Carrying platform capable of lifting

A bearing platform and lifting rod technology, applied in the field of mechanical processing, can solve the problems of bar loss of balance, bar tilt, inconvenient and inaccurate bar feeding, etc., to reduce labor intensity, easy positioning, and increase the scope of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

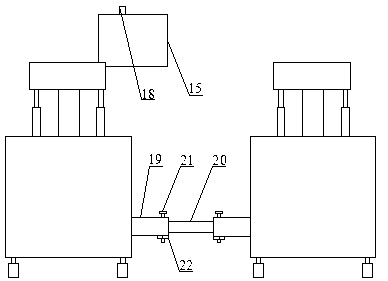

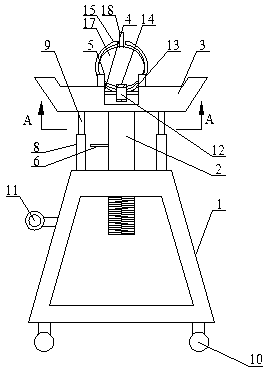

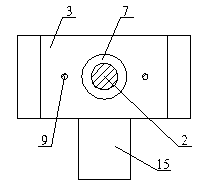

[0040] Such as Figure 1~Figure 5 As shown, the lifting platform includes at least two bearing mechanisms, the connecting cylinder 19 arranged on the bearing mechanism, the connecting rod 20 inserted into the adjacent connecting cylinder 19 at both ends and the fixing pin 21 penetrating through the connecting cylinder 19 and the connecting rod 20, The carrying mechanism includes a bracket 1, a lifting rod 2, a supporting platform 3, a runner 12 and a rotating shaft 13. The top of the bracket 1 is provided with a threaded hole, the lower part of the lifting rod 2 is a threaded section 201, and the upper part of the lifting rod 2 is a cylindrical section 202. The threaded section 201 is threadedly matched with the threaded hole, and the cylindrical end 202 is connected with the bottom of the supporting platform 3. The supporting platform 3 is provided with a groove 4, and the runner 12 is rotated and fixed in the groove 4 through the rotating shaft 13, and the anti-tilt cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com