Scraper conveyor load monitoring device and chain tension estimation method

A scraper conveyor and monitoring device technology, applied in conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of difficult positioning, poor sealing, periodic stress changes, etc., and achieve convenient monitoring and power supply replacement. The effect of easy and easy evaluation of chain tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

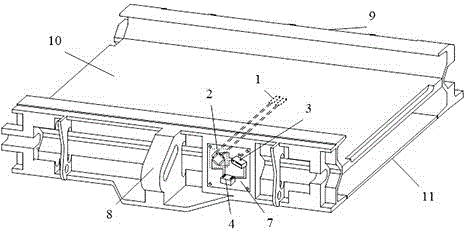

[0033] Such as figure 1 As shown, the scraper conveyor load monitoring device of the present invention includes a strain gauge 1, a half-bridge circuit 2, a wireless signal transmitter 3, a power supply 4, a strain gauge baffle 6, a push side channel side steel 8, a shovel Coal side channel side steel 9, middle plate 10, bottom plate 11, remote control center, drive shaft of the driving part of the scraper conveyor, hydraulic cylinder of the hydraulic tensioning device of the scraper conveyor; the drive shaft is provided with a torque sensor, The hydraulic cylinder is equipped with a pressure gauge;

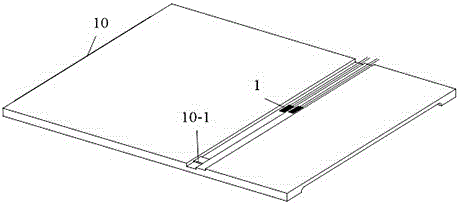

[0034] Such as figure 2 As shown, there are two parallel transverse grooves with different depths on the lower side of the middle plate 10, and the deeper parallel transverse grooves are welded with a positioning plate 10-1 on the side of the channel side steel 9 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com