Coal mine tunnel supporting method

A technology for roadway support and coal mine roadway, which is applied in mining equipment, earthwork drilling, installation of bolts, etc. The effect of strengthening the support effect and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

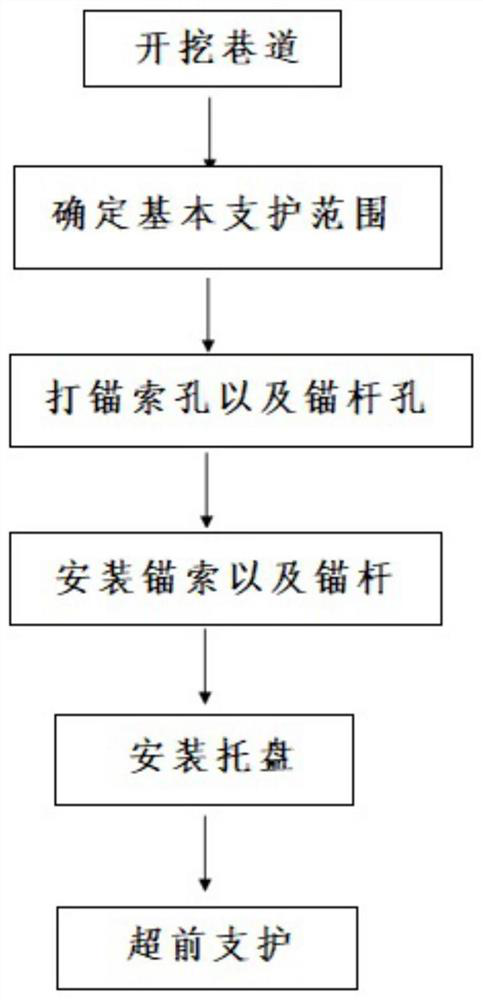

[0033] The present embodiment provides a coal mine roadway support method, comprising the following steps:

[0034] S1: Excavate the roadway according to the actual geological conditions of the coal mine.

[0035] S2: Determine the impact risk zone in the roadway, and then determine that the basic support range of the roadway is 200-250m ahead of the current working face, preferably 200m.

[0036] S3: Drill anchor cable holes in the impact dangerous area, and drill anchor bolt holes in the non-impact dangerous area.

[0037] S4: Install anchor cables and anchor rods into the anchor cable holes and anchor rod holes in the impact dangerous area and non-impact dangerous area respectively, and the tops of the anchor cables and anchor rods pass through the coal sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com