Steel ball surface development device and method

A technology of steel balls and accommodating grooves, which is used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of high false detection rate and insufficient rolling and unfolding of steel balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

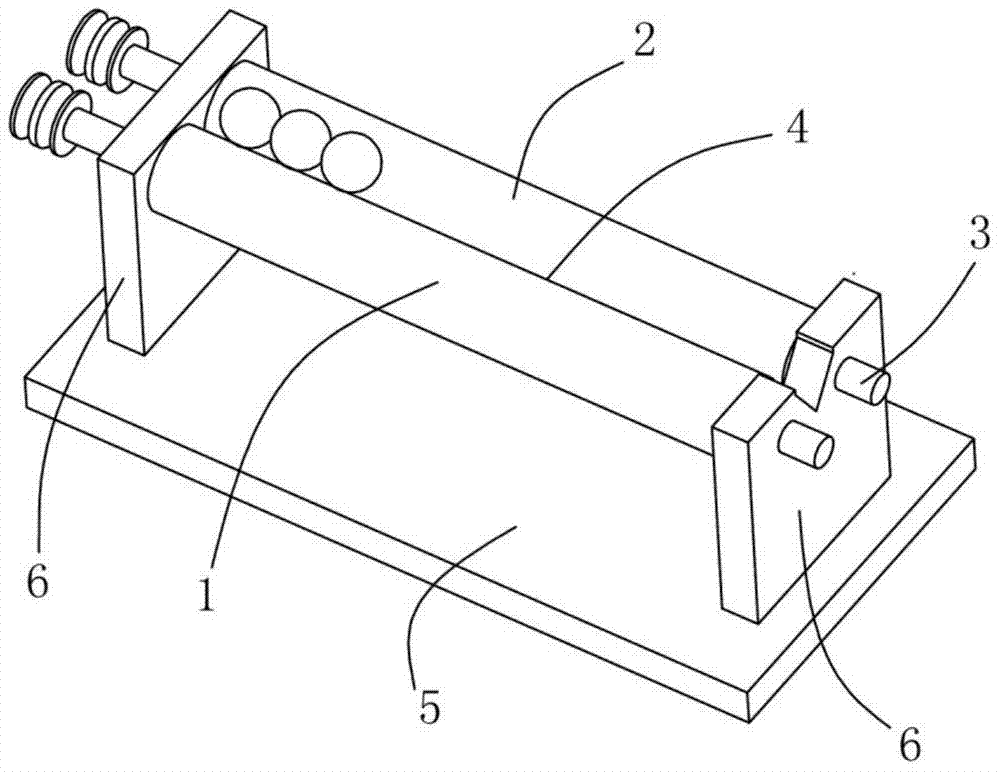

[0031] Example 1, see figure 1 Shown:

[0032] This embodiment comprises two roller bars 1, and these two roller bars 1 include rotating shaft 3 and rolling sleeve 2, and rolling sleeve 2 is elongated cylindrical shape, and its material is plexiglass, and rolling sleeve 2 is set on rotating shaft 3, steel The contact between the ball and the roller sleeve 2 made of plexiglass can prevent the steel ball from being scratched or bumped, and can also reduce the rolling friction of the steel ball on the roller sleeve 2 . The two rollers are rotatably erected on two opposite supporting plates 6 , the roller sleeve 2 is located between the two supporting plates 6 , and the two supporting plates 6 are fixedly arranged on the base 5 .

[0033] The two roller bars 1 are arranged side by side in parallel, and there is a gap between the two roller bars 1 to avoid mutual friction when the roller bars 1 rotate, and an accommodating groove 4 for carrying steel balls is formed between the tw...

Embodiment 2

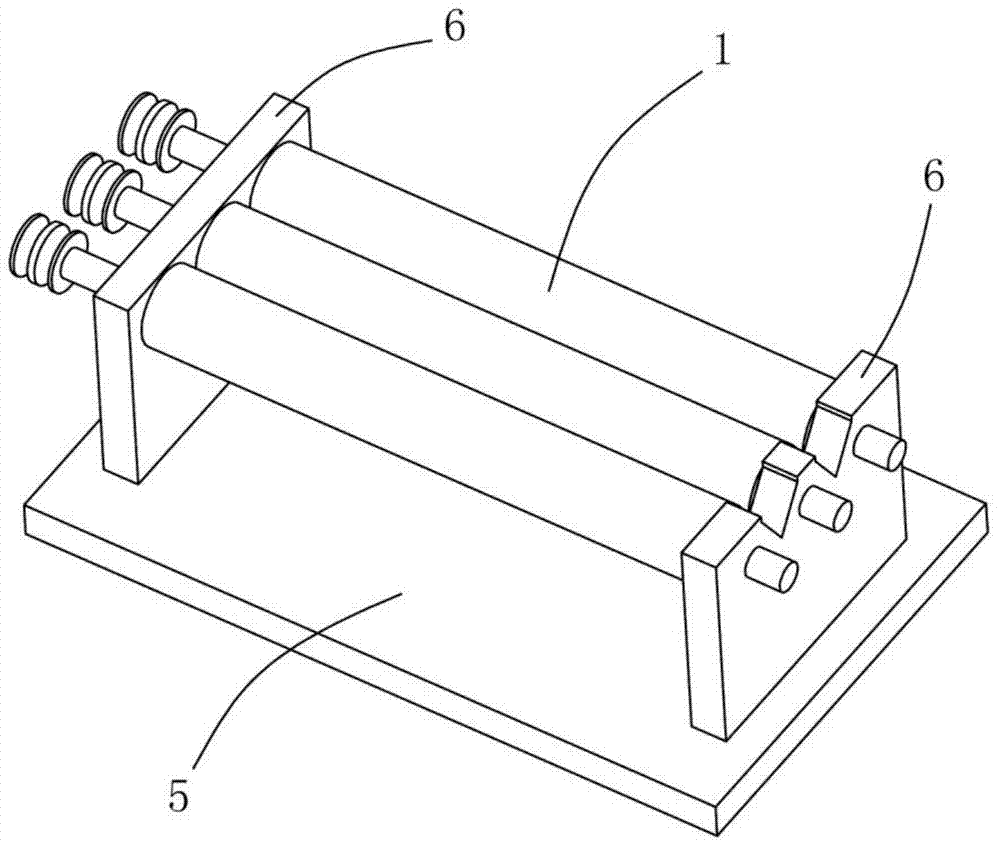

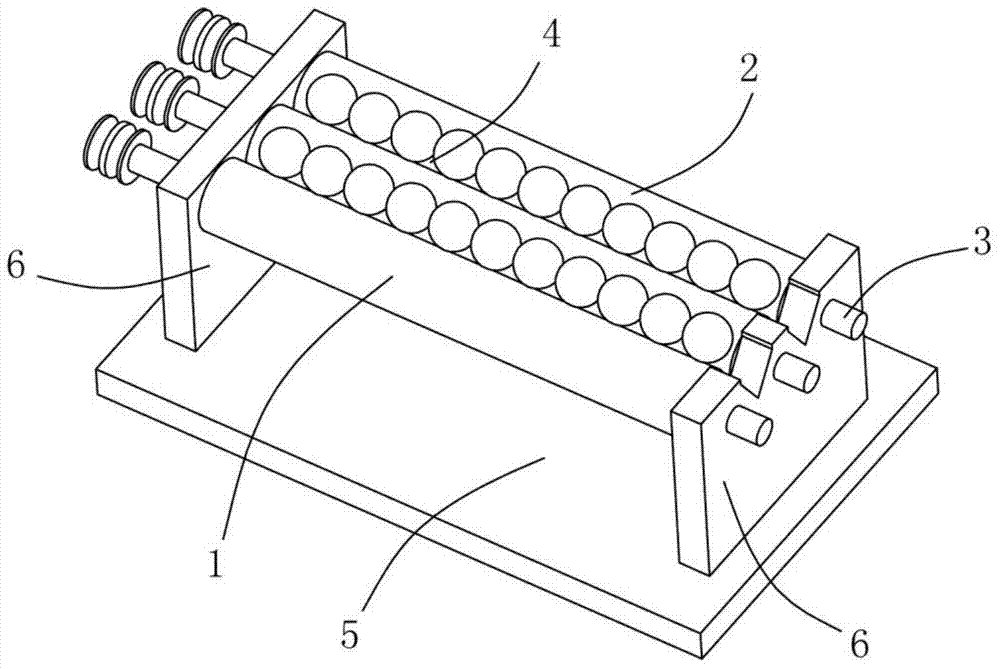

[0037] Example 2, see figure 2 and image 3 Shown:

[0038] The difference between this embodiment and Embodiment 1 is that this steel ball surface unfolding device includes three roller bars 1, the three roller bars 1 are arranged side by side, and two accommodating grooves 4 are formed, and the three roller bars 1 are in the same direction. synchronous rotation.

[0039] When the camera is used to capture the surface image of the steel ball, the camera is set above the roller bar 1, and the visual recognition area of the camera only needs to cover the area where more than three continuous steel balls in the accommodating tank 4 are located. Usually the viewfinder range of the camera is circular or rectangular, and the steel balls in the accommodating groove 4 are arranged in a straight line, so there are still a large number of unused areas in the viewfinder range of the camera. In this embodiment, three rolling bars 1 The main purpose of setting side by side is to mak...

Embodiment 3

[0042] Example 3, see Figure 4 and Figure 5 Shown:

[0043] In this embodiment, a steel ball surface unfolding device with three roller bars 1 arranged side by side is used as an example for illustration. It is fixed on two support plates 6 by screws. The block 7 is provided with a limit stop groove 8 corresponding to the accommodation groove 4, and the limit stop groove 8 acts as a limit stop to the steel ball in the accommodation groove 4, preventing the steel ball from moving from the accommodation groove 4. Roll out on both sides.

[0044] The limit stop groove 8 is a vertical through groove structure, and the limit stop groove 8 is located directly above the accommodating groove 4 , and the camera captures the image of the upper surface of the steel ball in the accommodating groove 4 through the limit stop groove 8 .

[0045] The stop block 7 is made of light-colored plexiglass, and a number of soft light beads 9 are installed along the groove wall of the limit stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com