Swing rod link direct-impact coal shoveling machine

A technology of coal shovel and linkage, which is applied in the field of pendulum-linked direct flushing coal shovel, can solve the problems of large impact force damage of the punch, damage of the guide rail, and reduction of the service life of the shearer, so as to reduce damage, Effect of reducing shear force and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

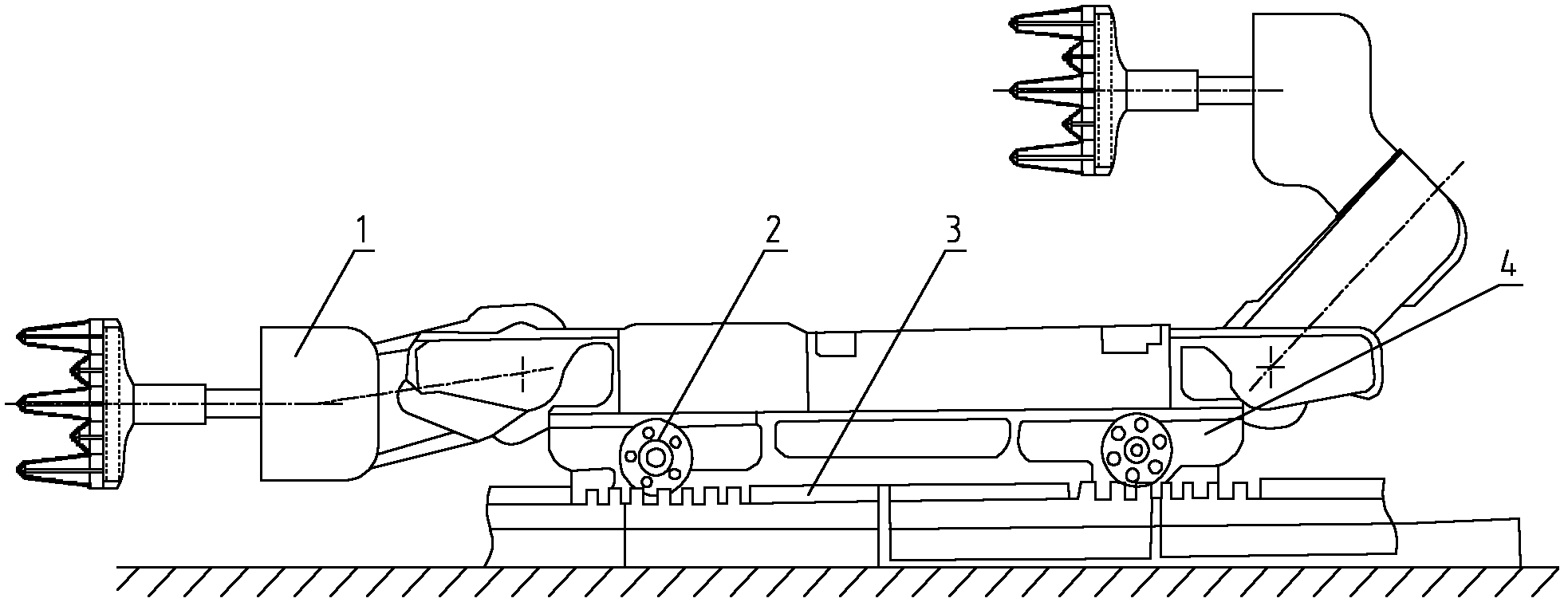

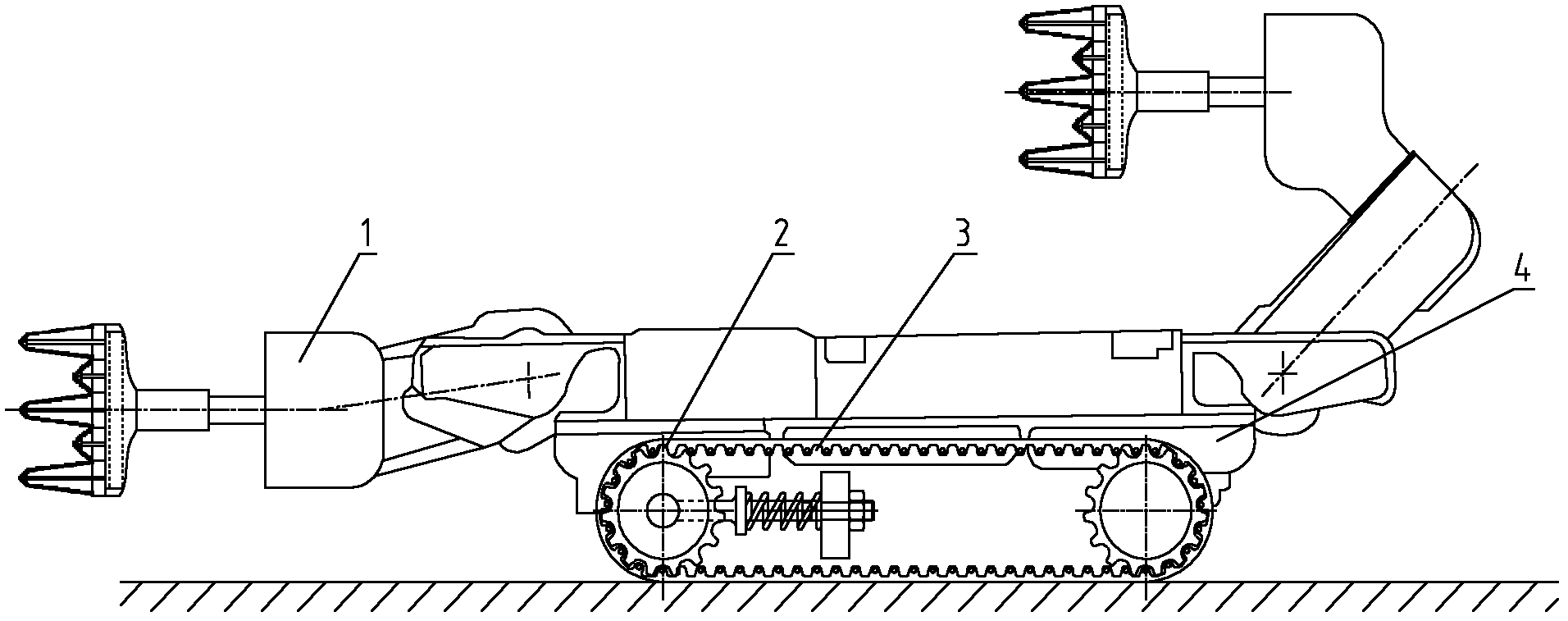

[0034] Figure 1 to Figure 3 It is the pendulum-linked straight flushing coal shovel described in Embodiment 1. The coal shearer includes a fuselage on which a frame, a traveling mechanism, an impact device 1 , a driving device 2 and a traction device 4 are arranged. The traveling mechanism in the present embodiment adopts running guide rail 3, figure 1 The running guide rail 3 shown is a rack and pinion structure; figure 2 The running guide rail 3 shown is a chain. Start the driving device 2 to make the whole body move along the moving guide rail 3, and drive the impact device 1 to impact the falling coal.

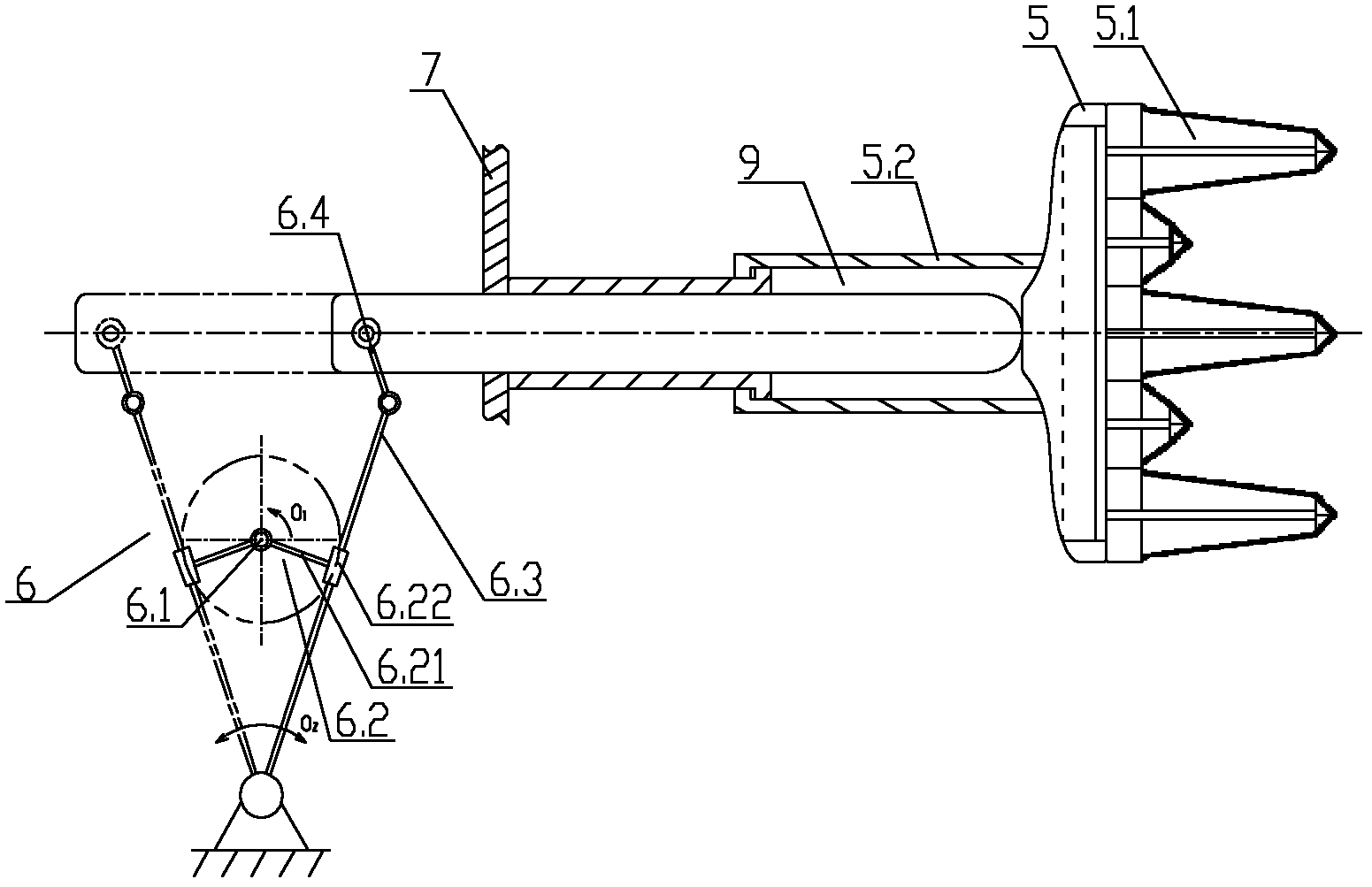

[0035] The impact device adopted in this embodiment is a shoveling device whose rotational force becomes a linear impact force. There is a guiding mechanism. The rotary force becomes linear impact force and the punching device includes a punching mechanism 5 and a rotary force becomes a linear impact force mechanism 6. The punching mechanism 5 includes a shovel head...

Embodiment 2

[0042] Figure 4 It is the rod-linked straight flushing coal shovel described in embodiment 2. The difference from Embodiment 1 is that one end of the stroke rod 5.2 in this embodiment is fixedly connected to the shovel head 5.1, and the other end is hinged to the straightening link 6.4 of the swing rod 6.3. The frame is provided with a guiding mechanism, and the straightening connecting rod 6.4 drives the stroke rod 5.2 and the shovel head 5.1 to do linear reciprocating motion along the guiding mechanism.

[0043] Others are with embodiment 1.

Embodiment 3

[0045] Figure 5 It is the rod-linked straight flushing coal shovel described in embodiment 3. The difference from Embodiment 1 is that the rotating part 6.2 includes a rotating shaft 6.1, a rotating handle 6.21 and a guide rod 6.23. One end of the rotating handle 6.21 is connected with the rotating shaft 6.1, the other end is connected with the guide rod 6.23, and the other end of the guide rod 6.23 is connected with the fork 6.3. The rotation of the rotation shaft 6.1 drives the rotation of the rotation handle 6.21. When the rotation handle rotates, the power is transmitted to the guide rod 6.3 through the guide rod 6.23, so that the guide rod 6.3 swings, and the swing of the guide rod 6.3 drives one end of the straightening rod 6.4 to drive the impact. Rod 9 makes linear reciprocating motion along travel rod 5.2 and guide mechanism, and impact shovel head 5.1 and travel rod 5.2 move forward during impact rod 9 moves forward.

[0046] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com