Ball/disc spring vibration-isolating device

A ball and disc spring technology, applied in the field of combined shock isolation devices, can solve problems such as ball positioning troubles, sticking difficulties, bottom plate rolling out, etc., to simplify the design and construction process, reduce secondary disasters, and simple earthquake resistance measures Effect

Inactive Publication Date: 2012-02-01

QINGDAO TECHNOLOGICAL UNIVERSITY

View PDF6 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the other hand, its quality and performance are difficult to distinguish from the appearance, and it has a strong quality concealment

[0009] ③It is difficult to paste with other materials: rubber is generally difficult to connect with the concrete surface of the building. In rubber shock-isolating pads, special adhesives are generally used to connect the rubber with the connecting steel plate, which also increases the cost.

[0010] ④ Relatively little experience in the use of materials: compared with steel and concrete, rubber as the main structural material lacks experience in use

Although the rolling ball plus spring return device has a good shock isolation effect, its position limiting ability is not good. When the earthquake is strong, the rolling ball may roll out from the bottom plate, and the positioning of the rolling ball is also very troublesome.

Such as the Chinese patent authorized and announced on May 23, 2001, the announcement number is CN2431333Y, which discloses a new type of building isolation and energy consumption device. The sliding layer, the upper and lower contact surfaces are spherical, and the rolling ball is equipped with a concave reset plate shock isolation device. Due to the existence of the rolling ball, it has a good shock absorption effect, and the groove can effectively control the rolling of the rolling ball. And the positioning is also convenient and reliable, but since there are no other measures to limit the rolling amount of the rolling ball, the rolling ball may still roll out from the concave reset plate

And it only has a good shock absorption effect in the horizontal direction, and the vertical shock absorption effect is not good.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

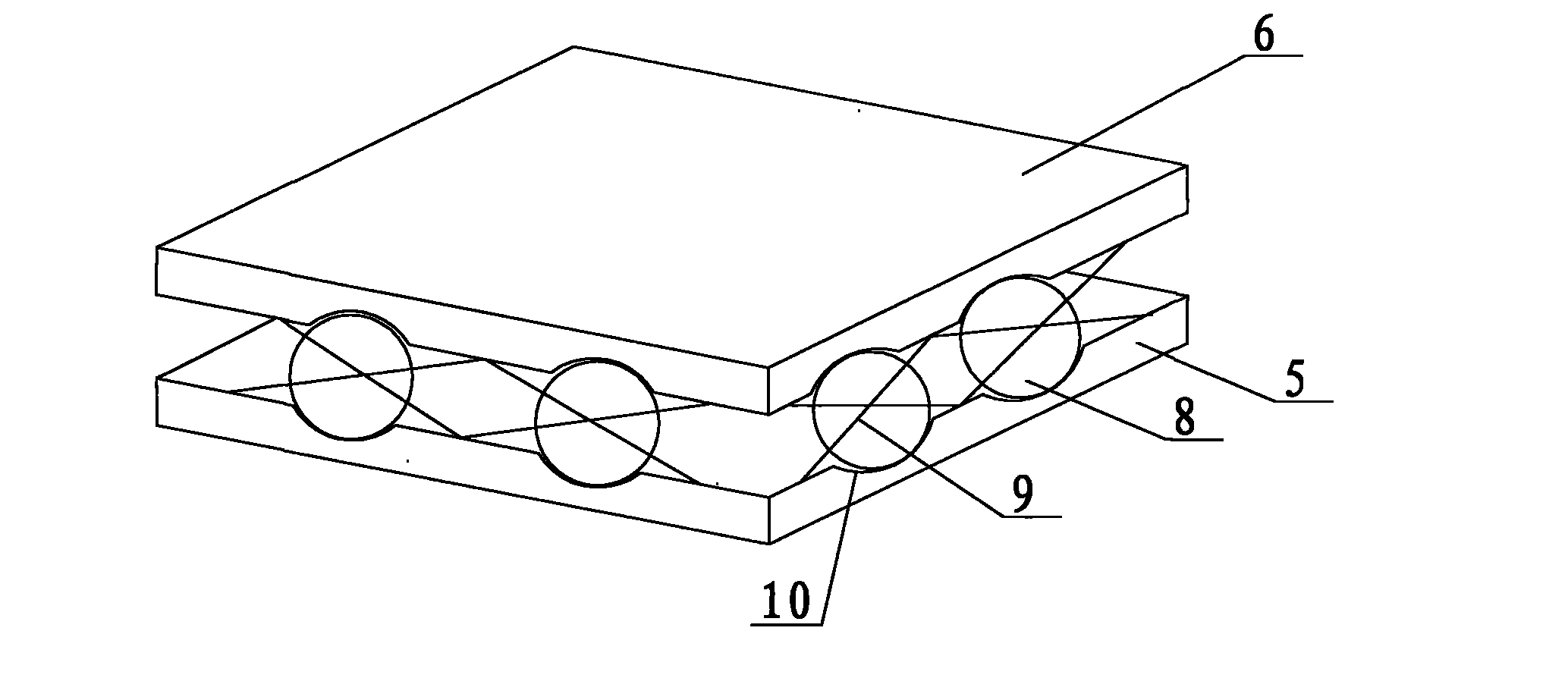

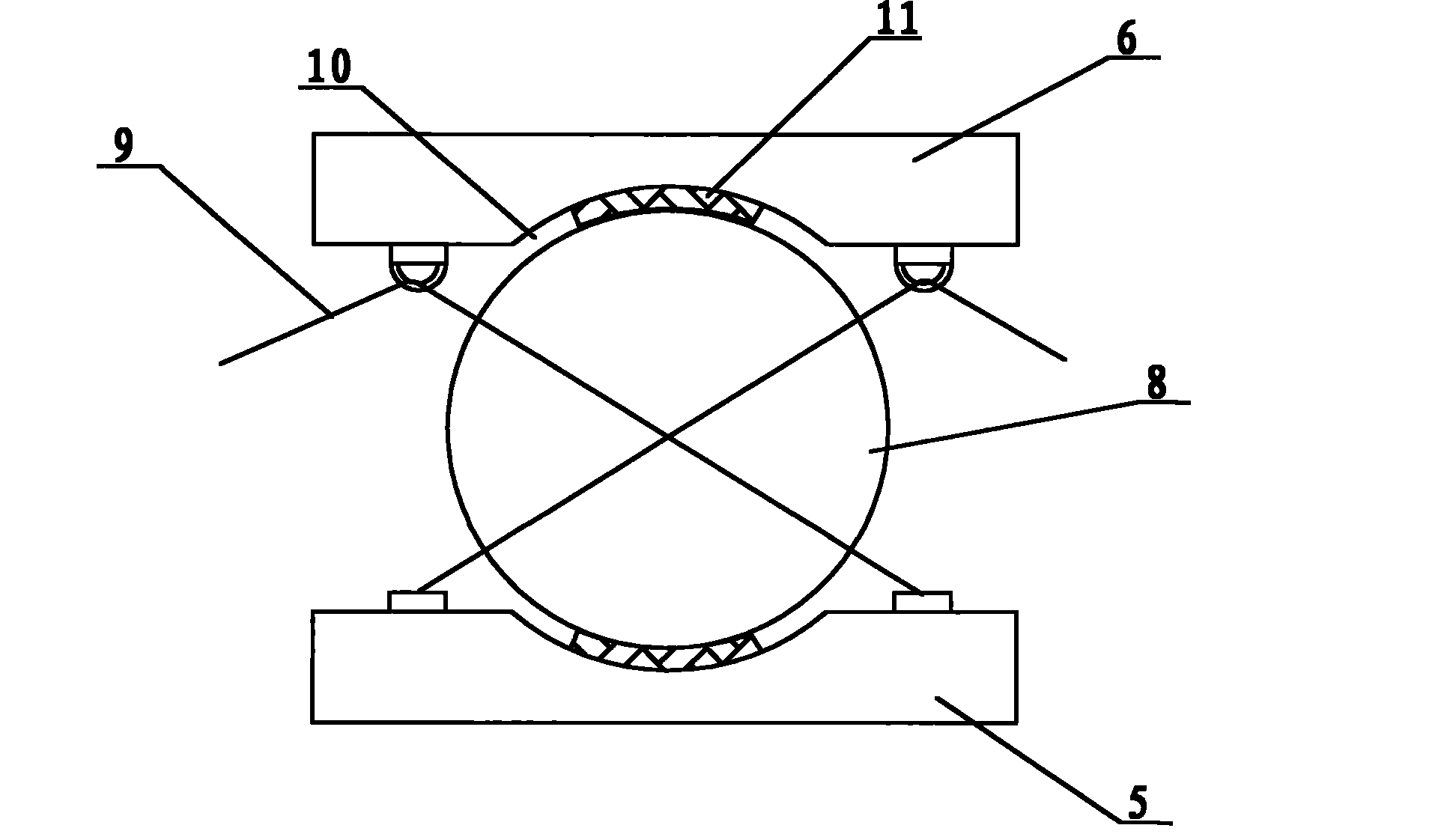

[0035] Ball 8 is a sphere.

Embodiment 2

[0037] The upper and lower sides of the ball 8 contact the groove 10 as spherical surfaces, and the shapes of other surfaces can be arbitrarily set according to requirements.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

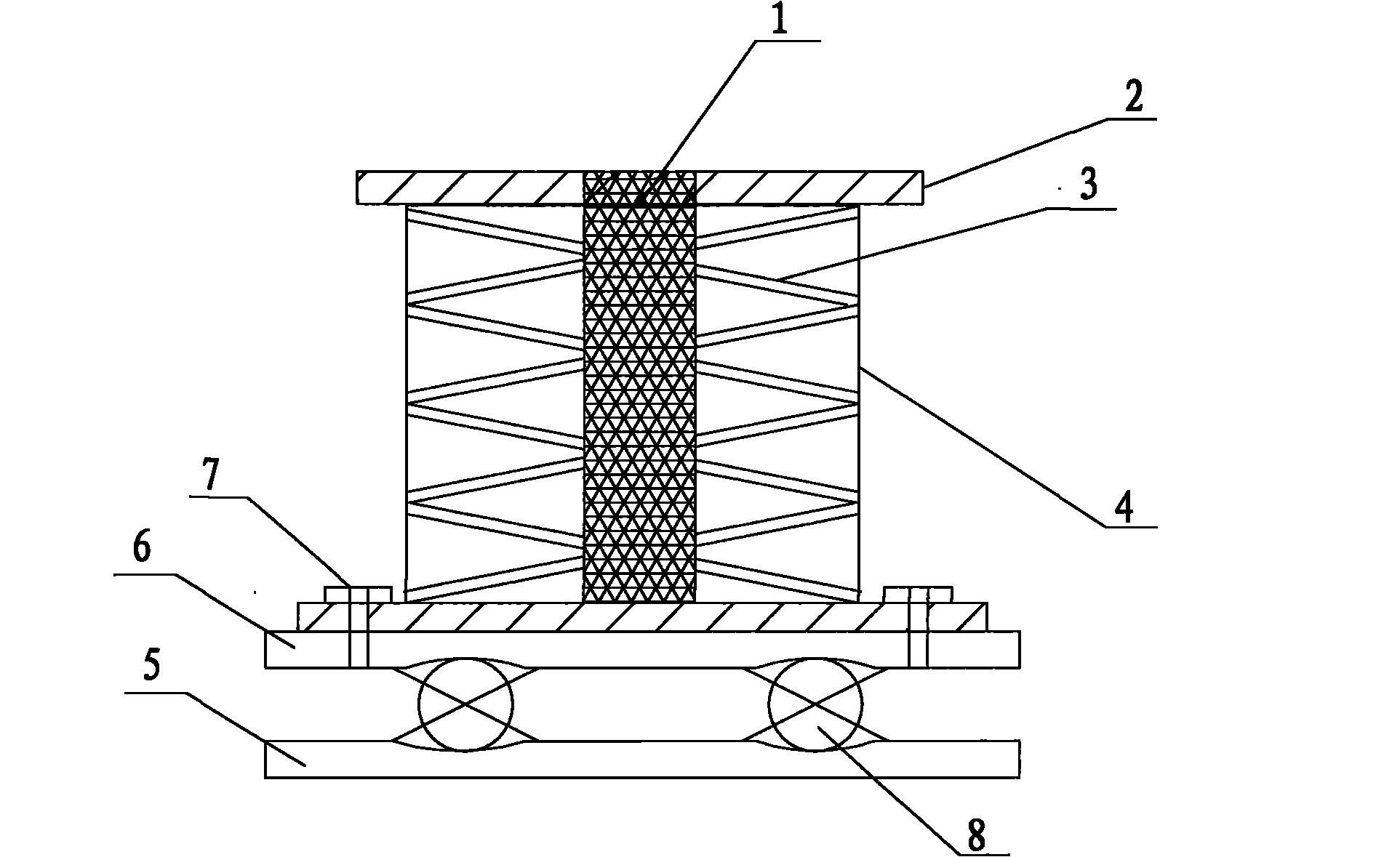

The invention relates to a vibration-isolating device, in particular to a combined vibration-isolating device. A ball / disc spring vibration-isolating device comprises a vibration-isolating support, and the upper end of the vibration-isolating support is connected with a damper. The device is not only suitable for a newly-built structure, but also suitable for anti-seismic reinforcement and post-earthquake repair of an original structure. Moreover, the device is applicable to ordinary civilian housings, civil engineering such as structures, bridges and the like, as well as storey-increased buildings and shifting buildings. The device can also be applied in vibration isolation and reduction of instruments and equipment and has low manufacturing cost and broad application prospects.

Description

technical field [0001] The invention relates to a shock isolation device, in particular to a combined shock isolation device. Background technique [0002] Base isolation currently mainly includes: laminated rubber bearings, friction-slip isolation element bearings, rolling pendulums, rolling balls, roller bearings and other bearings, and combined isolation. Among them, laminated rubber bearings are the most widely used, reaching more than 90%. [0003] (1) Laminated rubber bearing [0004] The laminated rubber bearing is formed by laminating steel plates and rubber. The thickness of each layer of rubber and steel plates is only a few millimeters, and the middle is bonded with glue. Such a structure makes it have a large vertical bearing capacity, and it will also have a large deformation in the horizontal direction. The upper and lower sealing plates of the support are relatively thick, and the sealing plate and the connecting steel plate are connected by bolts, and the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B1/36E01D19/04E04B1/98

Inventor 隋杰英公衍文刘文峰

Owner QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com