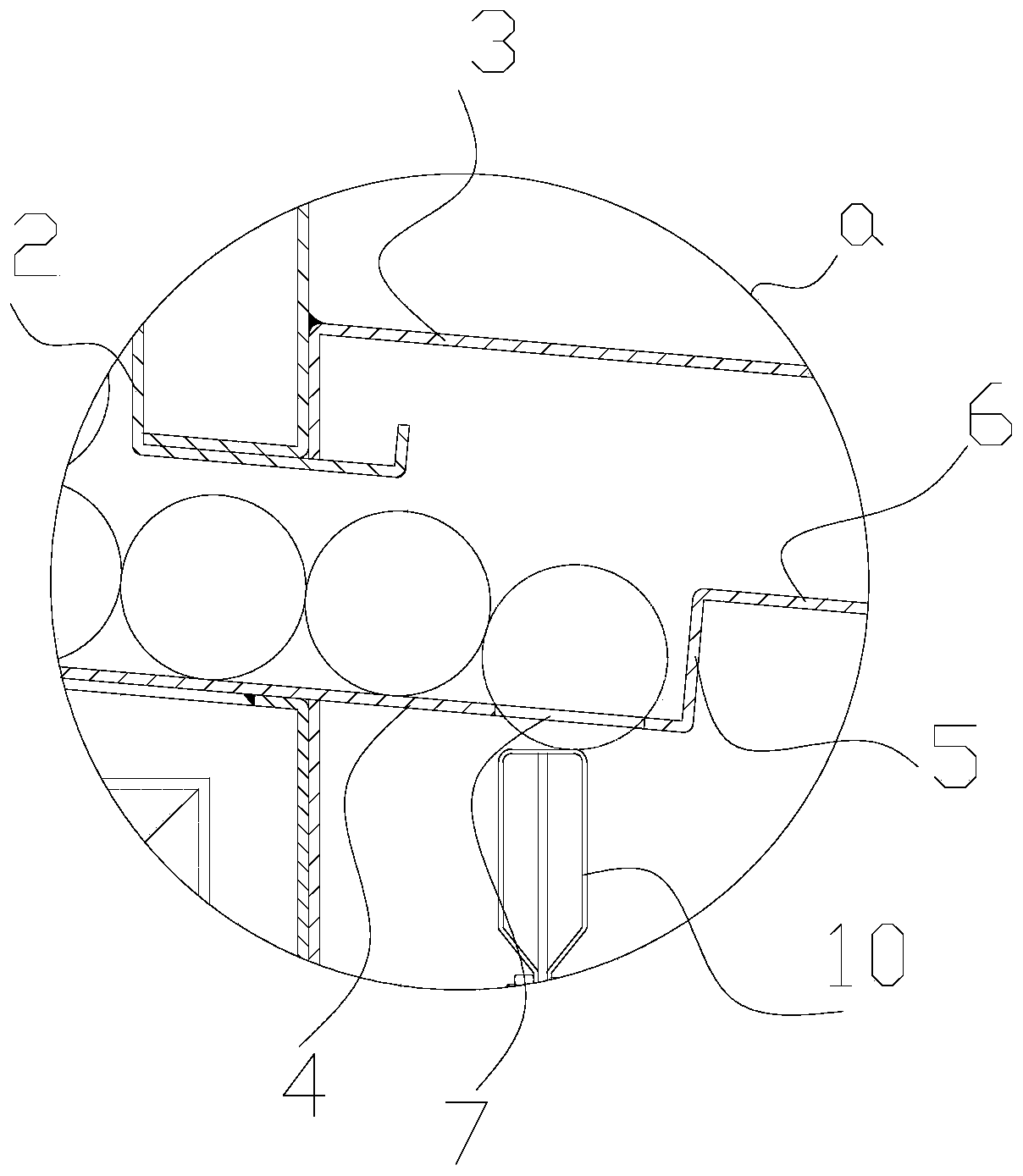

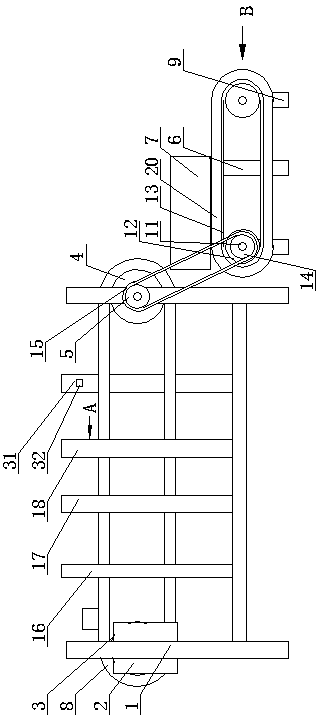

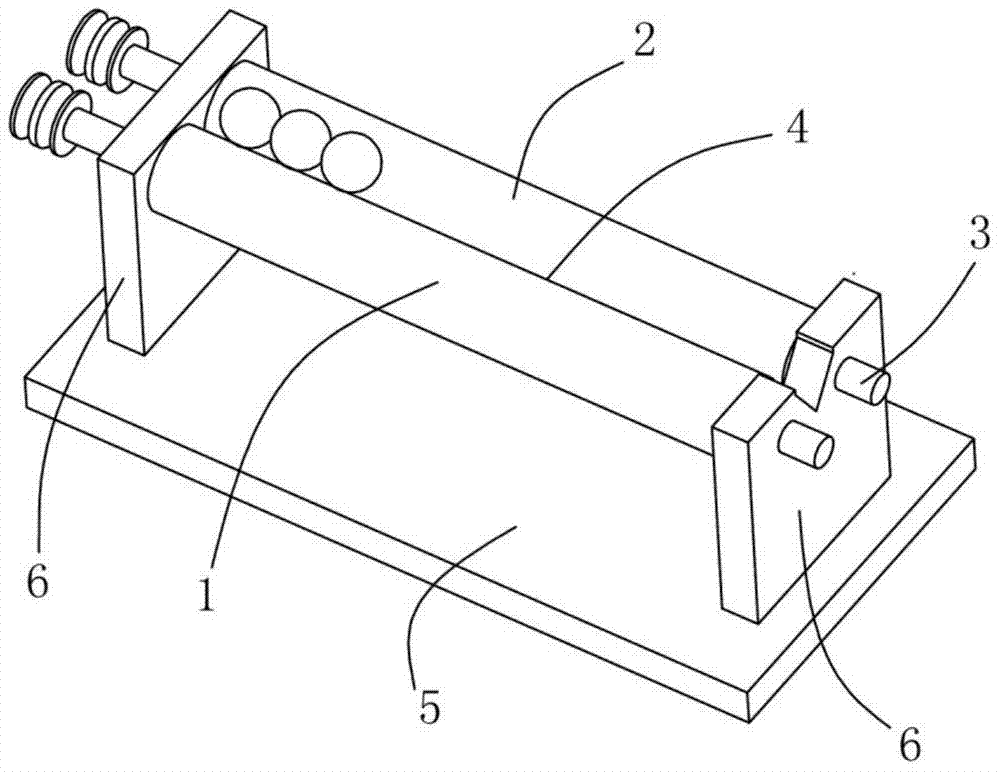

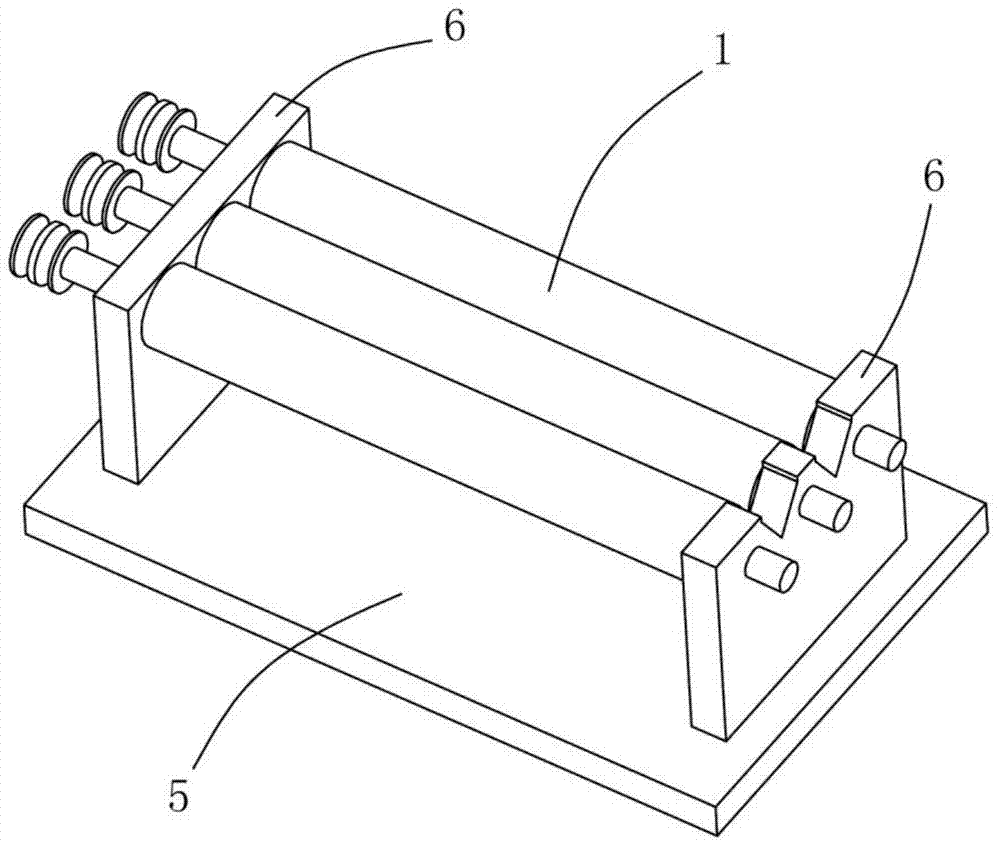

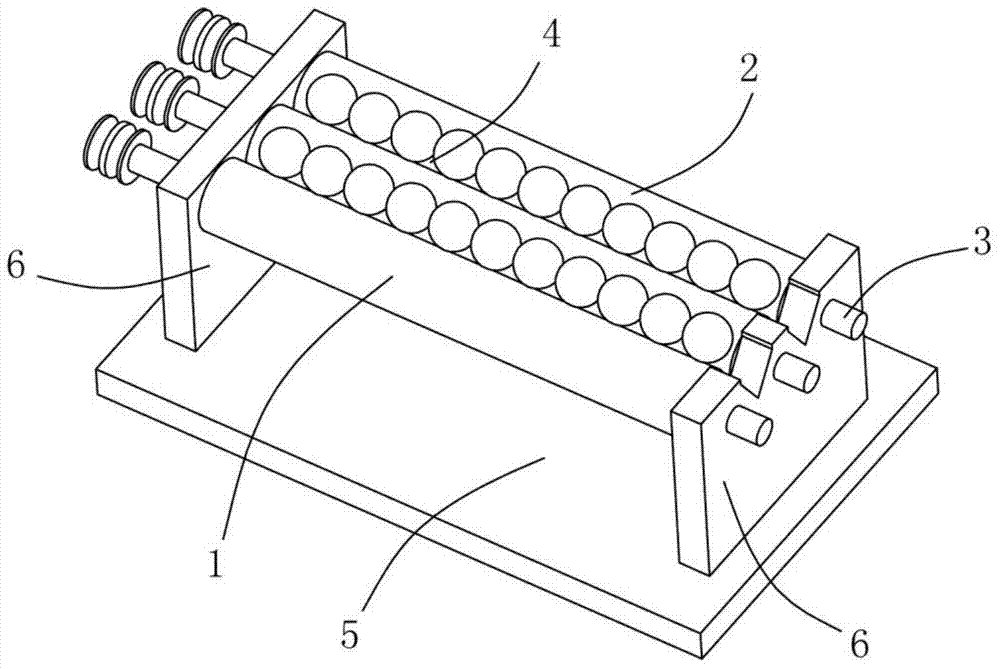

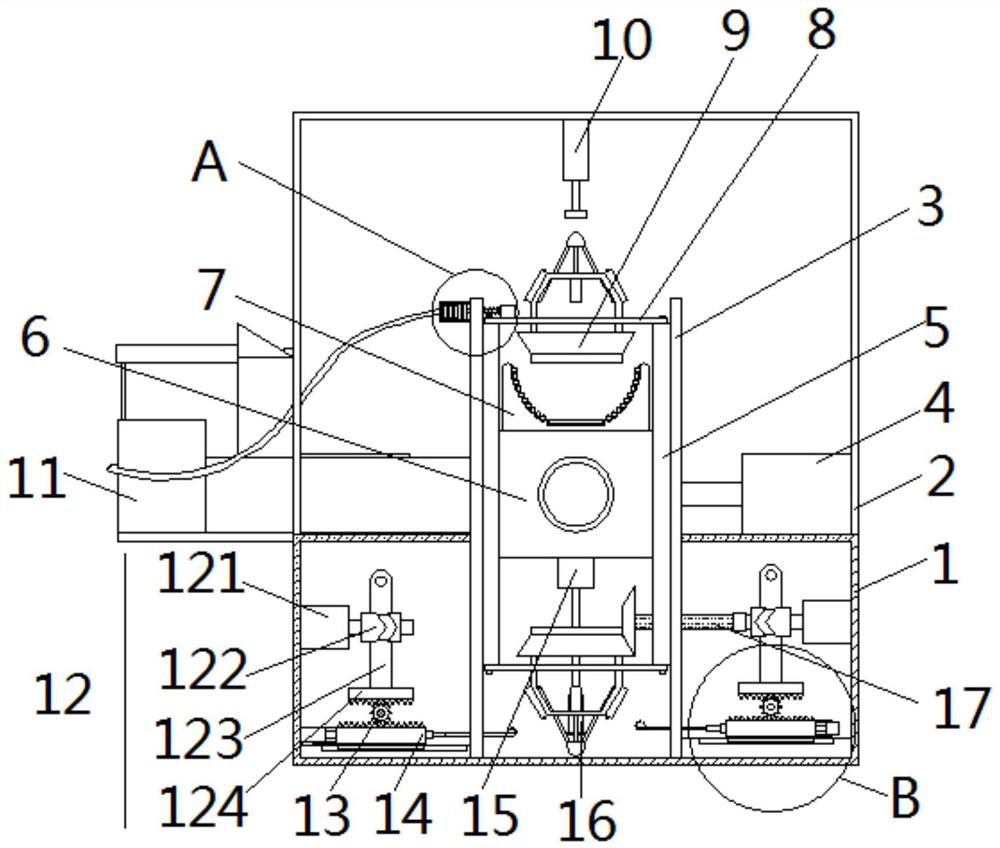

Steel ball surface defect detection sorting equipment

ActiveCN104190634AImprove fullyHigh false positive rateOptically investigating flaws/contaminationCleaning using toolsMetallurgySurface cleaning

The invention discloses steel ball surface defect detection sorting equipment. The steel ball surface defect detection sorting equipment comprises a steel ball size screening device, a steel ball surface cleaning device, a steel ball surface unfolding device, a camera, a sorting device and a control module, wherein the steel ball size screening device comprises two parallel rolling shafts; the steel ball surface cleaning device comprises a trapezoid rotary table and a rotary sleeve covering the rotary table; the steel ball surface unfolding device comprises at least two rolling bars, wherein a containing groove is formed between two adjacent rolling bars, and at least one rotatable rolling bar in the two adjacent rolling bars can be used for driving steel balls to roll in the containing groove in synchronism with the rolling bars. The equipment disclosed by the invention can screen out the out-of-size steel balls and can clean the surfaces of the steel balls so as to prevent the false detection caused by blots on the surfaces of the steel balls; in combination with the specific steel ball surface unfolding device, the steel ball surface defect detection storing equipment can rapidly and accurately sort the steel ball sizes and the steel ball surface defects, and the steel ball sorting efficiency is greatly promoted.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

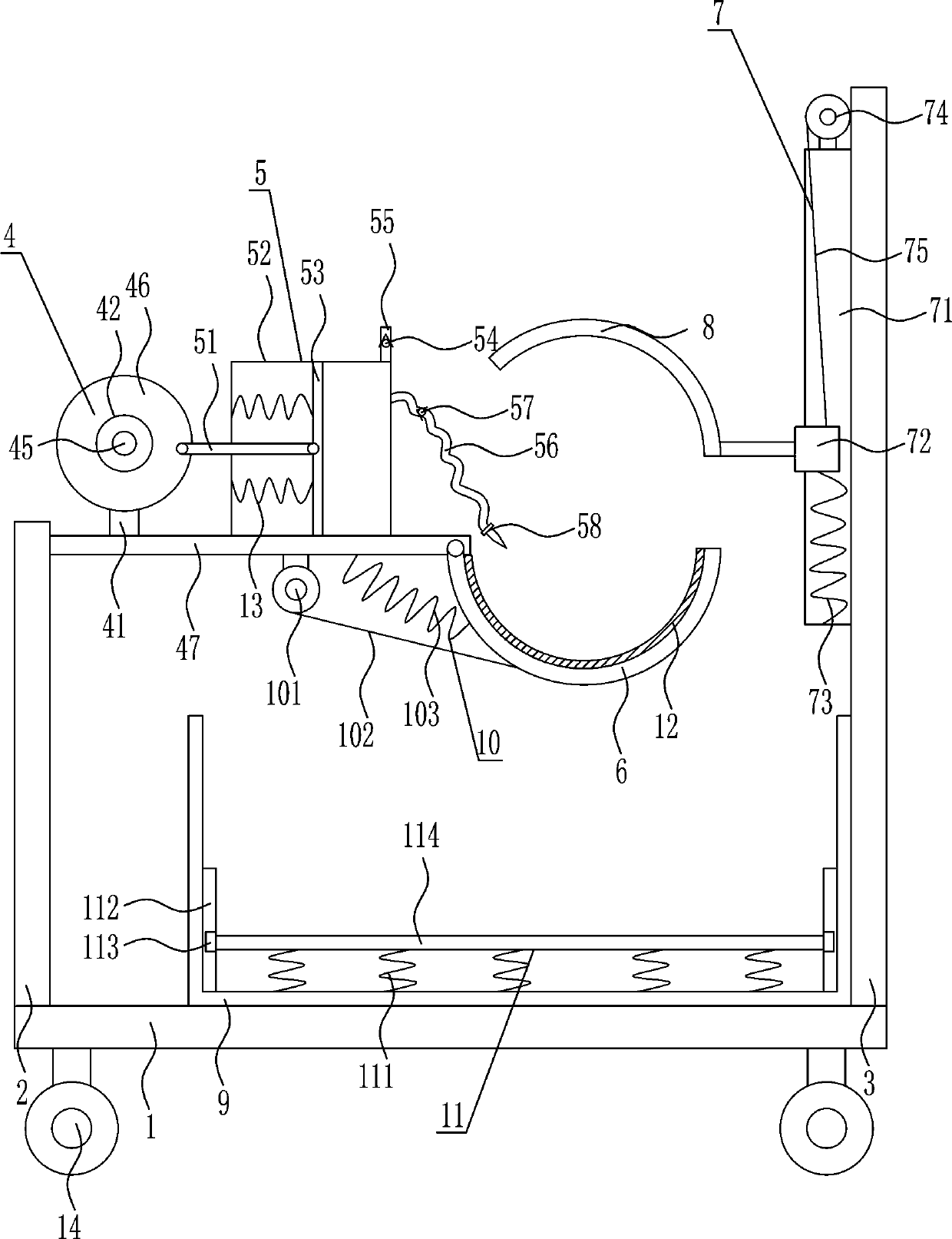

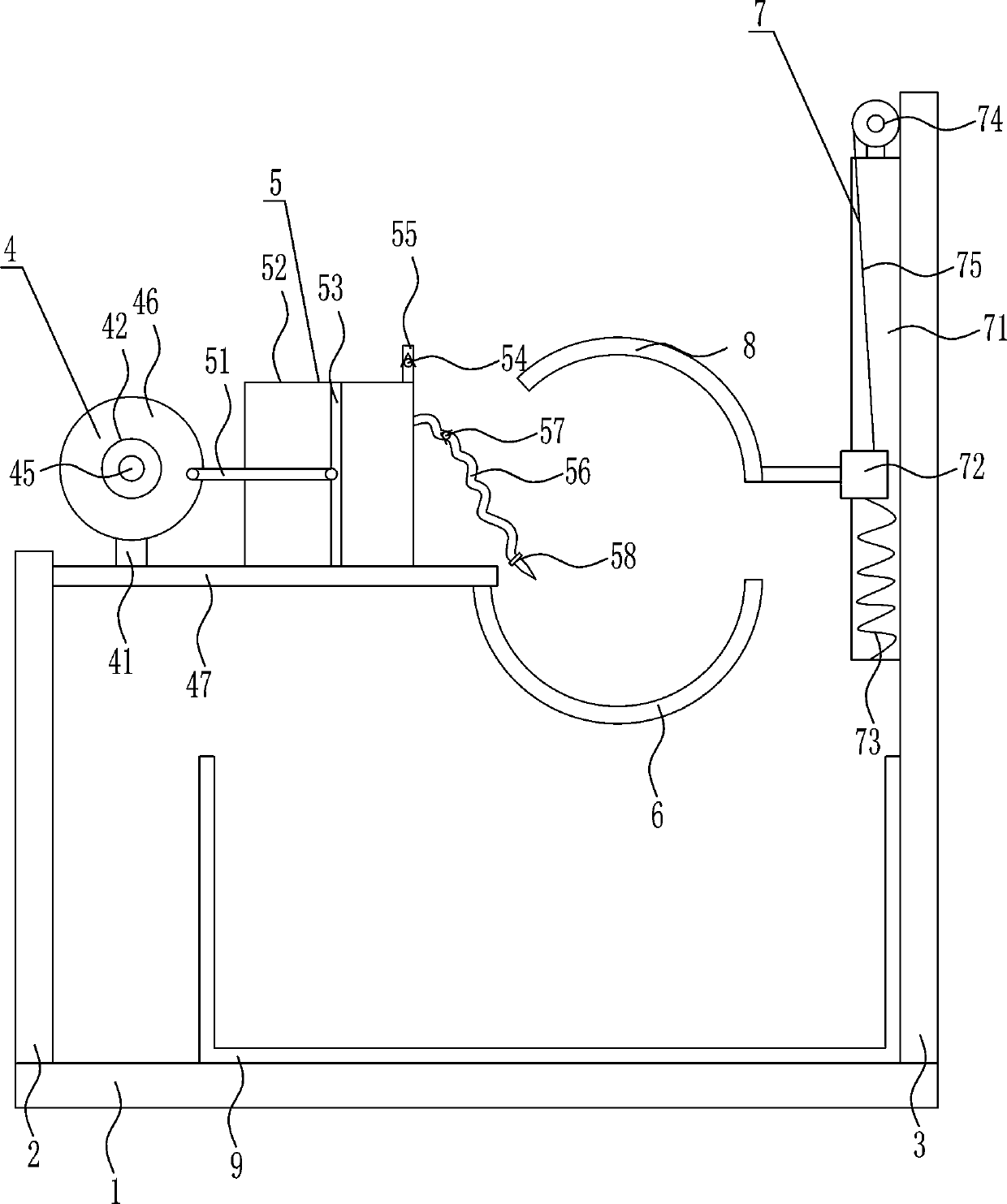

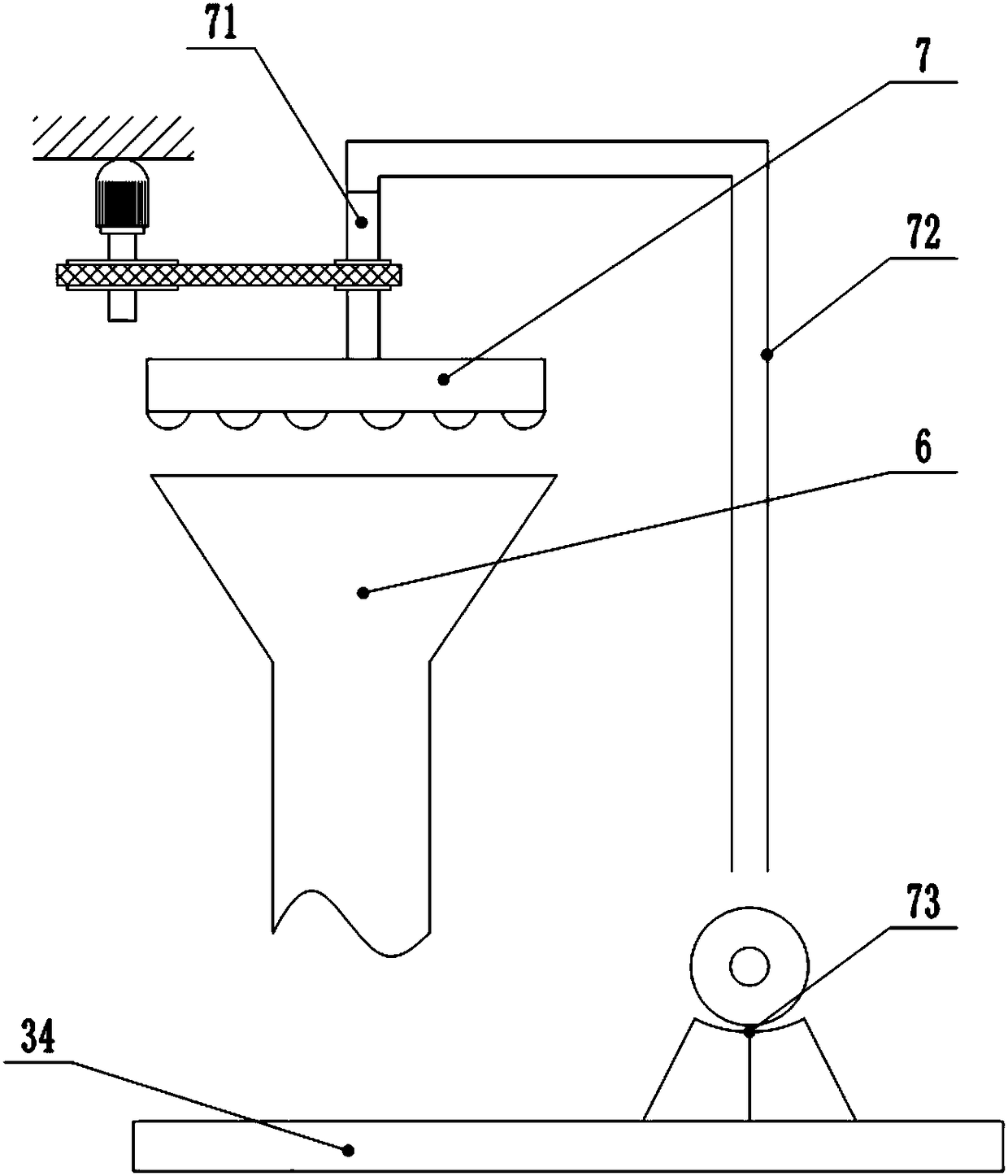

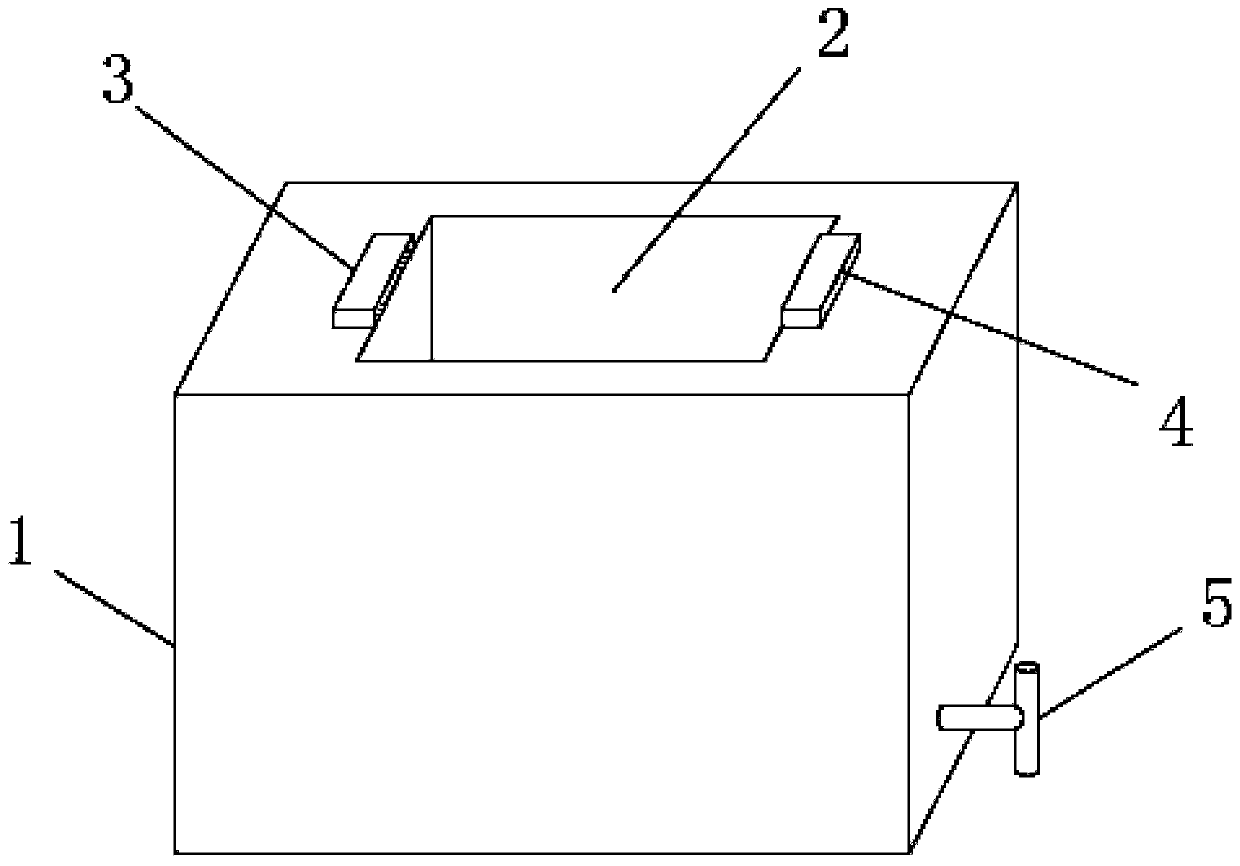

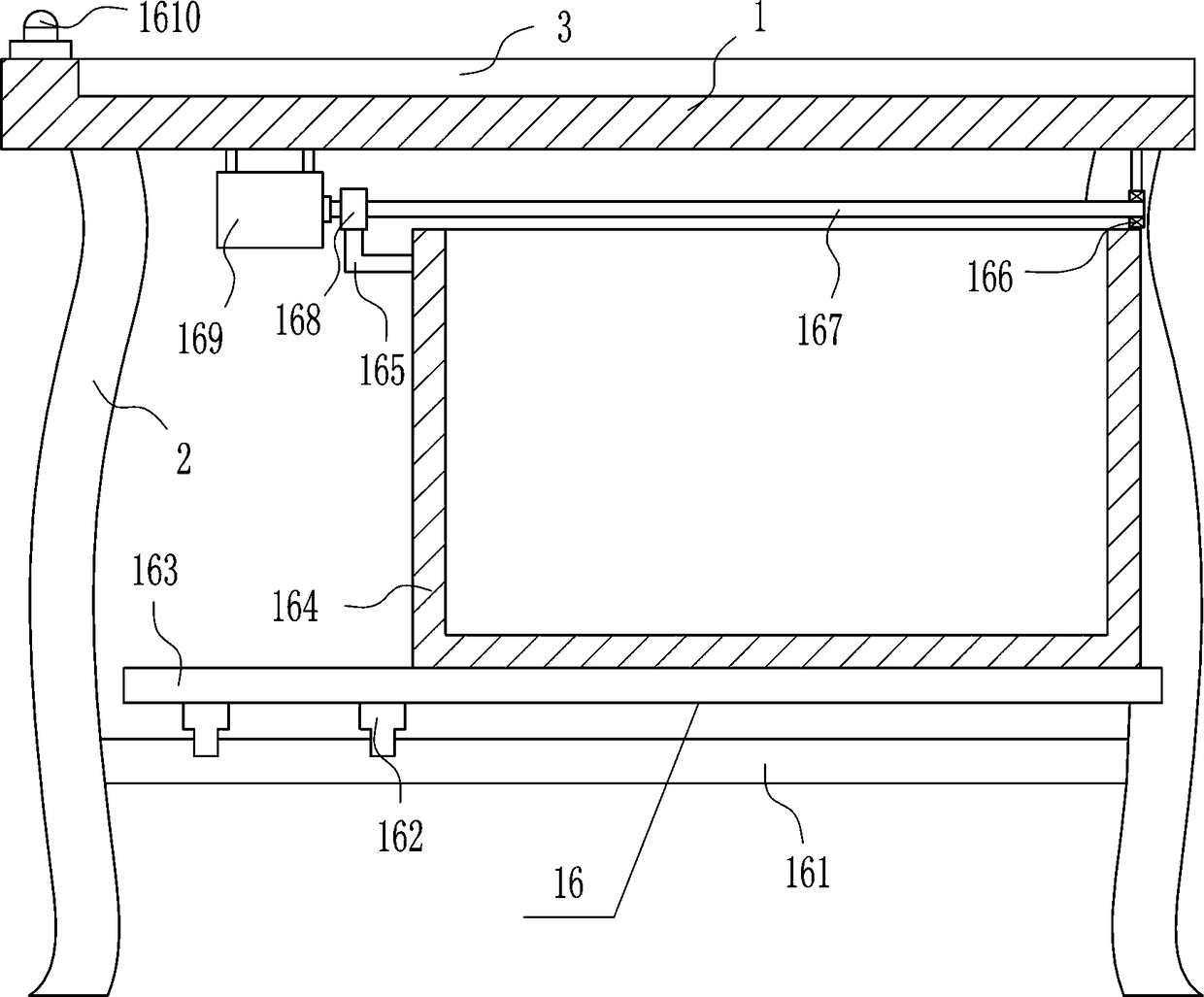

Basketball production inflating device for sports

InactiveCN107694052APrevent rolling outTo achieve the shock absorption effectHollow inflatable ballsMechanical engineering

Owner:宋述雄

Kiwifruit cleaning dehairing device

The invention discloses a kiwifruit cleaning dehairing device. The device comprises a base, a box body, a first gear and a hopper; a supporting post is arranged on the base; the top of the supportingpost is provided with a first air bag; the hopper passes through the first gear and extends into the box body; a plurality of baffles are connected to the bottom of the first gear; the baffles are rotatably connected to the box body; the inner side of the baffles are provided with a plurality of second air bags with brushes; the first gear engages with a half gear; the half gear is fixed with a rotating shaft which is rotatably connected to a frame; the other side of the half gear is provided with a second gear; the second gear is fixed with a gear shaft which is rotatably connected to the frame; the gear shaft is connected to a first bevel gear; the first bevel gear engages with a second bevel gear; the second bevel gear drives a transmission mechanism through a tensioning shaft; and a cleaning device is arranged above the hopper, and a water pump supplies the cleaning device with water. The device can carry out automatic dehairing and cleaning on kiwifruits, and reduce the intensityof manual operation.

Owner:务川自治县绿一果农业开发有限公司

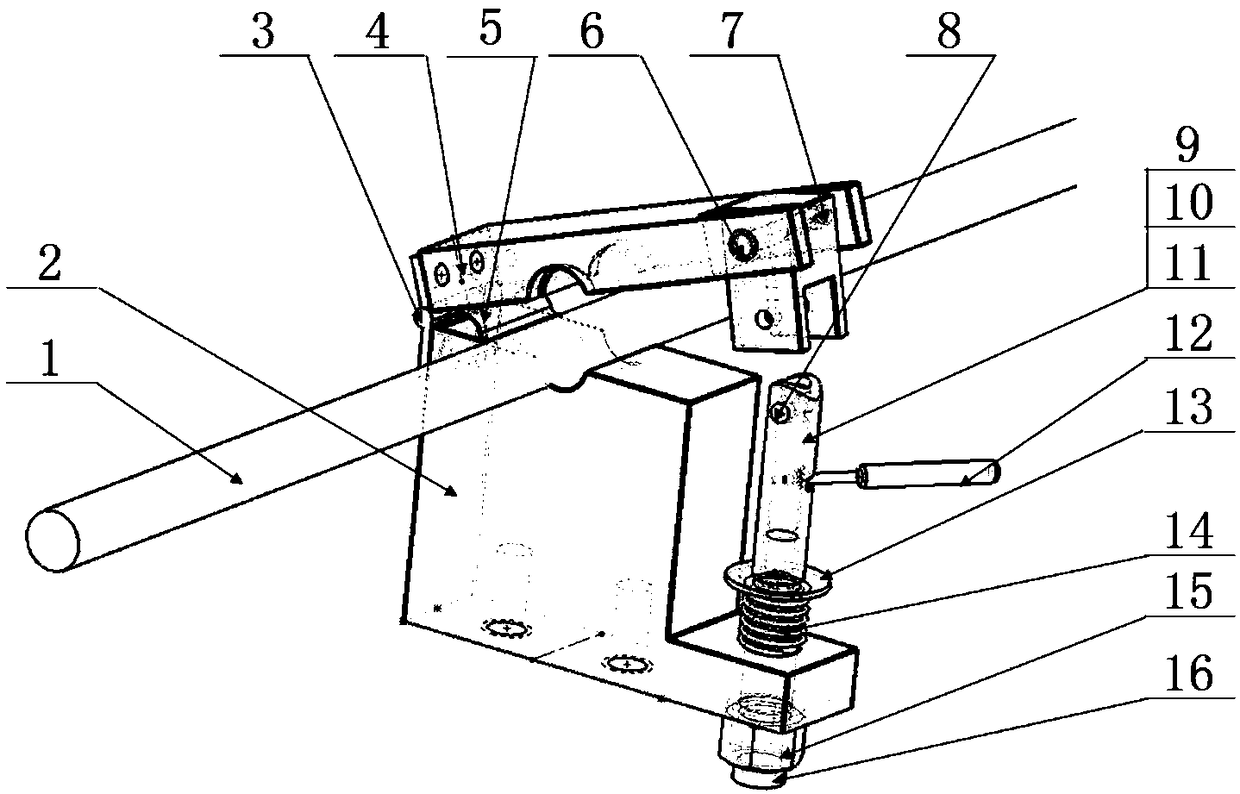

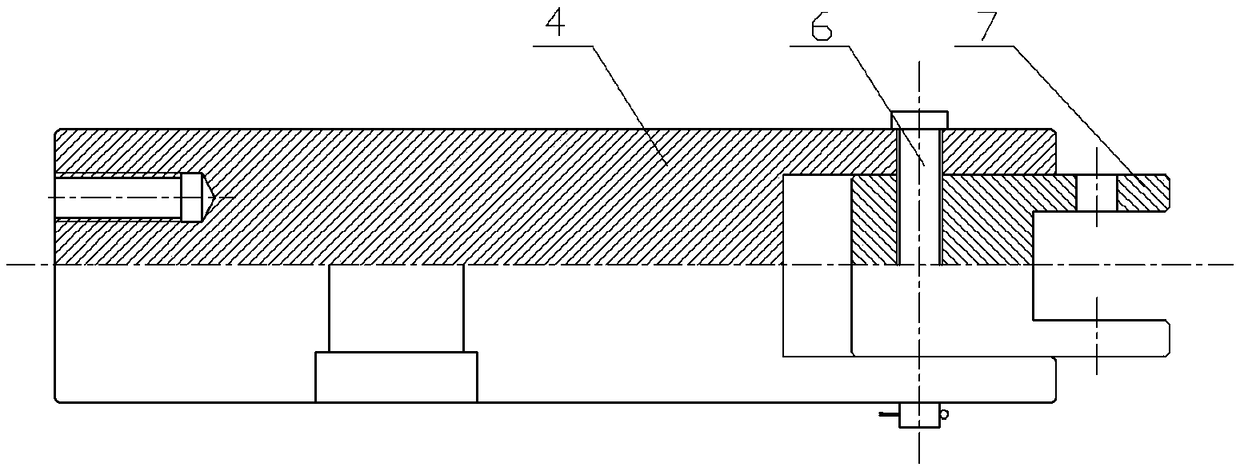

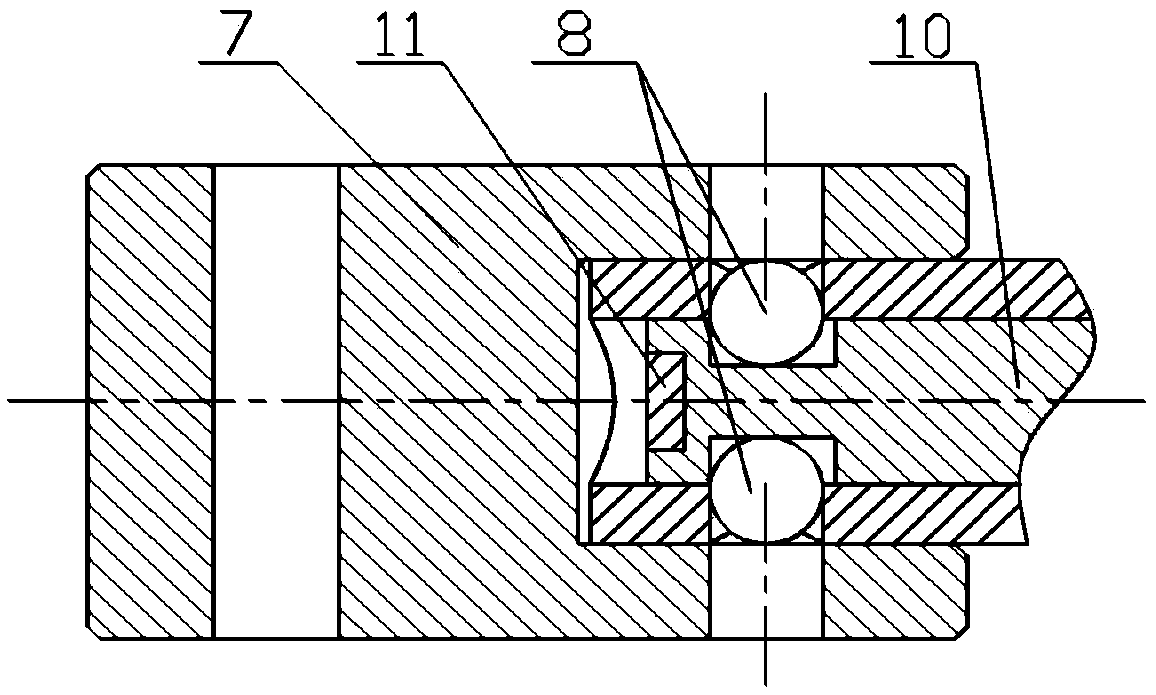

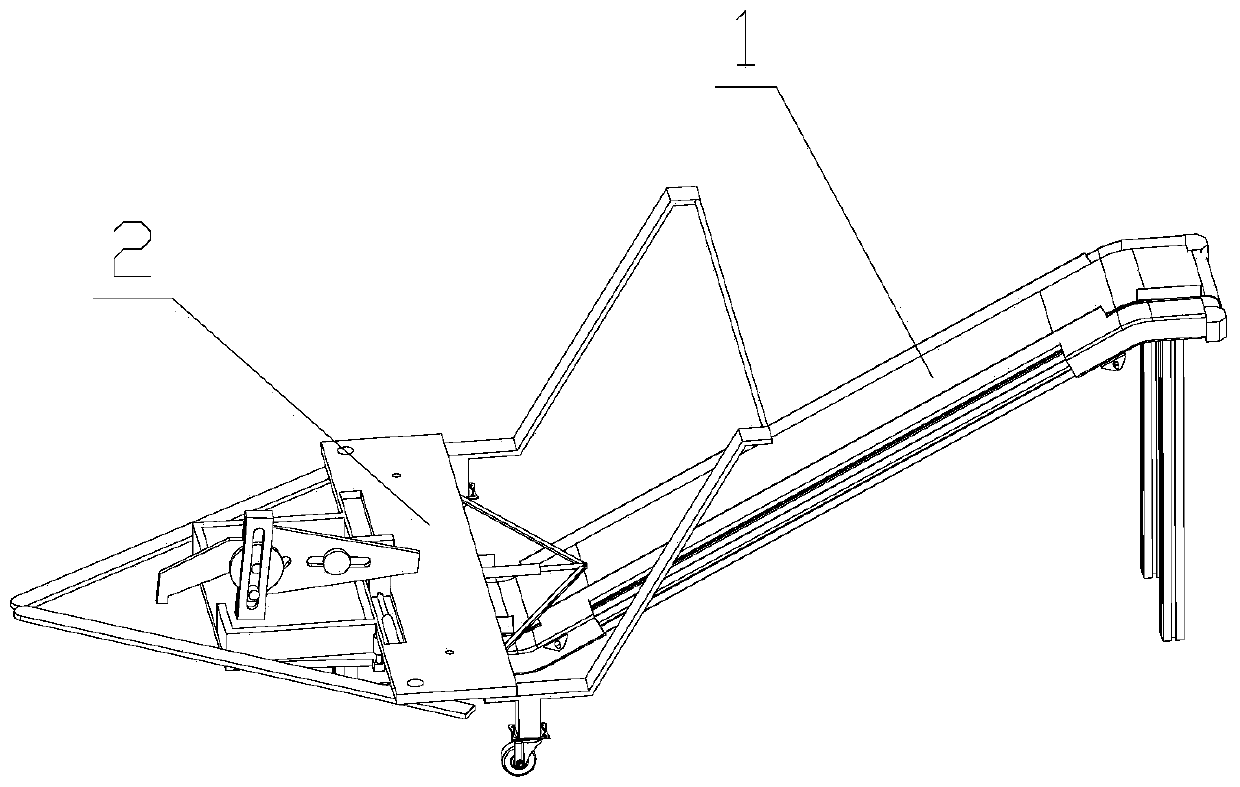

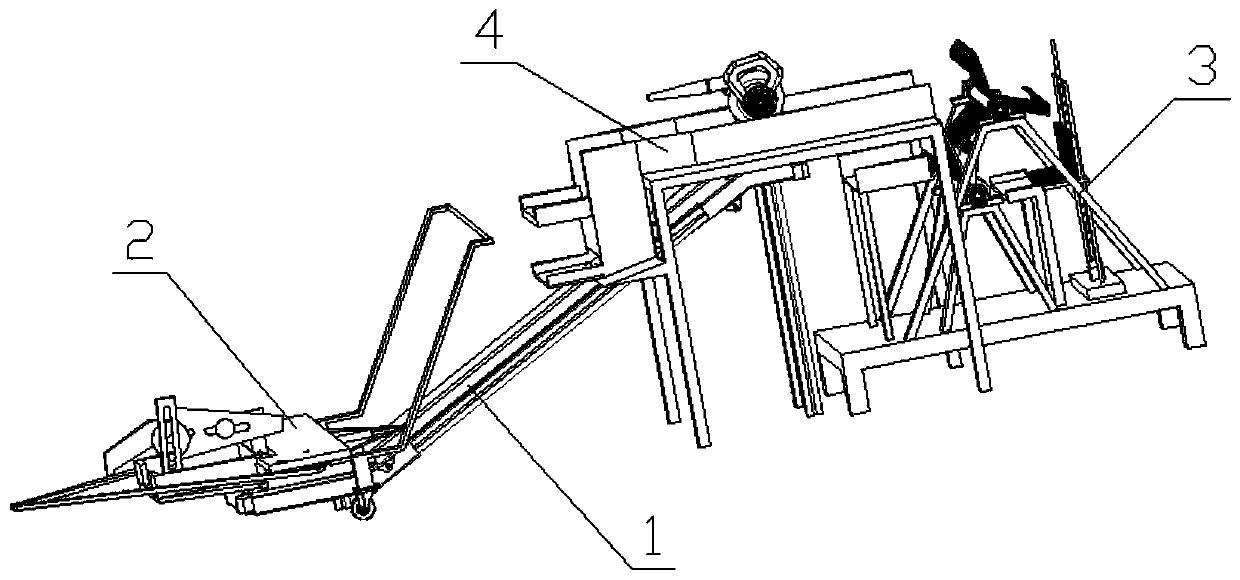

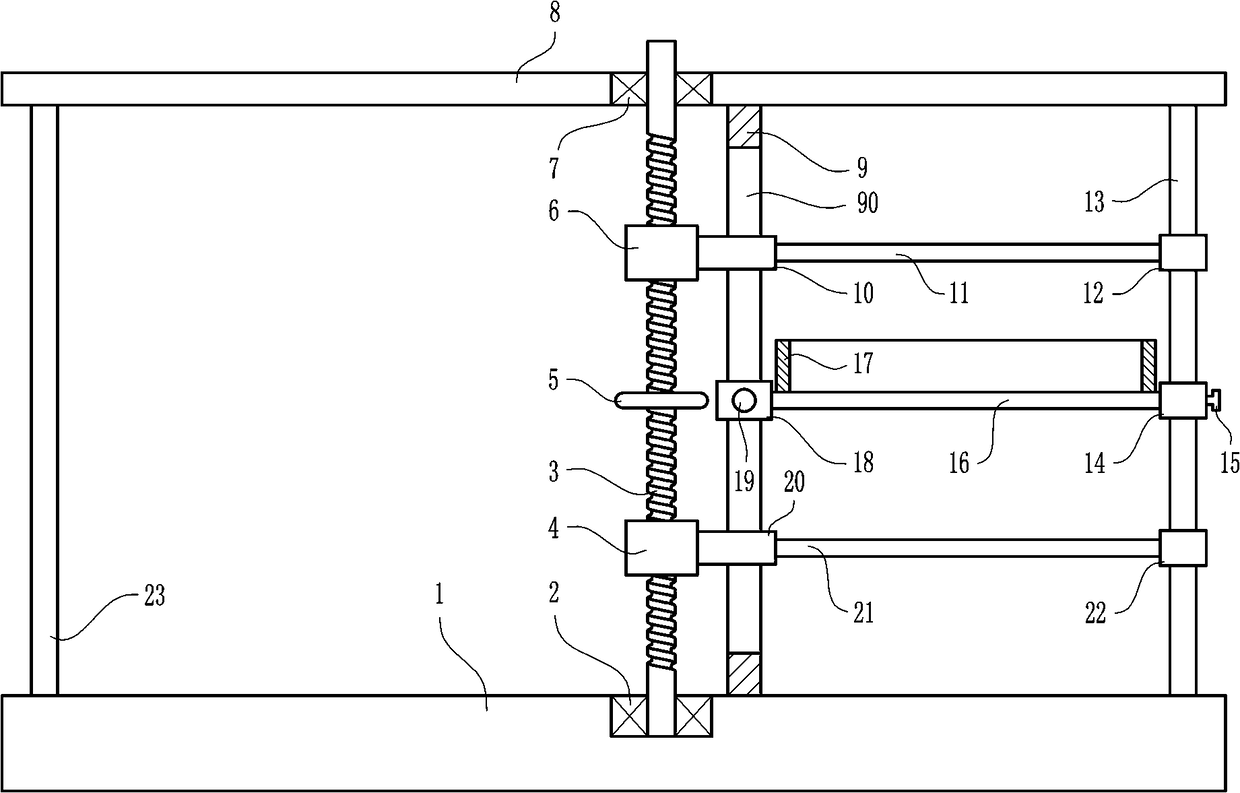

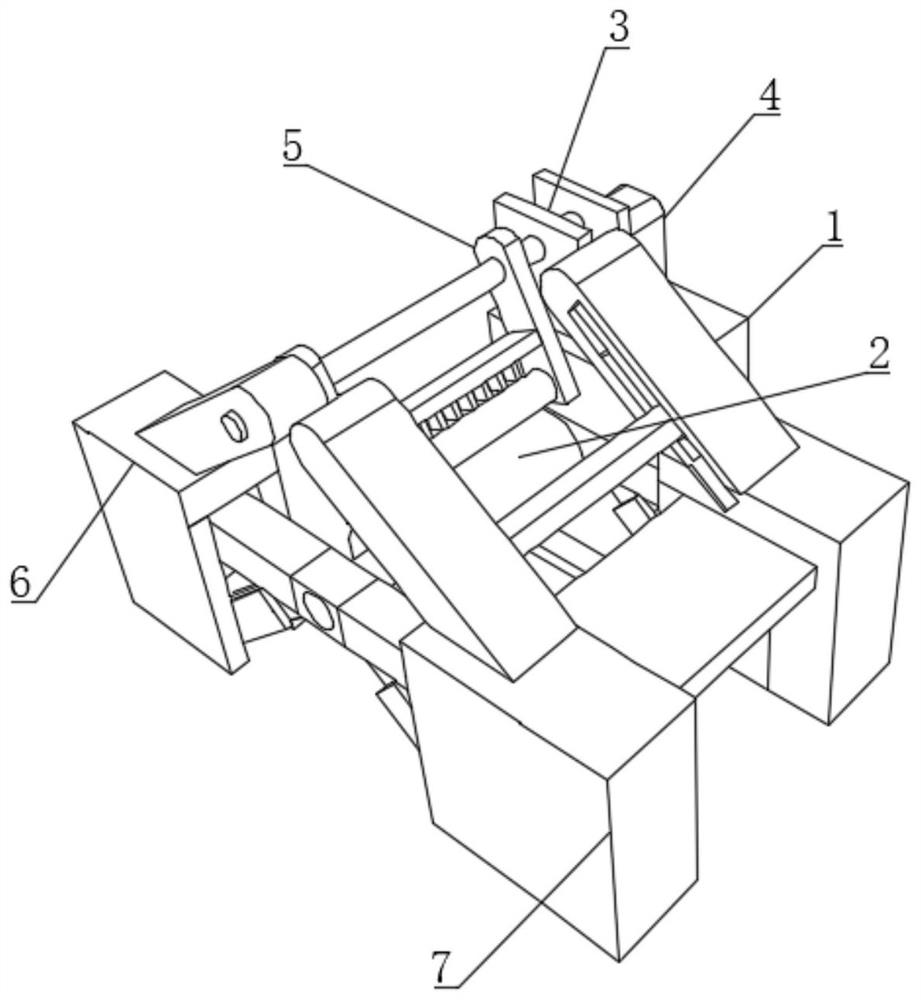

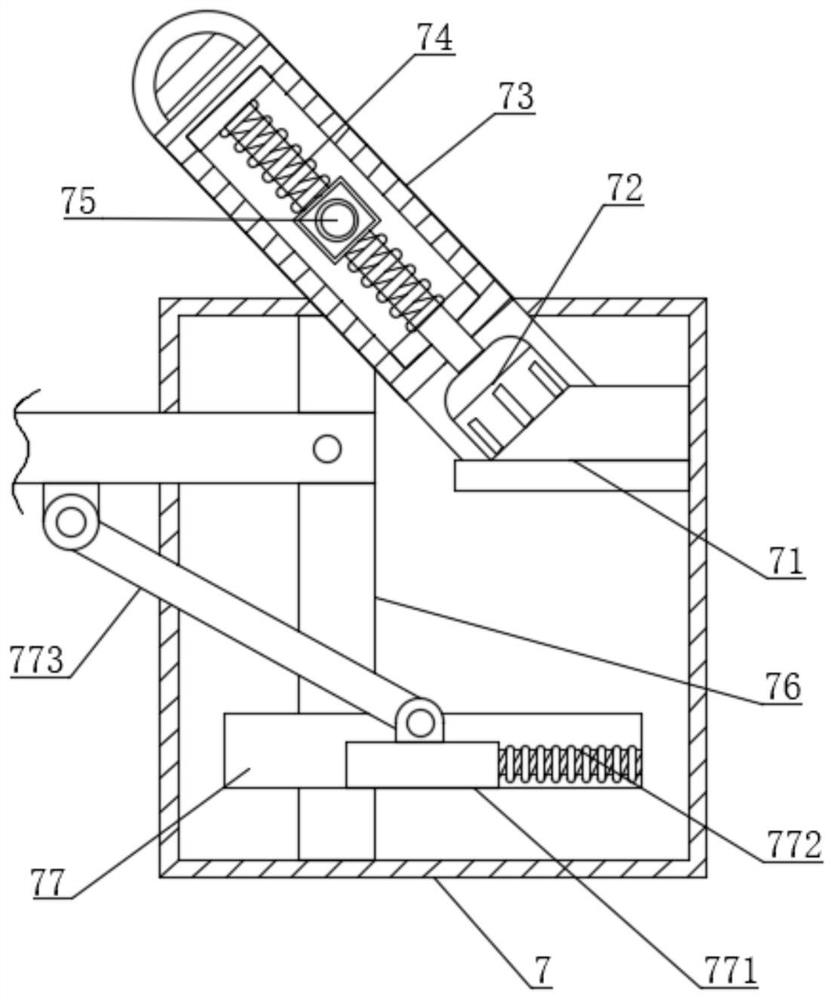

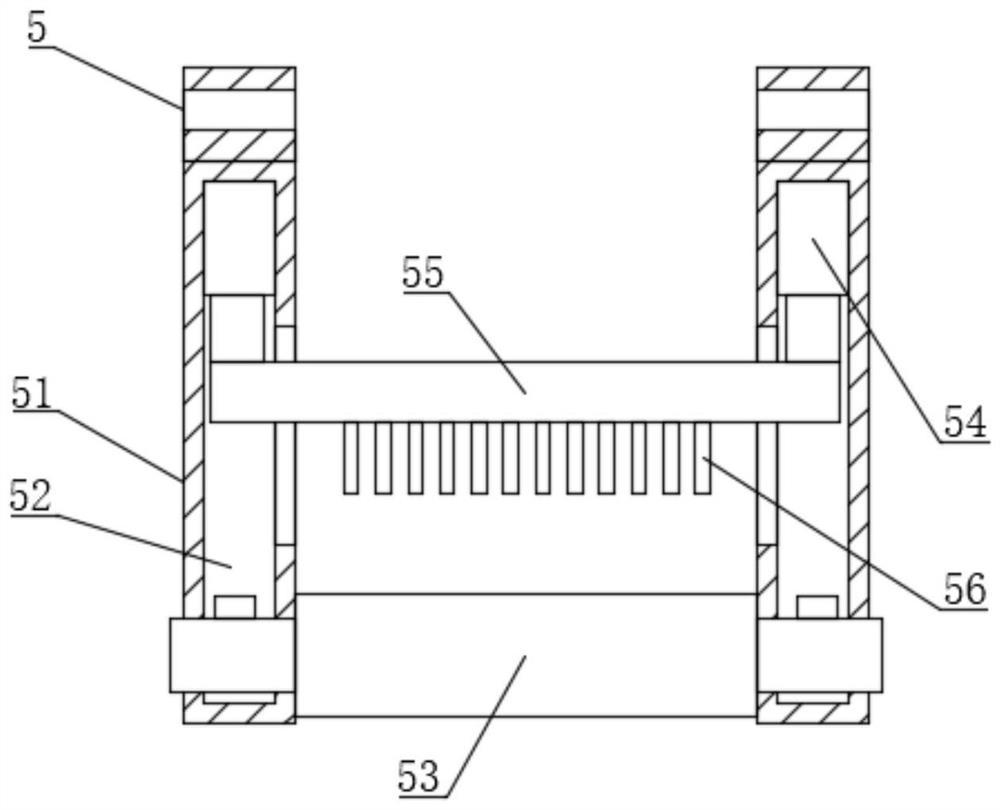

Split-type hopkinson torsion bar energy storing and releasing device as well as operation method thereof

ActiveCN108645696AGuaranteed repeatabilityPracticalMaterial strength using steady torsional forcesEngineeringEnergy analysis

The invention discloses a split-type hopkinson torsion bar energy storing and releasing device as well as an operation method thereof, which can realize impact torsion energy storing and releasing bya simple mechanical structure. The apparatus comprises a hopkinson incident bar, a clamping mechanism, a releasing mechanism, and a guiding mechanism. The operating method is characterized in that theHopkinson incident bar is clamped by the clamping mechanism and guiding mechanism, the torque storage is realized, by designing the releasing device, the stored torsion energy is subjected to instantrelease, so that the shock loading effect can be simulated, and the impact experiment simulation condition is provided; and at the same time, the loaded shock loading is determined by torsion turns numbers, which is conveniently controlled; the split-type hopkinson torsion bar energy storing and releasing device is suitable for different loading devices, and is repeatedly usable without materialconsumption. The device has the advantages of simple structure, low cost, easy control, and convenient operation.

Owner:XI AN JIAOTONG UNIV

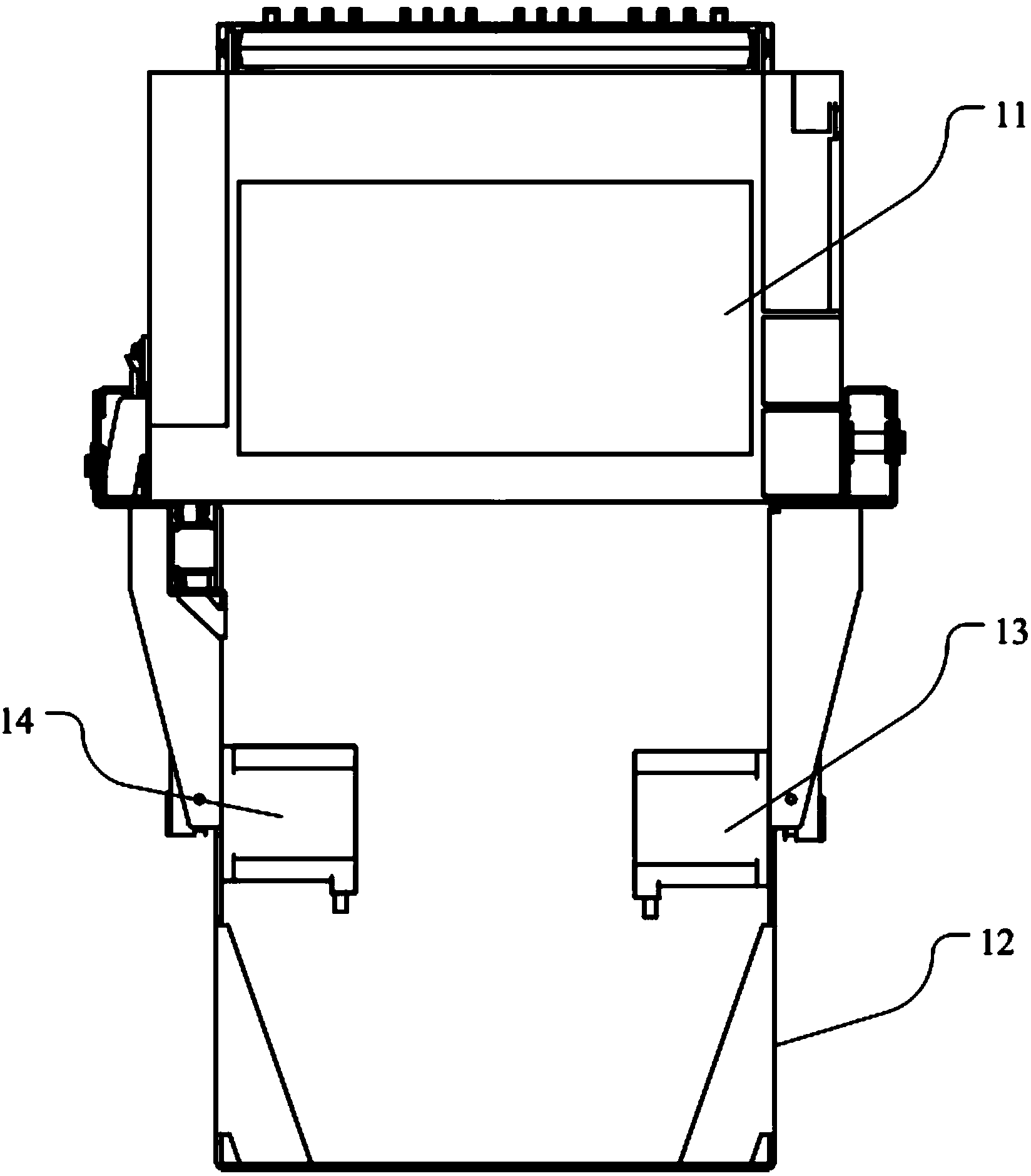

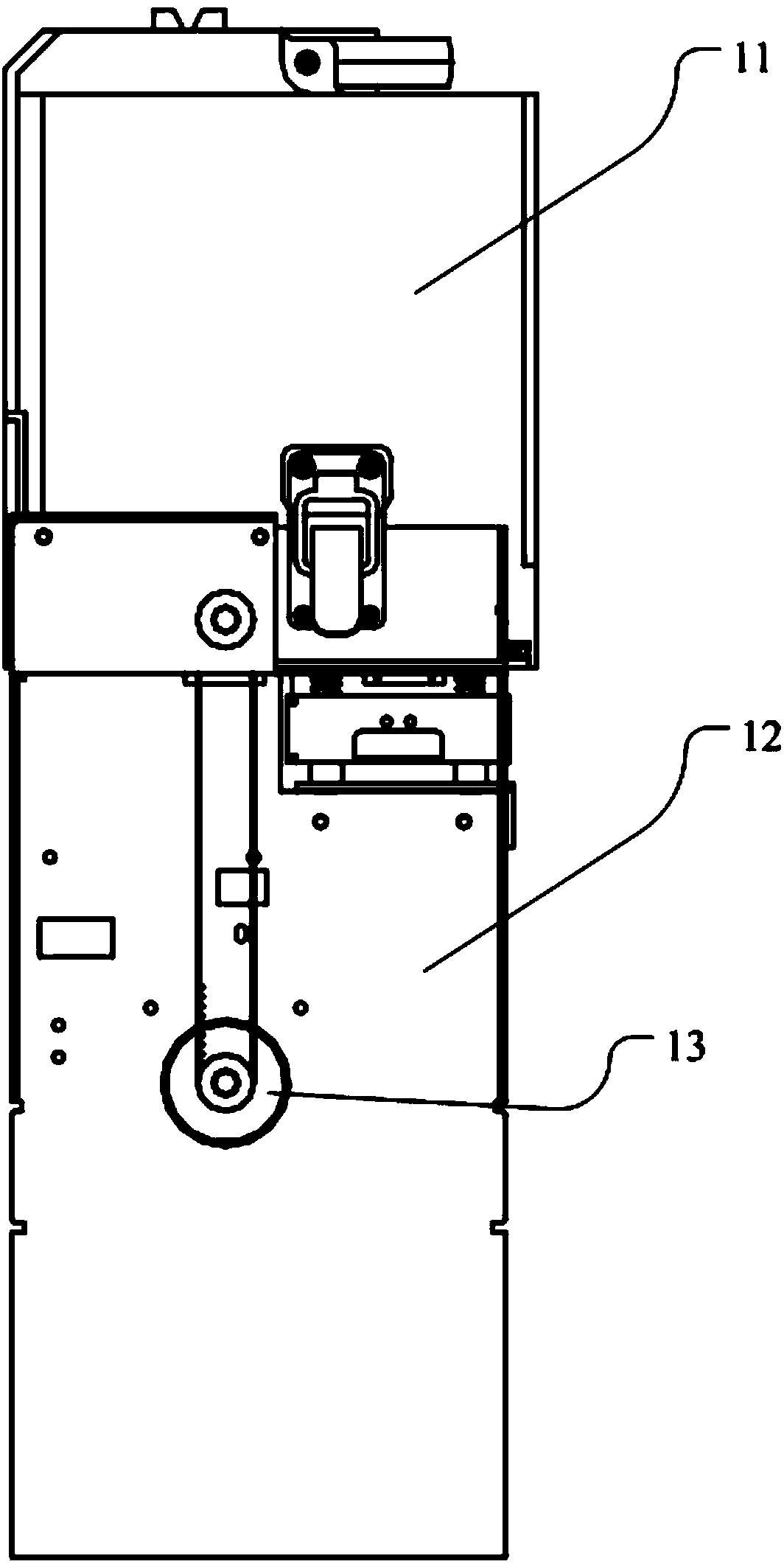

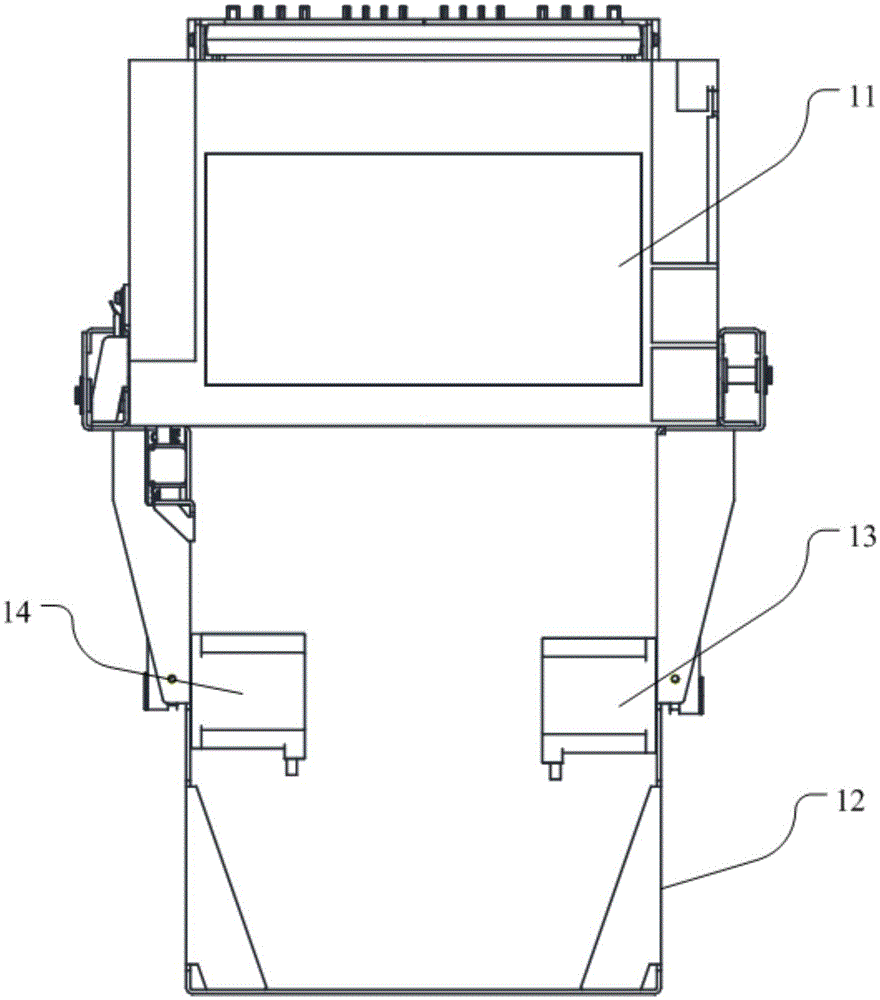

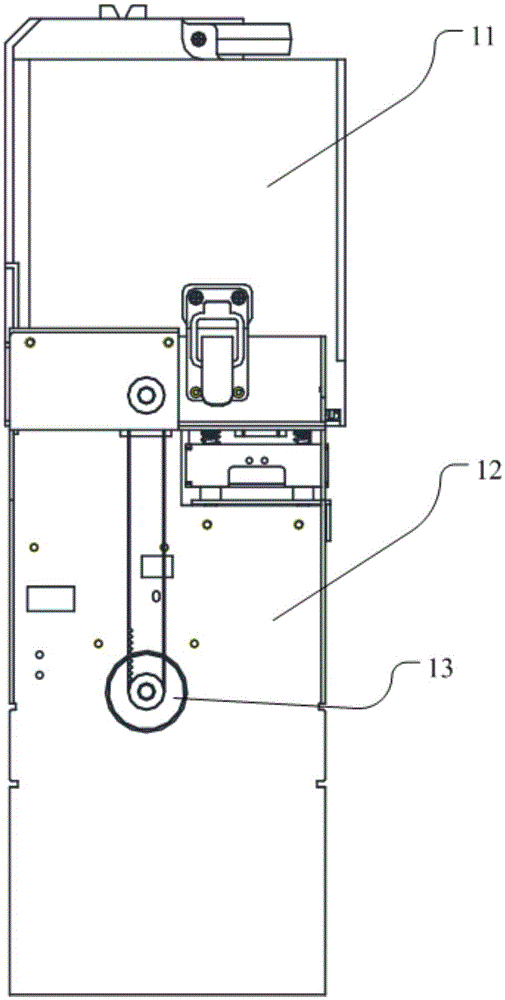

Portable drum type banknote box and ATM

ActiveCN104036587AReduce volumeReduce weightPaper-money testing devicesCoin/currency accepting devicesSelf lockingElectromagnet

The embodiment of the invention discloses a portable drum-type banknote box. In this way, the banknote box device is smaller in size, lighter in weight, convenient to assemble, disassemble and move and capable of performing audit work on a plurality of ATMs; in addition, a locking function is achieved, and the situation that banknotes are exposed and rolled out by human poke can be effectively prevented. The portable drum-type banknote box comprises a shell (42), a large winding drum gear (36), a small winding drum gear (35), a connecting socket (38) and a self-locking mechanism. The self-locking mechanism comprises an electromagnet (34), a spring (40), a spring (41), a lock rod (30), a lock rod (31) and a pull rod (33). The upper end of the pull rod (33) is installed to the electromagnet (34) in a paired mode, and the lower end of the pull rod (33) is movably connected with the lock rod (30). The embodiment of the invention further provides an ATM. The banknote device can be smaller in size, lighter in weight, convenient to assemble, disassemble and move and capable of performing audit work on the ATMs; in addition, the locking function is achieved, and the situation that the banknotes are exposed and rolled out by the human poke can be effectively prevented.

Owner:GRG BAKING EQUIP CO LTD

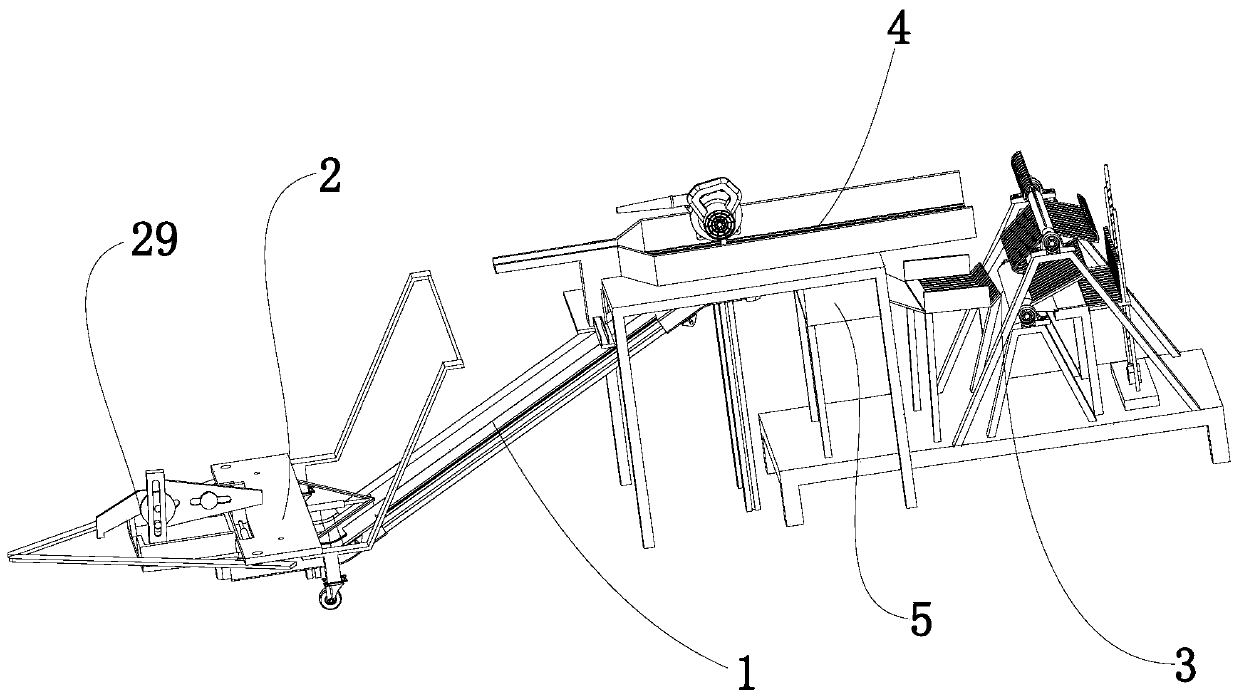

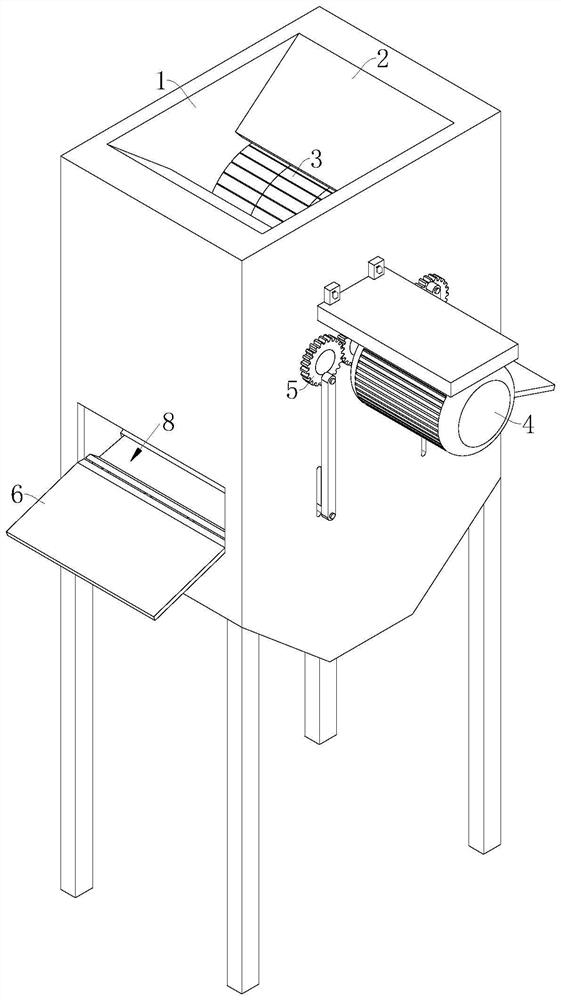

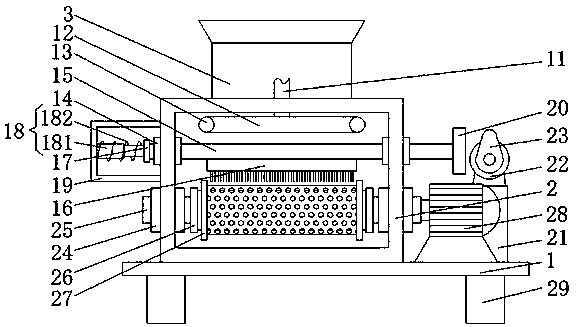

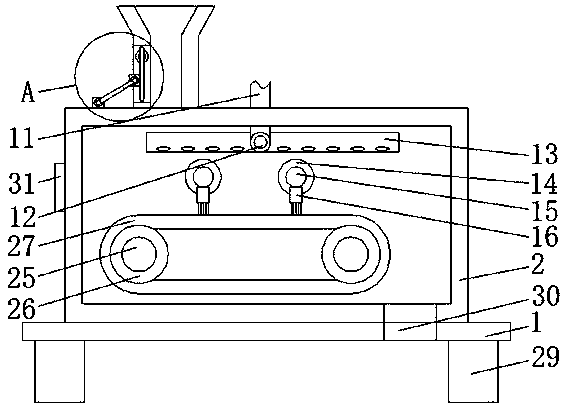

Method for collecting and processing table tennis balls for training

InactiveCN111569378ASolve technical problems with low work efficiencyPrevent impact on training qualityBall sportsGradingDust controlEngineering

The invention relates to a method for collecting and processing table tennis balls for training. The method comprises the following steps: (1) picking up: picking up scattered table tennis balls; (2)collecting: collecting the table tennis balls picked up in the step (1) together; (3) washing: putting the table tennis balls collected in the step (2) into a washing mechanism for washing, and then performing draining for a preset time; (4) cleaning: carrying out dust and water removal on the table tennis ball treated in the step (3) in a dust and water removal mechanism; and (5) screening: putting the table tennis balls treated in the step (4) into a screening mechanism for screening.According to the method for collecting and processing table tennis balls for training, table tennis balls canbe automatically picked up, dust and impurities on the table tennis balls are effectively removed, defective products are screened, and the training quality is improved.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

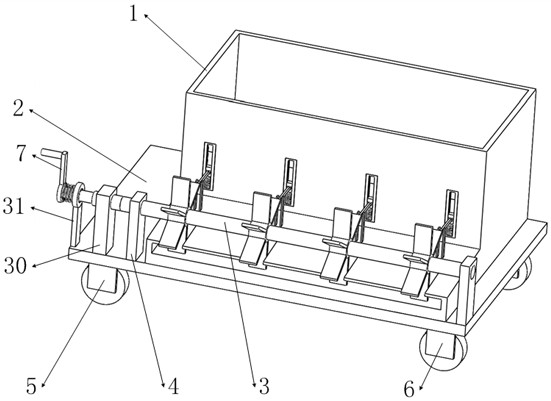

Safety-type steel pipe packing device for construction site

ActiveCN111620143AEasy to move up and downAvoid cloggingConveyorsLarge containersDrive shaftClassical mechanics

The invention belongs to the technical field of building material stacking, and particularly relates to a safety-type steel pipe packing device for a construction site. The safety-type steel pipe packing device comprises a stacking shell, a driving shaft, fixed casters, steering casters, an adjusting mechanism and an anti-blocking mechanism; a telescopic inner rod is pushed to move towards the bottom of a telescopic outer sleeve, so that a first fixing ring releases the limitation to the telescopic inner rod, a handle after being transmitted drives the driving shaft to rotate, shifting plateson a ring sleeve shift steel pipes out of a discharging groove in order so as to prevent a large number of steel pipes from rolling out of the discharging groove at one time, and then the potential harm to a user caused by the fact that the large number of steel pipes roll out is avoided as well; moreover, an anti-blocking plate in the anti-blocking mechanism can effectively prevent blocking caused by accumulation and squeezing of the large number of steel pipes, so that it is ensured that the steel pipes stacked in a stacking tank enter the discharging groove continuously; and when the steelpipes in the discharging groove do not need to be discharged, the rotation of the driving shaft is limited, so that the shifting plates on the ring sleeve do not rotate in a counterclockwise direction, and the steel pipes are prevented from injuring people.

Owner:谦谨建设集团有限公司

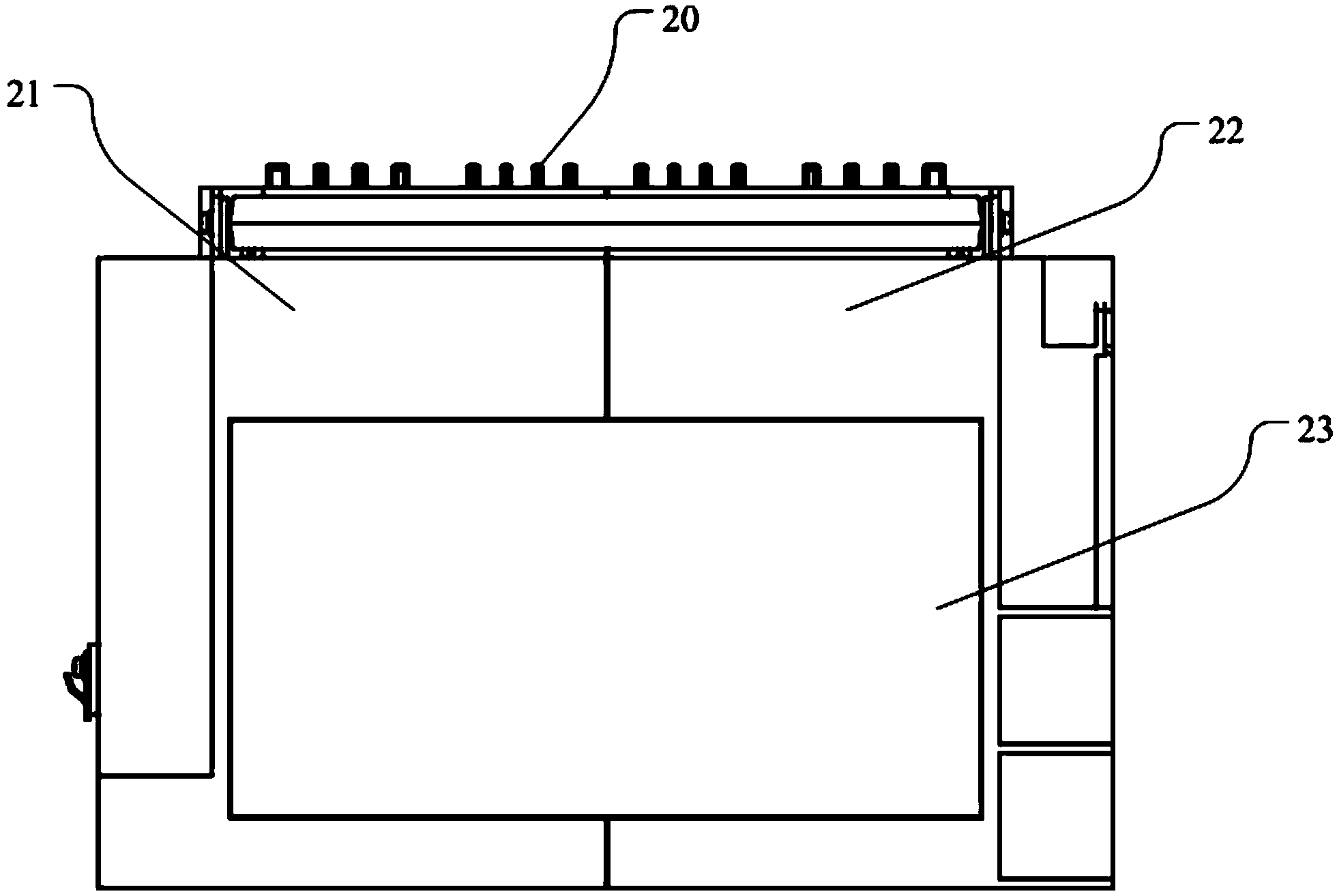

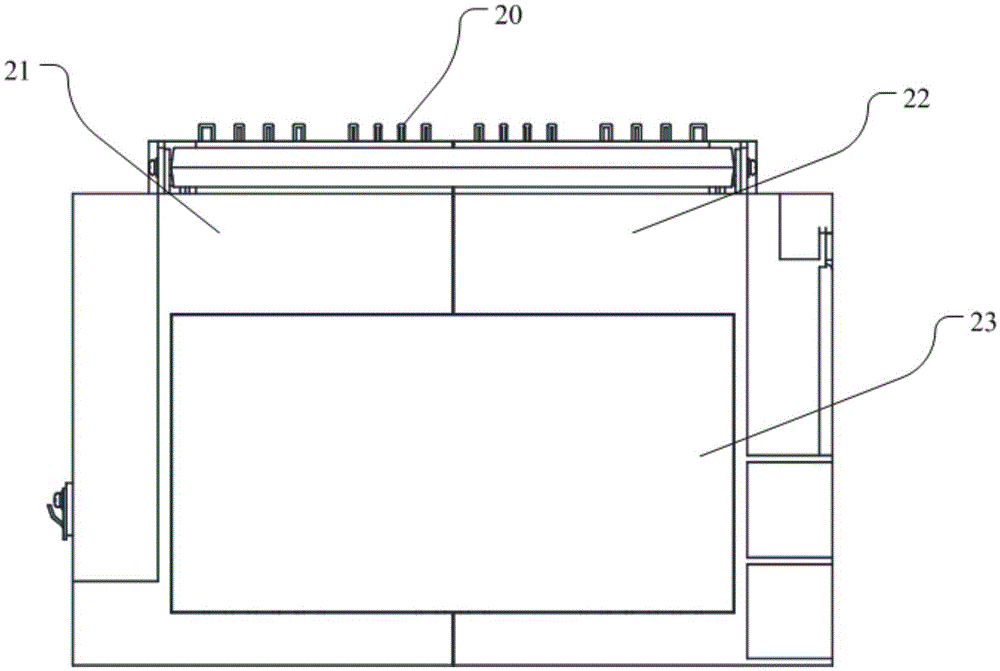

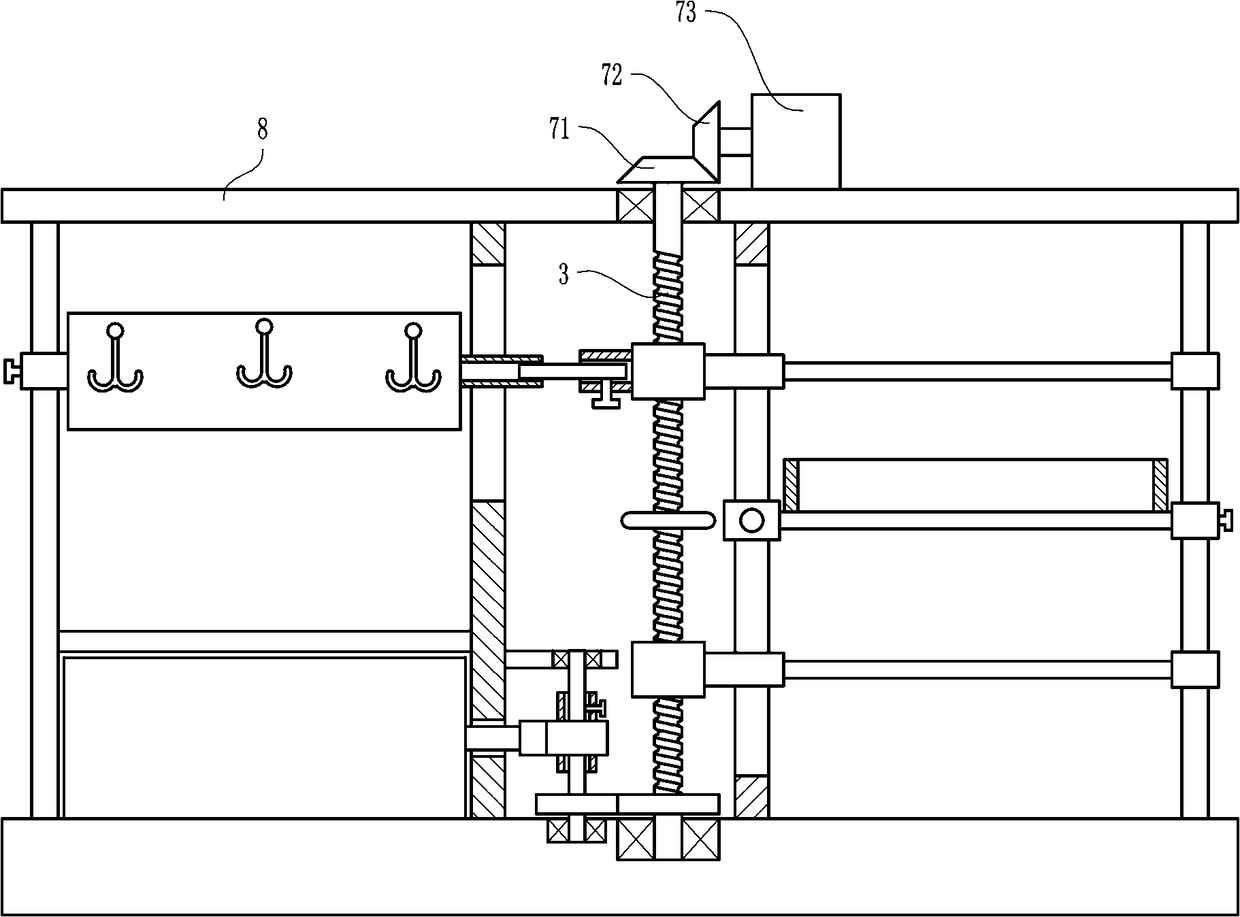

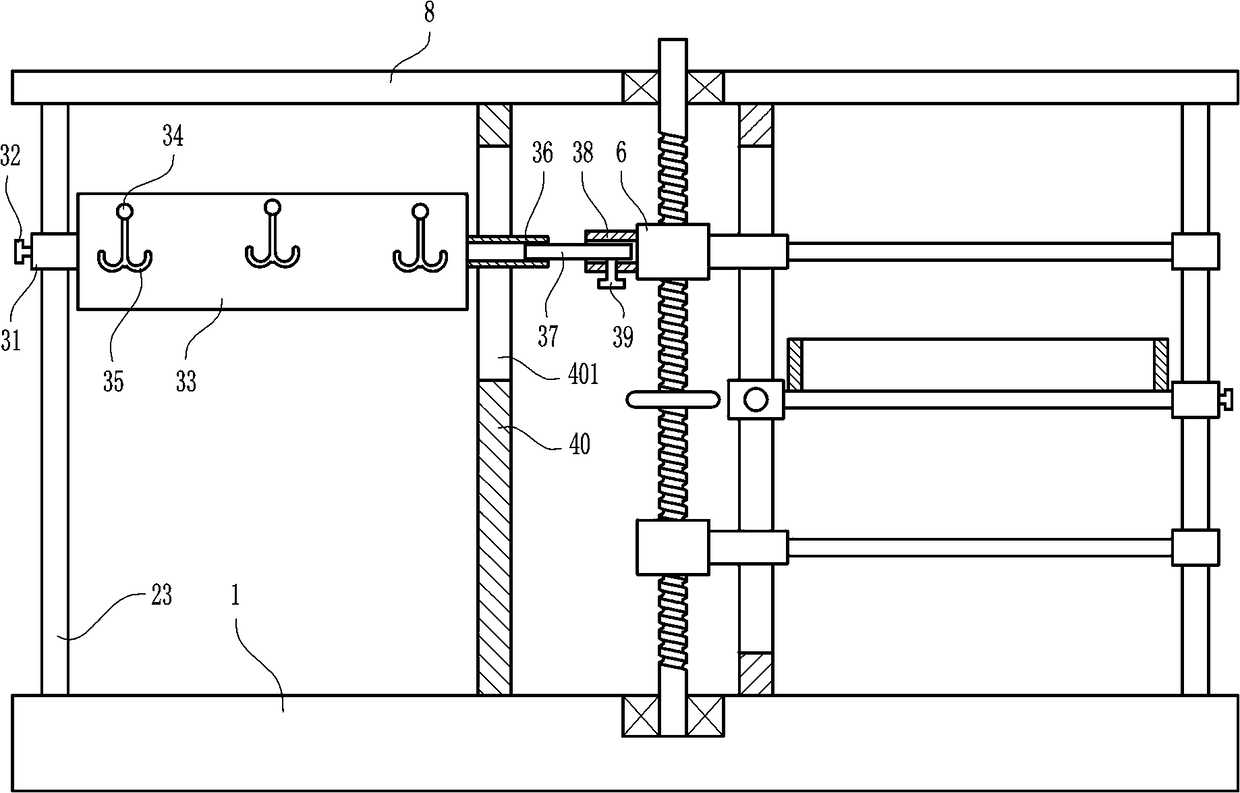

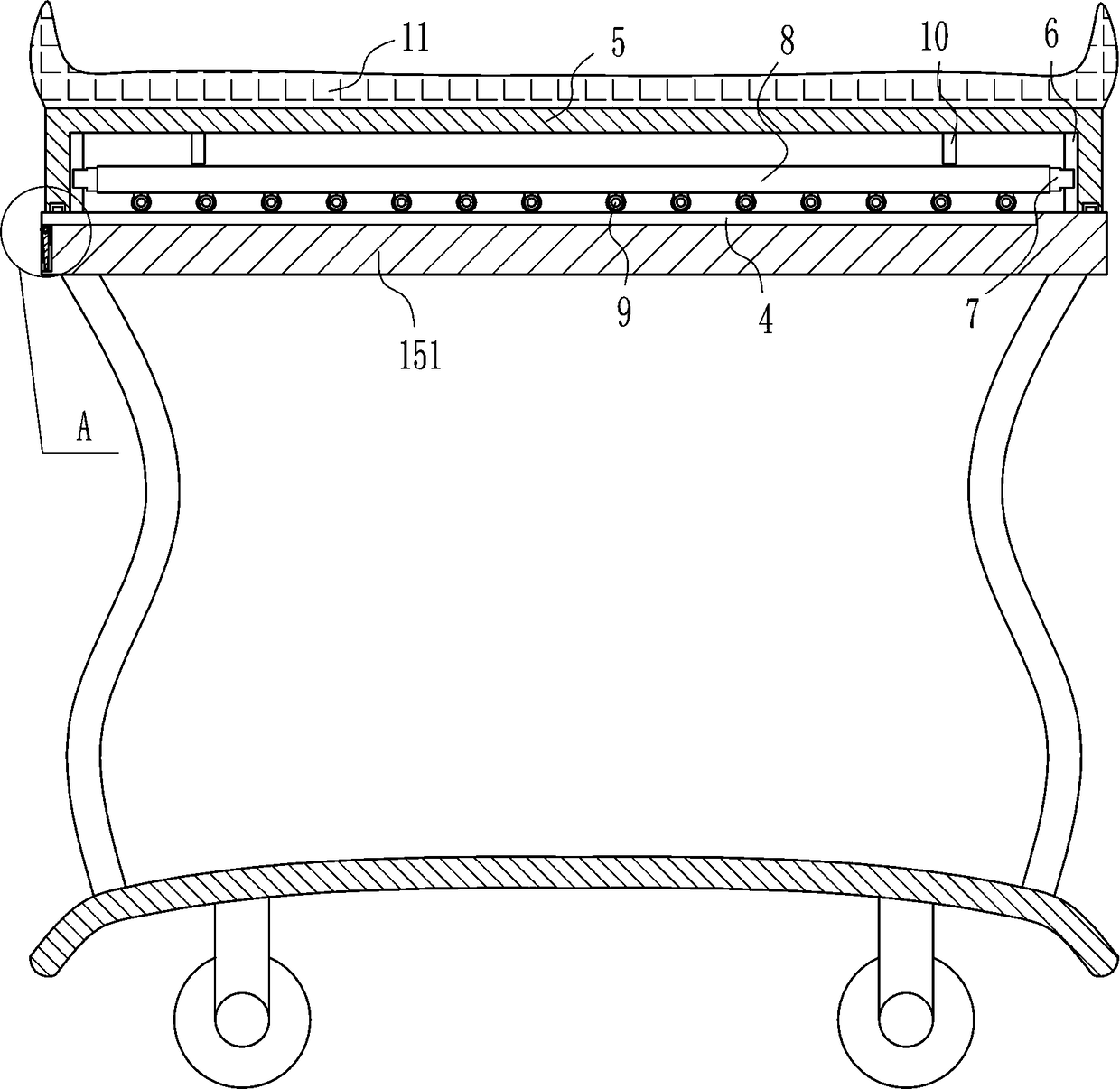

Line hooking and knotting equipment for badminton production and manufacturing

InactiveCN112206488AImprove automationPrevent rolling outBall sportsRacket sportsMechanical engineeringIndustrial engineering

The invention provides line hooking and knotting equipment for badminton production and manufacturing. The equipment comprises a box body, an n-shaped plate, an output mechanism, a loading mechanism,a feeding mechanism, a telescopic driving mechanism, a line hooking mechanism and a line releasing mechanism; the top of the box body is fixedly connected with the n-shaped plate, and the center of the top of the box body is notch-shaped; side plates are vertically and fixedly connected to the positions, located on the left side and the right side of the notch, of the bottom in the box body, the tops of the side plates extend to the outer side of the box body, and a corrugated plate driving a blowing device is fixedly connected to the side, close to the blowing device, of the top of the supporting plate; and a groove is formed in the center of one side, close to the blowing device, of the corrugated plate. A first electric push rod is fixedly connected to the center of the lower end of thetop of the n-shaped plate, a fixing plate is fixedly connected to the top of the box and located on the rear side of the fixing block, and a pushing device is longitudinally and fixedly installed onthe side, close to the fixing block, of the fixing plate by corresponding to a feeding channel. The invention provides line hooking and knotting equipment for badminton production and manufacturing, and a problem of low working efficiency caused by manual feeding of badminton hook line knotting in the prior art is solved.

Owner:张宇

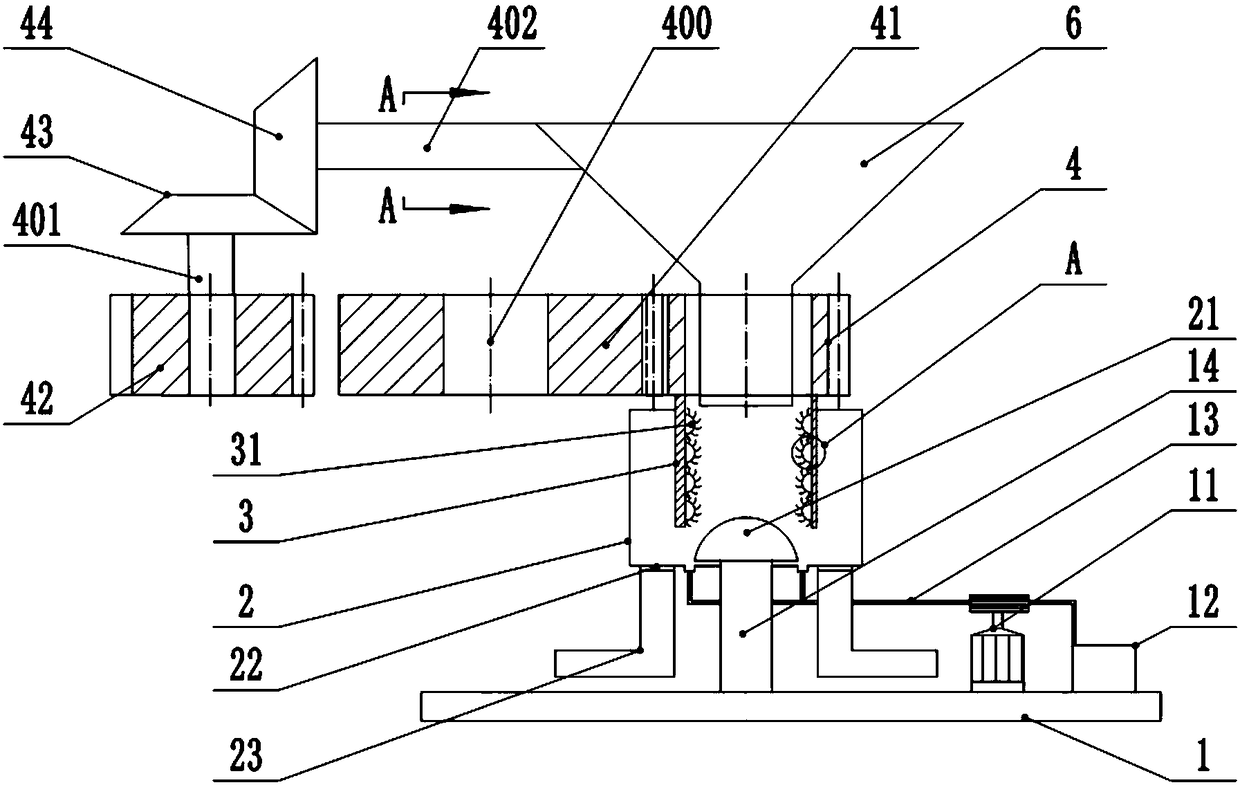

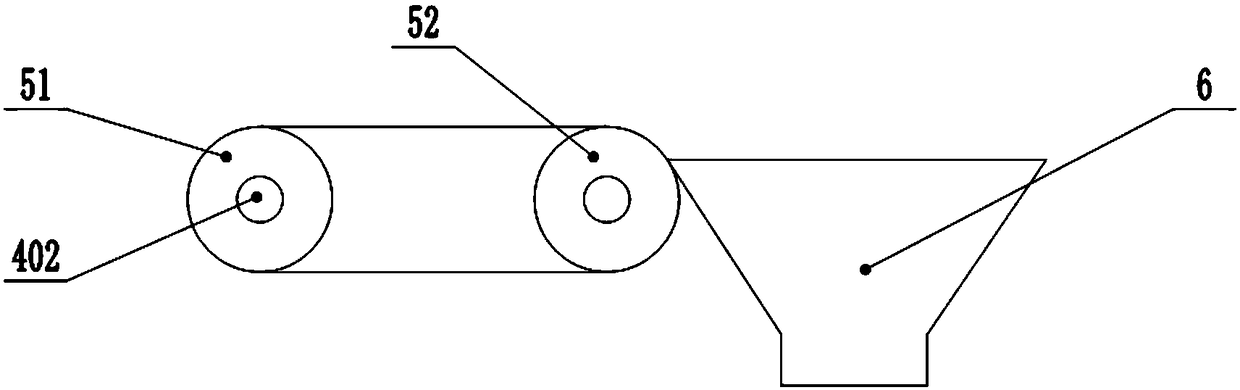

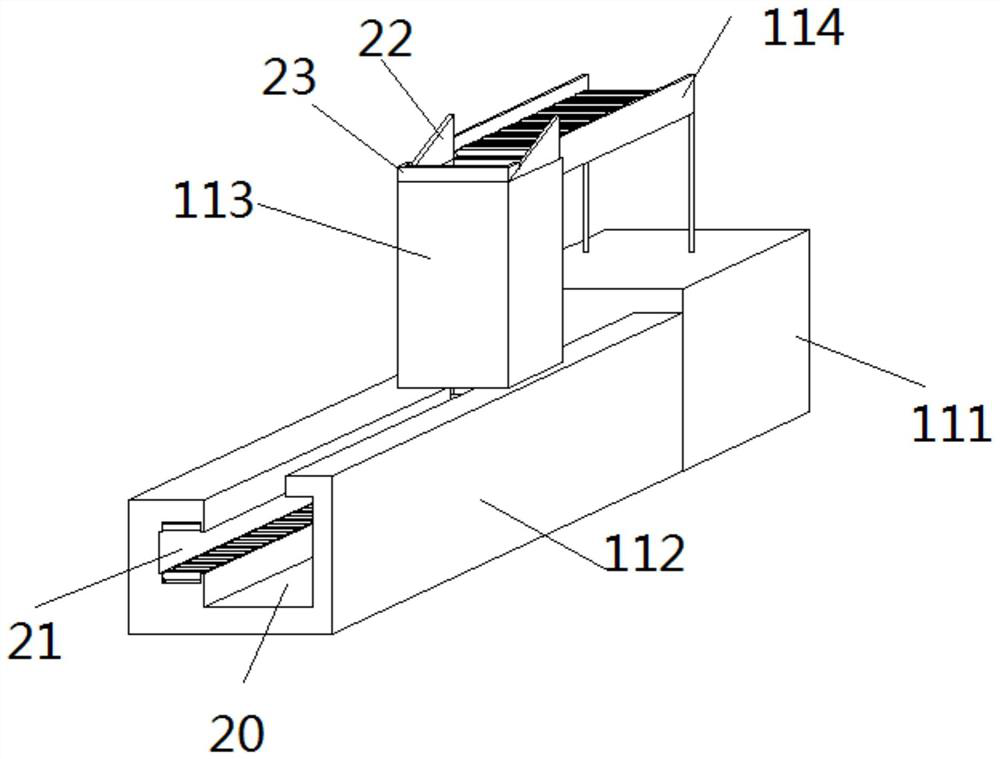

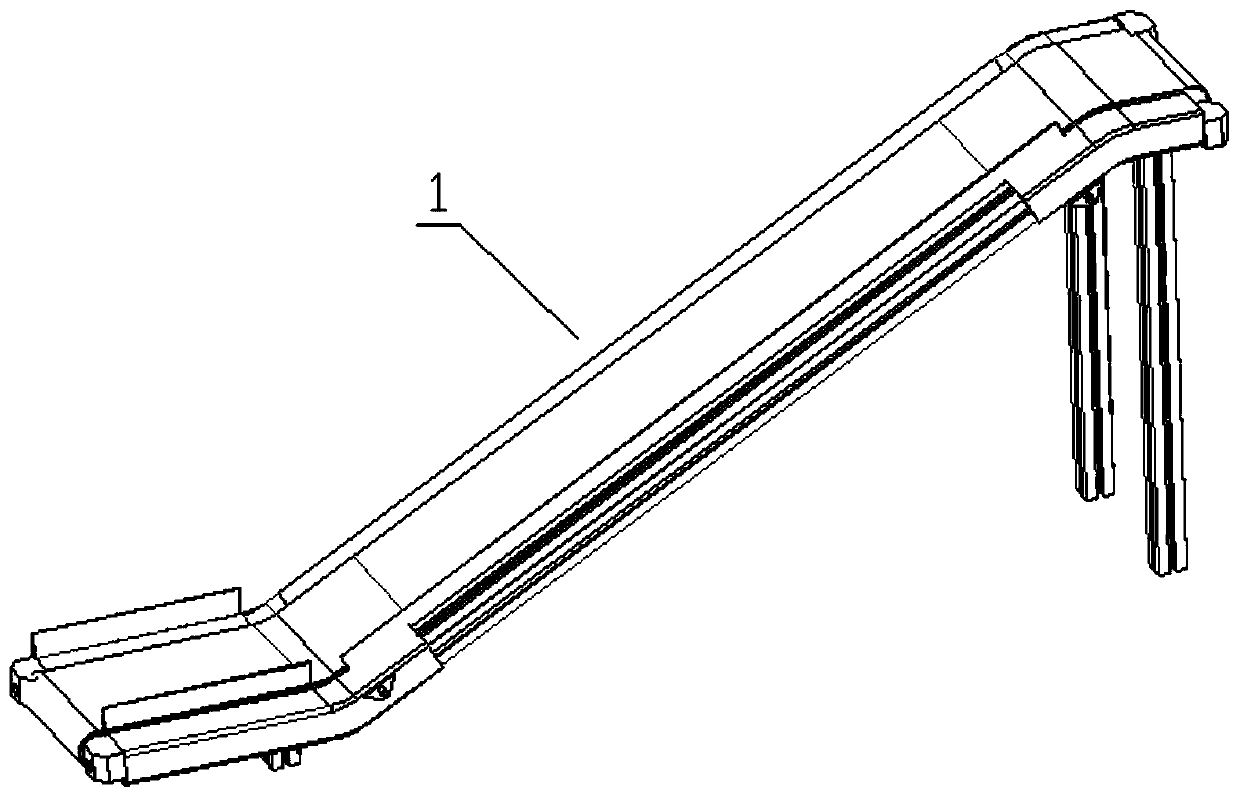

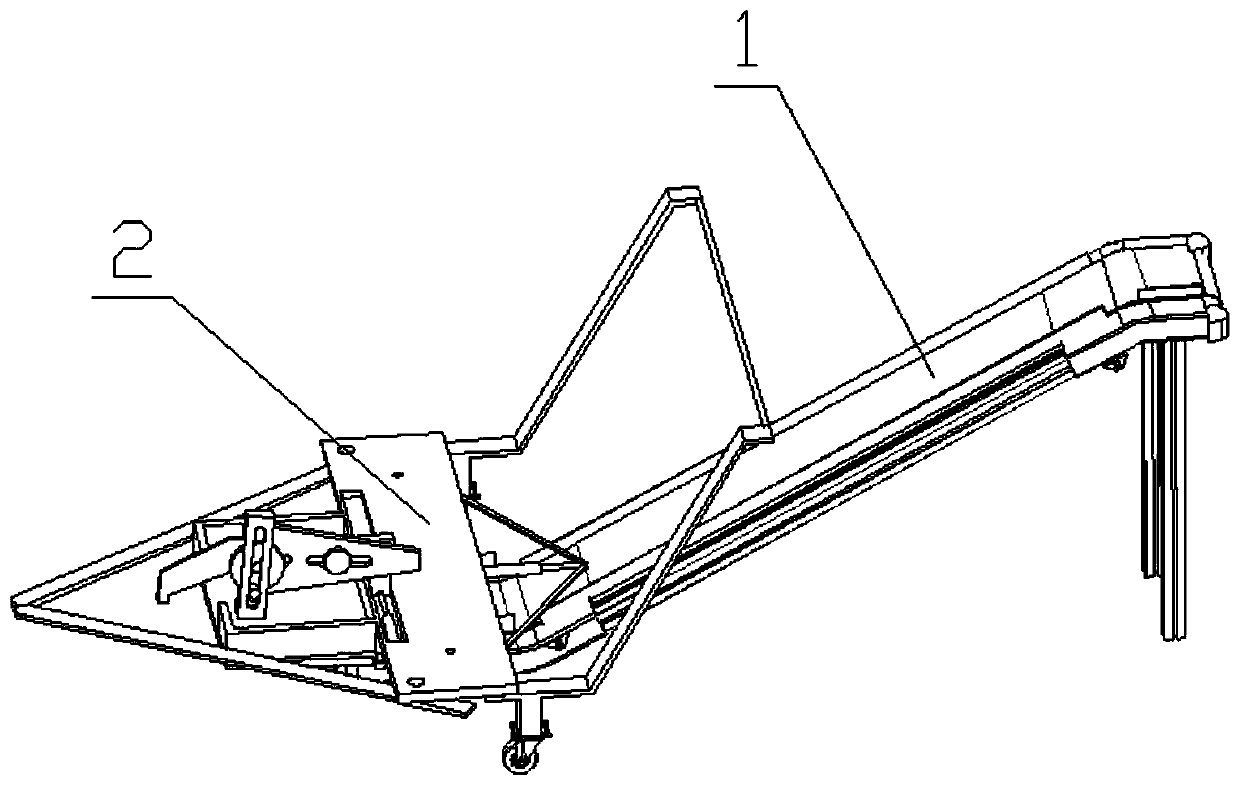

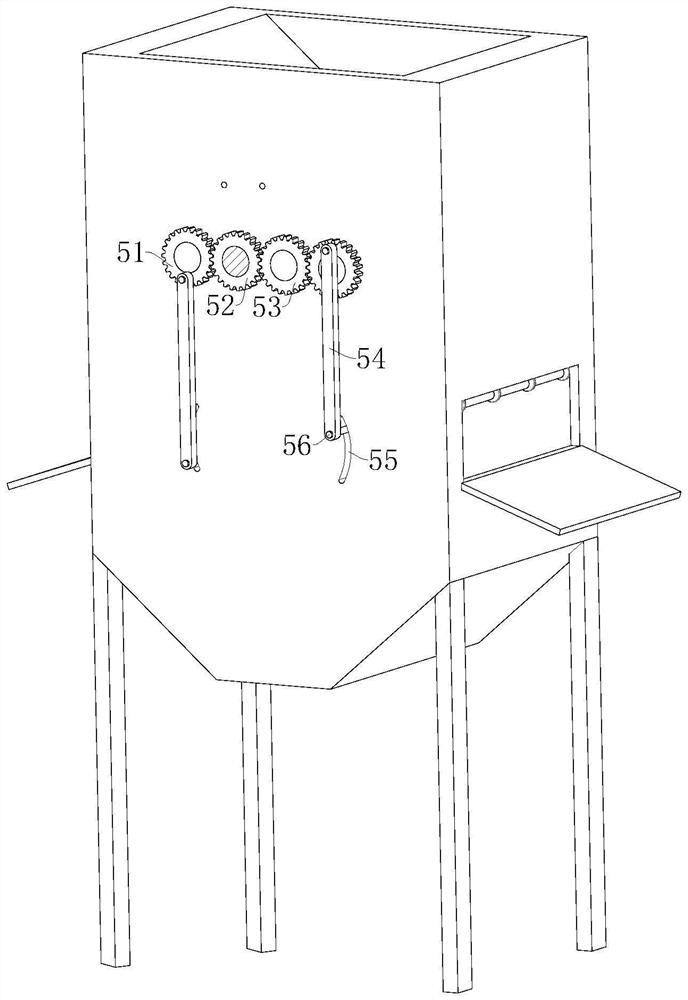

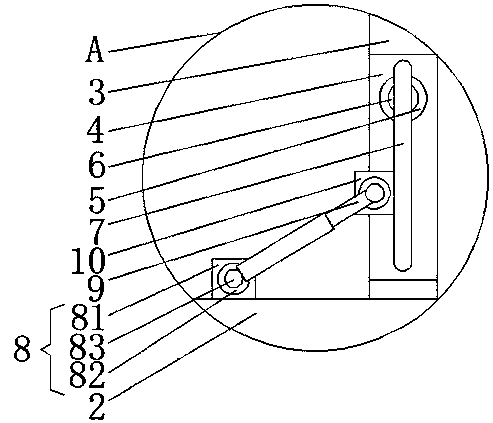

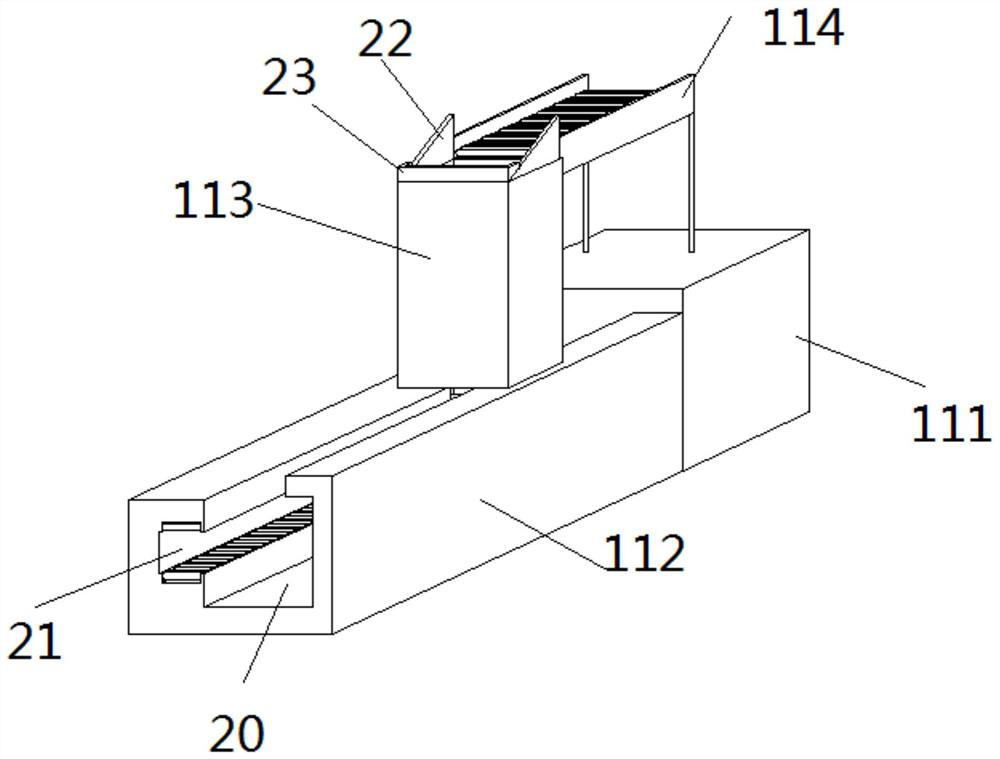

Table tennisball picking device and table tennis ball picking method

InactiveCN111569376ASolve technical problems with low work efficiencyPrevent impact on training qualityBall sportsGradingSports equipmentDust control

The invention provides a table tennis ball picking device and a table tennis ball picking method, and belongs to the technical field of sports equipment. The technical scheme is as follows: the devicecomprises aconveying mechanism, and the conveying mechanism comprises an input end and an output end; a picking mechanism is arranged at the input end of the conveying mechanism; the picking mechanism is used for picking up table tennis balls,and a dust removal mechanism is arranged at the output end of the conveying mechanism; the dust removal mechanism is used for dedusting the picked table tennis balls, ascreening mechanism is arranged at the position close to the dedusting mechanism and arranged on the upper portion of the output end of the conveying mechanism, the conveying mechanism conveys the table tennis balls picked by the picking mechanism from the input end to the output end, and the table tennis balls are screened by the screening mechanism after being dedusted by the dust removal mechanism. The table tennis ball picking device has the beneficial effects that the problem that people need to bend down and knees when picking table tennis balls manually is solved, the tabletennis balls can be collected efficiently, dust and impurities in the collected table tennis balls can be removed, meanwhile, the deformed table tennis balls can be screened out, and the training quality is improved.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

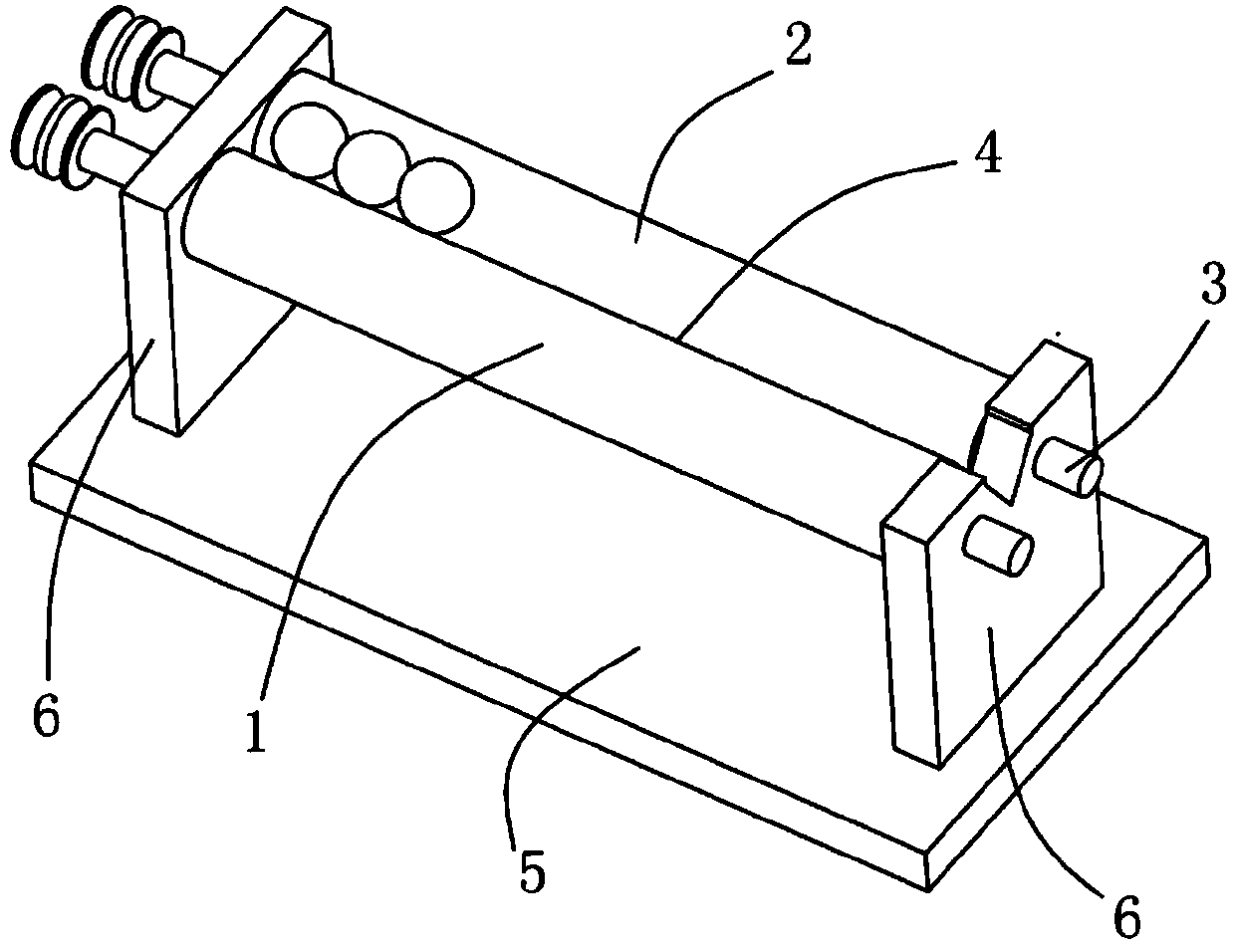

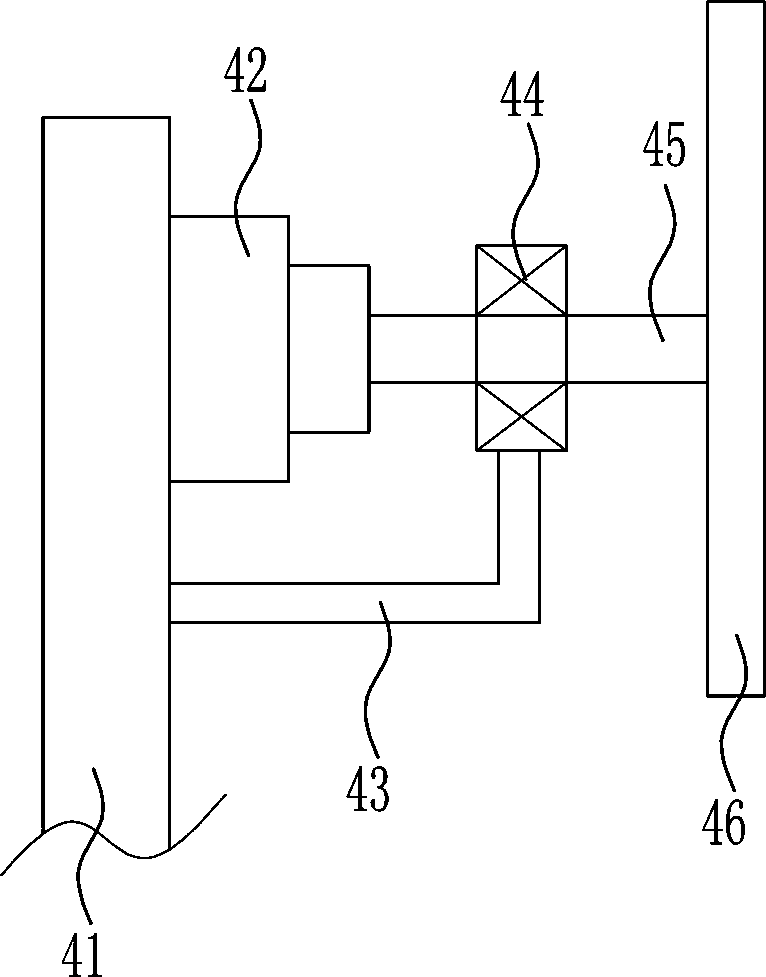

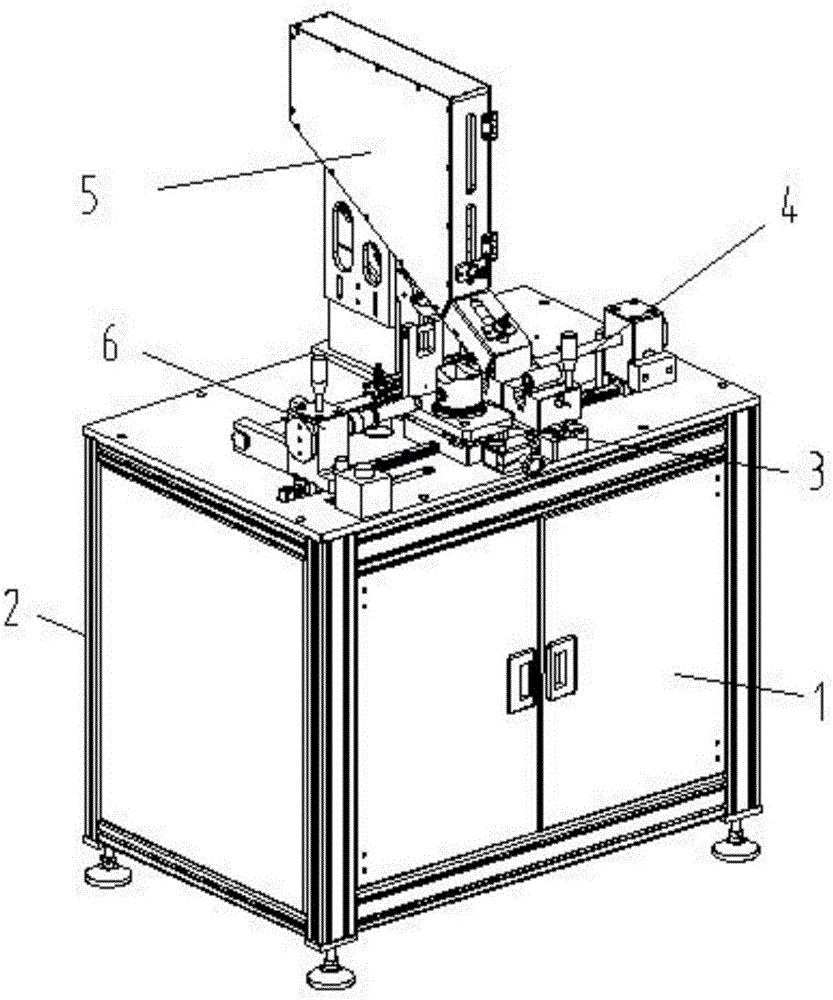

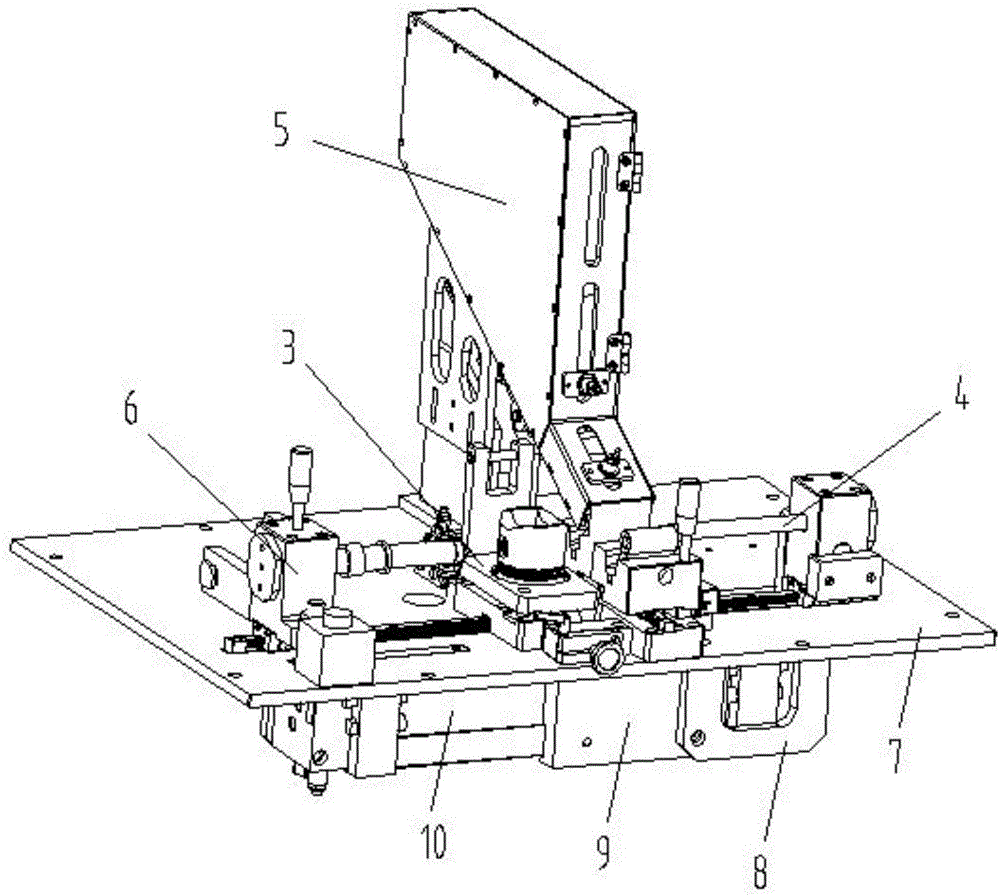

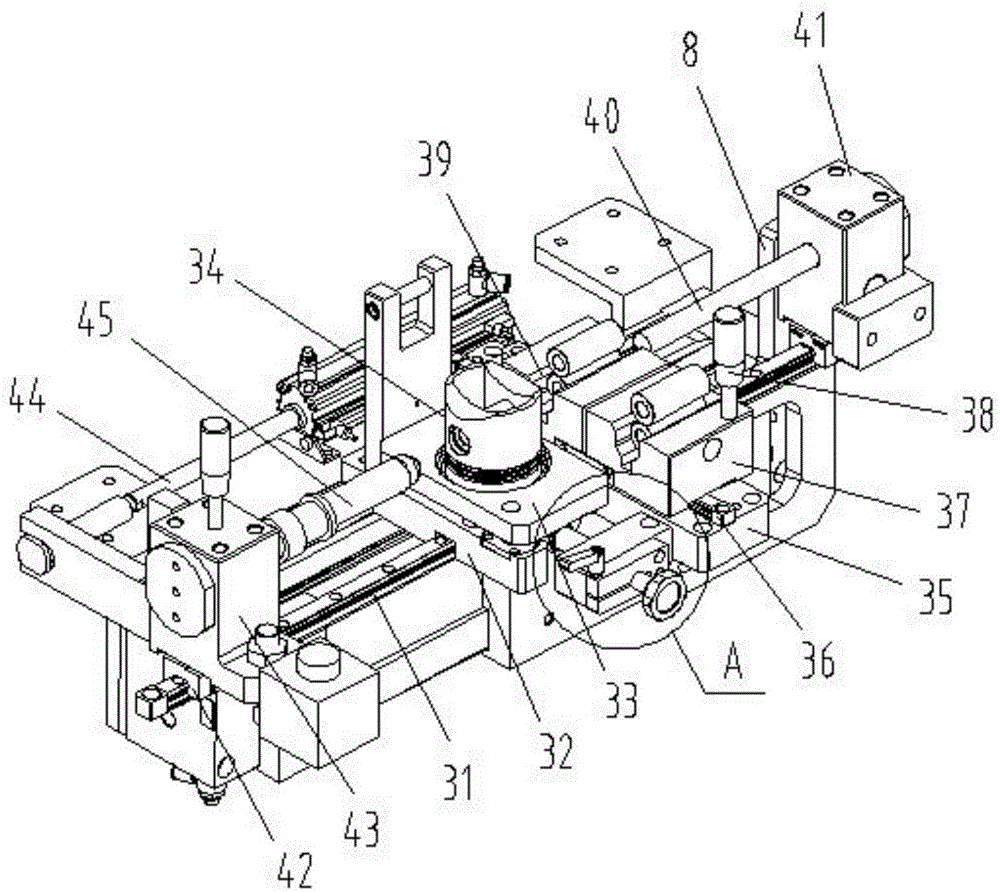

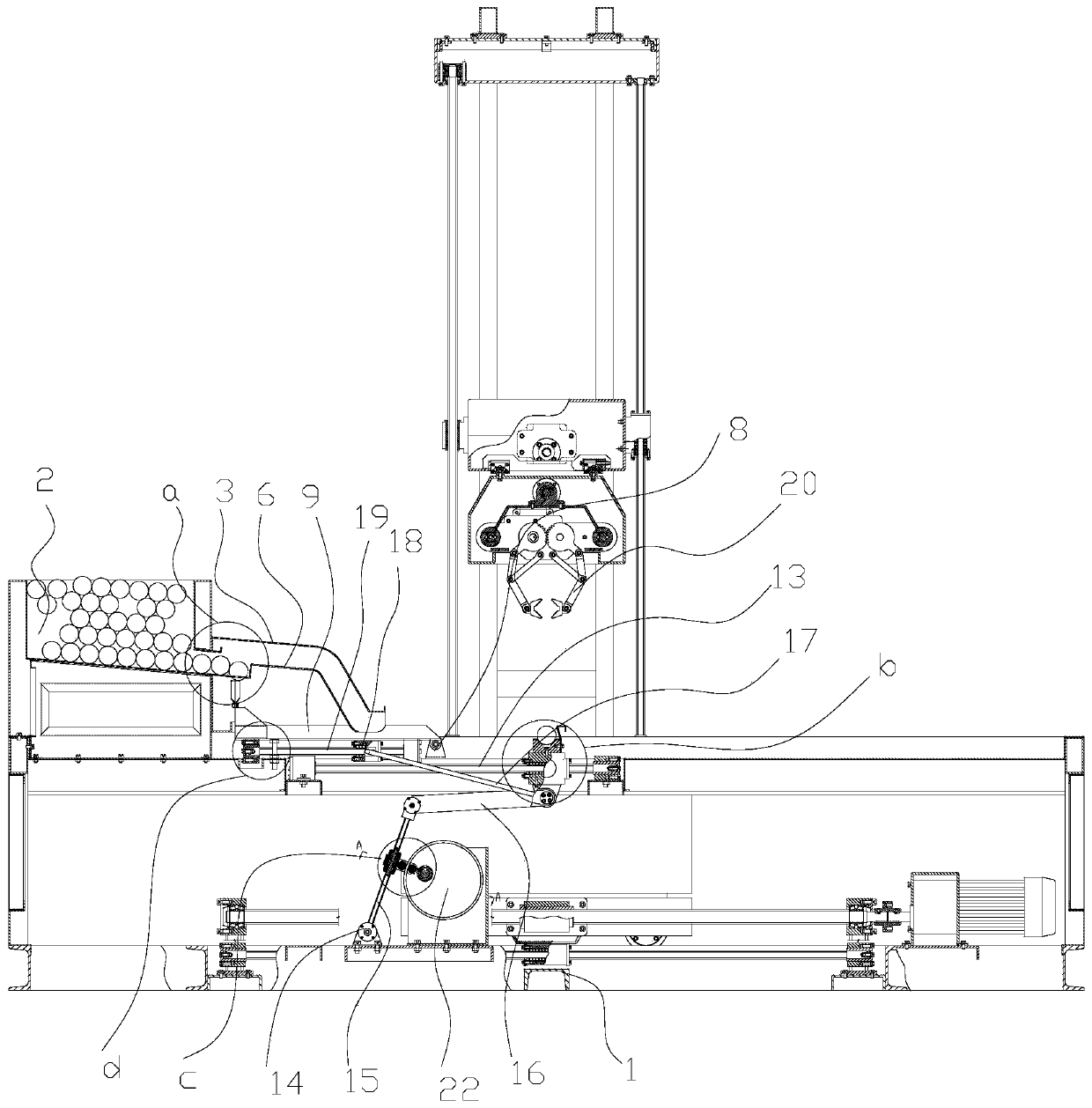

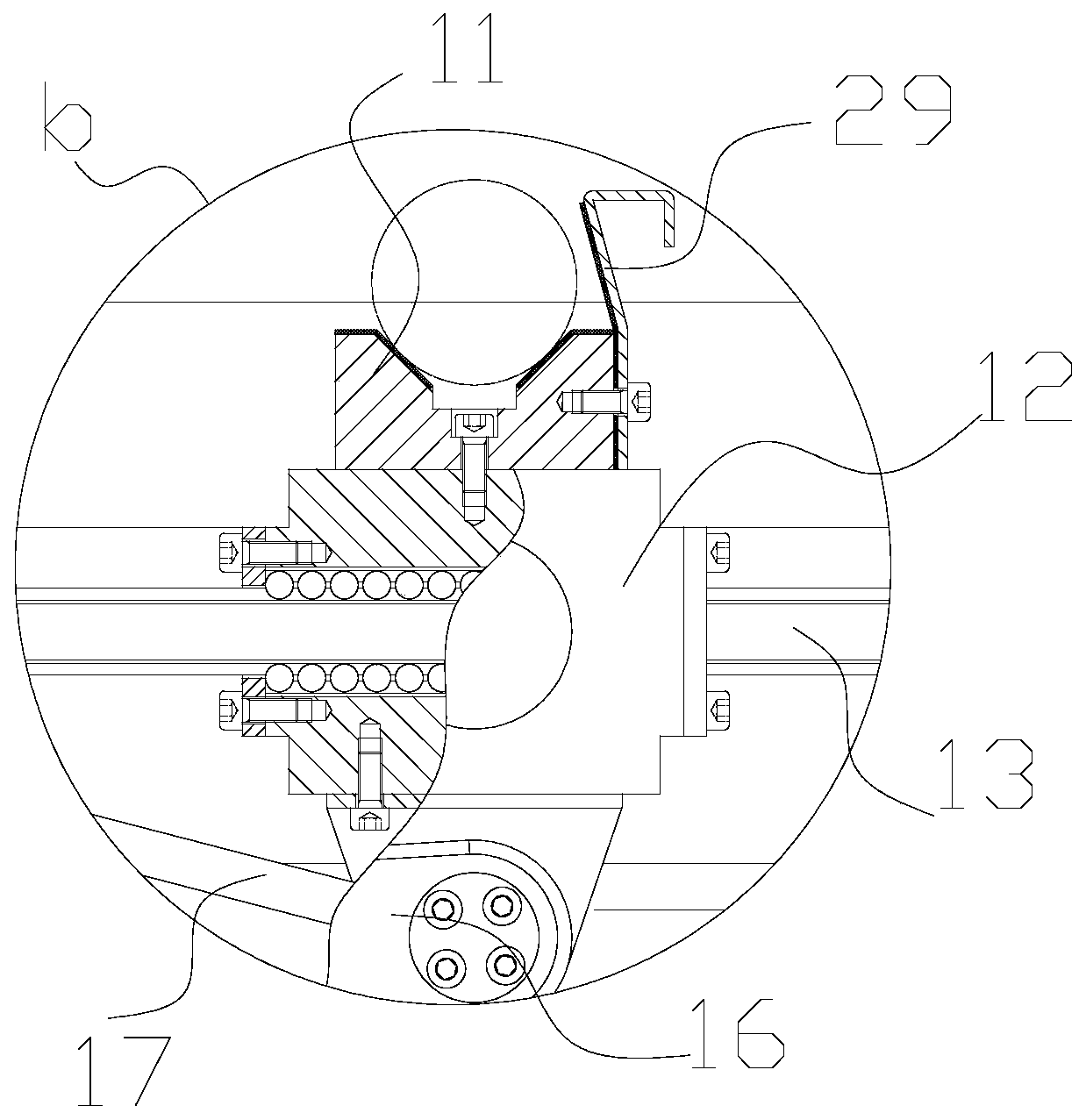

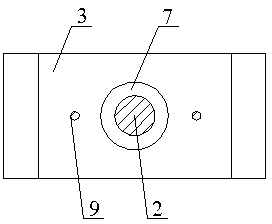

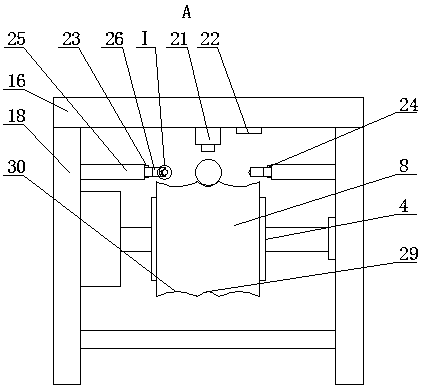

Automatic assembling machine for piston pin

ActiveCN106736434AImprove plug efficiencyReduce plug-in timeMetal working apparatusPistonDistribution control

The invention relates to an automatic assembling machine for a piston pin. A power distribution control box is arranged on a rack, a working platform is arranged on the power distribution control box, a fixing device and a bolt mechanism which are in fit with each other are arranged on the working platform, the fixing device comprises a fixed seat on the working platform, and a fixing plate in fit with a piston is arranged on the fixed seat; the bolt mechanism comprises a mounting base arranged at the right side of the fixed seat, a loading block is arranged on the mounting base, a loading chute in fit with the piston pin is formed in the loading block, the loading chute is in locational fit with a bolt hole of the piston, a pushing device in fit with the loading chute is arranged at the right side of the loading chute, and the pushing device is connected with the power distribution control box. The automatic assembling machine for the piston pin has the advantages that the piston is fixed by virtue of the fixing device, the piston pin in the loading chute is pushed into the piston pin hole by virtue of the bolt mechanism in fit with the fixing device, bolting efficiency is greatly improved, bolting time is shortened, and bolting strength also can be accurately controlled, so that inserted depth of the piston pin is appropriate, and multiple piston pins are the same in the inserted depth.

Owner:安徽鼎立智能制造股份有限公司

Transmission mechanism with inclined plane

InactiveCN103754551APrevent rolling outControl devices for conveyorsChutesEngineeringMechanical engineering

Owner:CHONGQING MING SHIELD ELECTROMAGNETIC VALVE

Adjusting and screening type underground coal gangue separating device

The invention belongs to the technical field of coal gangue separation and relates to an adjusting and screening type underground coal gangue separating device. The device comprises a box body, two feeding baffles, pressure separation devices, a driving motor, a transmission mechanism, a gangue discharging sliding plate, a screening mechanism and a coal outlet; the feeding baffles are symmetrically welded onto the top of the box body; two sets of pressure separation devices are symmetrically mounted below the feeding baffles and are rotationally connected to the interior of the box body; one end of each pressure separation device is connected with the transmission mechanism; the transmission mechanism is located on the outer side of the box body; one side of the transmission mechanism is connected with the driving motor; the driving motor is fixed to the side wall of the box body through screws; and screening and filtering mechanisms are mounted below the pressure separation devices. According to the adjusting and screening type underground coal gangue separating device, the crushing pressure can be adjusted in time according to different hardness of gangue in raw coal, the situation that the gangue is crushed due to the fact that the pressure of the separating device is too large can be prevented, the coal and the gangue cannot be mixed together. The separating device is wide in application range and high in universality.

Owner:ANHUI UNIV OF SCI & TECH

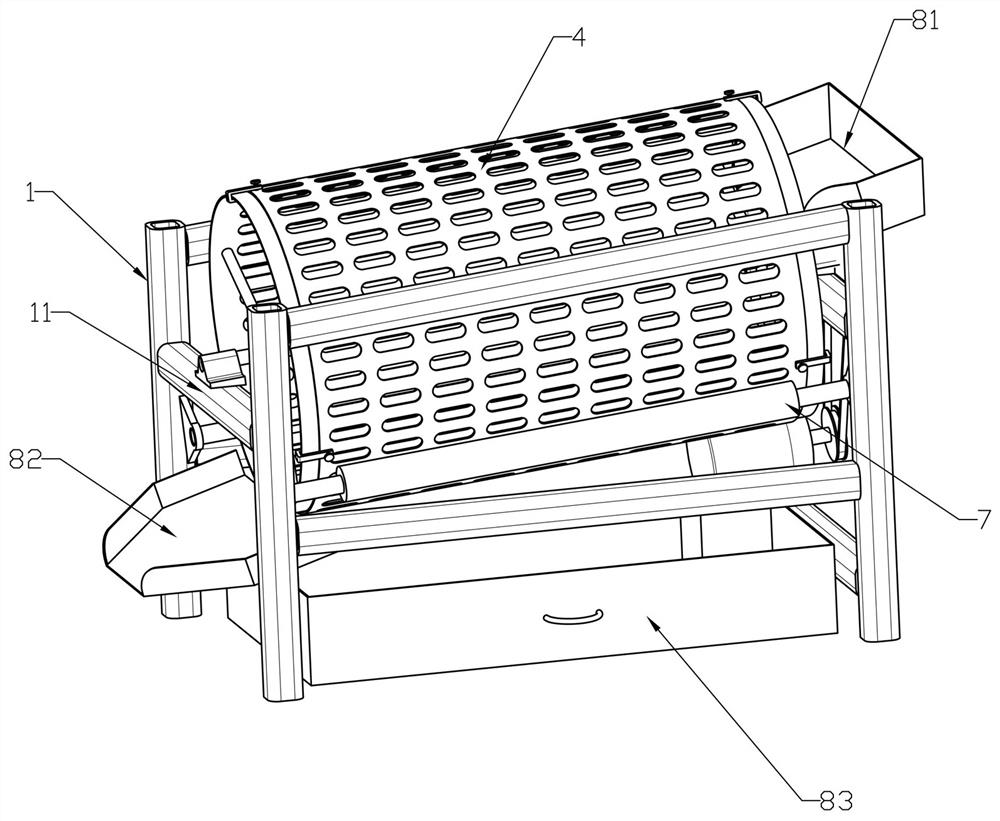

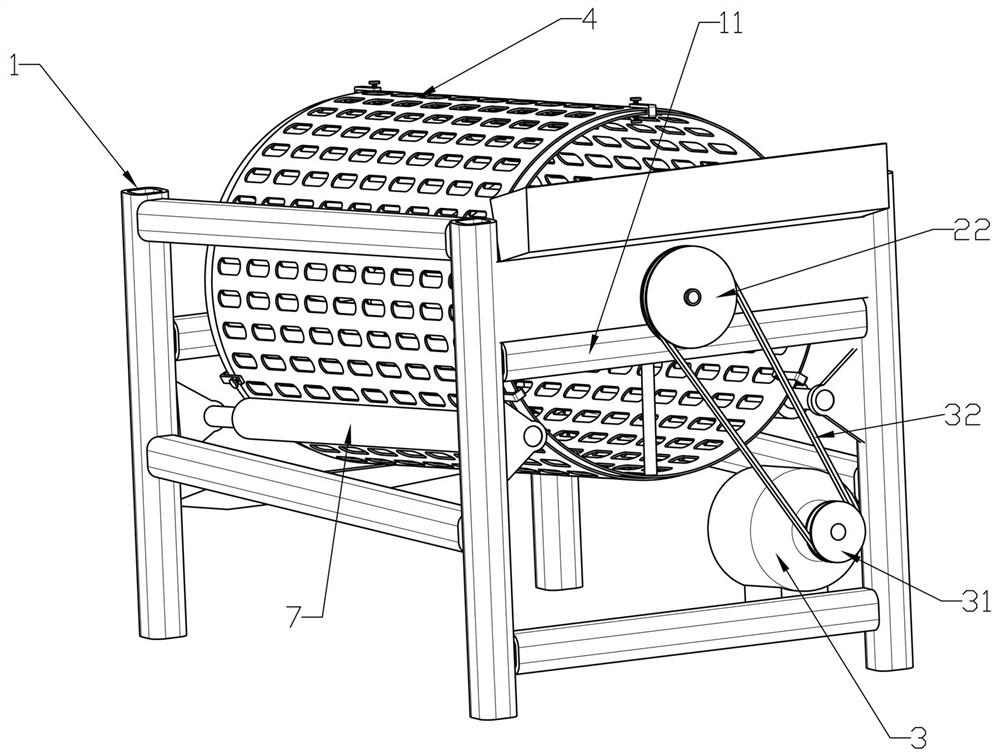

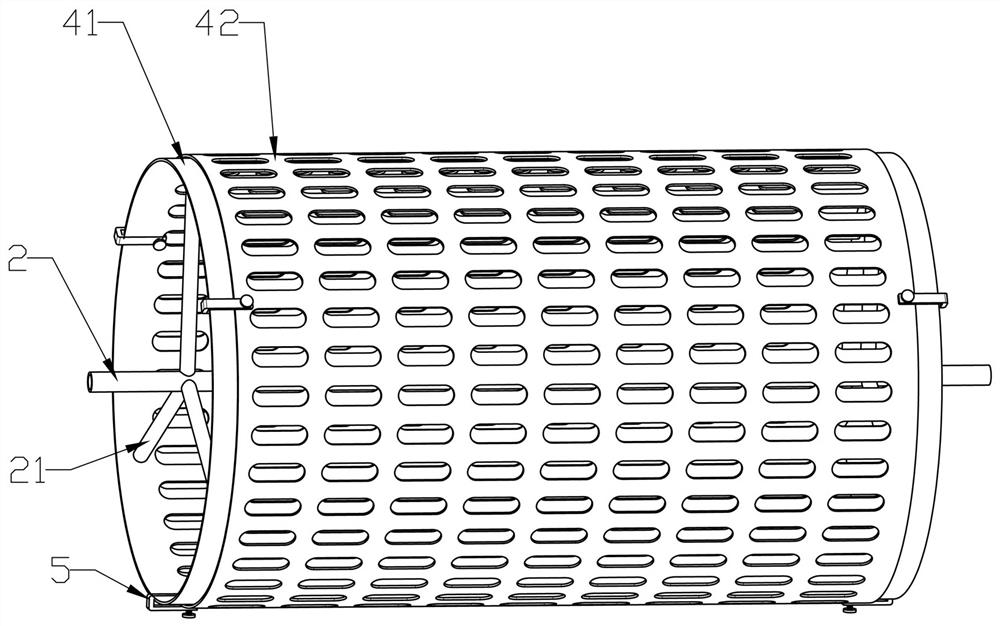

Adjustable peanut sorting machine

PendingCN111659604AEasy to adjustEasy to operateSievingScreeningAgricultural engineeringElectric machinery

The invention discloses an adjustable peanut sorting machine. The adjustable peanut sorting machine comprises a machine frame, and an anti-blocking sorting device is arranged on the machine frame; theanti-blocking sorting device comprises a fixing supporting shaft, a drum driving motor, an adjustable screen drum and an anti-blocking roller, the fixing supporting shaft is rotatably fixed on the machine frame, one end of the fixing supporting shaft is in transmission connection with the drum driving motor, and the front end of the fixing supporting shaft is inclined downwards; and the adjustable screen drum comprises an inner screen drum body and an outer screen drum body. The adjustable peanut sorting machine is simple in structure; when the adjustable peanut sorting machine is in use, thesize of meshes of the screen drum can be adjusted according to the size of peanut pods on the site, it is not needed to replace the screen drum, and operation is convenient; besides, peanut pods blocking the meshes can be removed when the screen drum rotates, and the working efficiency is improved; and moreover, peanut pods can be put into the screen drum to a saturated state at a time, it is notneeded to put to-be-sorted peanut pods into the sorting machine continuously, and use is convenient.

Owner:河南省农业科学院长垣分院

Self-feed feeding device

PendingCN111348418AReduce labor costsPlace stableConveyorsConveyor partsAgricultural engineeringReclaimer

The invention provides a self-feed feeding device. The self-feed feeding device comprises a rack, a feeding groove assembly, a material ejection turning plate assembly, a material taking assembly, a transmission assembly and a driving assembly; the feeding groove assembly comprises a groove body and a discharging hopper, a material ejection opening is formed in the discharging hopper, and the groove body is used for containing steel pipes; the material ejection turning plate assembly comprises a first hinge seat, a connecting groove and a material ejection block, and the material taking mechanism comprises a material taking groove, a material taking sliding block and a material taking sliding rail; the transmission assembly is used for driving the connecting groove to rotate, the connecting groove is used for driving the material ejection block to upwards penetrate through the material ejection opening to eject the steel pipes and then discharge the steel pipes from the discharging hopper, the steel pipes roll to the material taking groove after being discharged, and the transmission assembly can drive the material taking groove to move to the grabbing position of a manipulator; and the driving assembly is used for driving a rocker to reciprocate left and right. Due to the adoption of the technical scheme, the self-feed feeding device can save time and labor, and can reduce thelabor cost.

Owner:CHONGQING ELECTRIC POWER COLLEGE

Round steel lifting mechanism

InactiveCN103274336AAvoid the problem of losing balance and fallingProcess stabilityLifting framesArchitectural engineeringScrew thread

Owner:四川东方能源科技股份有限公司

A portable drum type cash box and an atm machine

ActiveCN104036587BReduce volumeReduce weightPaper-money testing devicesCoin/currency accepting devicesLocking mechanismSelf locking

A portable drum-type banknote box and an ATM having the portable drum-type banknote box. The portable drum-type banknote box comprises a shell (42), a large winding drum gear (36), a small winding drum gear (35), a connecting socket (38) and a self-locking mechanism. The self-locking mechanism comprises an electromagnet (34), a first spring (40), a second spring (41), a first locking rod (30), a second locking rod (31) and a pull rod (33). The upper end of the pull rod (33) is installed to the electromagnet (34) in a paired mode, and the lower end of the pull rod (33) is movably connected with the first locking rod (30). The portable drum-type banknote box has a small size and light weight, is convenient to assemble / disassemble and move and is capable of performing audit work on multiple ATMs; and achieves a locking function so as to effectively prevent the banknotes from being exposed and rolled out by human poke.

Owner:GRG BAKING EQUIP CO LTD

Fermented soya bean steaming device having function of controlling capacity

The invention discloses a fermented soya bean steaming device having a function of controlling capacity. The fermented soya bean steaming device comprises a bottom plate, wherein the upper surface ofthe bottom plate is fixedly connected with the lower surface of a housing; a feeding hopper is arranged on the upper surface of the housing; a through hole is formed in the back surface of the feedinghopper; and first bearings are clamped to the upper side of the left side surface and the upper side of the right side surface of the inner wall of the through hole. According to the fermented soya bean steaming device having the function of controlling capacity disclosed by the invention, the feeding hopper, a baffle plate, a first rotating device, an electric push rod, a second rotating device,an air inlet pipe, a second through pipe, sliding rods, brushes, a telescopic device, a cam and a second motor are arranged, so that raw materials can be more uniform to heat; besides, the speed of steaming the raw materials is increased; the height of two sides of the surface of a transmission mesh belt is higher than that of the middle surface, so that the condition that when the raw materialsfall down to the transmission surface, the raw materials roll out can be avoided, and the condition when the raw materials are overturned by the brushes, the raw materials are overturned from the transmission mesh belt can be avoided; the heating speed of the raw materials is increased, and the processing efficiency of the raw materials is improved.

Owner:WUXI SUYA FOOD CO LTD

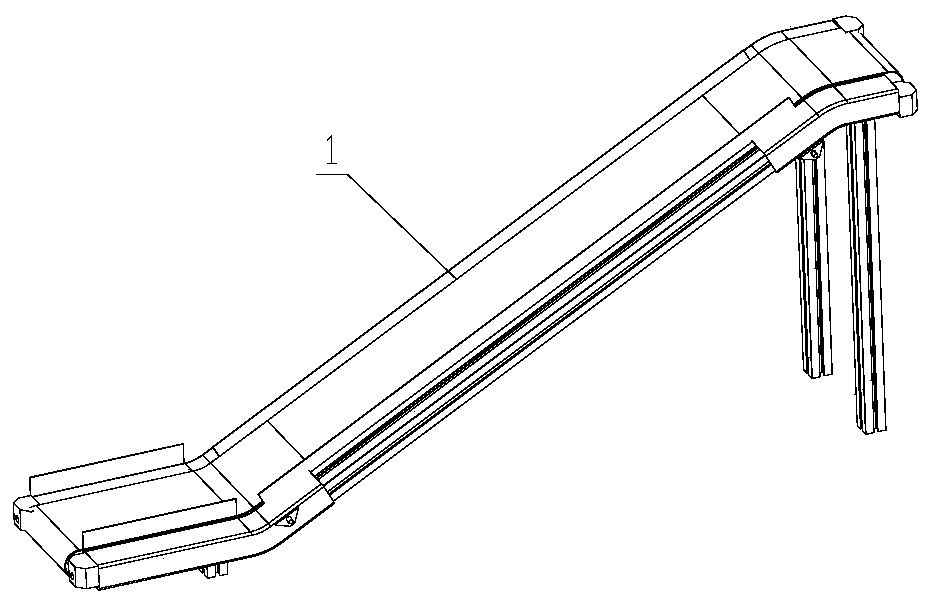

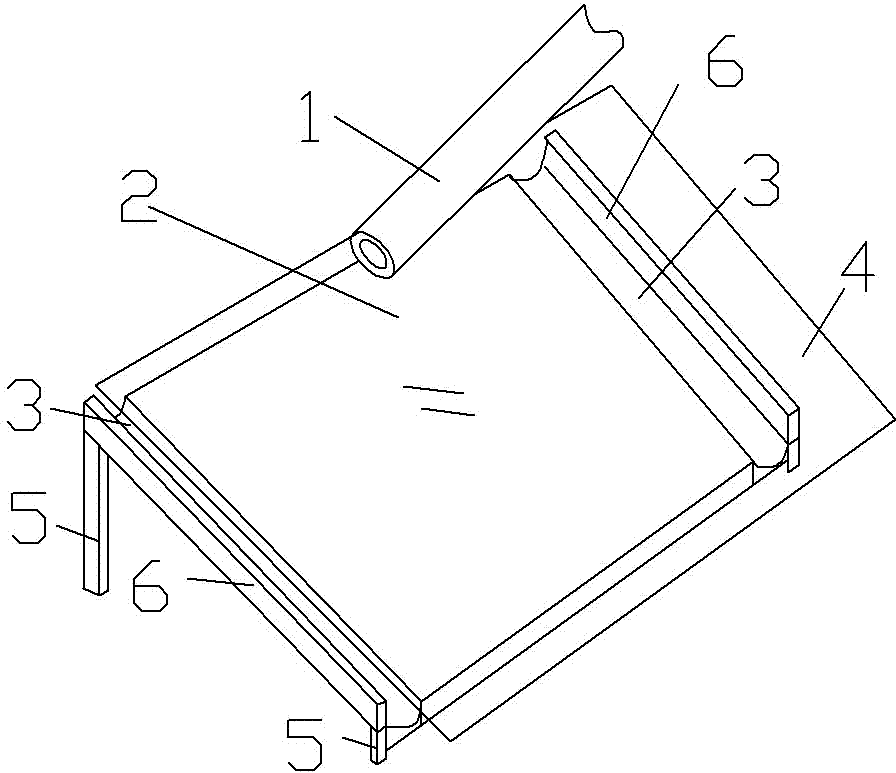

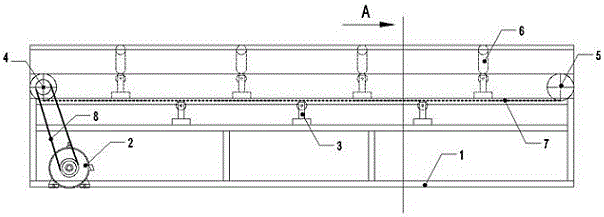

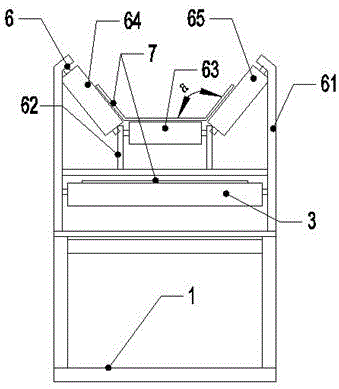

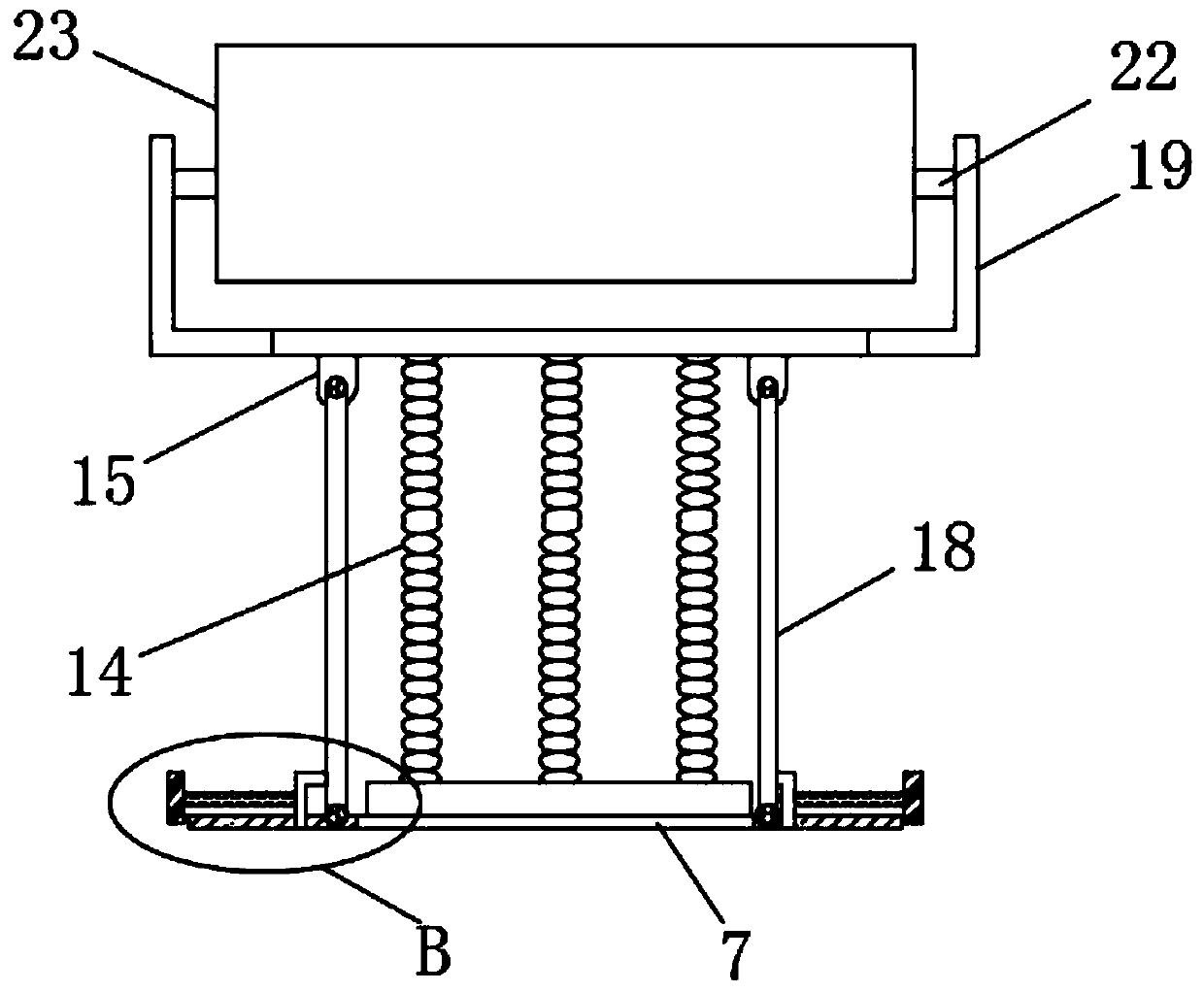

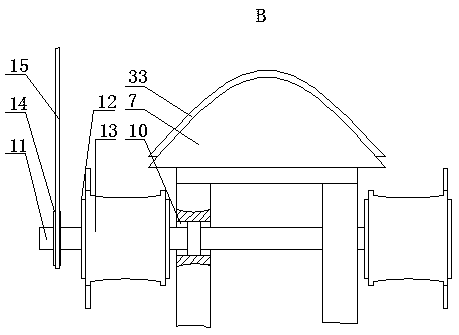

Battery conveying device

PendingCN106586373APrevent rolling outExtended service lifeConveyorsRollersElectrical batteryPulp and paper industry

The invention relates to a battery conveying device. The battery conveying device comprises a frame (1). The frame is characterized in that an upper supporting roller part (6) is formed by two long brackets (61) which are symmetrically fixed on the top layer of the frame (1), two short brackets (62), an upper supporting roller (63), a left supporting roller (64) and a right supporting roller (65); the two short brackets (62) are fixed on the frame (1), the upper supporting roller (63) is movably connected between the two short brackets (62), the left supporting roller (64) is movably connected between the long bracket (61) and the short bracket (62) on the left side of the upper supporting roller (63), the right supporting roller (65) is movably connected between the long bracket (61) and the short bracket (62) on the right side of the upper supporting roller (63), and the mounted left supporting roller (64), the upper supporting roller (63) and the right supporting roller (65) form a trapezoidal groove structure. According to the battery conveying device provided by the invention, two sides of a conveyor belt entering the upper supporting roller upwarp through the trapezoidal groove structure, so that a battery is well prevented from rolling out of the conveyor belt.

Owner:YANCHENG CITY LONG XIANG MACHINERY MFG PLANT

Adjustable-type storage rack for medical apparatus and instruments

InactiveCN108577971AMeet the needs of usePrevent rolling outSurgical furnitureNursing accommodationSlide plateBiomedical engineering

Owner:山西白求恩医院

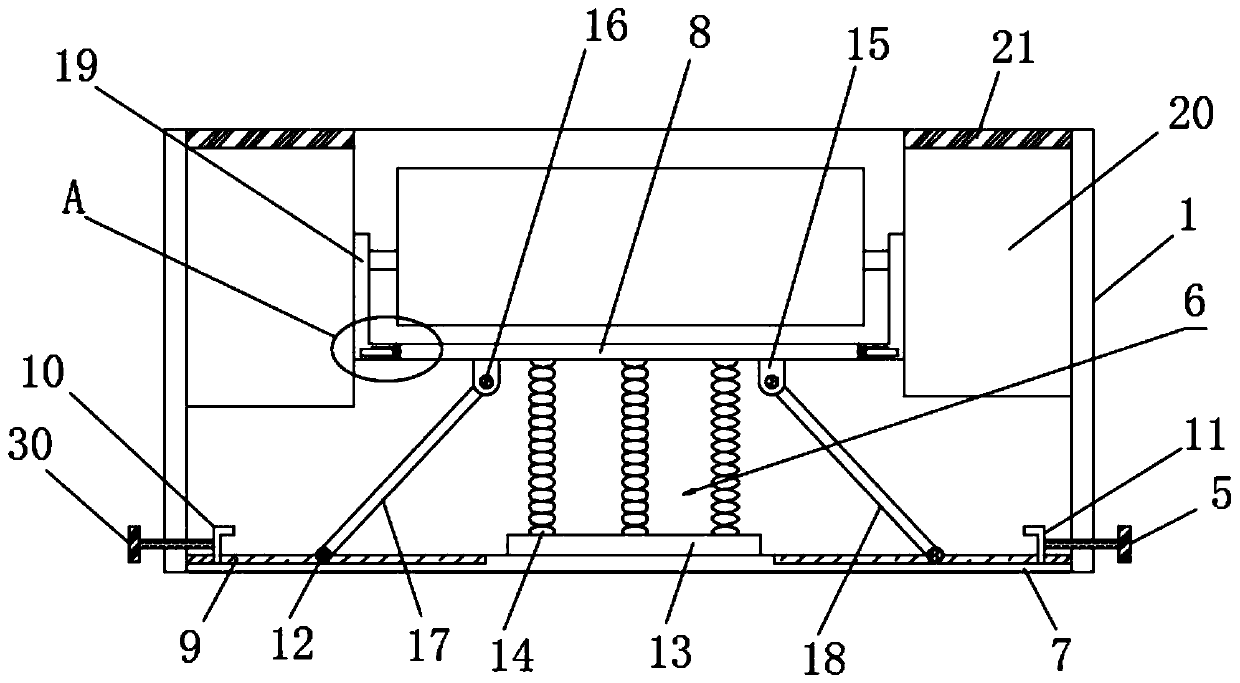

Storage device with supporting mechanism for LED lamp

ActiveCN109835593AEasy to useEasy to storeDischarging meansDamagable goods packagingEngineeringLED lamp

The invention discloses a storage device with a supporting mechanism for an LED lamp. The storage device comprises a device main body and the supporting mechanism, a lifting hollow cavity is formed inthe middle of the inner part of the device main body, the supporting mechanism is located in the lifting hollow cavity, a left limiting plate and a right limiting plate are respectively mounted at the top end of the two side walls of the lifting hollow cavity, and a right pushing rod is mounted on the position, close to the bottom end, of the device main body. According to the storage device withthe supporting mechanism for the LED lamp, the LED lamp can be nicely ejected out and withdrawn in the storage device, thus the LED lamp is conveniently used and stored, the storage device with the supporting mechanism for the LED lamp is convenient and fast, applicability is high, meanwhile a mounting side plate can be limited and fixed, the stability of the LED lamp in use is guaranteed, it canbe effectively prevented that sliding rolling balls roll out of a sliding groove in the sliding process, the good limiting and stability effects are achieved, normal rotating of a moving rod is guaranteed, and the whole storage device is convenient to move.

Owner:YANYANG LAMP SET TIANCHANG CITY

Intelligent station change device of industrial automation production line

The invention discloses an intelligent station change device of an industrial automation production line. The device comprises a first bracket; a motor is fixedly mounted on the back surface of a vertical rod on the left front side of the first bracket; a longitudinal driving roller is arranged behind the motor; the front end of a rotating shaft of the driving roller is fixedly connected with a rotating shaft of the motor; the back end of the rotating shaft of the driving roller is movably connected with the front surface of a vertical rod on the left back side of the first bracket; a longitudinal driven roller is arranged on the right side of the driving roller; the back side of a rotating shaft of the driven roller is movably connected with the front surface of a vertical rod on the right back side of the first bracket through a bearing; the front end of the rotating shaft of the driven roller penetrates through a vertical rod on the right front side of the first bracket, and is movably connected with the vertical rod; and the driving roller and the driven roller are movably connected through a first conveying belt. A controller can control an electric extension rod to realize automatic distribution of circular shafts, so that a mode of manually distributing the circular shafts is saved, the time and the physical strength of workers are saved, and the large-scale production is facilitated.

Owner:XUCHANG UNIV

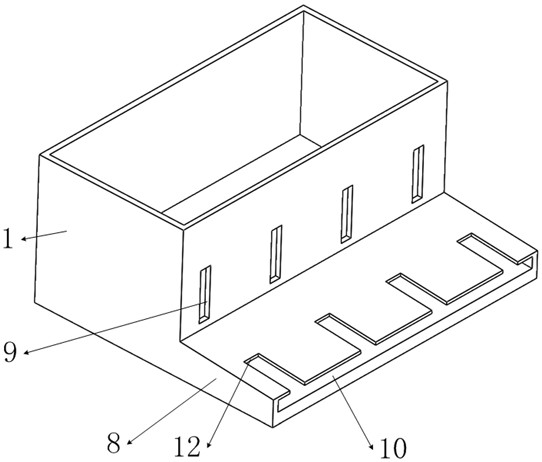

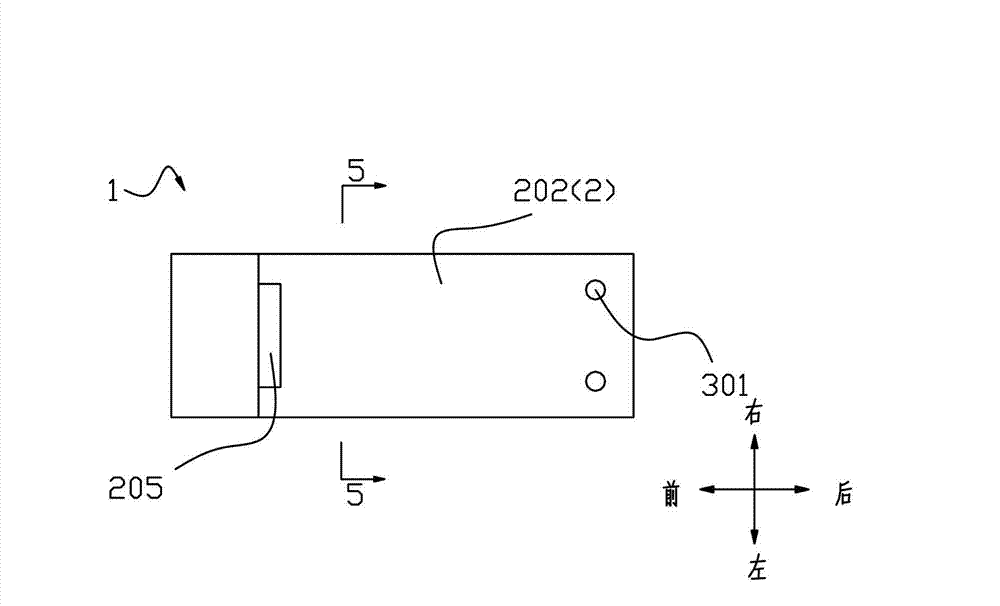

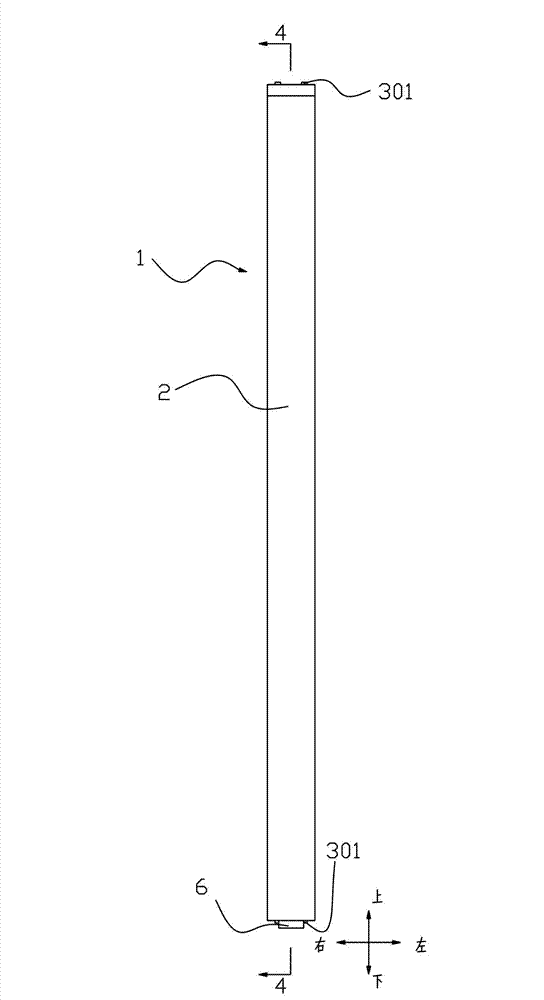

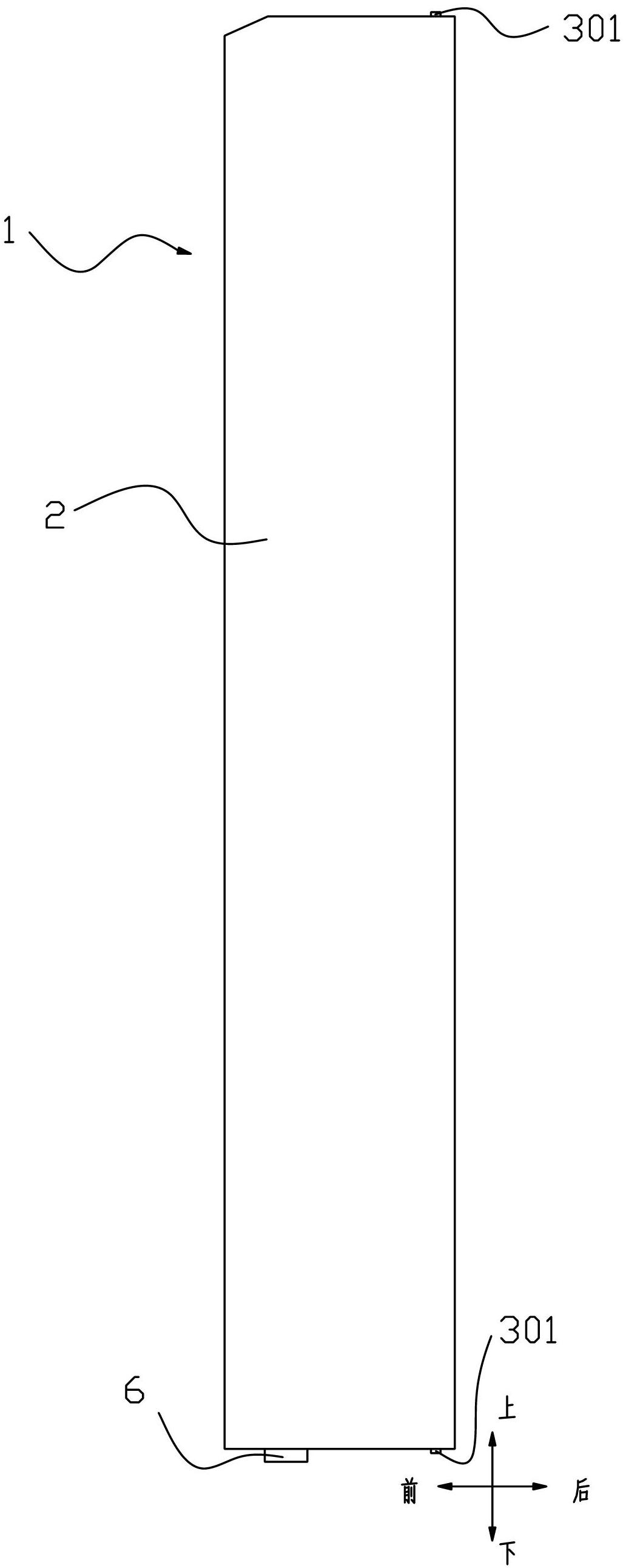

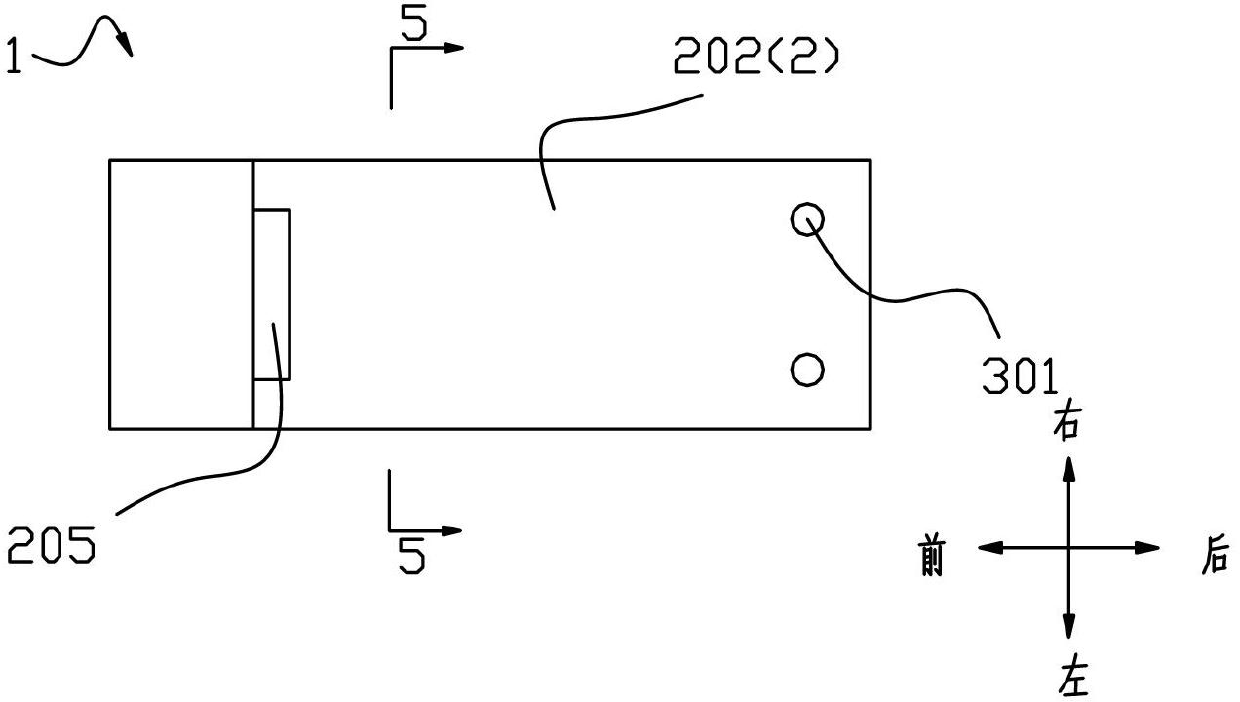

Measurement device and method for moving speed and mass distribution of sand grains of wind-blown sand creeping layer

ActiveCN102680202BPrevent rolling outGuaranteed accuracyAerodynamic testingFluid speed measurementMeasurement deviceEngineering

The invention relates to a measurement device and a measurement method for the moving speed and mass distribution of sand grains of a wind-blown sand creeping layer. The measurement device comprises a separation chamber; and the separation chamber is provided with an entrance (205) and a separation wall (4), wherein the entrance (205) is arranged at the top wall of the separation chamber, the separation wall (4) is arranged between the top wall and the bottom wall, the bottom wall is opposite to the top wall, a plurality of separation ports (7) are sequentially and parallelly arranged on the separation wall (4) from top to bottom, and each separation port (7) is connected with a corresponding collection component (8). According to the measurement method for the moving speed and mass distribution of the sand grains of the wind-blown sand creeping layer, supposing that the horizontal distance between the entrance (205) and the separation wall (4) is x0, the vertical distances between the upper end and the lower end of an i-th separation port (7) and the entrance (205) are respectively yi1 and yi2, and then, the velocity range of horizontal initial velocities of the sand grains entering the i-th separation port (7) is expressed by a formula (shown in a drawing).

Owner:BEIJING NORMAL UNIVERSITY

Measurement device and method for moving speed and mass distribution of sand grains of wind-blown sand creeping layer

ActiveCN102680202APrevent rolling outGuaranteed accuracyAerodynamic testingFluid speed measurementMeasurement deviceEngineering

The invention relates to a measurement device and a measurement method for the moving speed and mass distribution of sand grains of a wind-blown sand creeping layer. The measurement device comprises a separation chamber; and the separation chamber is provided with an entrance (205) and a separation wall (4), wherein the entrance (205) is arranged at the top wall of the separation chamber, the separation wall (4) is arranged between the top wall and the bottom wall, the bottom wall is opposite to the top wall, a plurality of separation ports (7) are sequentially and parallelly arranged on the separation wall (4) from top to bottom, and each separation port (7) is connected with a corresponding collection component (8). According to the measurement method for the moving speed and mass distribution of the sand grains of the wind-blown sand creeping layer, supposing that the horizontal distance between the entrance (205) and the separation wall (4) is x0, the vertical distances between the upper end and the lower end of an i-th separation port (7) and the entrance (205) are respectively yi1 and yi2, and then, the velocity range of horizontal initial velocities of the sand grains entering the i-th separation port (7) is expressed by a formula (shown in a drawing).

Owner:BEIJING NORMAL UNIVERSITY

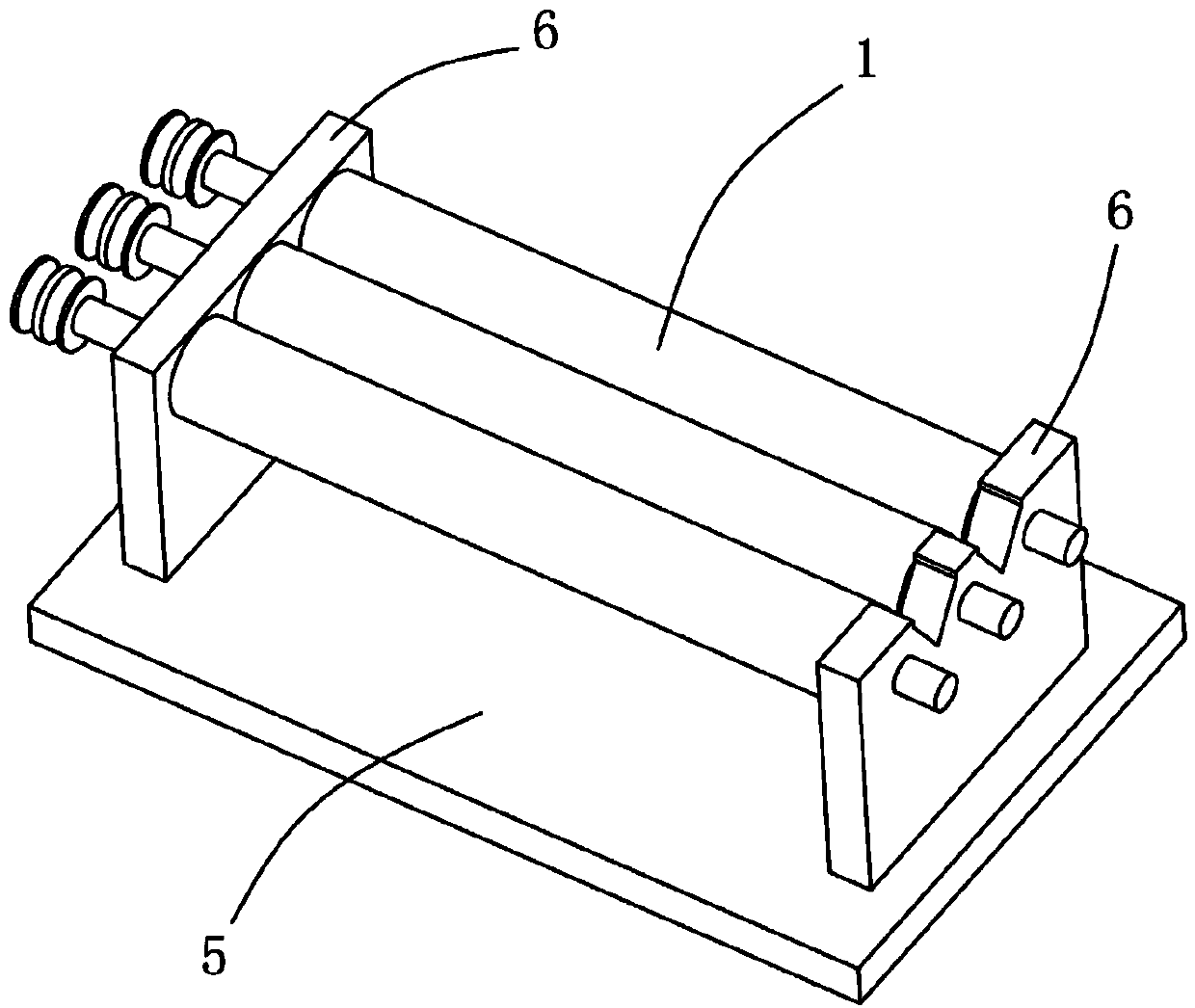

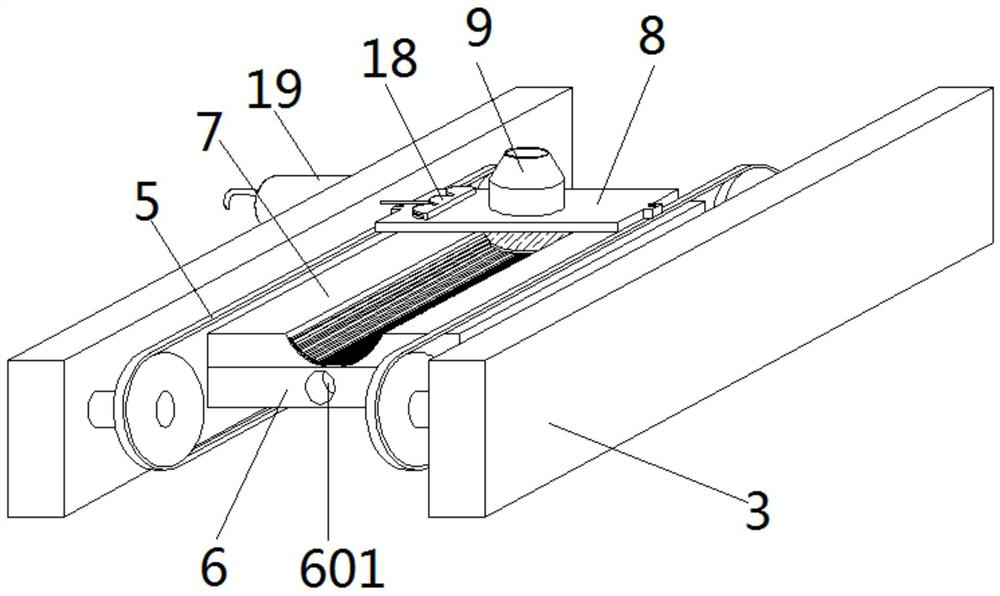

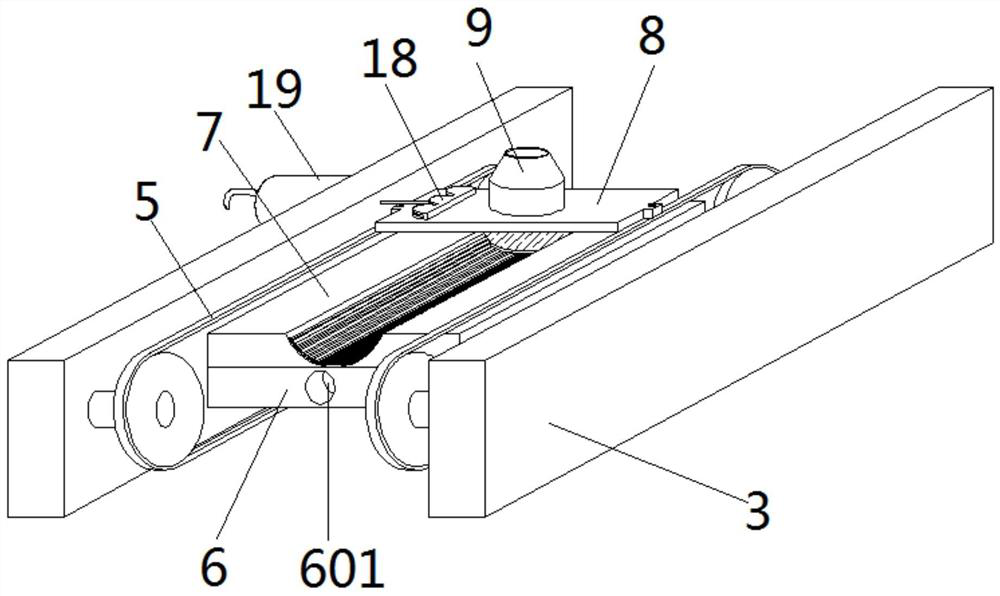

Steel ball surface development device and method

ActiveCN104267039AImprove fullyAvoid missing detectionMaterial analysis by optical meansSortingImaging processingMetallurgy

The invention discloses a steel ball surface development device and method. The steel ball surface development device comprises at least two rolling bars, an accommodating groove for supporting a steel ball is formed between the two adjacent rolling bars, the steel ball can roll from one end of the accommodating groove to the other end under the action of self-gravity, and at least one of the two adjacent rolling bars can be used for driving the steel ball so that the steel ball and the rolling bar synchronously roll in the accommodating groove. The device can utilizes self-gravity of the steel ball to drive the steel ball to carry out rolling development along one direction and simultaneously utilize the rolling bars to drive the steel ball to carry out rolling development along the other direction so that the problem that the prior art does not realize complete rolling development thereby producing a high false detecting rate is solved. The method can form a complete steel ball surface image by reduction of shooting frequency thereby improving steel ball surface image taking efficiency, and has small taken image overlapping regions thereby reducing image processing redundancy data and shortening steel ball surface defect identification processing time.

Owner:NINGBO MINGKE MOLD

Medicinal post-operation transferring sickbed for patient

The invention relates to a transferring sickbed, in particular to a medicinal post-operation transferring sickbed for a patient. In order to solve the technical problems, the medicinal post-operationtransferring sickbed for the patient does not need to lift the post-operation patient, avoids that pains are generated by wound tearing, and further can store articles. In the technical scheme, the medicinal post-operation transferring sickbed for the patient comprises a bed board and others; supporting legs are symmetrically installed on the left side and the right side of the bottom of the bed board, a first sliding groove is formed in the right side of the top of the bed board, a second sliding groove is formed in the left side of the top of a trolley, and a groove is formed in the upper portion of the left side face of the trolley. According to the medicinal post-operation transferring sickbed, the post-operation patient is lifted on a soft cushion, a frame is pushed to move leftwards,then the patient can be nursed above the bed board and does not need to be lifted again, and it is avoided that wounds are prevented from being torn again; through a storage device, the articles canbe stored and are conveniently used for the patient, and the effects that it is unnecessary to lift the post-operation patient, pains generation caused by wound tearing is avoided, and the articles can be stored are realized.

Owner:杜赣

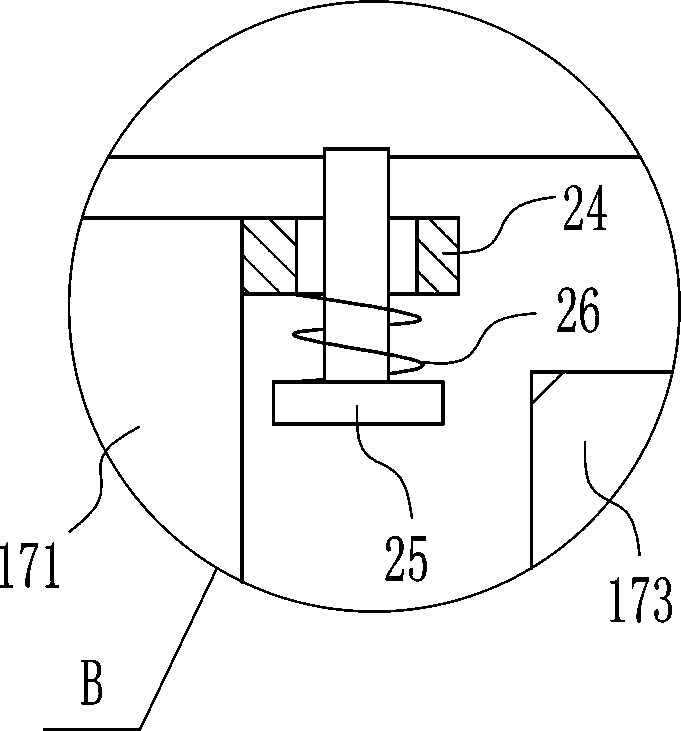

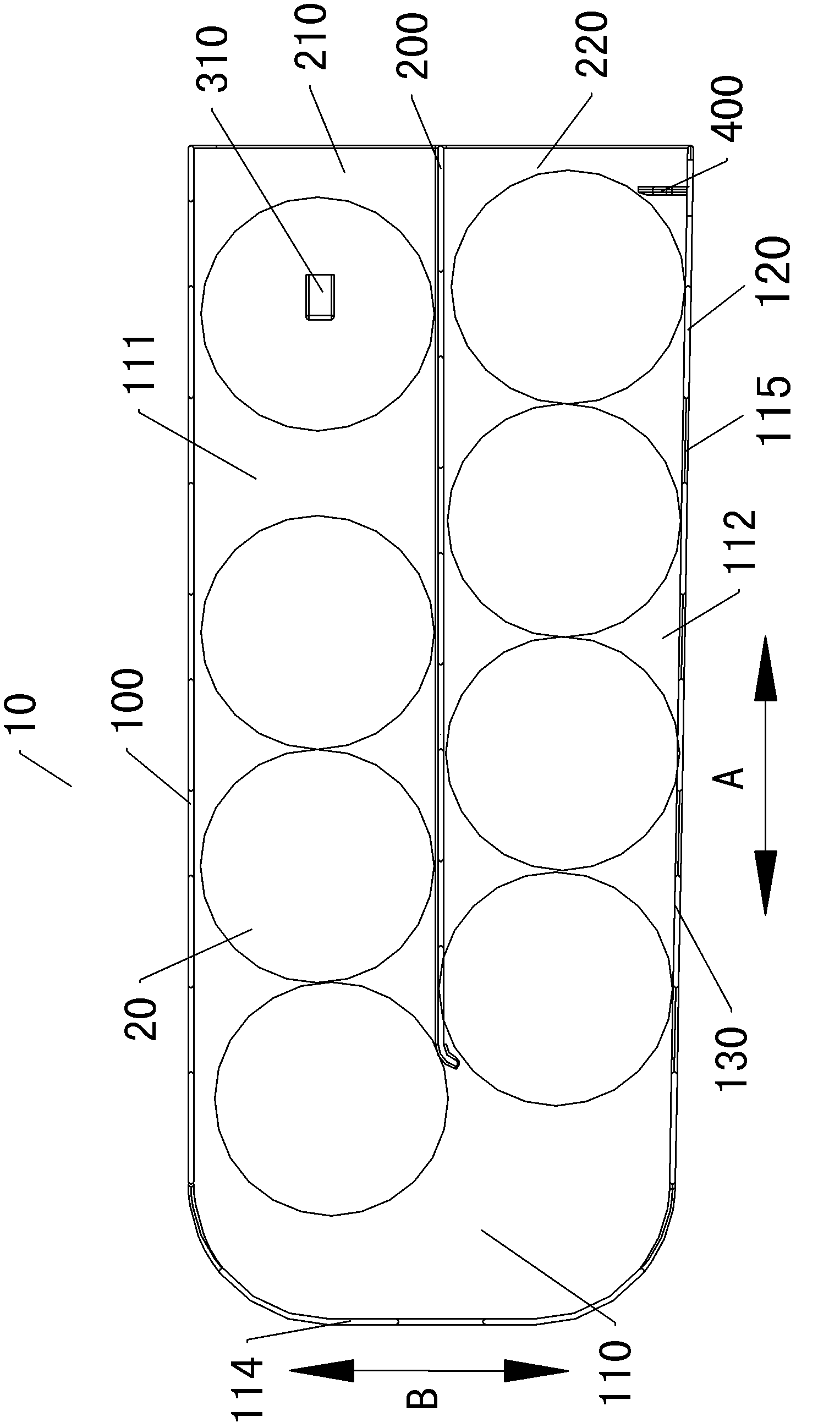

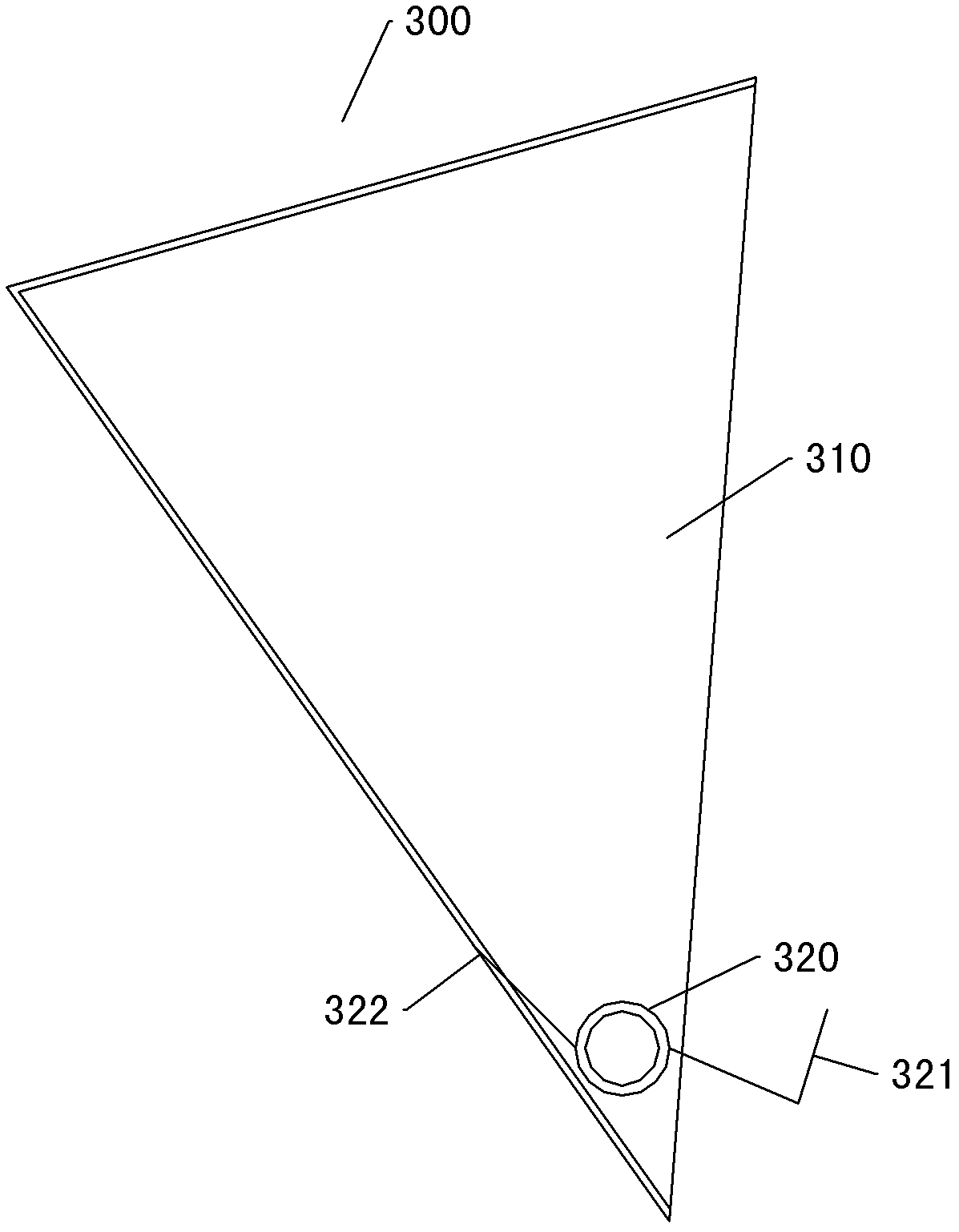

Can rack and refrigerator with the same

ActiveCN102494499BPrevent rolling outLighting and heating apparatusSupportEngineeringRefrigerated temperature

The invention discloses a pop can rack and a refrigerator provided with the same. The pop can rack comprises a body, a partition plate, and a can entrance stop assembly, wherein an accommodation cavity is limited in the body, and the front end of the accommodation cavity is open; the partition plate is arranged on a side wall of the accommodation cavity so as to partition the accommodation cavity into an upper accommodation cavity and a lower accommodation cavity, a preset distance is reserved between the rear end of the partition plate and a rear wall of the accommodation cavity, the upper accommodation cavity is provided with a can inlet, and the lower accommodation cavity is provided with a can outlet; and the can entrance stop assembly is arranged on a side wall of the upper accommodation cavity, and extends out of the side wall of the upper accommodation cavity so as to move between the stop position where the forward movement of cans is stopped and the retraction position where the can entrance stop assembly retracts toward the side wall of the upper accommodation cavity so as to allow the pop cans to move backwards. According to the pop can rack, the cans can be stored more stably.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

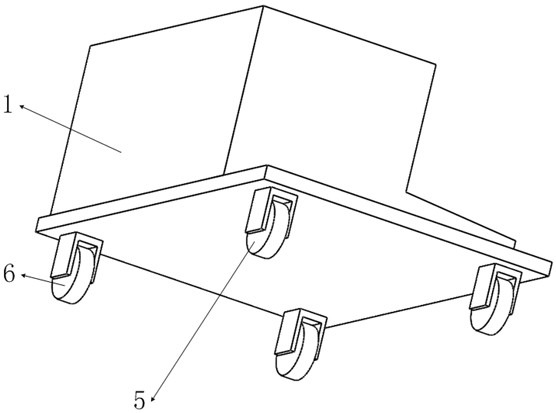

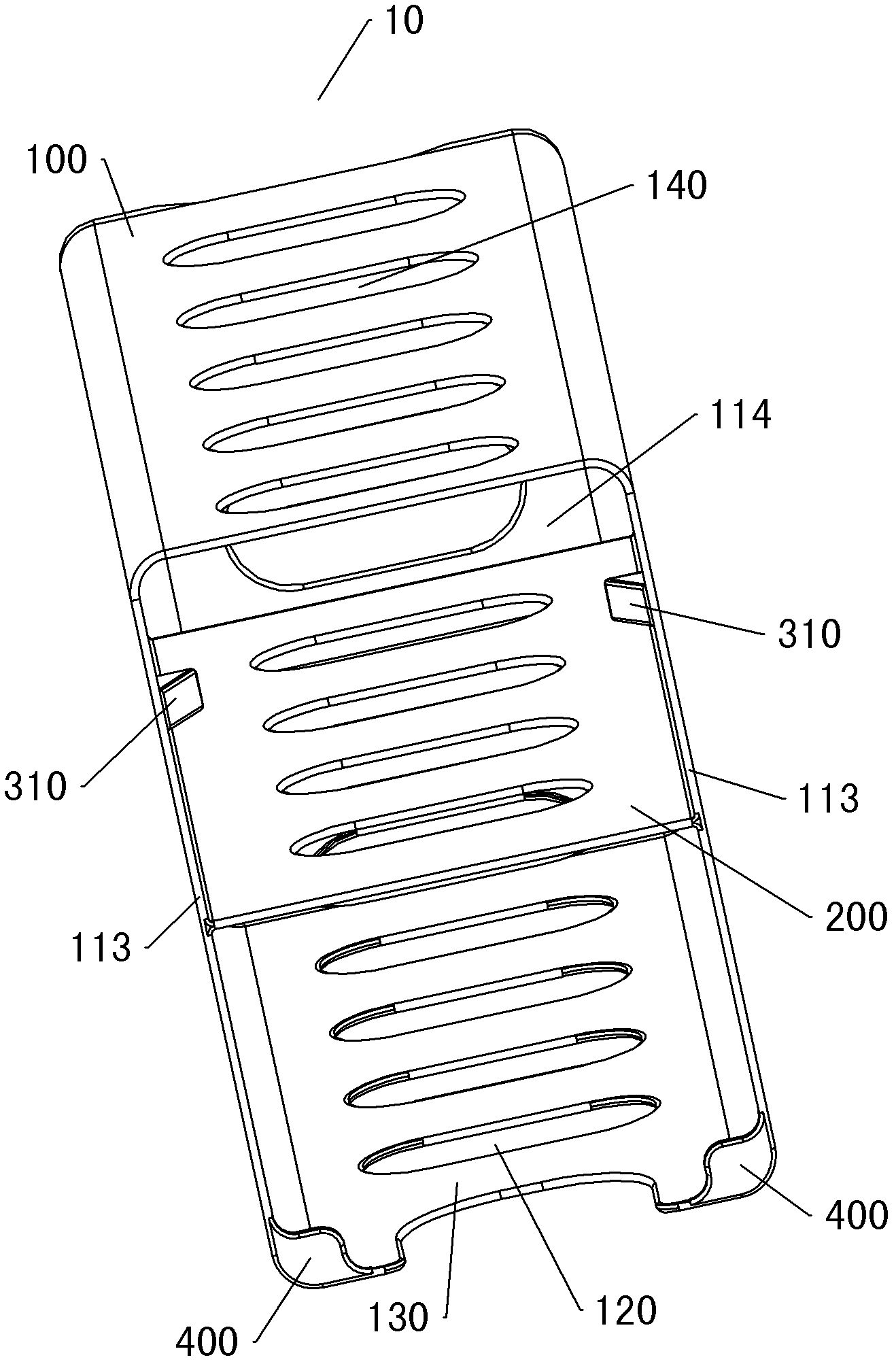

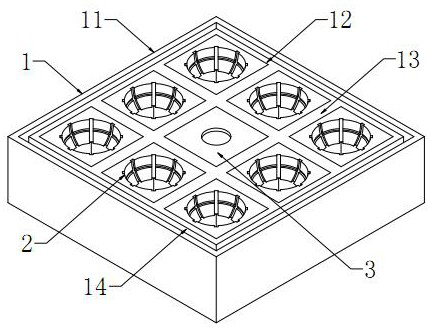

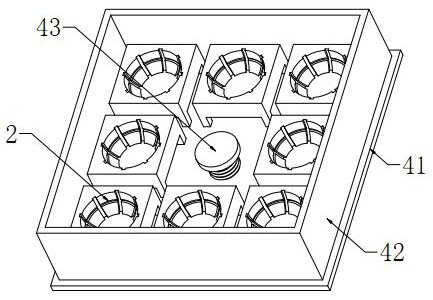

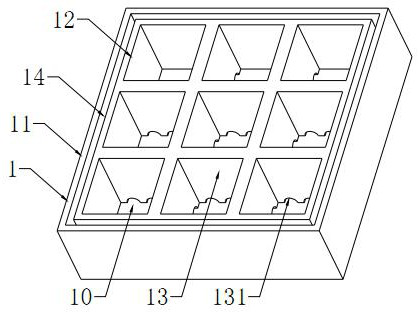

A controllable ripening packaging box for kiwifruit

ActiveCN111319874BPlay a protective effectPrevent rolling outFruit and vegetables preservationClosuresBiotechnologyKiwi fruit

The invention discloses a controllable ripening packing box for kiwi fruit, which comprises a box body, a positioning box, a ripening control mechanism and a cover body. The side of the box body adopts a double-layer design. The kiwi fruit is placed overhead on the positioning box. The mutual extrusion and collision outside the packaging box will not directly affect the kiwi fruit, which will protect the kiwi fruit. Get out, the ripening control mechanism produces ethylene gas to accelerate the ripening of kiwi fruit. The controllable ripening packing box for kiwi fruit according to the invention has the advantages of reasonable structure, convenient use, safety and reliability, etc., and effectively solves the problem that the existing kiwi fruit packing box does not have a ripening device.

Owner:LIUPANSHUI NORMAL UNIV

Hook thread knotting equipment for badminton production

InactiveCN112206488BImprove automationPrevent rolling outBall sportsRacket sportsHook wireStructural engineering

Owner:张宇

Coating roller replacing device of strip steel production line

ActiveCN114308520AEasy to replaceEasy to storeLiquid surface applicatorsCoatingsElectric machineryStrip steel

The invention discloses a coating roller replacing device of a strip steel production line, and relates to the technical field of strip steel production, the coating roller replacing device comprises a transmission mechanism, one side of the transmission mechanism is movably connected with a conveying roller, the top of the transmission mechanism is fixedly connected with a supporting frame, and one side of the supporting frame is fixedly connected with a first motor; the first motor extends to the outside of the supporting frame, and the outer surface of an output shaft of the first motor is fixedly connected with a smearing mechanism. Through cooperation of a telescopic rod and a cleaning rod, the telescopic rod controls the cleaning rod to move within the range of a third sliding groove, so that a cleaning brush makes contact with the outer surface of the coating roller, paint and other substances adsorbed on the outer surface of the coating roller are conveniently cleaned, and meanwhile the area for cleaning the coating roller is enlarged through an arc-shaped plate; and the rubber pad is convenient for reducing friction force during rotation of the coating roller and uniformly removing impurities such as anti-rust oil adsorbed on the outer surface of the coating roller, so that the problem that the coating roller cannot be cleaned and the yield of strip steel is influenced is solved, and the effect of cleaning the coating roller is achieved.

Owner:DEQING JIUGANG METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com