Adjustable peanut sorting machine

An adjustable, sorting machine technology, applied in the direction of solid separation, filter screen, grille, etc., to achieve the effect of convenient operation, improve work efficiency and shorten screening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

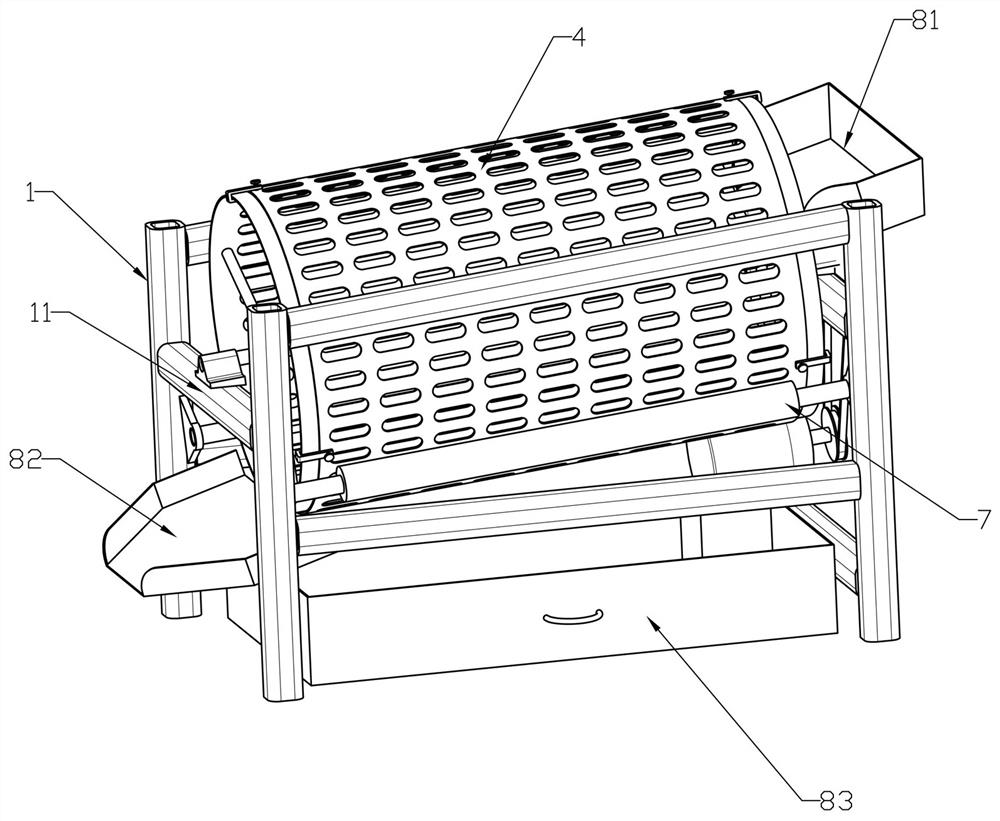

[0033] When the existing peanut sorting machine is in use, it is necessary to replace the screen of the corresponding size according to the size of the peanut pods at the sorting site, and the replacement of the screen is difficult and needs to be replaced by a special person, and the replacement takes a long time, and the operation is inconvenient. During the process, peanuts are also easy to block the sieve holes, which affects the screening efficiency of peanut pods, and when cleaning the peanuts blocked in the sieve holes, it needs to be shut down for cleaning, which reduces the operating efficiency and increases the screening time. In order to ensure the sorting quality, it is necessary for a special person to input a small amount of peanut pods to be screened into the sorting machine continuously, so as to prevent the peanut pods from being directly discharged from the discharge port without being screened, which will affect the sorting quality. , inconvenient to use.

...

Embodiment 2

[0047] The similarities between Embodiment 2 and Embodiment 1 will not be described again. The difference is that anti-blocking rubber rollers are provided in parallel on the left and right sides of the adjustable screen drum.

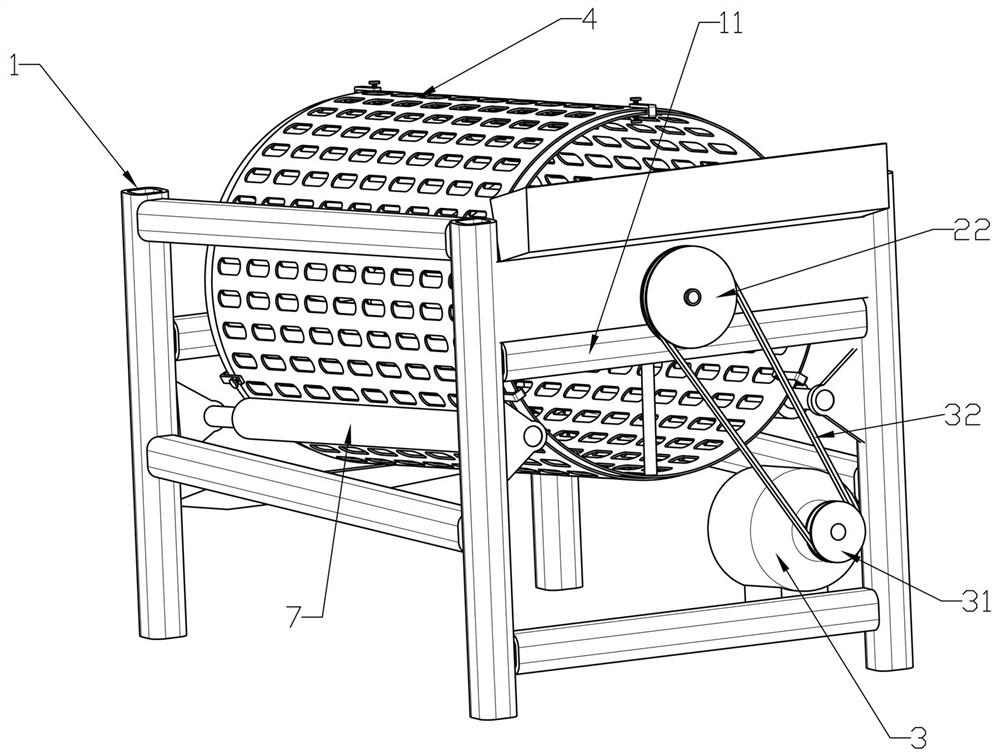

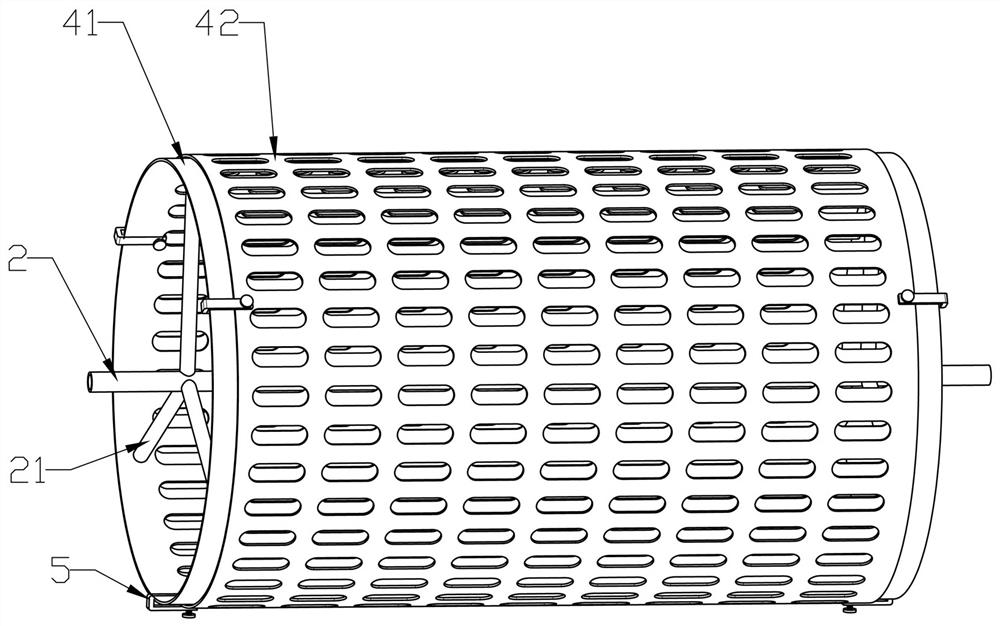

[0048] As shown in Figure 2, the left and right sides of the adjustable screen drum 4 are all provided with anti-blocking rubber rollers 7 in parallel, and the anti-blocking rubber rollers 7 include a fixed shaft 71 and a rubber roller 72, and the front and rear ends of the fixed shaft 71 are provided with The bearing seat is fixed on the frame on the adjacent side of the adjustable screen drum 4 by bolts, and the central axis of the fixed shaft 71 after fixing is parallel to the central axis of the adjustable screen drum 4 in the same vertical plane. , the rubber roller 72 is coaxially set on the fixed shaft 71, and the circumferential side of the rubber roller is in tangential meshing contact with the circumferential side of the adjustable screen drum...

Embodiment 3

[0051] The similarities between Embodiment 3 and Embodiment 2 will not be described again, and the difference is that handles are fixed on the left and right sides of the small fruit collection box.

[0052] like Image 6 As shown, the left and right sides of the small fruit collection box are fixed with handles 831. When in use, the small fruit collection box can be placed under the adjustable screen drum 4 or the small fruit collection can be done by pushing and pulling the handle 831. Case 83 is taken out from adjustable screen cloth drum 4 below, and it is easy to use and operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com