A large-scale support method and support device for roadway truss anchor cables

A technology of truss anchor cables and support devices, which is applied in the direction of tunnels, shaft equipment, installation of anchor rods, etc. It can solve the problems of inability to transfer prestress, easy shear failure of steel strips or steel beams, and sudden drop in support effect. Achieve the effects of improving the stress state of the roof, preventing roadway roof fall accidents, and improving the stability of the roof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

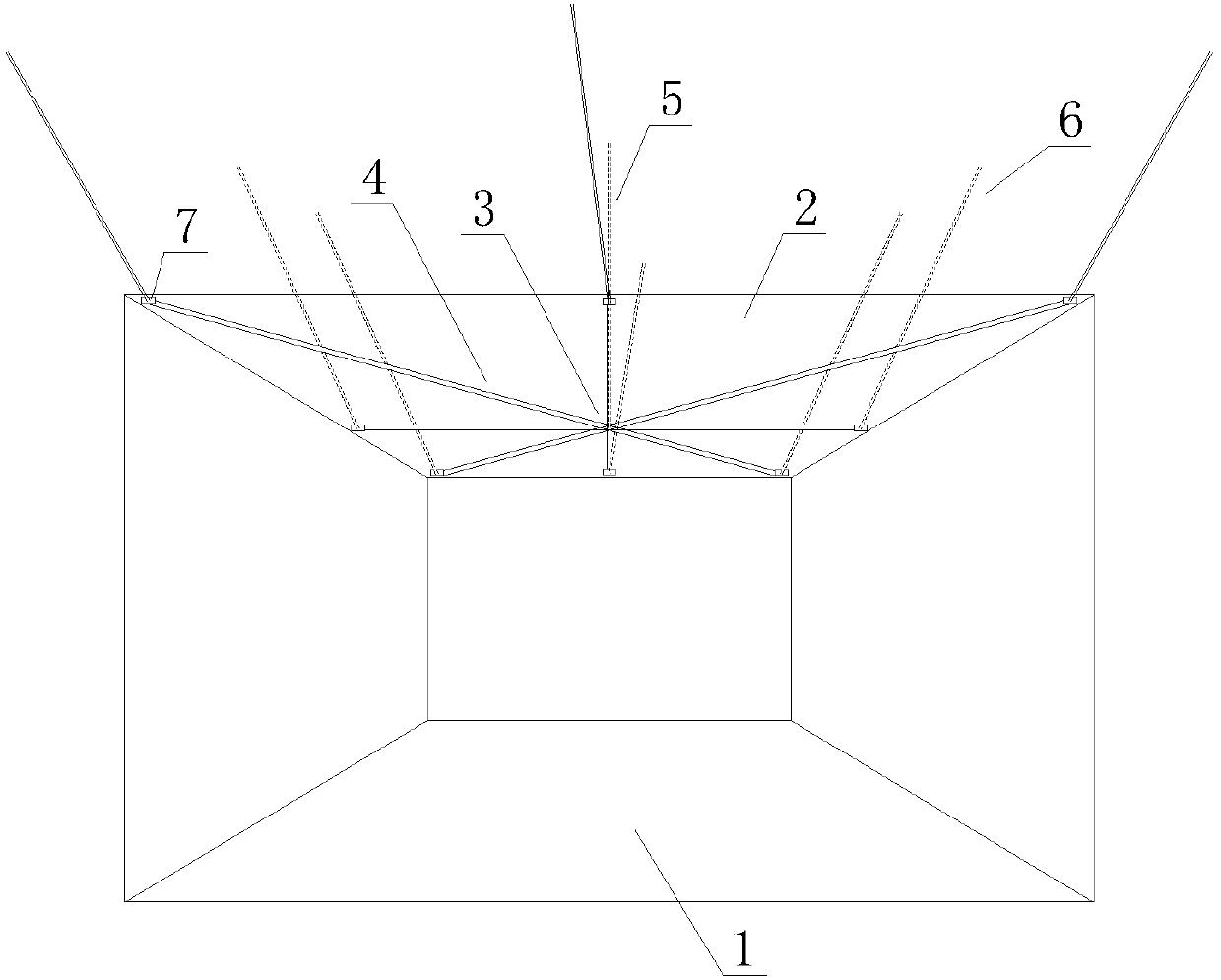

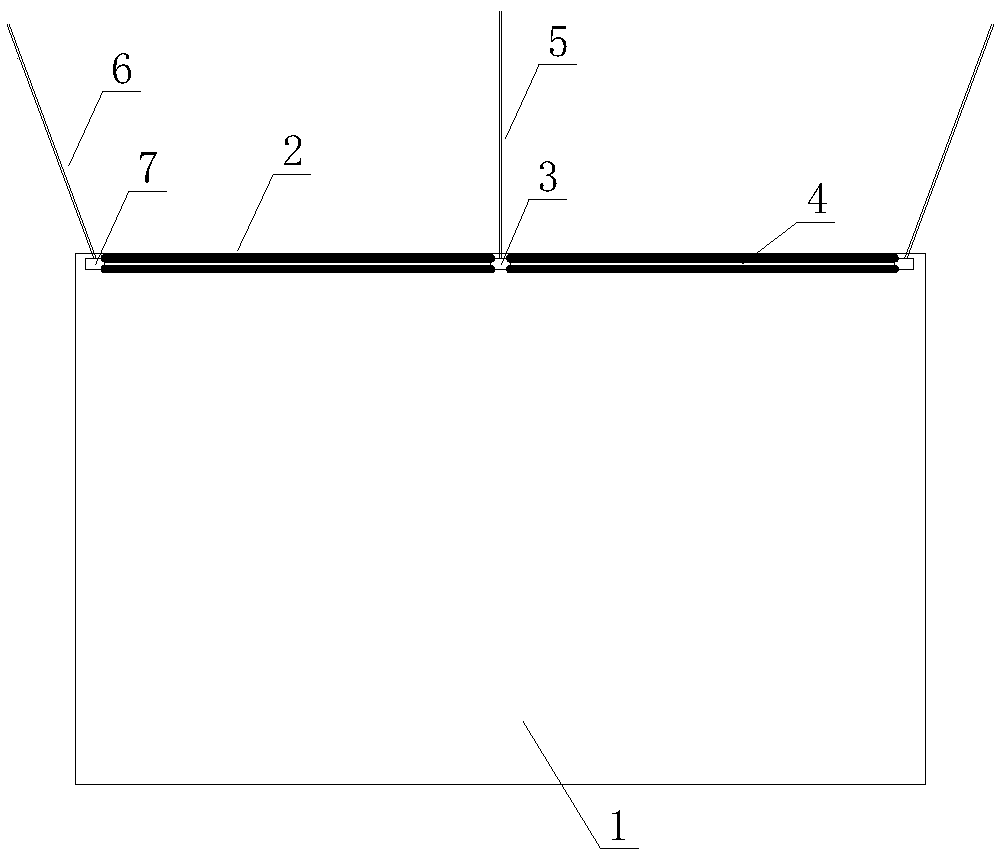

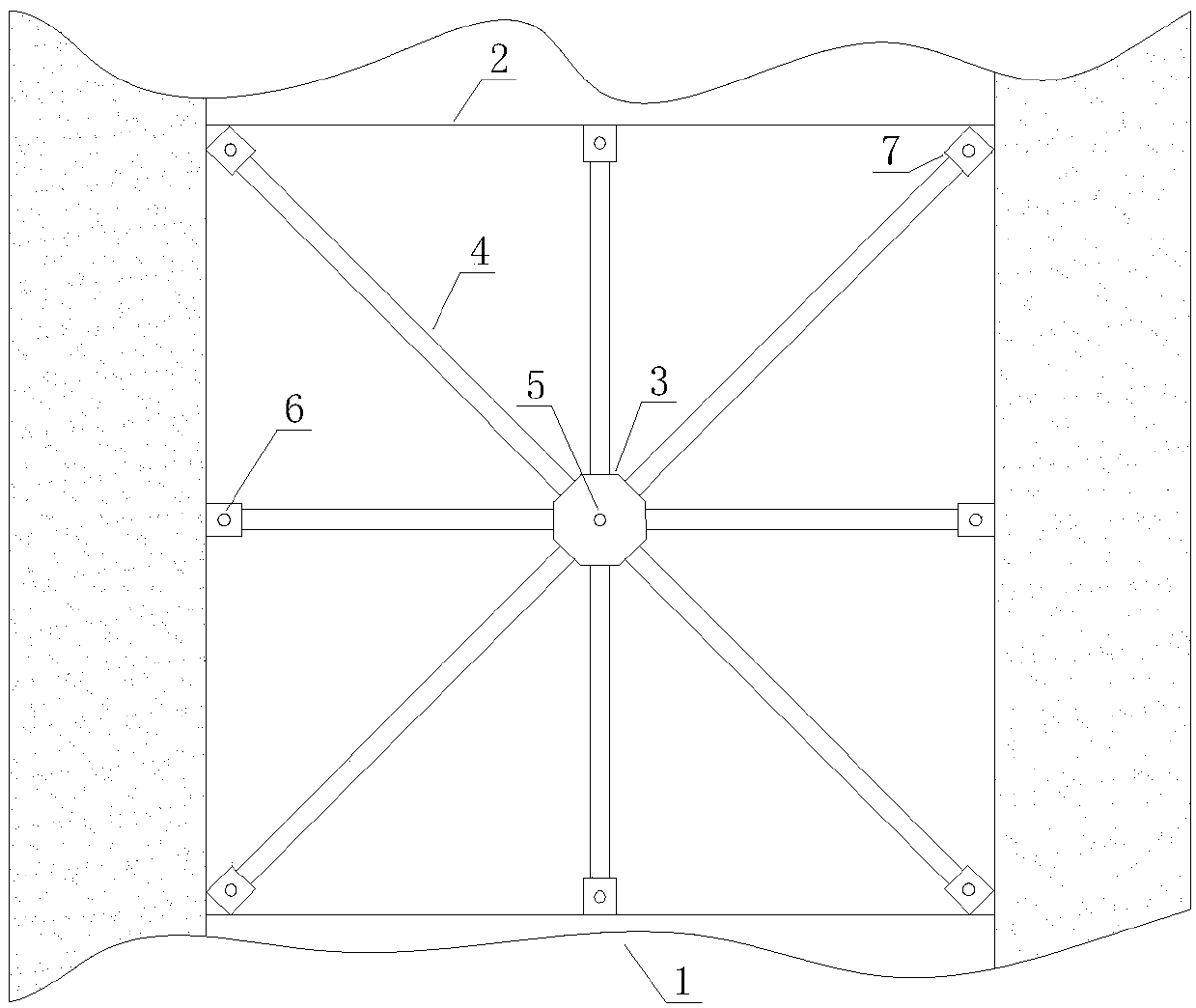

[0037] The invention provides a large-scale support method and support device for roadway truss anchor cables, which are used to form a large-scale extrusion stress area above the surface of the roadway roof, improve the support capacity of the roadway roof, and thereby enhance the stability of the roadway roof At the same time, the support device can adapt to the magnitude of the horizontal force generated by the horizontal movement of the roadway roof, and has a stable structure and strong support for the roadway roof.

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0039] Such as Figures 1 to 3 As shown, the supporting device of this embodiment includes: eight pairs of telescopic trusses 4; a truss composite member 3 for combining and connecting multiple pairs of telescopic trusses and distributing multiple pairs of telescopic trusses around it in multiple directions; Vertical anchor cables ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com