Anchor force test simulation comprehensive experimental device

An experimental device and anchoring force technology, applied in the direction of measuring devices, mechanical devices, force/torque/power measuring instruments, etc., can solve the problems of low accuracy, reduce the reinforcement effect of anchor bolts, time-consuming and labor-intensive problems, and achieve high accuracy , good effect, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

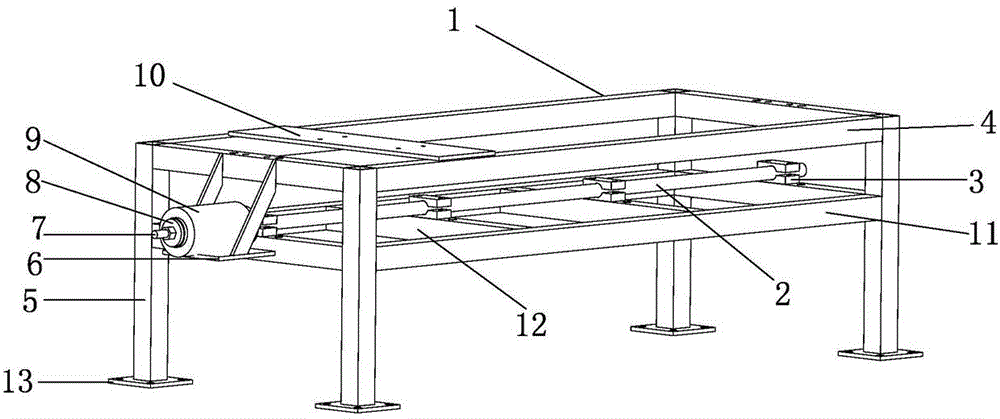

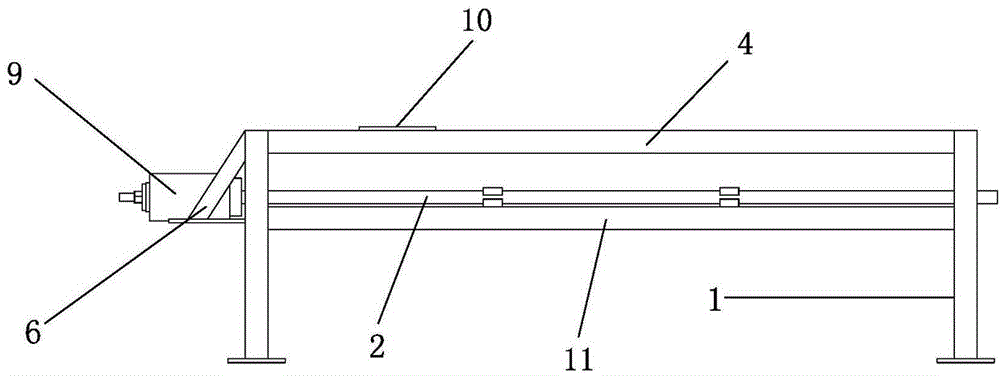

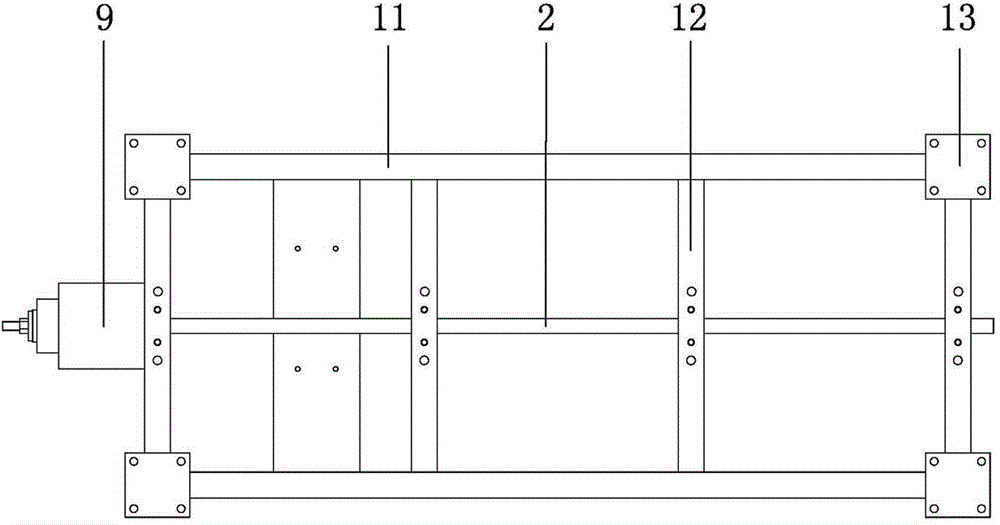

[0010] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] Depend on Figure 1-4 Given, the present invention comprises frame, steel pipe, anchor rod and annular oil cylinder, and frame 1 is made of support leg 5, upper frame 4 and lower frame 11, is fixed on the foundation through anchor bolt, and 4 support legs 5 are welded respectively On the four corners of the horizontal upper frame 4 and the lower frame 11, the front portion of the frame 1 is equipped with an oil cylinder mounting plate 6, an annular oil cylinder 9 is installed on the oil cylinder mounting plate 6, and a support 10 is installed on the upper frame 4, and the support 10 The top is equipped with a manual pump and a digital display meter (not shown in the figure), the steel pipe 2 is fixed on the lower frame 11 via the splint 3, one end of the anchor rod 7 is anchored in the steel pipe 2 through the anc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com