Round steel lifting mechanism

A technology of round steel and cylinder, which is applied in the field of round steel hoisting mechanism, can solve the problems of potential safety hazards, the loss of balance of the round steel, falling of the round steel, and the injury of the staff, so as to achieve the effects of improving safety, easy positioning, and convenient hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

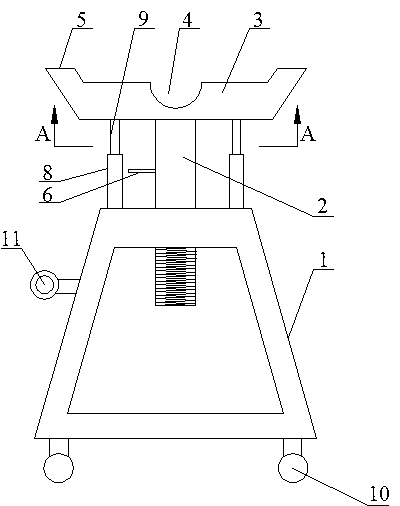

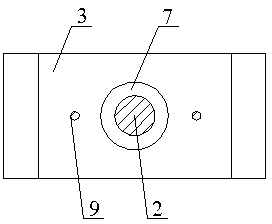

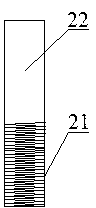

[0029] Such as Figure 1~Figure 3 As shown, the round steel lifting mechanism includes a bracket 1, a lifting rod 2 and a supporting platform 3, the top of the bracket 1 is provided with a threaded hole, the bottom of the lifting rod 2 is a threaded section 21, and the upper part of the lifting rod 2 is a cylindrical section 22. The segment 21 is screwed into the threaded hole, and the cylindrical end 22 is connected to the bottom of the supporting platform 3 .

[0030] In this embodiment, when in use, the middle part of the round steel is placed on the support platform 3, and then the up and down movement of the round steel is realized by rotating the elevating rod 2. Since the up and down movement of the round steel is realized through thread fit, the whole process is very stable without vibration, thereby avoiding the problem of the round steel losing its balance and falling.

[0031] In order to prevent the round steel from rolling back and forth on the support platform 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com