Digging and shovel impacting guide device of blocked coal shoveling machine

A technology of guiding device and coal shovel, which is applied in the direction of earthwork drilling, cutting machinery, etc., can solve the problems of uneven force, easy deviation, waste of resources, etc., and achieve easy maintenance, equipment heat dissipation, and manufacturing process Good, the effect of improving equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

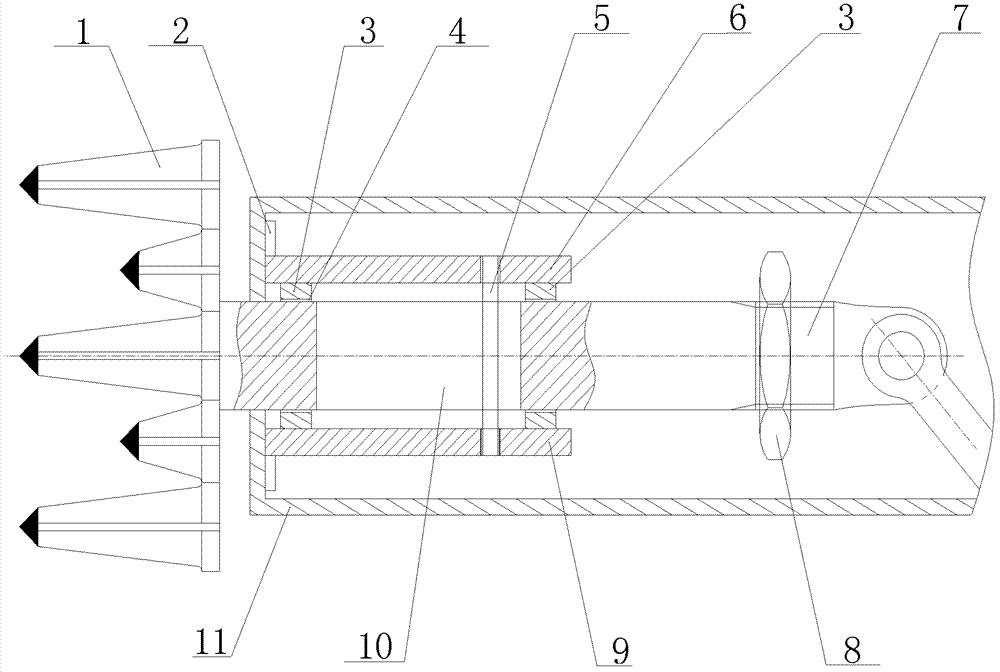

[0030] figure 1 It is the mining punching shovel guide device of the block coal shovel described in Example 1. The device includes a fixed seat 11 arranged outside the guide rod 7 of the mining ram. The front end of the digging ram guide rod 7 is fixedly connected with the digging ram 1, and the rear end is connected with the driving device. The front part of the digging ram guide rod 7 is provided with a guide ring fixing plate, and the guide ring fixing plate includes the guide ring upper fixing plate 6 And the lower fixing plate 9 of the guide ring, wherein the upper fixing plate 6 of the guiding ring is arranged above the guide rod 7 of the excavation punch, the lower fixing plate 9 of the guiding ring is arranged below the guiding rod 7 of the excavation punch, the upper fixing plate 6 and The lower fixing plate 9 of the guide ring is fixedly connected to the fixing base 11 through the connecting flange 2 respectively. There are two guide rings 3 spaced along the axial ...

Embodiment 2

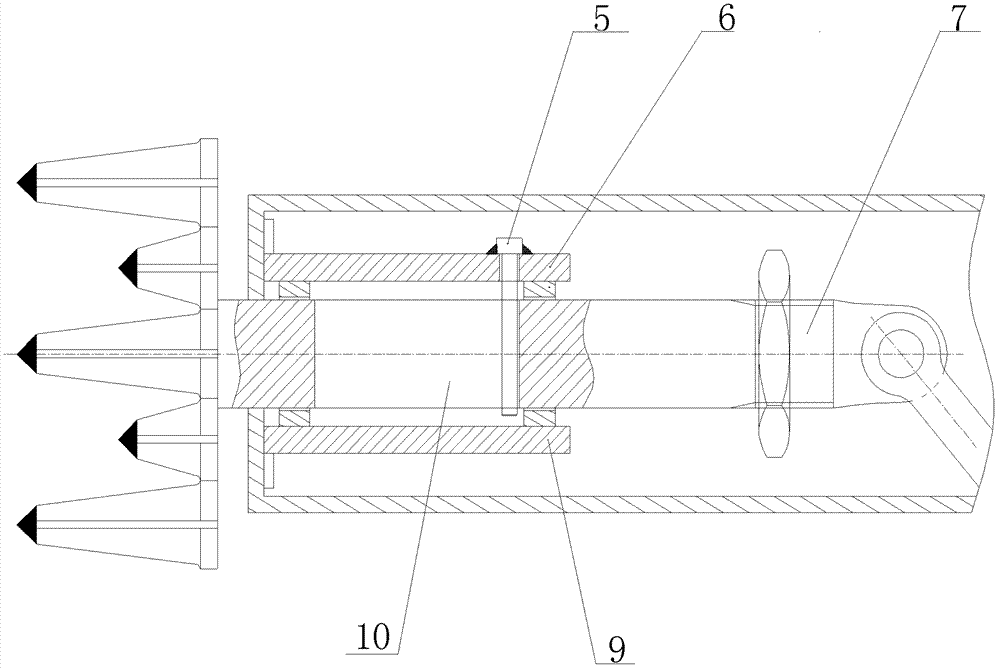

[0035] figure 2 It is the mining punching and shovel guide device of the block coal shovel described in Embodiment 2. The difference from Embodiment 1 is that one end of the anti-rotation bolt 5 is fixed on the fixing plate 6 on the guide ring, and the other end passes through the center of the guide rod 7 of the excavation shovel and slides along the chute 10 on the guide rod 7 of the excavation shovel. , not fixed on the lower fixing plate 9 of the guide ring.

[0036] In addition, the anti-rotation bolt 5 can also be only fixed on the lower fixing plate 9 of the guide ring, and the other end passes through the center of the guide rod 7 of the excavation blade and can slide along the chute 10 of the guide rod 7 of the excavation blade.

[0037] Others are the same as in Example 1.

Embodiment 3

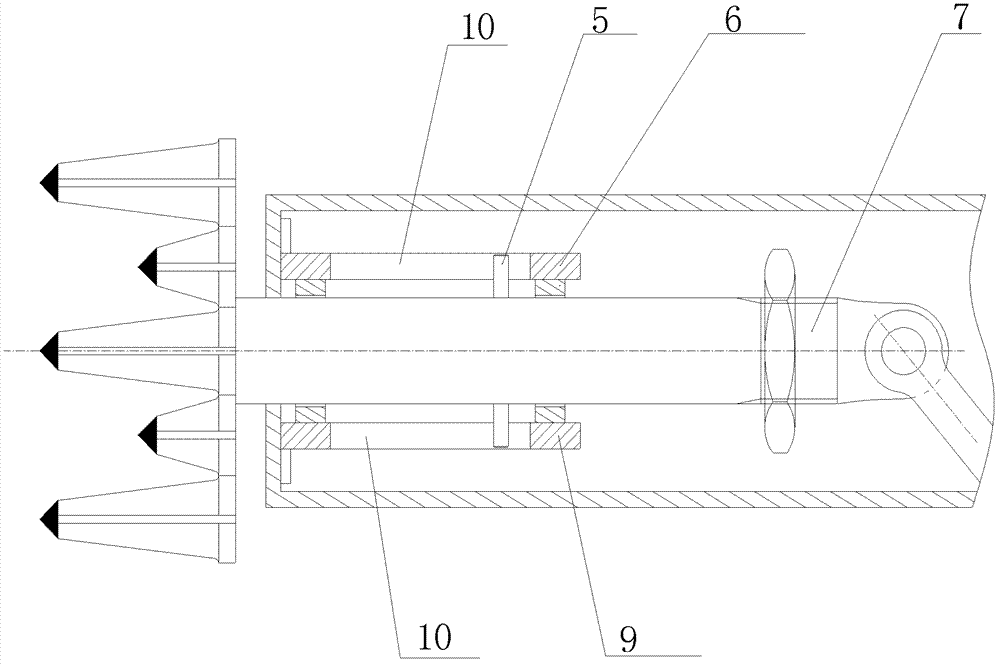

[0039] image 3It is the mining punching shovel guide device of the block coal shovel described in the third embodiment. The difference from Embodiment 1 is that the guide ring upper fixing plate 6 and the guide ring lower fixing plate 9 are provided with chute 10 along the axial direction of the guide rod 7 of the mining shovel. At this time, the anti-rotation bolt 5 is fixed on the On the shovel guide rod 7 , the anti-rotation bolt 5 can slide in the chute 10 of the guide ring upper fixing plate 6 and the guide ring lower fixing plate 9 , and simultaneously drives the mining shovel guide rod 7 to slide along the chute 10 .

[0040] The anti-rotation bolt 5 can also be in an integral structure with the guide rod 7 of the mining shovel.

[0041] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com