Safety-type steel pipe packing device for construction site

A construction-use, safe technology, which is applied in the field of safety-type steel pipe boxing devices for construction sites, can solve the problems of steel pipes rolling and collapsing, steel pipes easy to roll and fall, and hurting others, and achieve the effect of preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

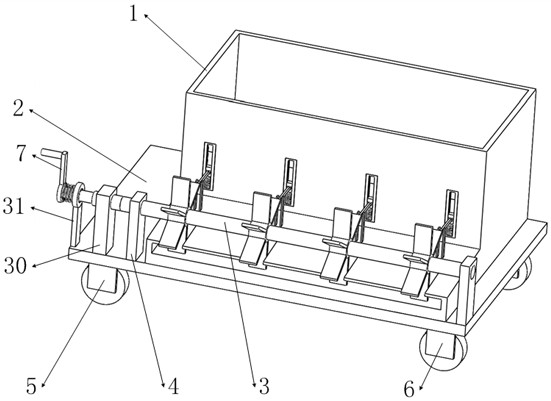

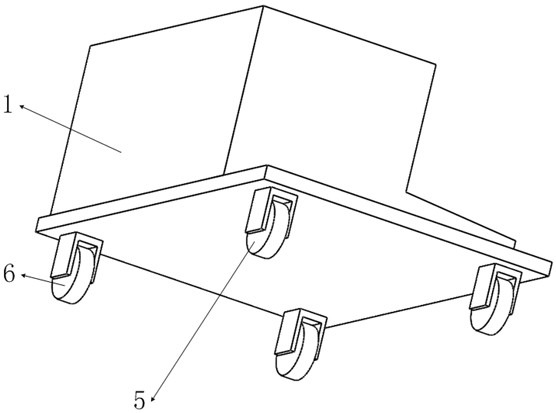

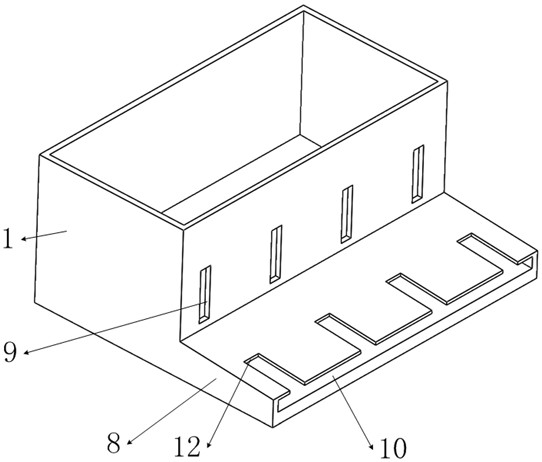

[0047] Such as figure 1 , 2 As shown, it includes a stacking shell 1 with a trapezoidal outlet shell 8, a base 2, a drive shaft 3, a first support plate 4, an orientation wheel 5, a steering wheel 6, an adjustment mechanism 7, and the outer circular surface is uniformly installed in the circumferential direction. There are ring sleeves 15 and anti-blocking mechanism 17 of a plurality of dials 14, such as figure 1 , 2 As shown, wherein the stacking shell 1 is installed on the upper surface of the base 2; as figure 2 As shown, two directional wheels 5 are symmetrically installed at one end of the lower surface of the base 2, and two steering wheels 6 are symmetrically installed at the other end; as image 3 , 4 As shown, there is a stacking groove 13 in the stacking shell 1, and there is a through discharge groove 10 in the trapezoidal outlet shell 8; Coplanar; on the side of the stacking groove 13 close to the ladder-shaped outlet shell 8, there are four through-through m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com