Electric suspended conveying system for clothing materials and implementation method for electric suspended conveying system

A technology for conveying systems and materials, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of high labor costs and achieve the effects of high automation, low cost, time-saving and labor-saving promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

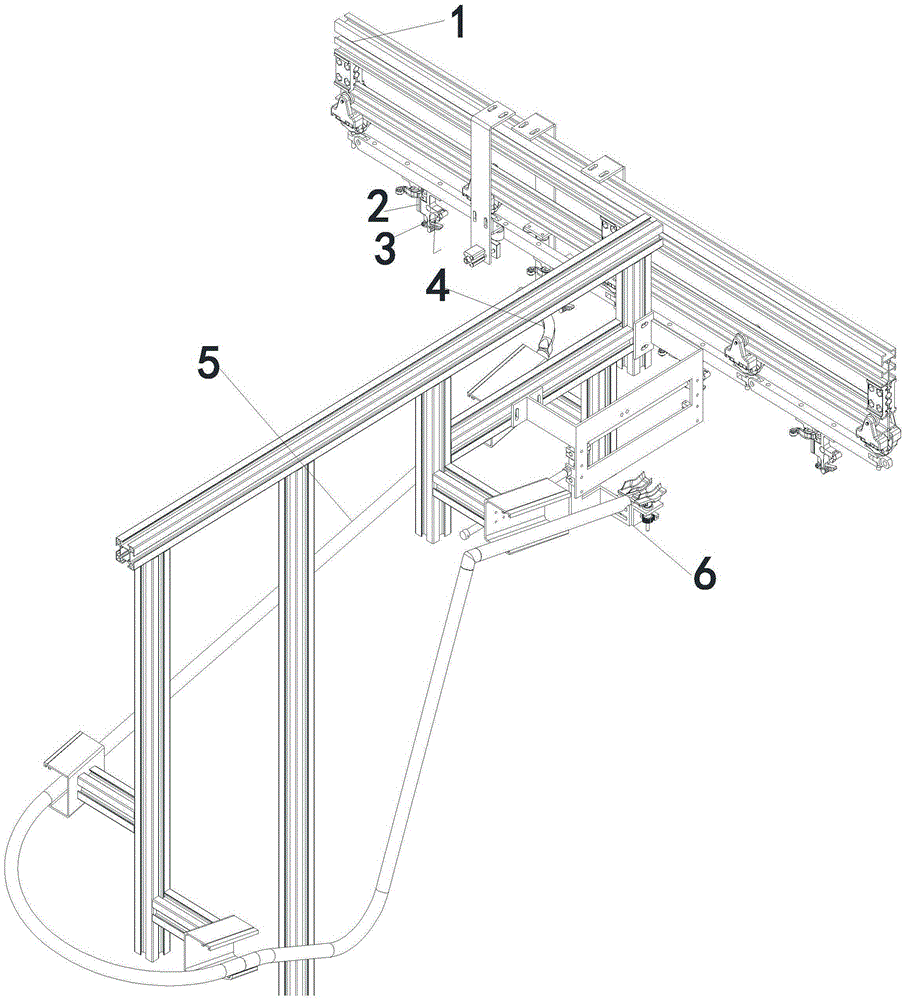

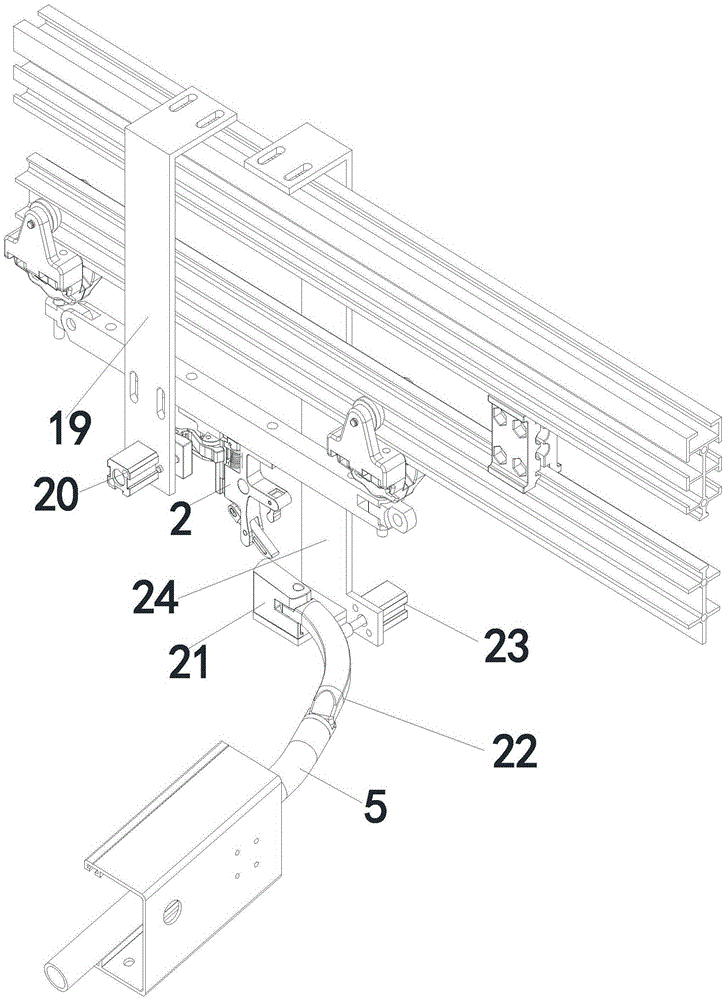

[0039] Such as Figure 1-7 As shown in the figure, an electric hanging conveying system for clothing materials includes a conveying track on which several clamping and releasing devices are provided, material roller hooks are provided on the clamping and releasing devices, and automatic shedding is provided on the side of the conveying track. The feeding mechanism and the automatic falling-off feeding mechanism are equipped with a material receiving device, and the exit of the material receiving device is equipped with an outbound automatic feeding mechanism.

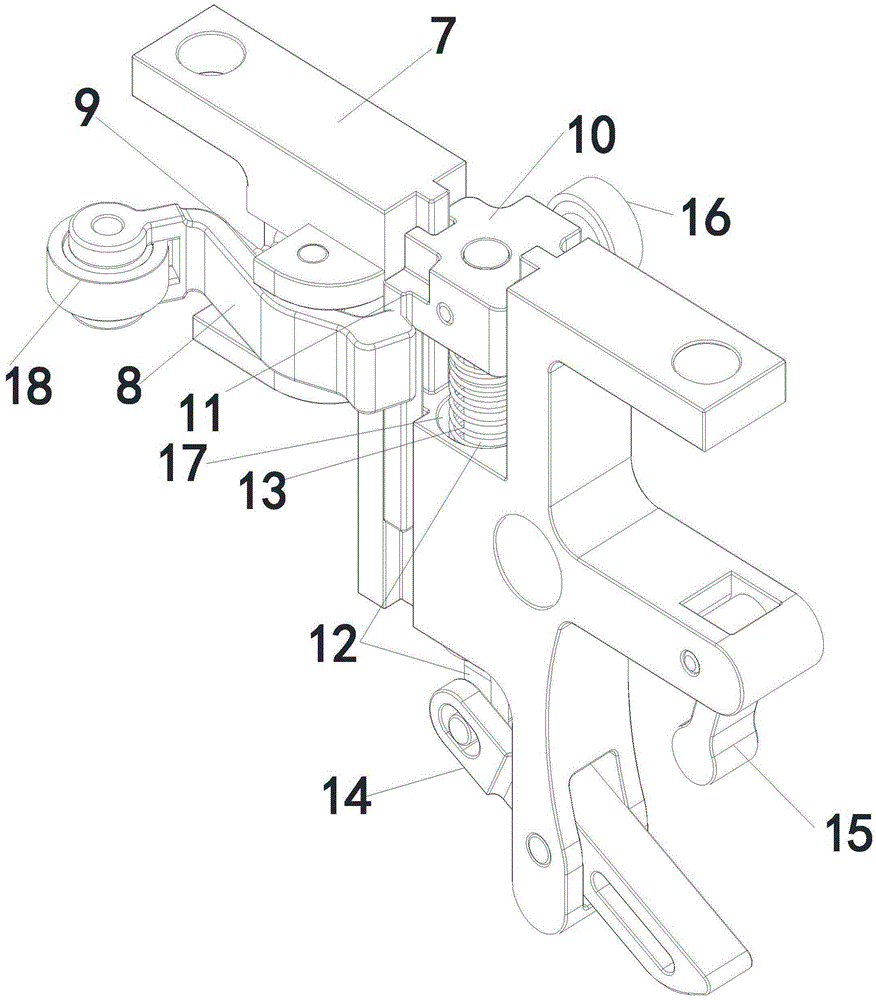

[0040] Such as figure 2 As shown, the clamping and releasing device in this embodiment includes a main body, a pressing piece is connected to one side of the main body, a pressing piece spring is arranged between the pressing piece and the main body, a pressing bar fixing block is sleeved in the main body to connect, and one end of the pressing piece Buckle the protrusion of the pressure rod fixing block, the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com