A top coal caving imitation coal flow gangue caving impact test system and its application

A technology of impact test and top coal caving, applied in educational appliances, teaching models, instruments, etc., can solve the problems of restricting the practical application of coal gangue identification technology, imperfect identification methods, lack of experimental devices, etc., and achieves ingenious structural design, error Small, precise effect of the test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

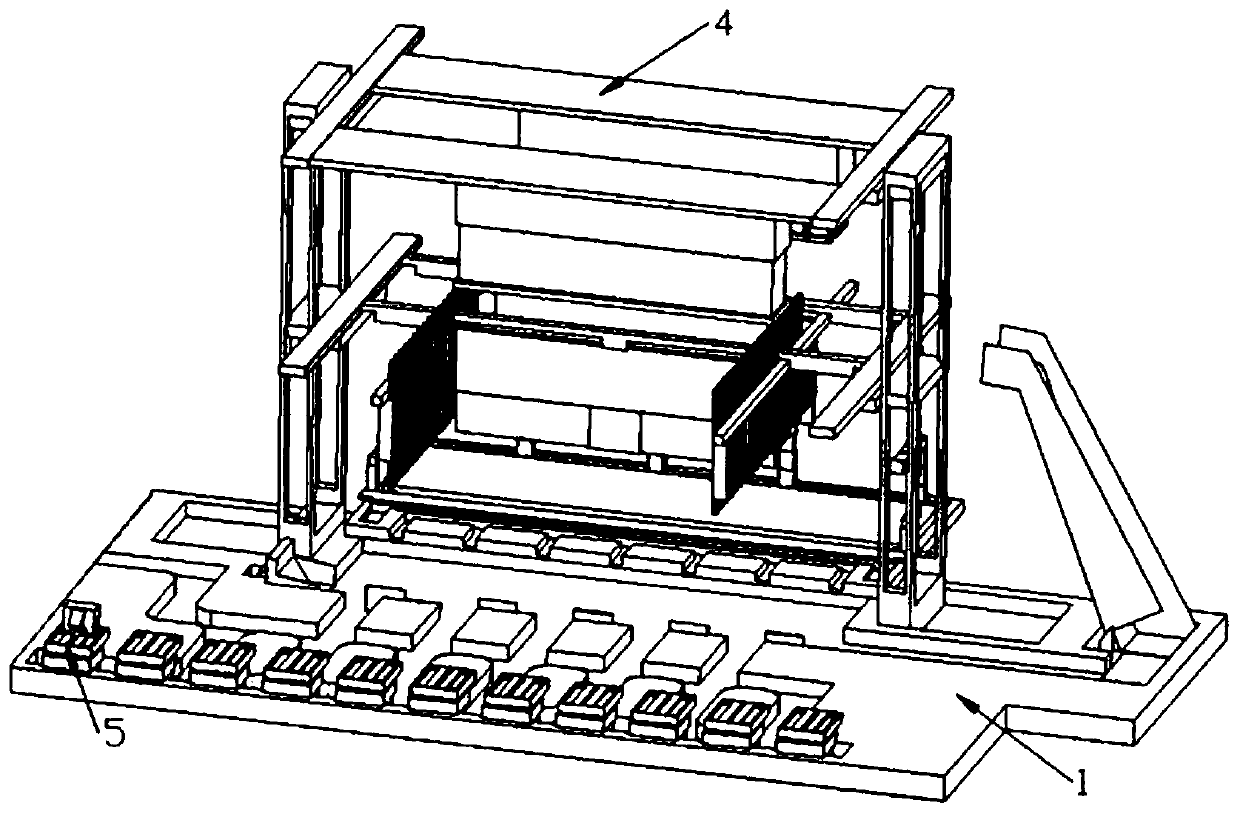

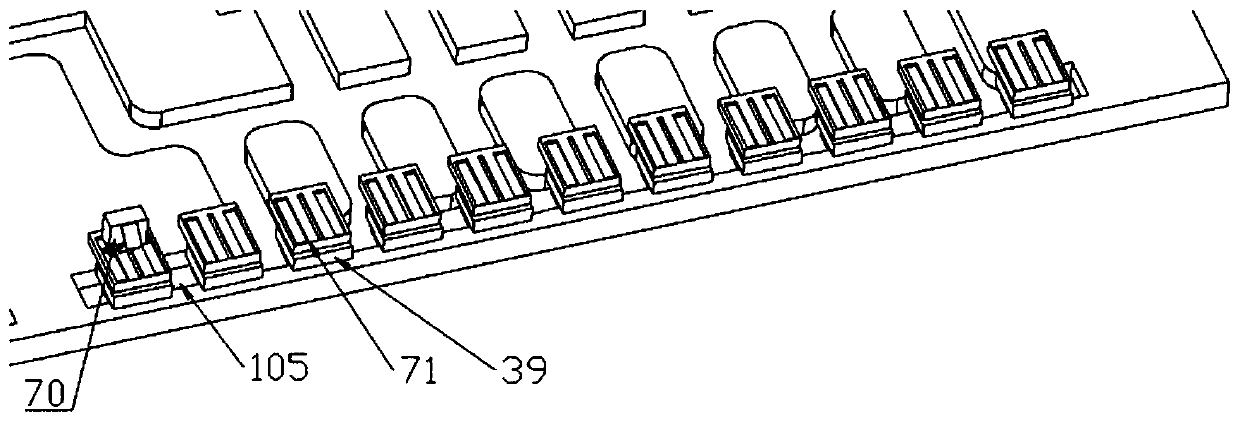

[0046] This embodiment provides a top coal caving imitation coal flow coal gangue drop impact test system, including a base 1 and an imitation coal flow fall device 4 arranged on the base, a coal gangue conveying device 401, a coal shoveling device 405 and multiple A top-coal caving hydraulic support working group 5; a plurality of top-coal caving hydraulic support working groups 5 are placed side by side in the top-coal caving support working group storage channel 105 opened on the base 1; And the imitation ore pressure loading device 402, the coal flow withholding device 403, the hydraulic support adjustment and release device 404, and the coal shoveling device 405 arranged on the side of the imitation coal flow release device 4 are used to push the coal gangue particles after the test to the coal mine. The gangue conveying device 401, the coal gangue conveying device 401 is arranged at one end of the imitation coal flow release device 4 for transporting the coal gangue parti...

Embodiment 2

[0054] A working method of the caving coal caving imitation coal flow coal gangue falling impact test system, using the test system described in Example 1 to simulate the working principle of caving coal caving: the hydraulic support of the single caving caving can be completed The simulated top-coal caving can also complete the simulated top-coal caving group of multiple top-coal caving hydraulic supports. The specific test steps are as follows:

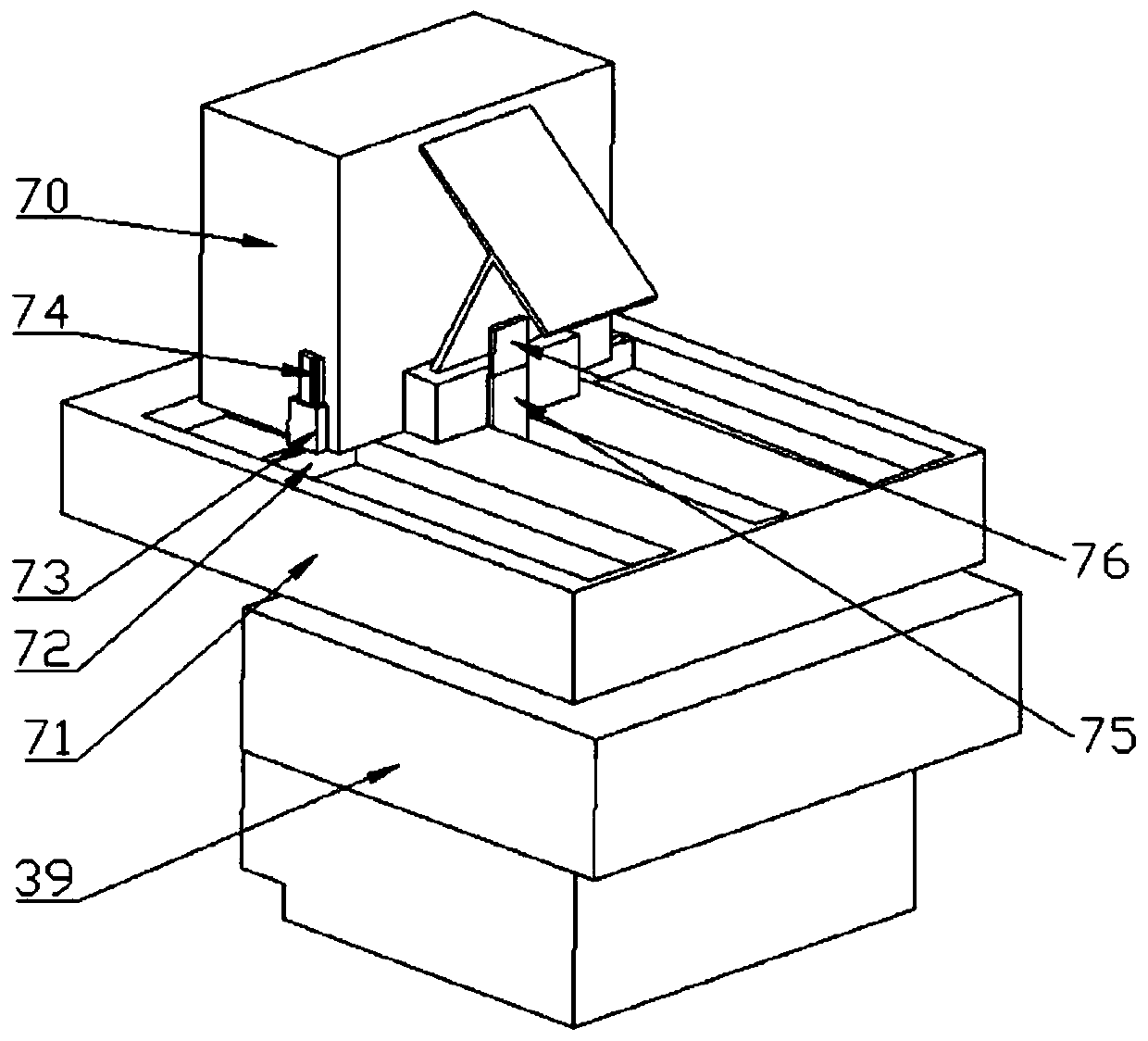

[0055]For the simulated top-coal caving of the single-frame top-coal caving hydraulic support: the top-coal caving support lateral baffle chute 72, the top-coal caving support lateral primary baffle 73, the top-coal support lateral secondary baffle 74. The top-coal caving support is facing away from the primary baffle 75, the top-coal caving support is facing away from the secondary baffle 76, and the top-coal caving hydraulic support 70 is fixed and positioned on the secondary moving seat 71 of the top-coal caving support group thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com