Split-type hopkinson torsion bar energy storing and releasing device as well as operation method thereof

A release device, separate technology, applied in the field of separate Hopkinson torsion bar energy storage and release device, to achieve the effect of meeting the experimental accuracy requirements, convenient operation, and ensuring repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

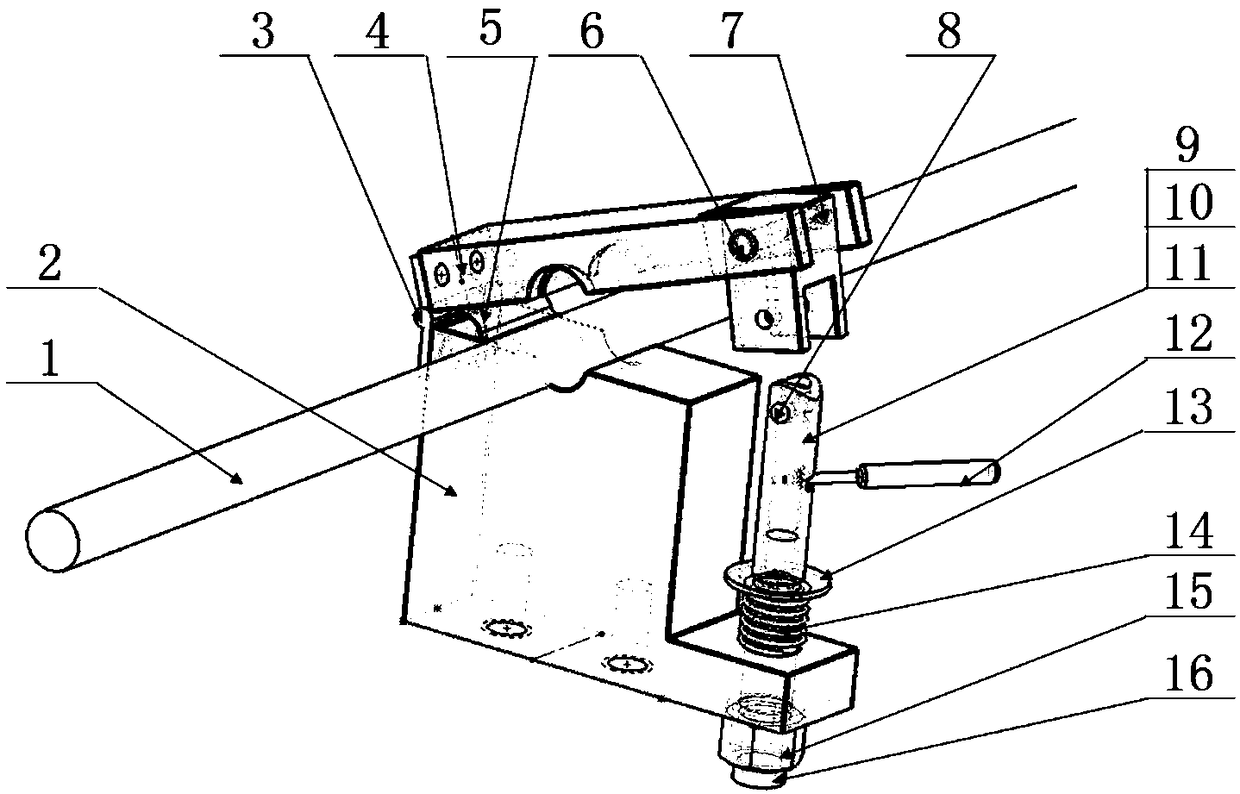

[0048] Such as figure 1 As shown, the present invention provides a separate Hopkinson torsion bar energy storage and release device. The overall working device is completely composed of mechanical structural parts, including a Hopkinson incident rod 1, a clamping mechanism, a releasing mechanism and an adjusting mechanism.

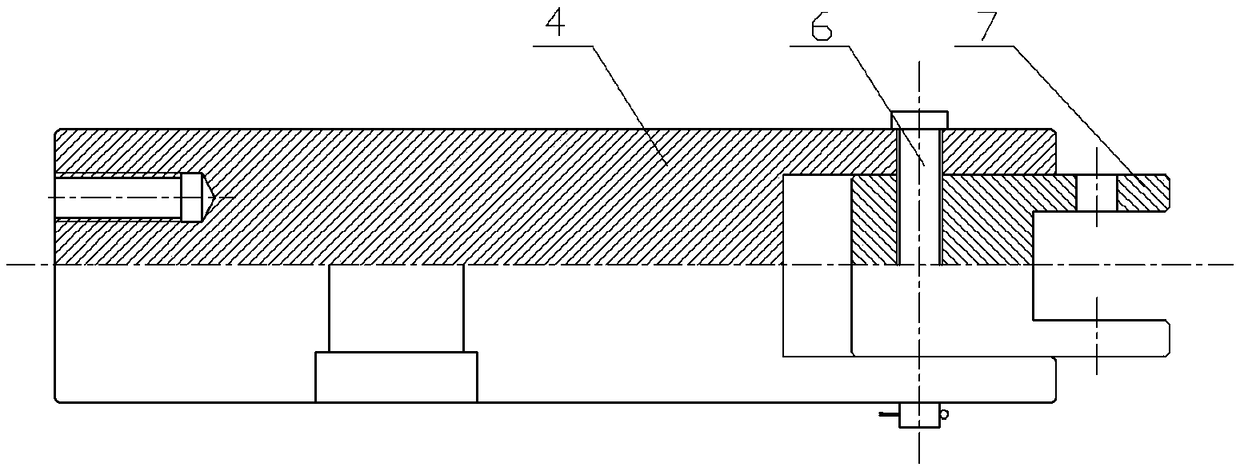

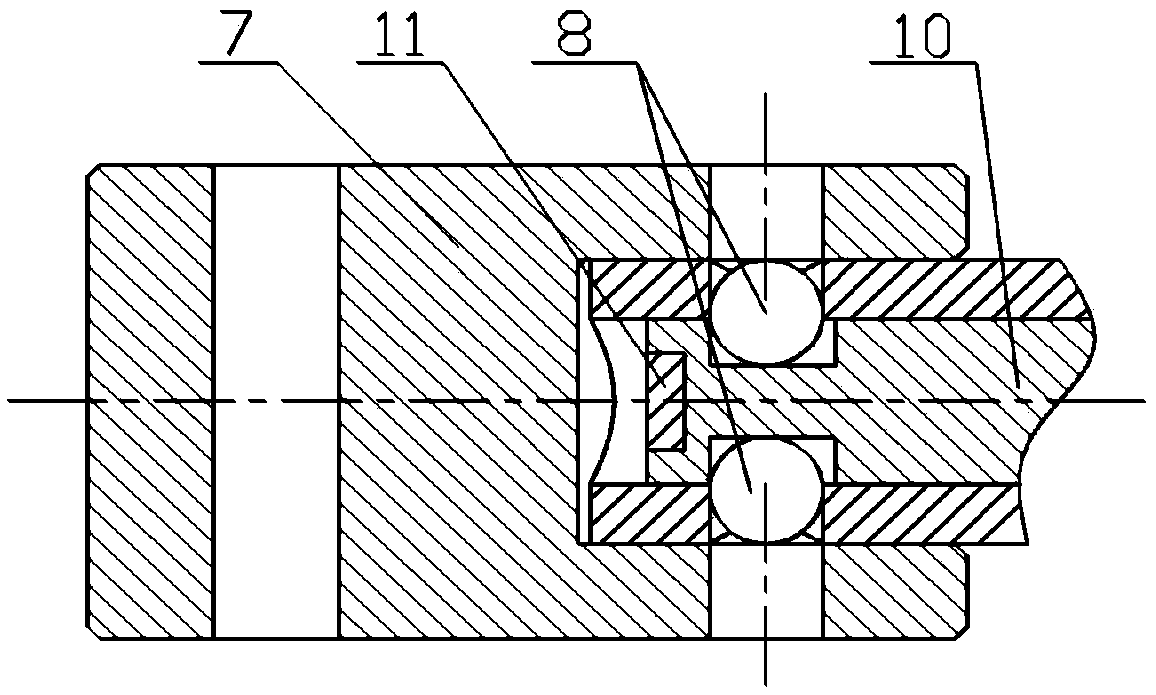

[0049] The clamping mechanism is used to clamp the Hopkinson incident rod, which consists of a base 2, a hinge 3, a gland 4, a spring leaf 5, a pin shaft 6 and a connecting joint 7, wherein the bottom of the base 1 has a threaded hole for Connect the test bench to achieve self-fixation. The base 1 and the gland 4 are connected by a hinge 3, the gland 4 is connected with the connecting joint 7 by a pin 6, the spring piece 5 is fixed on the base 2, and the upper surface is in contact with the gland 4, and is used for clamping after the rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com