Patents

Literature

34results about How to "Prevent roof fall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

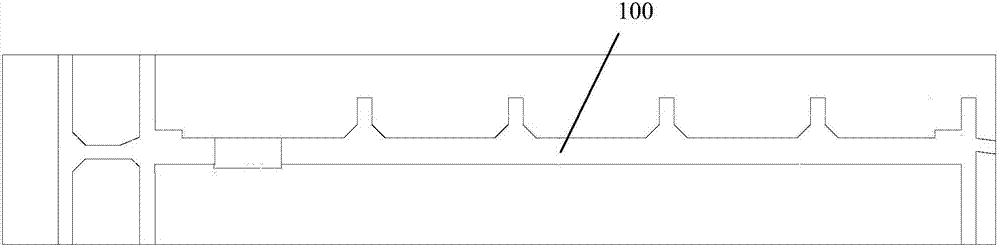

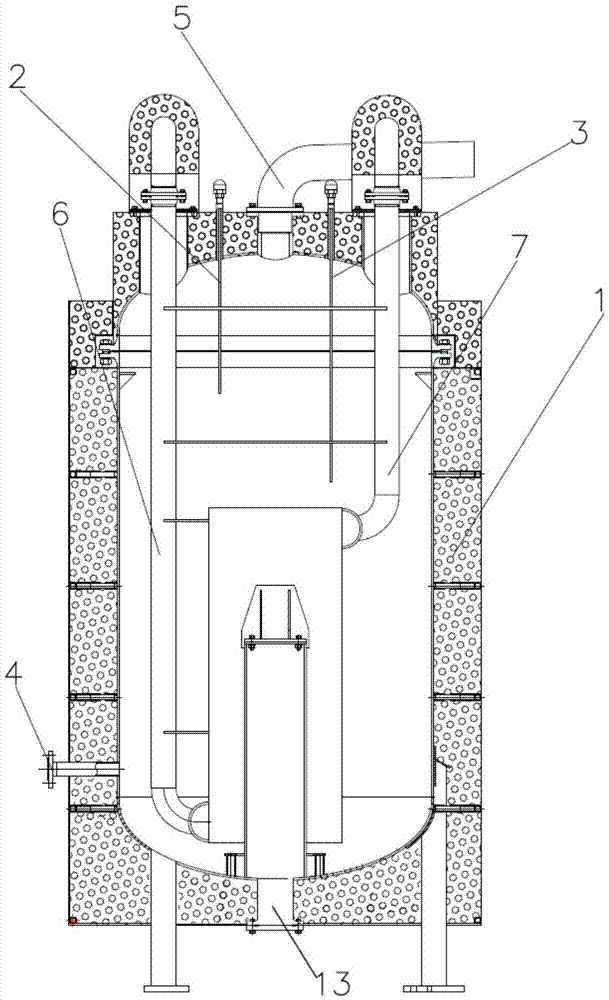

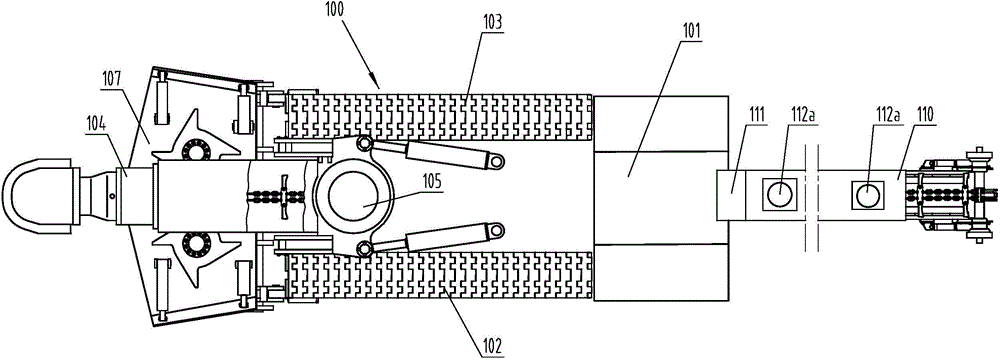

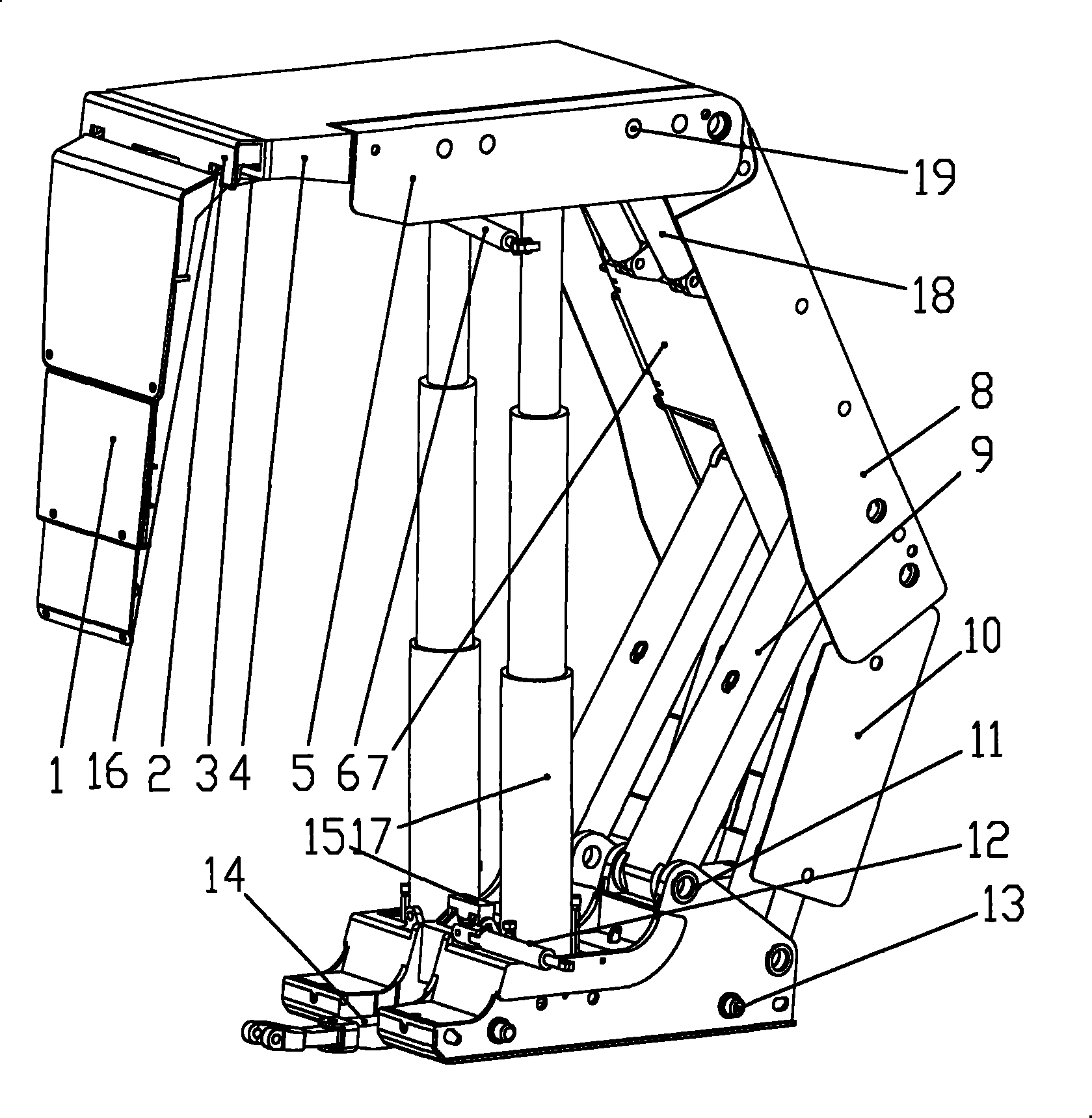

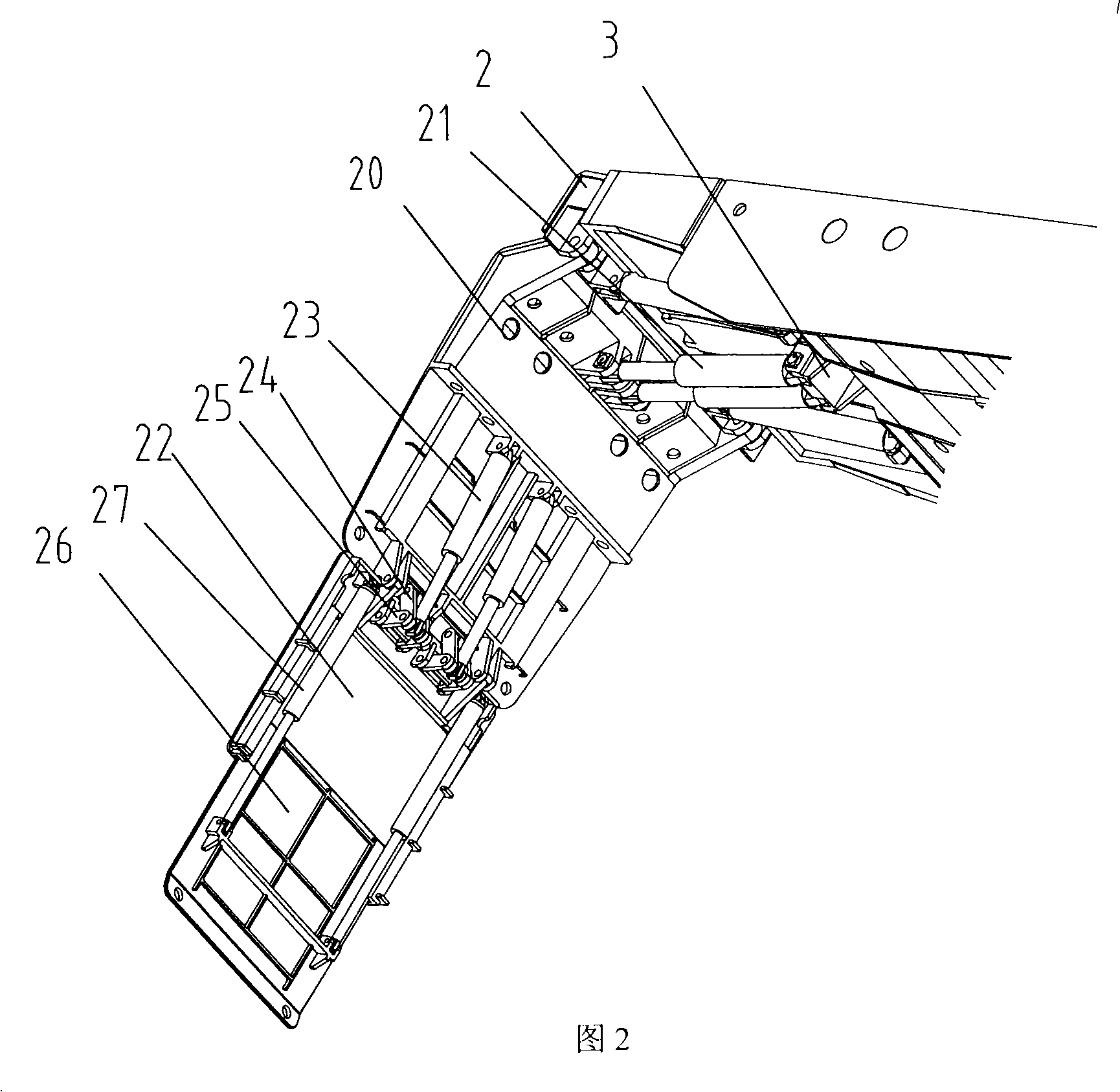

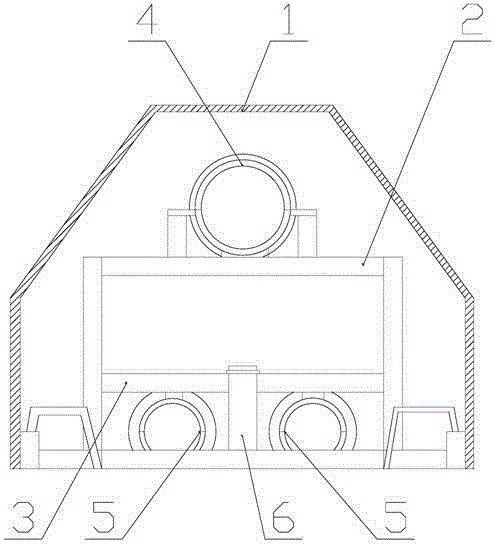

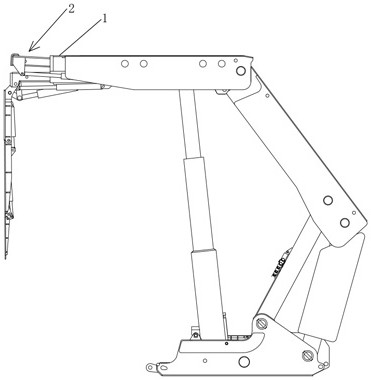

Overlarge mining height hydraulic support

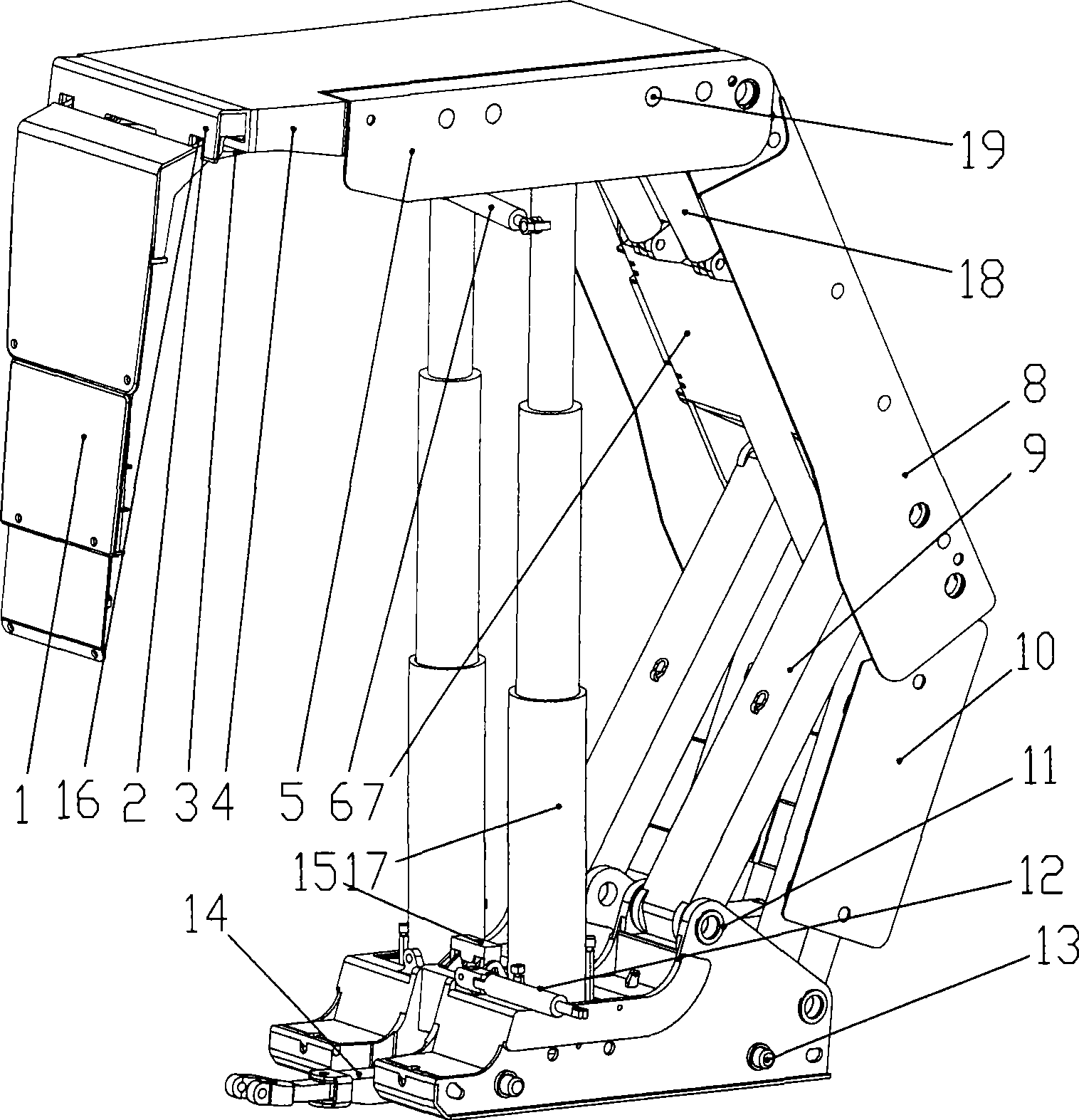

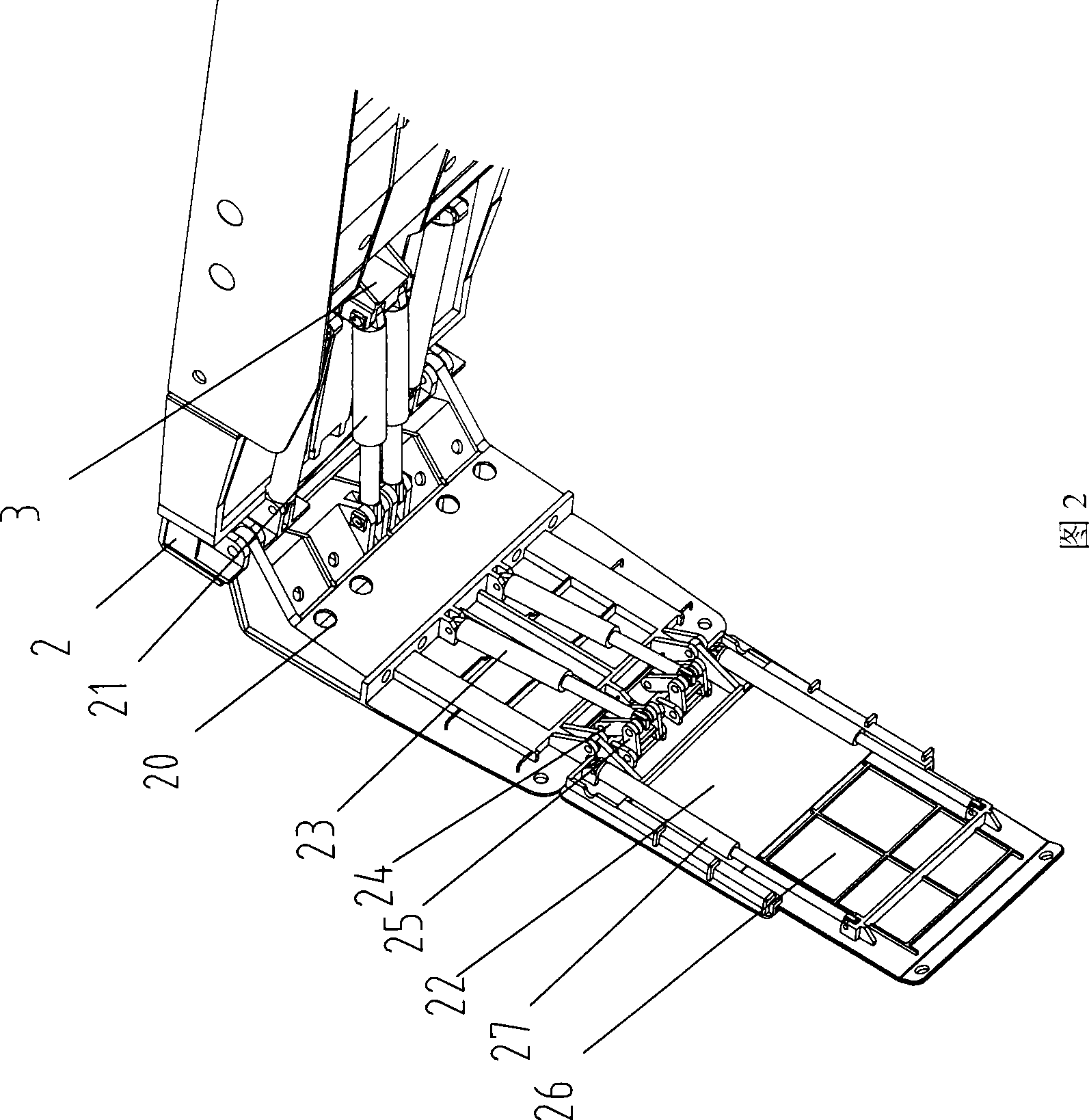

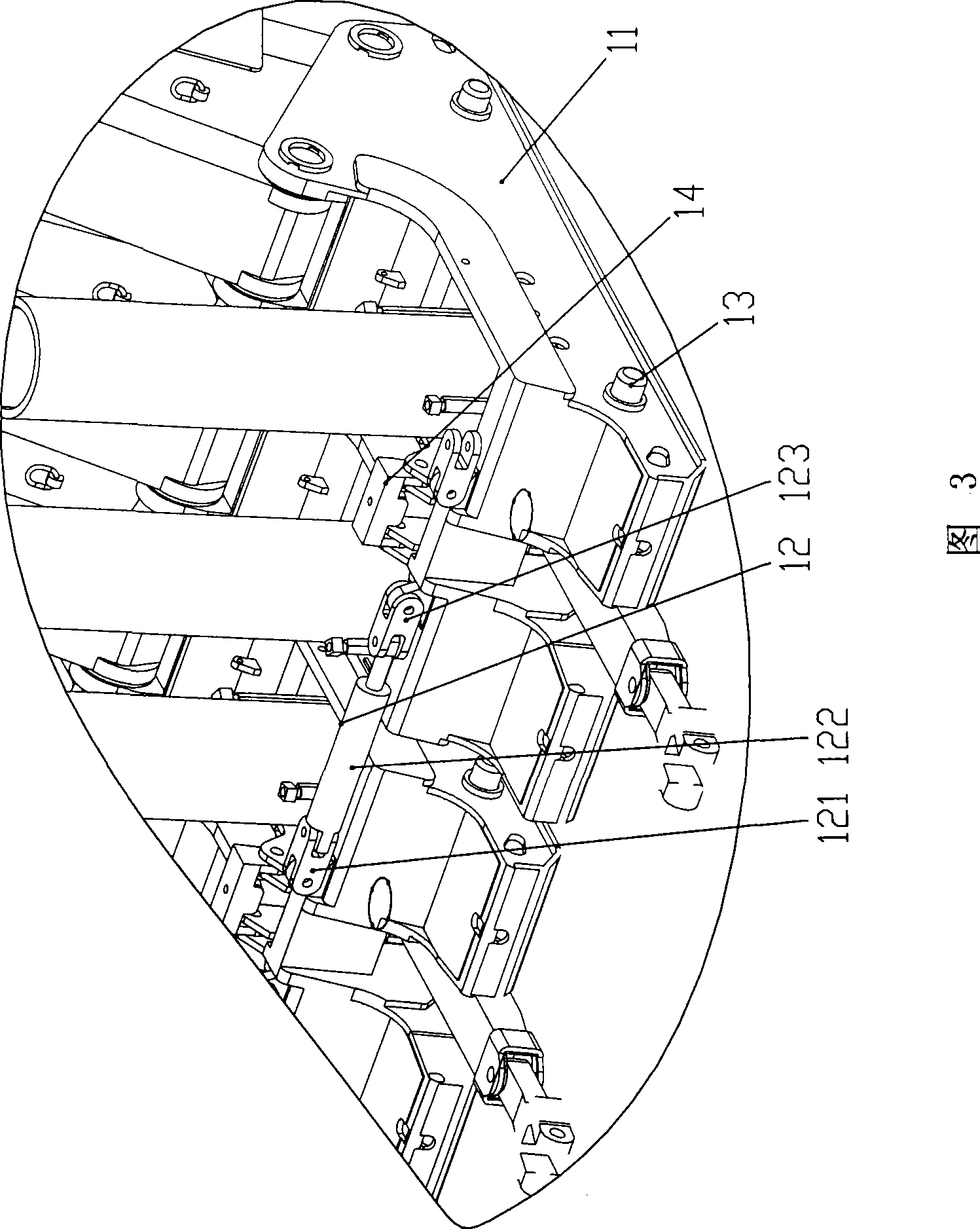

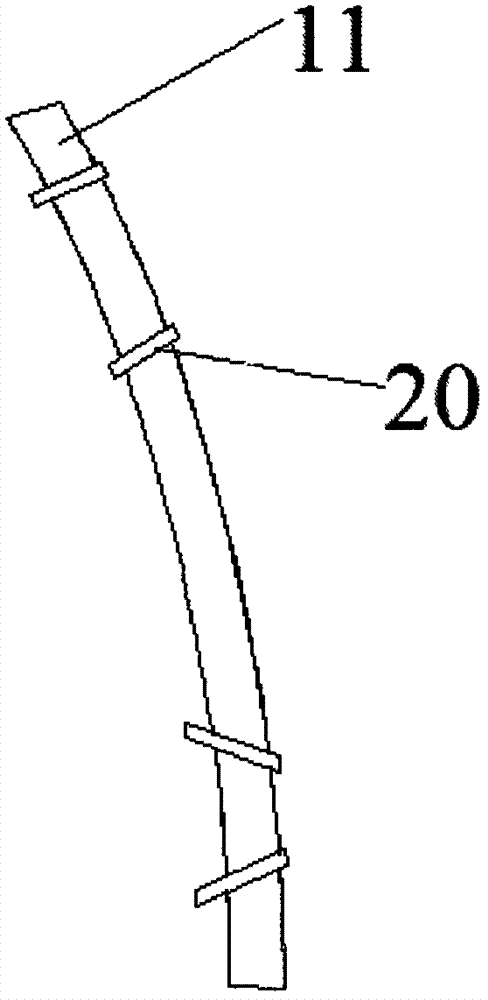

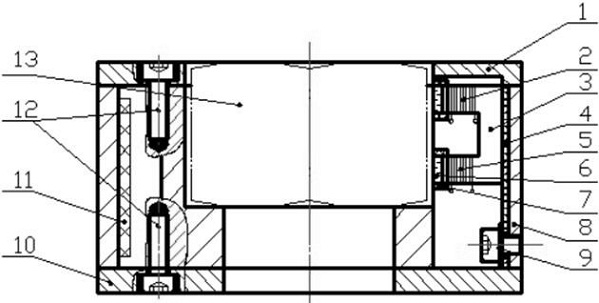

The invention relates to a super large mining height hydraulic support which comprises an opened rigid integrated base, wherein, two double-telescopic hydraulic upright posts are arranged on the base, and the upper ends of the upright posts are connected with a top beam; the rear of the top beam is connected with a screening beam; an edge protection device is connected with the telescopic beams which are in inner extension connection with the top beam; a balance jack is arranged between the top beam and the screening beam; the screening beam and the base are respectively connected with the front and rear connecting rods; a push jack is arranged on the base and is connected with a push rod; the front part of the top beam is provided with the telescopic beams, the middle part of the top beam is provided with a falling prevention device for the support, and bottom lifting, skid prevention and support regulation devices are arranged on the base; and a levelling device is arranged on a cross binding head on the front end of the push rod; the support adopts 2-meter width between centers, the maximum height ranges from 6.3 meters to 7.5 meters, and the front end of the telescopic beam is provided with a third-stage edge protection device which is not lower than half of the mining height. The support has obvious effects of controlling the wall caving of the coal wall of a super thick coalseam, the roof fall of the ceiling, and the stability of the hydraulic support.

Owner:CCTEG COAL MINING RES INST

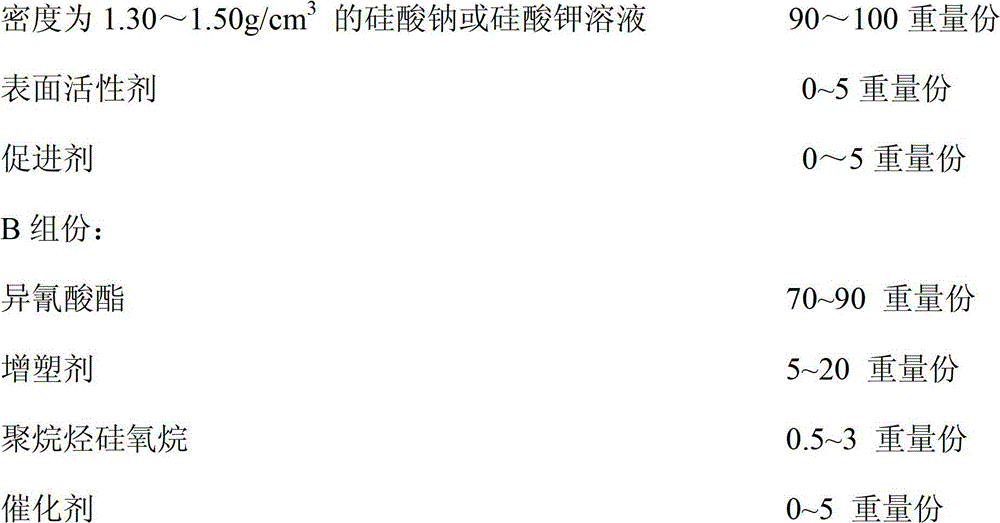

Chemical grouting material for reinforcing loose and broken bedrock

The invention relates to a chemical grouting material for reinforcing loose and broken bedrock. The invention provides a chemical grouting material for reinforcing the loose and broken bedrock, in order to improve the flash point, the burning point and the antistatic performance of the grouting material, reducing the temperature in polymerization reaction and lowering the cost. According to the technical scheme provided by the invention, the chemical grouting material for reinforcing the loose and broken bedrock comprises two components, including a component A and a component B; according to the formulas of the raw materials, the component A comprises 90 to 100 parts by weight of sodium silicate or potassium metasilicate solution, 0 to 5 parts by weight of surface active agent, and 0 to 5 parts by weight of accelerator; the component B comprises 70 to 90 parts by weight of isocyanate, 5 to 20 parts by weight of plasticizer, 0.5 to 3 parts by weight of polyalkane silicone, and 0 to 5 parts by weight of catalyst; the components A and B are uniformly mixed respectively; and in use, the components A and B are mixed according to the volume ratio of 1: 1. The chemical grouting material can be applied to quickly reinforcing the broken coal bed and rock bed and blocking water leakage.

Owner:HANGZHOU GUODIAN DAM SAFETY ENG

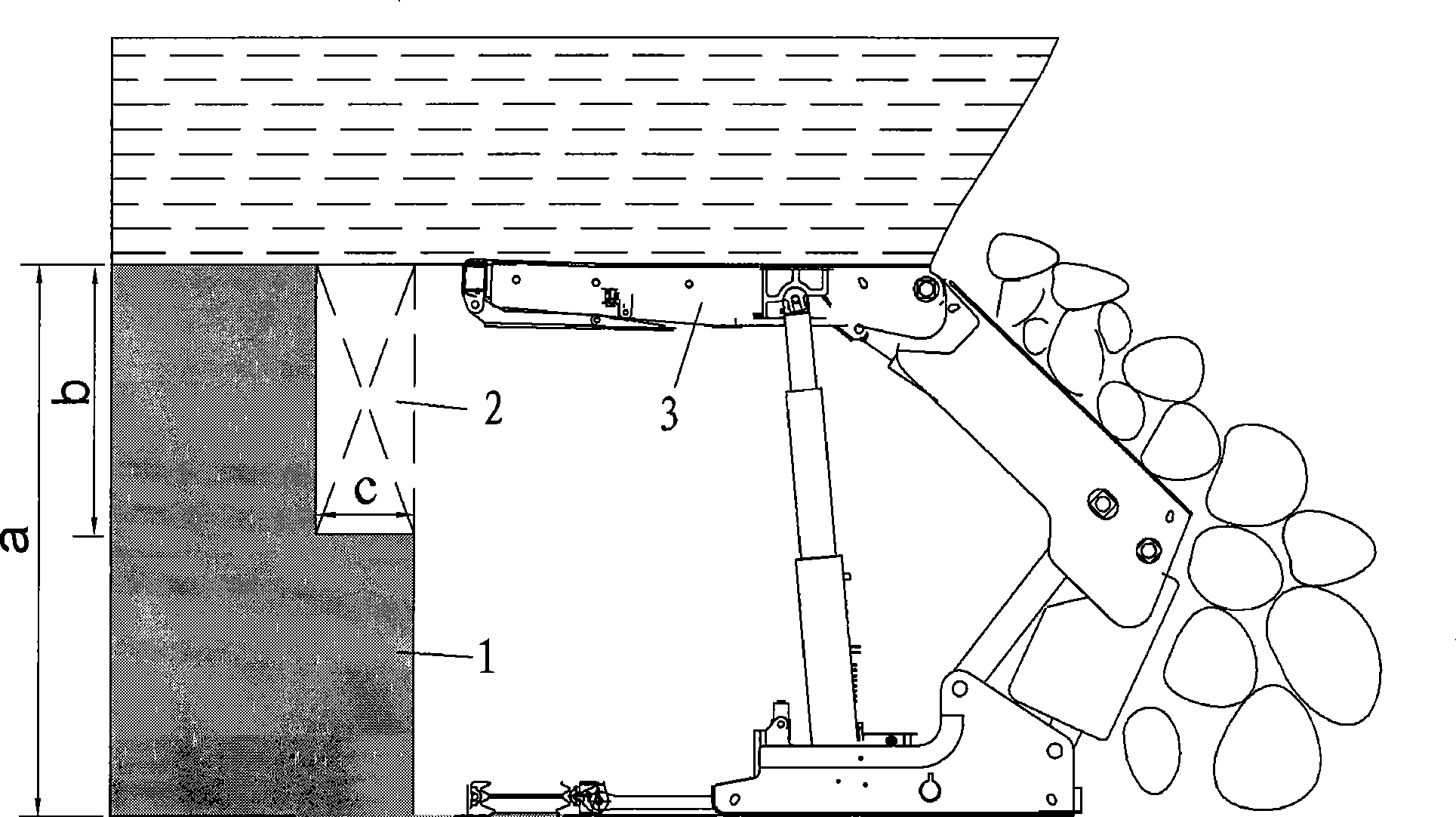

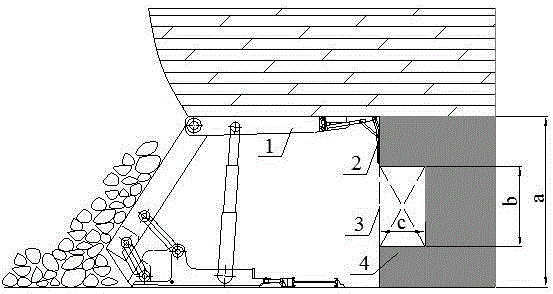

High mining height workface stepped coal cutting process

InactiveCN101418689APrevent roof fallGuaranteed stabilityUnderground miningSurface miningMining engineeringStressed state

Provided is a large mining height fully-mechanized step type coal cutting process. In a fully mechanized working face, a coal mining machine cuts the coal on the coal wall along the coal seam thickness direction to form a step on the coal wall, and then cutting coal for the step at lower part of the coal wall, and the processes are performed circularly in order; or the front and the rear rollers of the coal mining machines are adopted to directly perform upper and lower cutting to keep the cut coal wall having one step all the time; when the height of the coal wall of the coal mining working face is changed, the upper and lower height of the step of the coal wall is adjusted to make the height of the coal seam above the step always lower than the height of the coal seam under the step so as to the optimal stress state of the coal wall area, and to essentially improve the stability of the coal rock of the working face. The process not only can effectively control the large area rib spalling or end surface roof caving caused by long time stay of the large mining high coal wall, but also can work as an operation platform for outburst prevention circulation measure construction for the coal and gas projecting under the coal seam. The process is simple, convenient in construction, easy in operation, and has wide practicability.

Owner:CHINA UNIV OF MINING & TECH

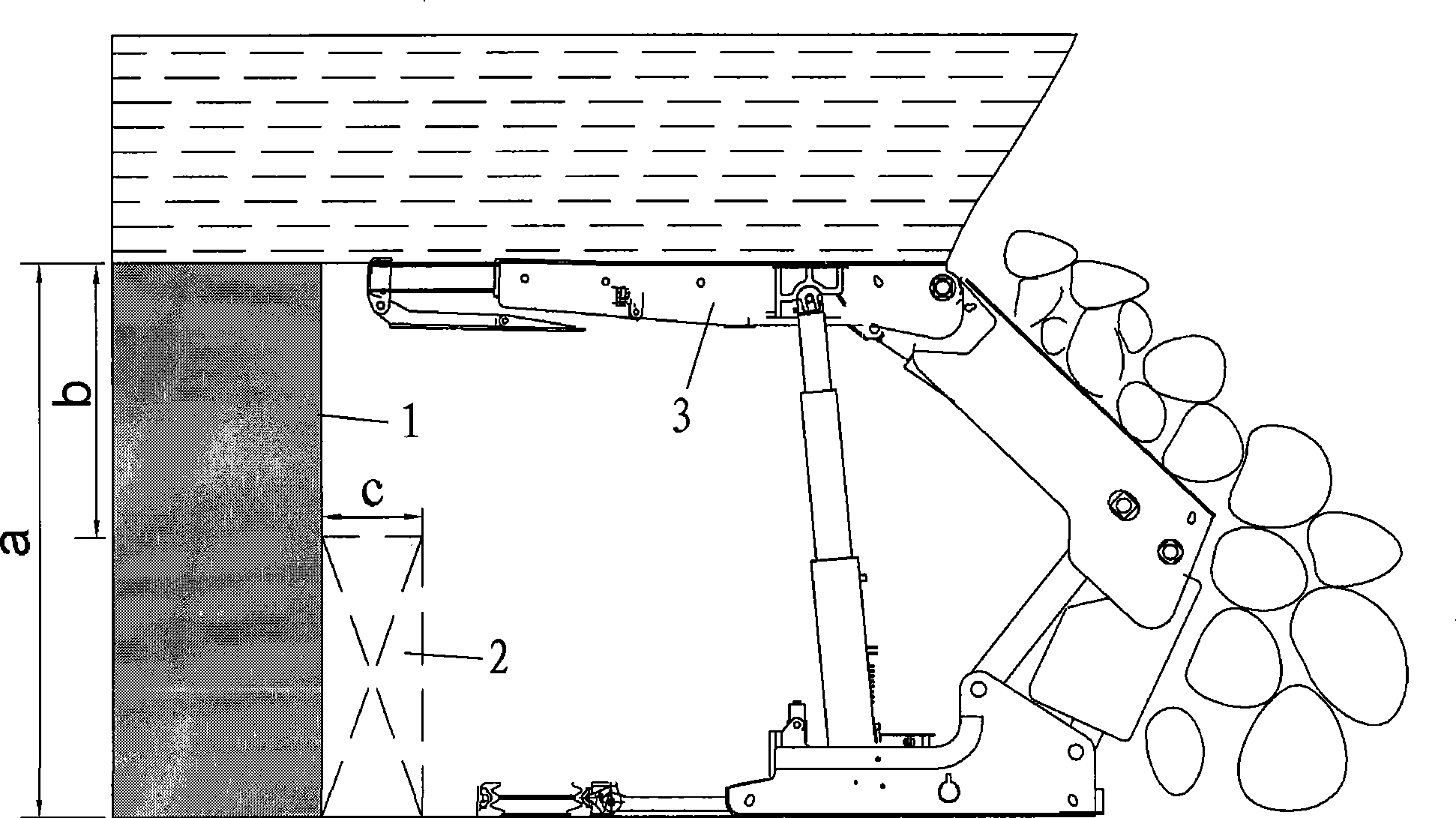

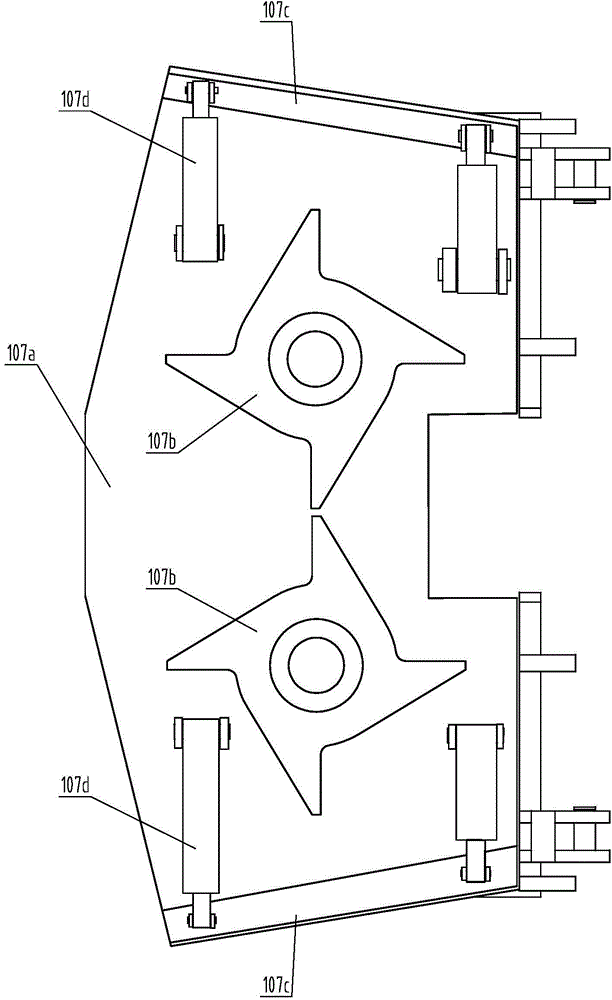

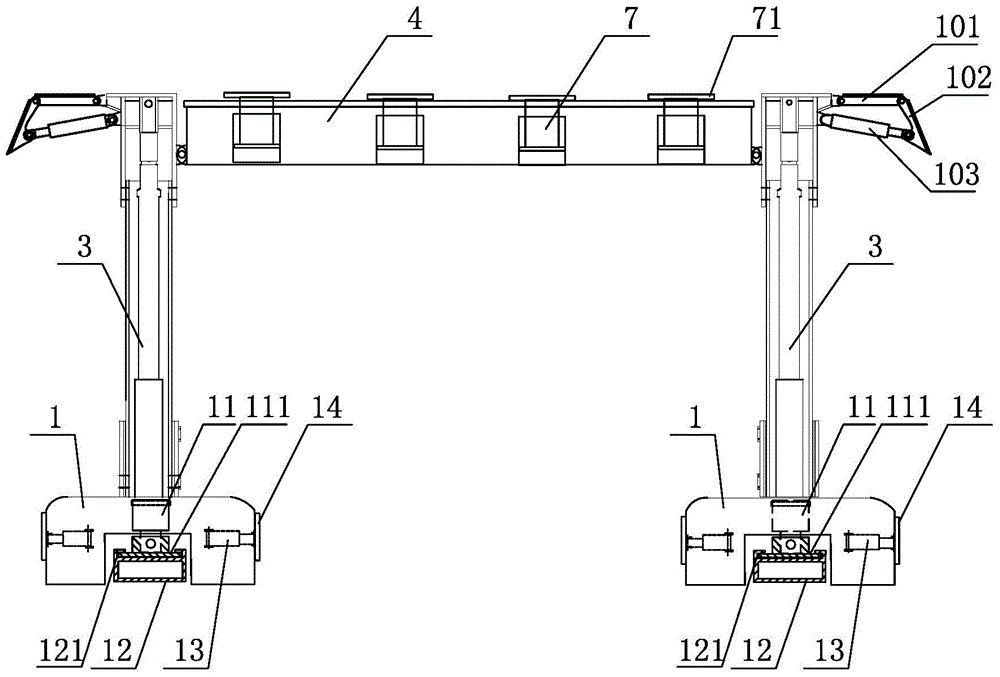

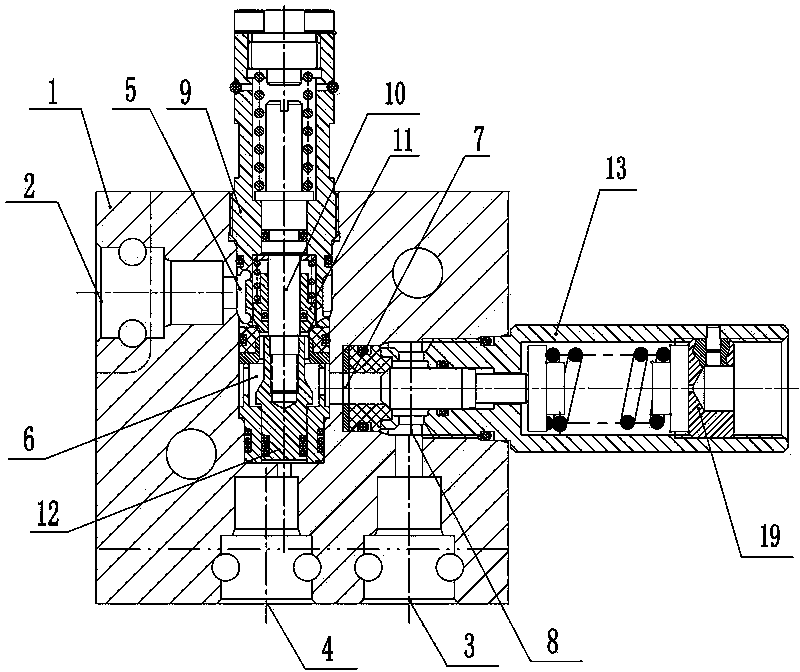

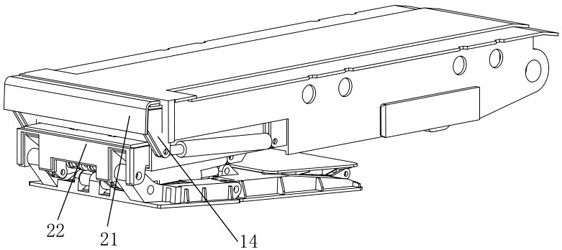

Four column protected type hydraulic prop frame for low position blasting down the roof coal

InactiveCN101105136AHigh recovery rateCoal discharge effect is goodDust removalFire preventionEngineeringCoal

The invention discloses a four-leg shield-type sublevel caving hydraulic support, which comprises four supporting hydraulic extension legs equipped on a pedestal. The top ends of the four supporting hydraulic extension legs are respectively hinged with a top beam; a forward extension beam is hinged at the front end of the top beam; a sprag is hinged at the front end of the forward extension beam, a sprag lifting jack is equipped on the forward extension beam, an ejector rod of the sprag lifting jack is hinged with the back part of the sprag; the back part of the top beam is hinged with the upper part of a shield beam; the lower part of the shield beam is hinged with the pedestal via the a four-bar linkage mechanism; a tail beam with box-shaped construction is hinged with the lower end of the shield beam, a tail beam lifting jack is equipped between the lower part of the tail beam and the lower part of the shied beam; and a slide track, an inserting plate equipped in the slide track and a inserting plate lifting jack for driving the inserting plate to carry out reciprocating movement along the slide track are equipped in the box of the tail beam. The invention is especially suitable for caving integrated mining working face under pitching coal bed, flat-pitching half hard coal bed and 'three-soft' coal bed conditions.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

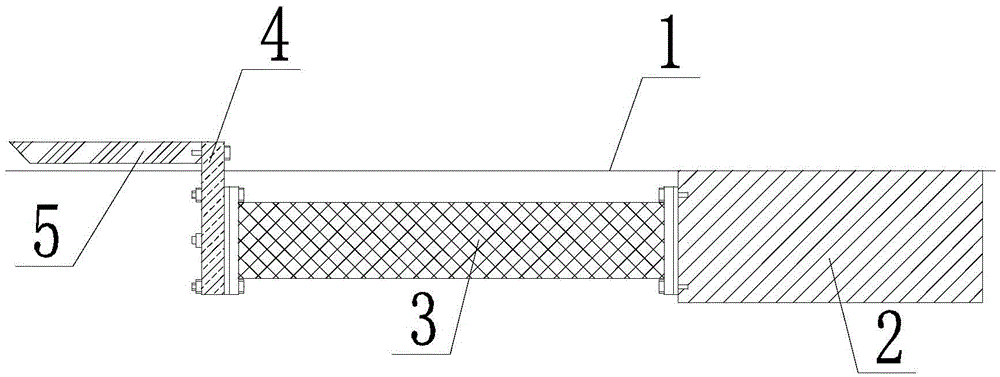

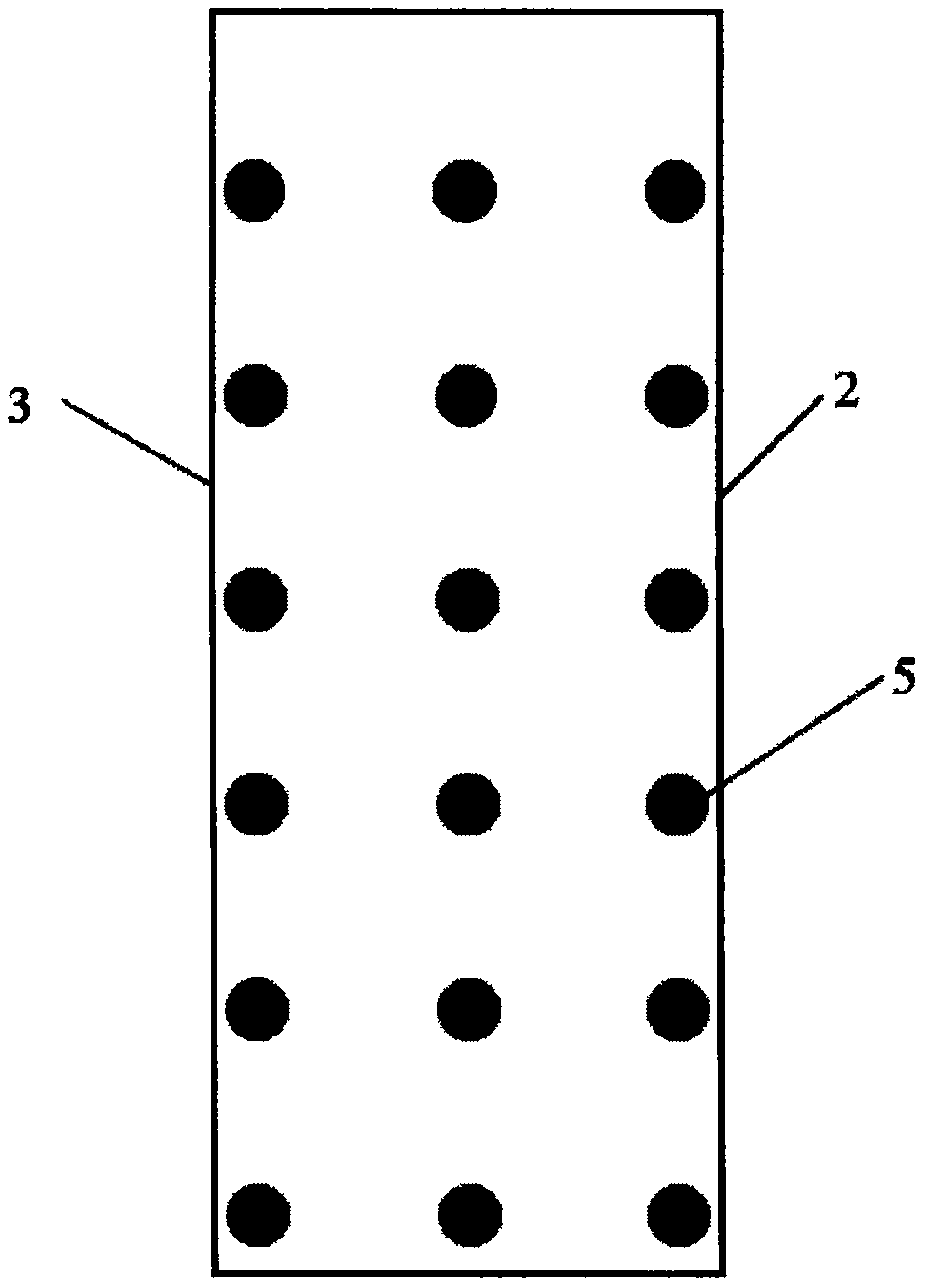

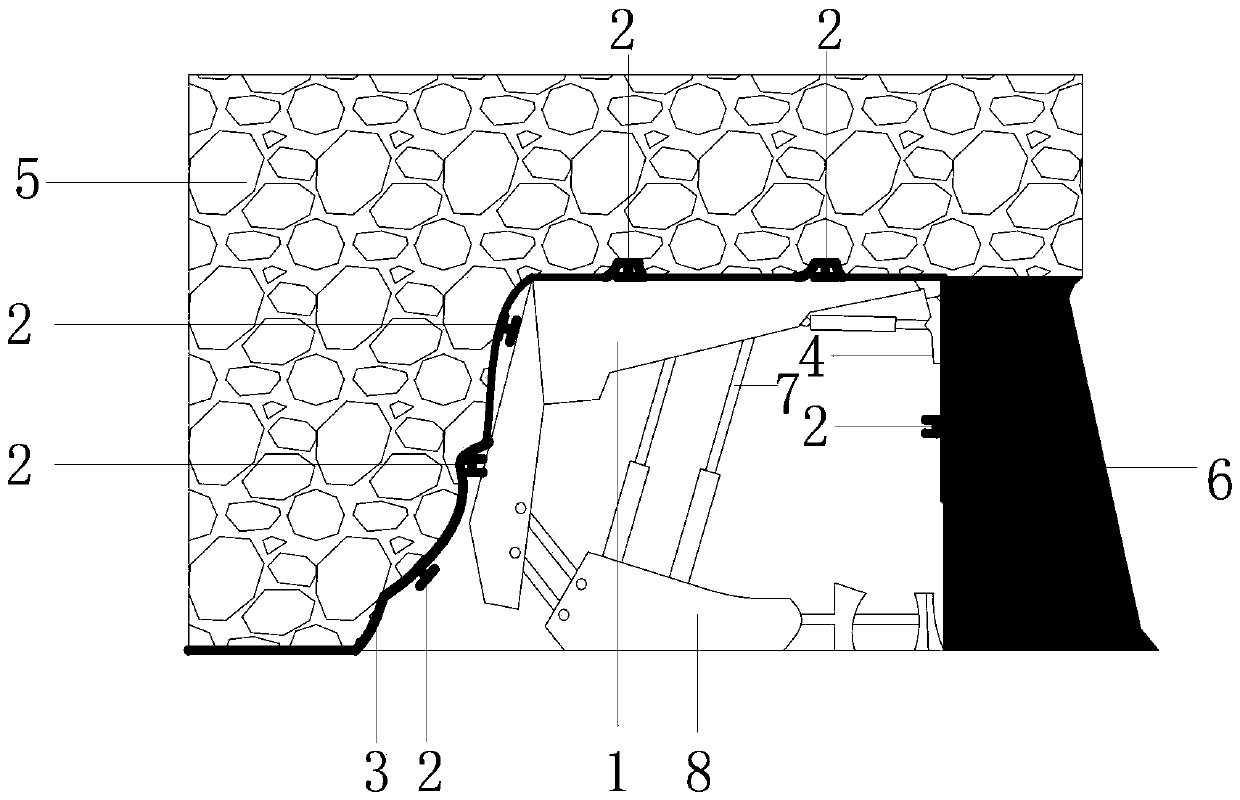

Supporting method of super-large section cutting hole of large-mining-height fully mechanized mining face of thin base rock

ActiveCN106939795AGuaranteed integrityPrevent roof fallUnderground chambersTunnel liningMolecular materialsRock bolt

The invention discloses a supporting method of a super-large section cutting hole of a large-mining-height fully mechanized mining face of a thin base rock. The supporting method comprises the following steps: carrying out primary supporting, wherein the primary supporting comprises first branch supporting and second branch supporting, the first branch supporting is supporting a tunnel by utilizing anchor rods and metal meshes after the cutting hole is tunneled primarily, and the second branch supporting is supporting the tunnel by utilizing anchor rods and a plastic mesh after the cutting hole is expanded secondarily; carrying out primary pressure releasing: after the primary supporting is finished, releasing surrounding rock stress at a moment first pre-set time interval before secondary supporting; carrying out the secondary supporting: after the cutting hole is completely molded, supporting by utilizing an arch rope and a high molecular material for the secondary supporting. According to the supporting method disclosed by the invention, the primary supporting is carried out in a tunneling process of a cutting hole tunnel; after the primary pressure releasing is carried out, the secondary supporting is carried out after the cutting hole tunnel is completely molded, and initiative supporting is carried out by phases; the integrity of a surrounding rock with the cutting hole is maintained, and accidents of roof fall and nicking are effectively prevented from occurring.

Owner:CHINA SHENHUA ENERGY CO LTD +1

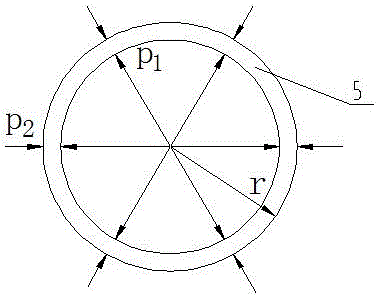

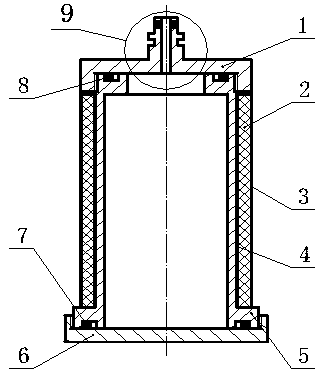

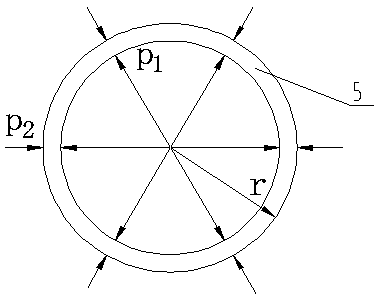

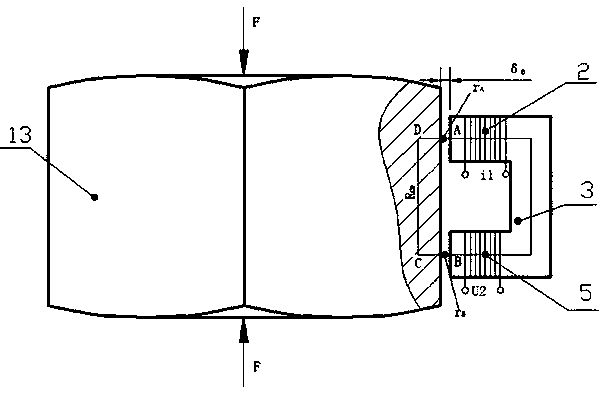

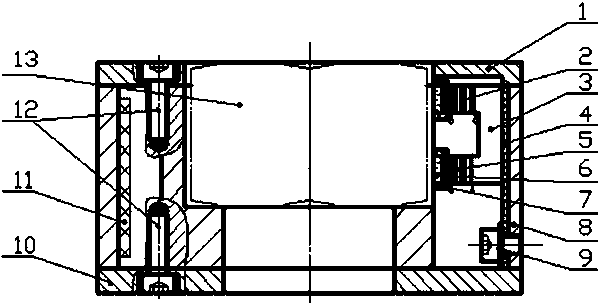

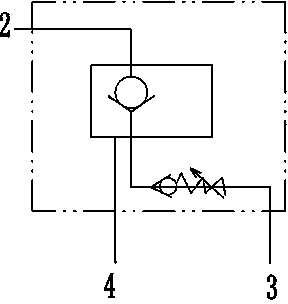

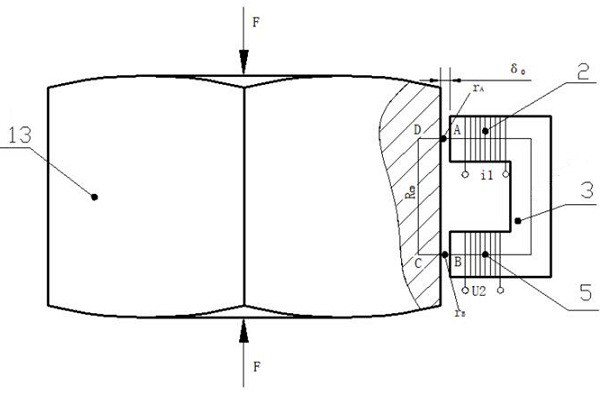

Liquid pressure monitoring device and monitoring method

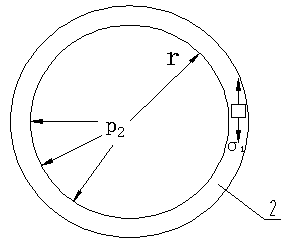

InactiveCN106768599APressure monitoringImprove reflective effectProps/chocksFluid pressure measurement by optical meansEngineeringIrradiation

The invention discloses a liquid pressure monitoring device and a monitoring method. The whole device is in a cylindrical structure. Upper and lower end covers are arranged at upper and lower parts of the cylinder. Upper and lower end covers contact a middle bearing tube. An inner space formed by the upper and lower end covers and the bearing tube is a bearing cavity. The upper and lower end covers and the bearing tube are in threaded connection. A male straight joint is arranged at the center of the top of the upper end cover, and is connected with a hydraulic support. A circular color-developing material is arranged on the outer side of the bearing tube. A circular reflective material is arranged between the color-developing material and the bearing tube. A circular polarizing plate is arranged on the outer side of the color-developing material. When the device is used for monitoring, the bearing tube is pressed, and the color-developing material produces circumferential tensile stress. Under the irradiation of a headlight, different colors can be clearly distinguished. Through the corresponding relationship between a color-pressure table, the pressure of the hydraulic support can be monitored. According to the invention, the slump of a roof can be effectively predicted to ensure the safe production of a coal mine.

Owner:TAIYUAN UNIV OF TECH

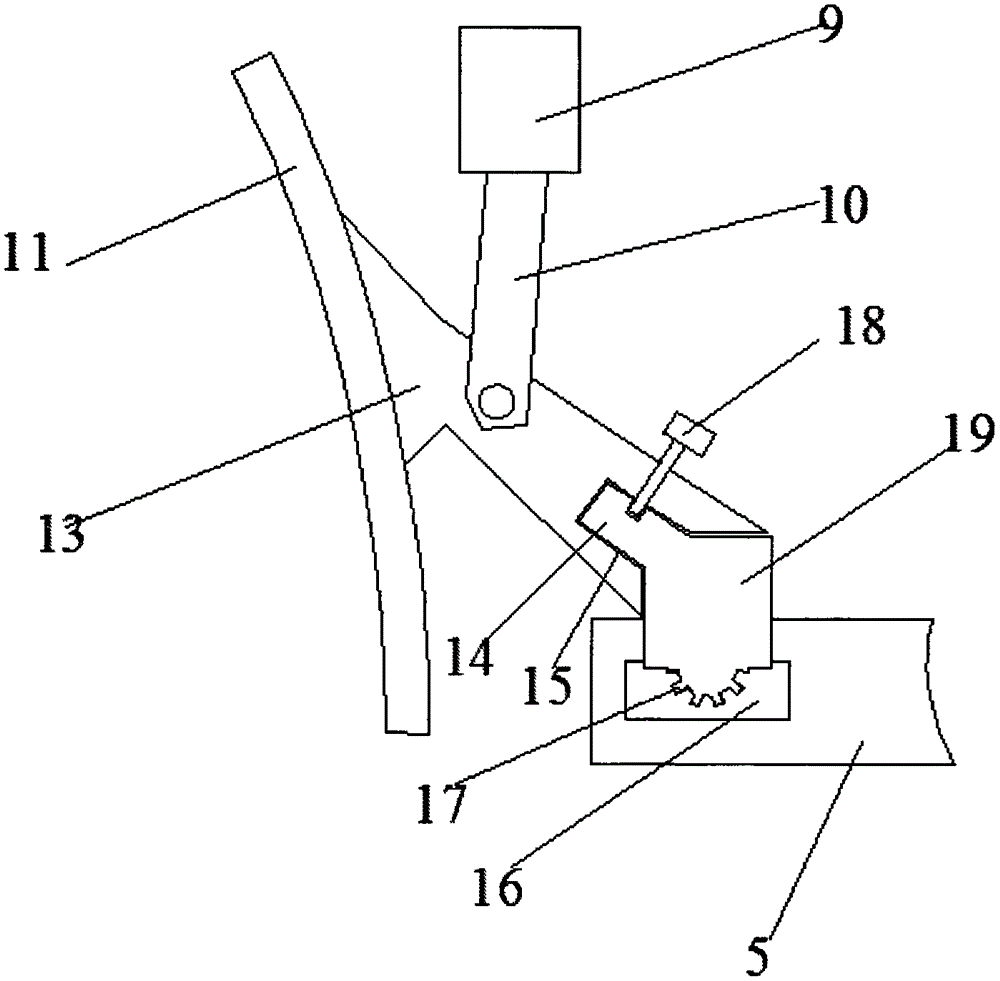

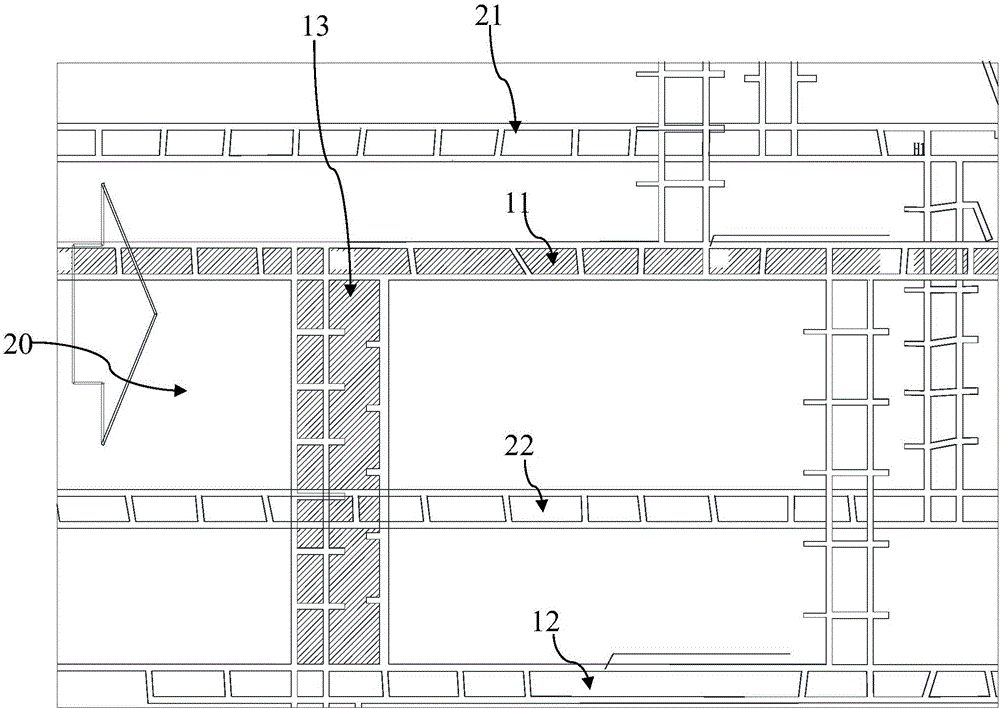

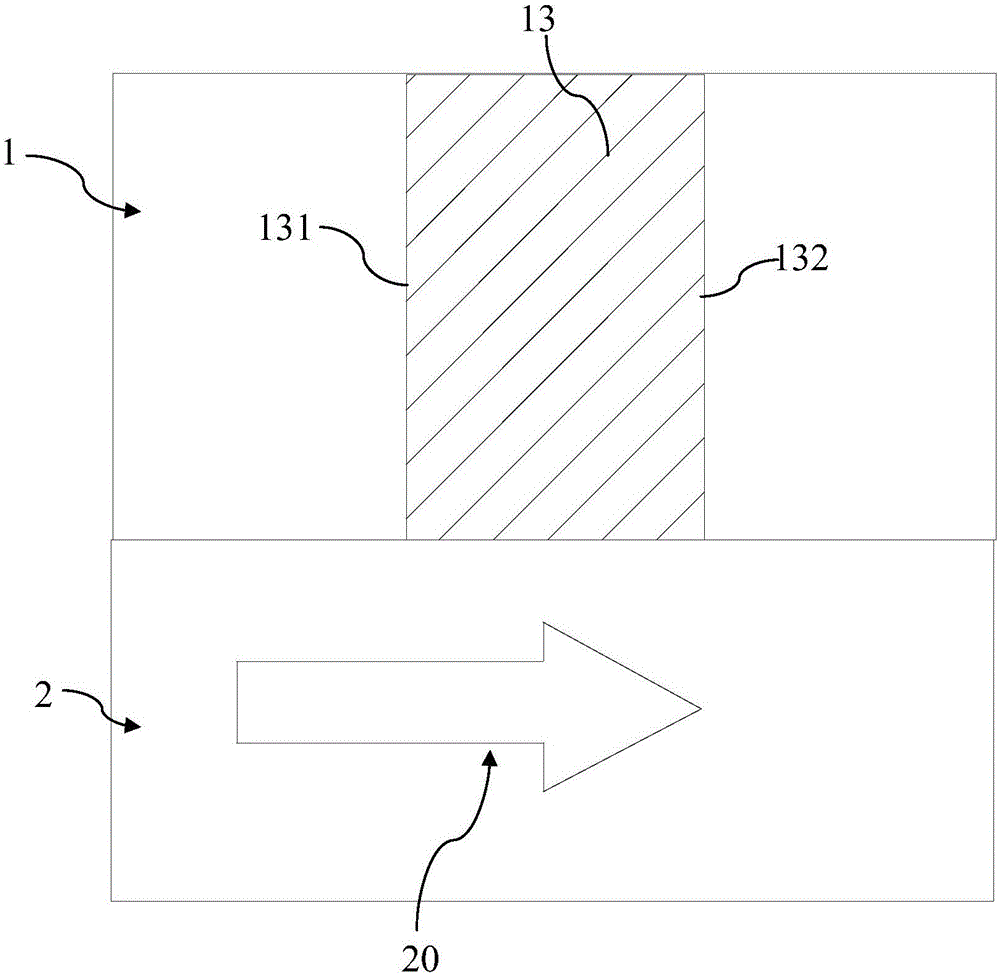

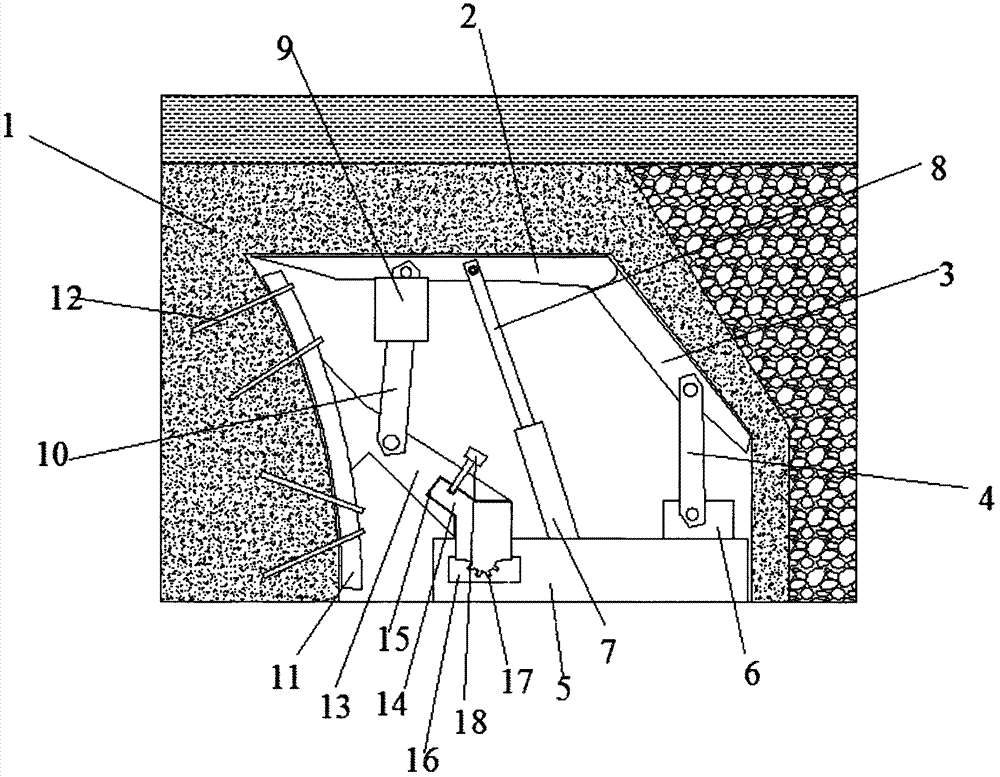

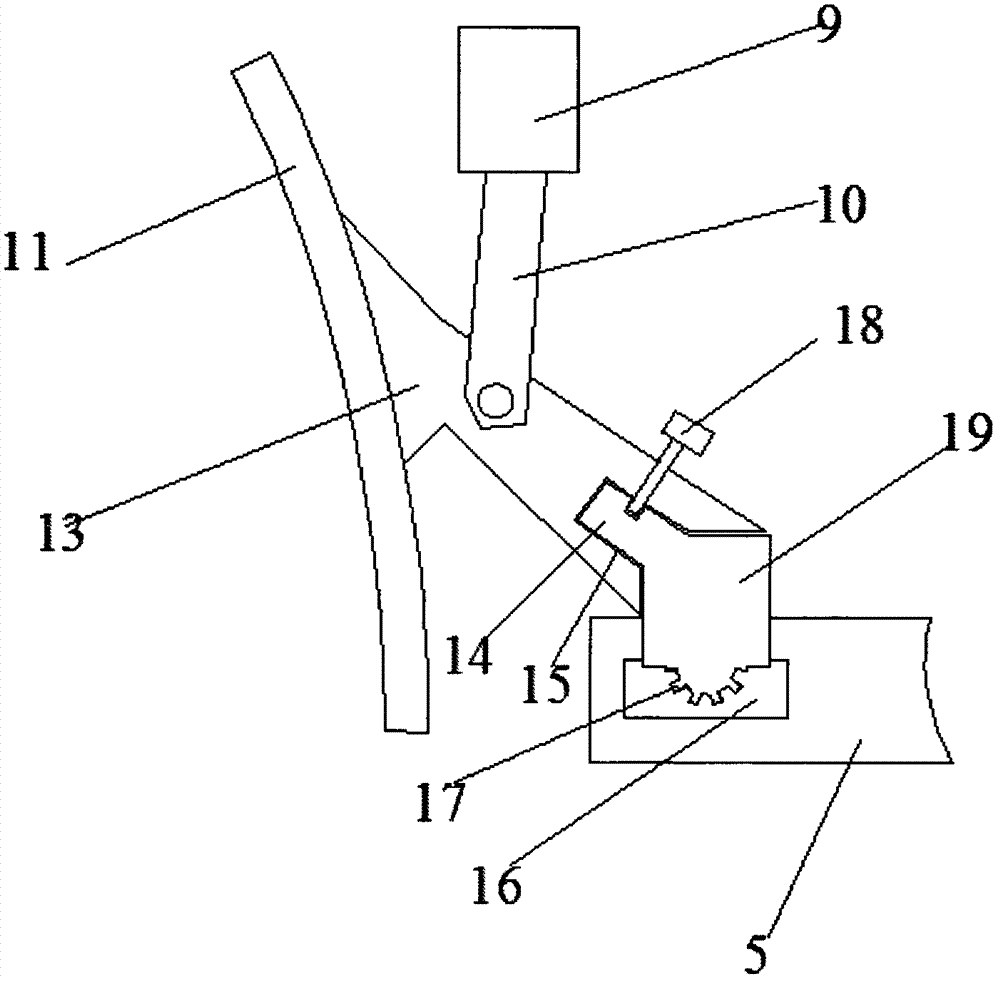

Stope coal wall caving control device

The invention provides a stope coal wall caving control device. The stope coal wall caving control device is characterized in that a hydraulic support device and a caving protection device are integrally arranged on the same support base, a hydraulic support top plate and a hydraulic support auxiliary plate of the hydraulic support device are arranged on the top of a coal seam, the caving protection device is arranged on a stope coal wall, and support protection angles of a caving protection plate of the caving protection device can be adjusted. The stope coal wall caving control device has the advantages that the hydraulic support device and the caving protection device are integrally arranged, the support protection angles of the caving protection plate can be adjusted, and accordingly the caving protection fastening property and safety can be greatly improved; the stope coal wall caving control device is provided with angle adjusting teeth, accordingly, angles of the caving protection plate can be conveniently adjusted, and the caving protection plate can be conveniently mounted; anchor rods are arranged on the protection plate, accordingly, the coal wall caving fastening property can be effectively improved under joint effects of the protection plate and the anchor rods, and roof collapse can be prevented; positioning protrusions are arranged on anchor rod holes, and accordingly the supporting convenience and accuracy of the anchor rods can be improved.

Owner:NORTH CHINA INST OF SCI & TECH

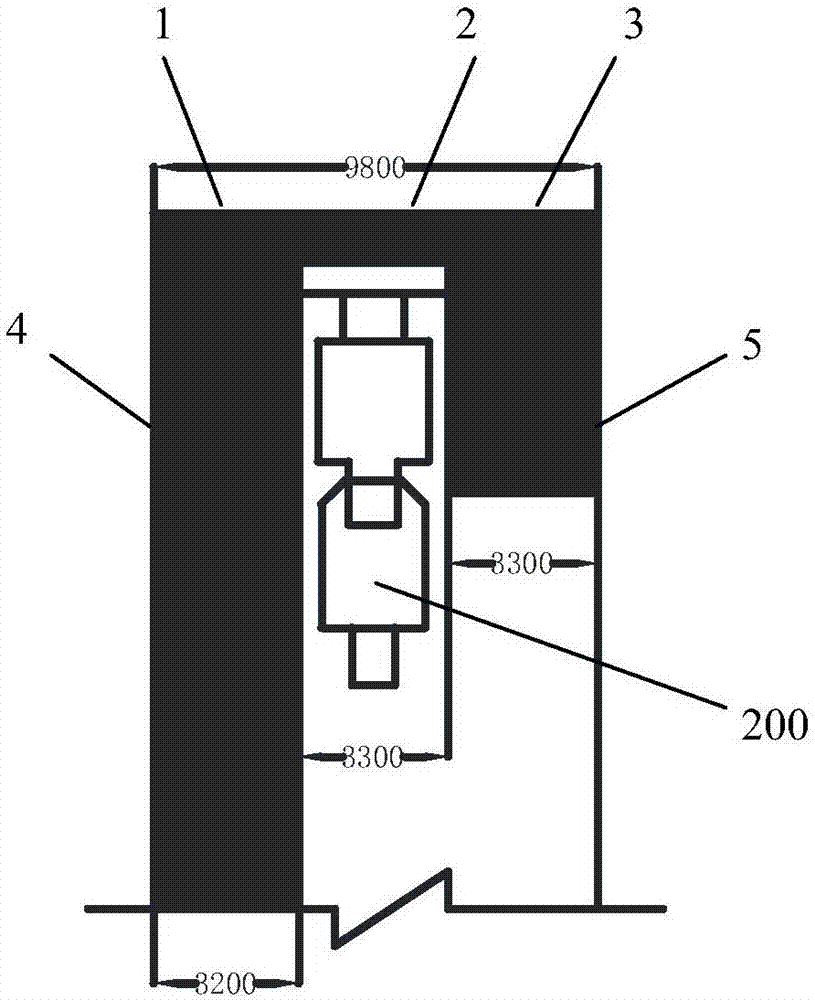

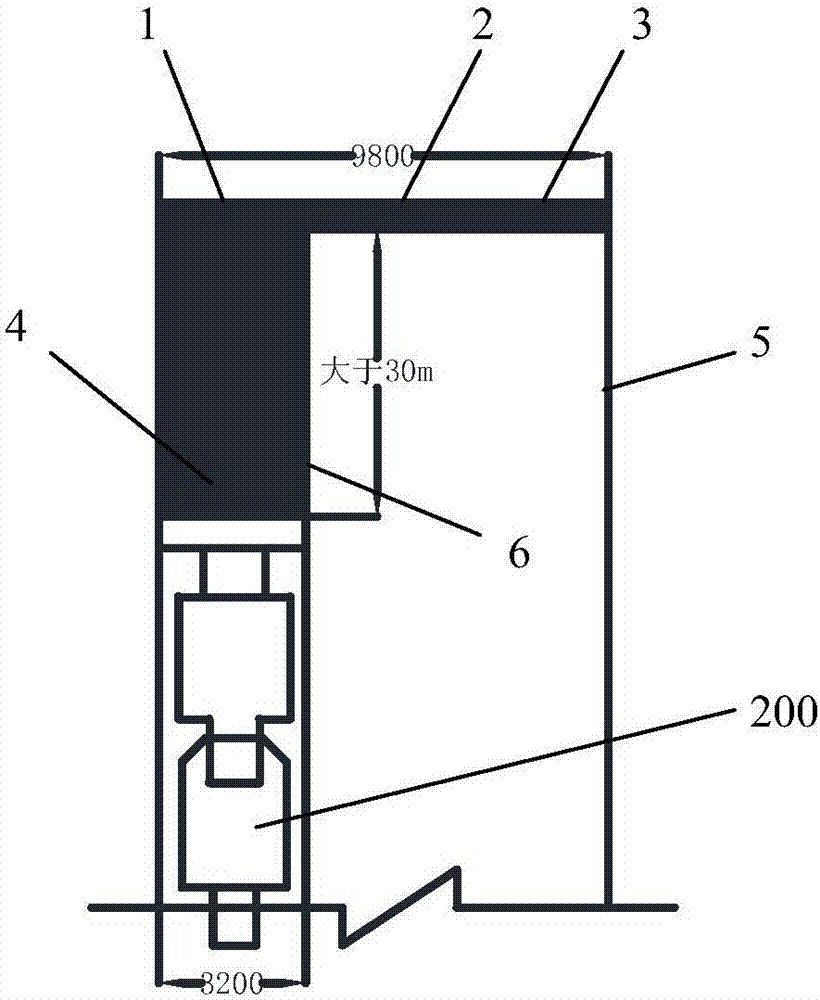

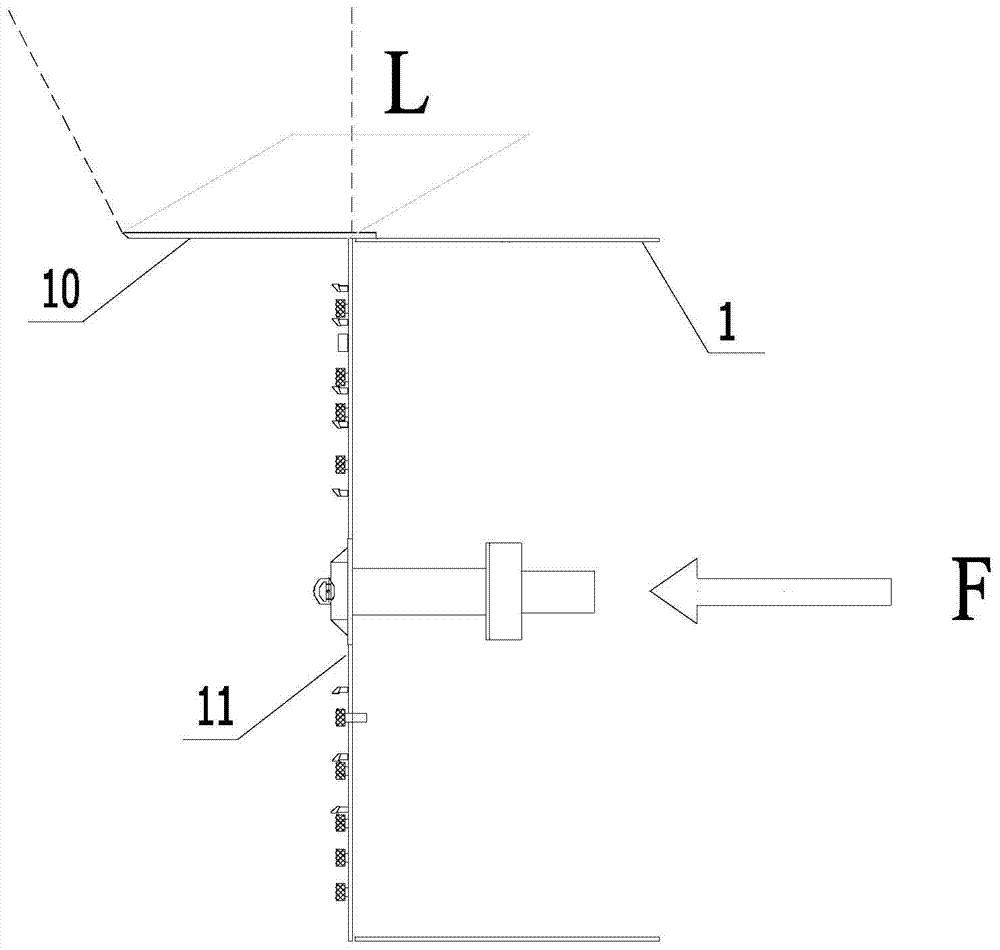

Construction method for preventing roof caving of shield in construction

ActiveCN105649640APrevent roof fallQuality is easy to controlUsing mechanical meansTunnelsControl qualityShield tunneling

The invention provides a construction method for preventing roof caving of a shield in construction. The construction method comprises the steps that 1, stratum investigation is performed along a shield path; 2, a cap peak device is installed on a shield tunneling machine; 4, the cap peak device is applied to shield construction. When the cap peak device is not adopted, the cap peak device is retracted into a cutterhead face through a hydraulic oil cylinder; when the shield enters the roof caving stratum, the cap peak device can stretch out by means of the hydraulic oil cylinder, the stretching-out length can be determined according to the condition of the stratum, and roof caving is prevented according to the stretching-out length of the cap peak. By adopting the construction method, roof caving of the shield on various geological conditions is prevented more easily and conveniently, the axis control quality is improved, and soil body disturbance and ground deformation are reduced.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +2

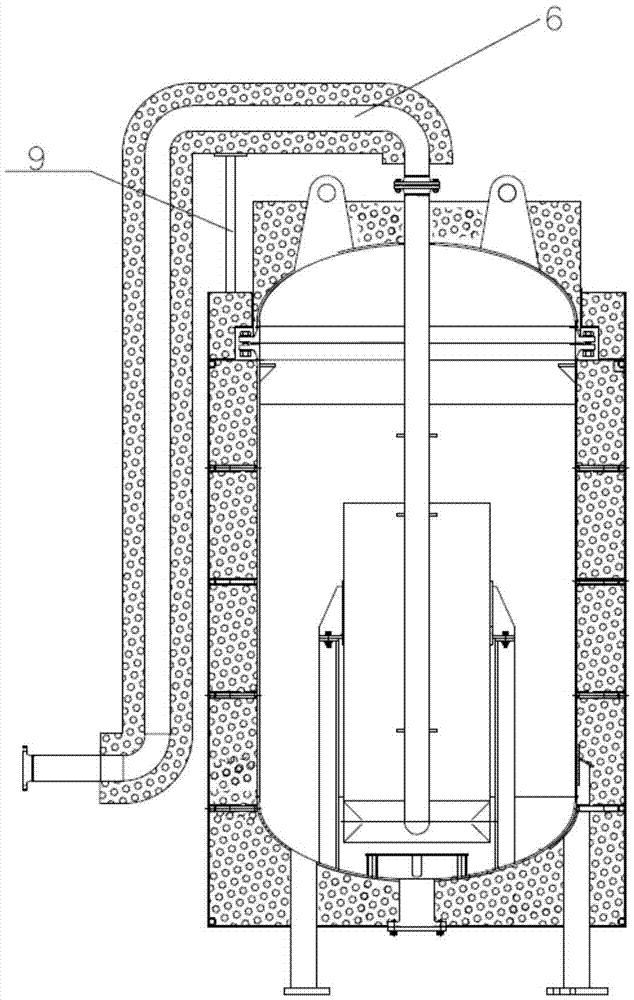

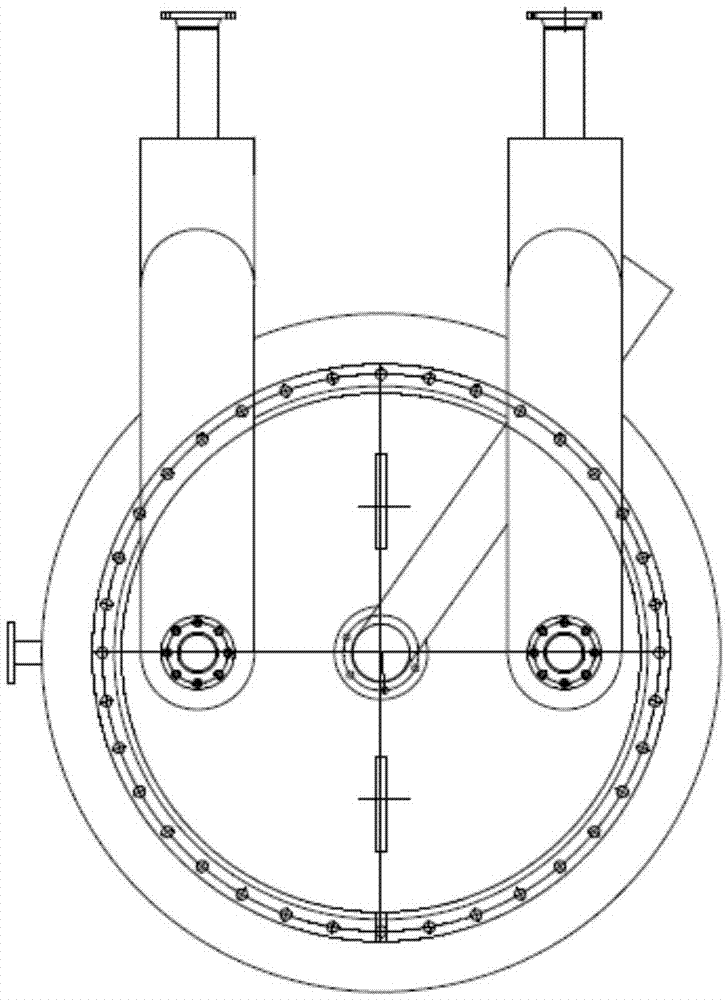

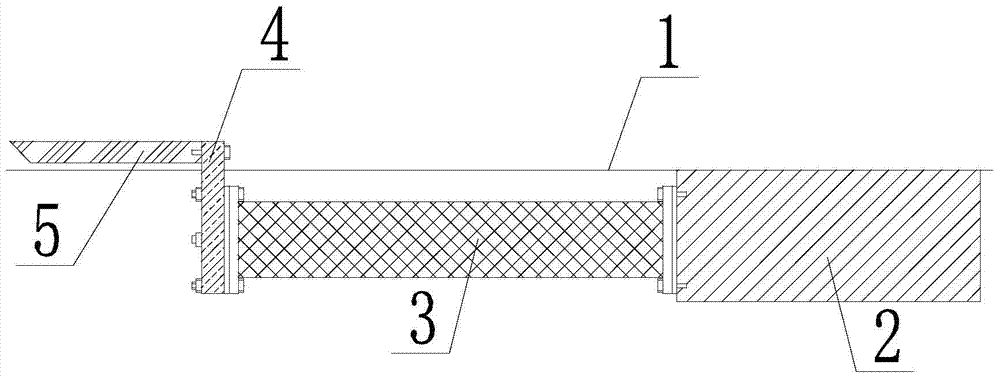

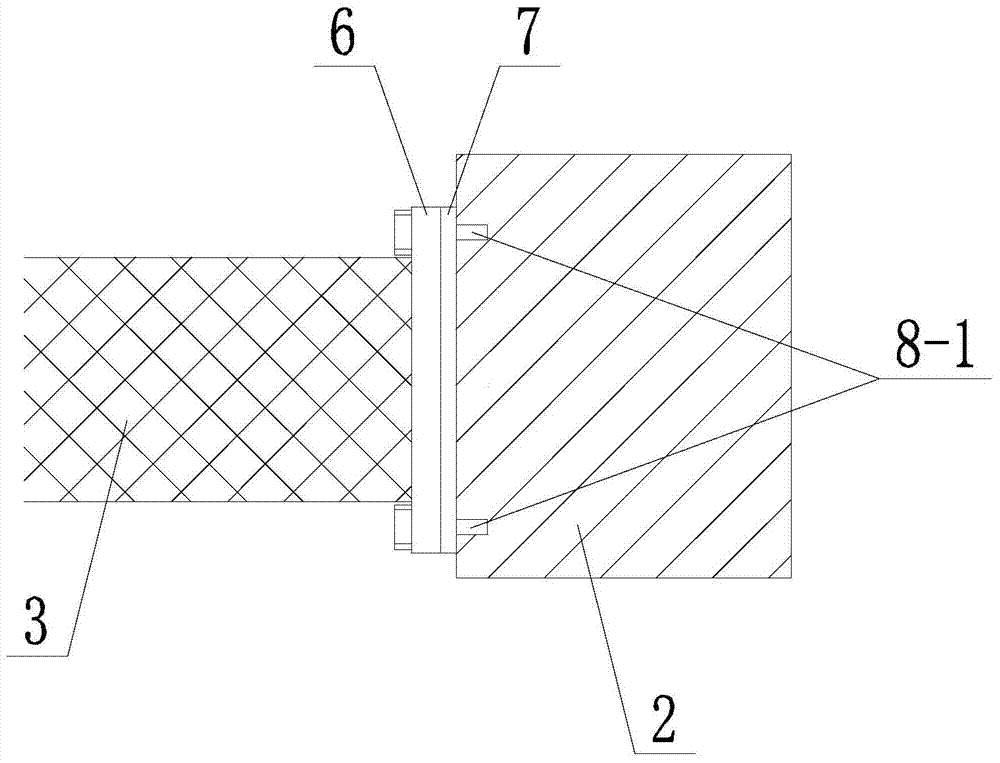

Subcooler for low-temperature liquid oxygen

InactiveCN105444528AEasy to adjust filling volumePre-cool slowlyLiquefactionStationary conduit assembliesLiquid level measurementNitrogen gas

The invention relates to a subcooler for low-temperature liquid oxygen. The subcooler comprises a liquid nitrogen storage tank, a cold exchange assembly, a high liquid level measurement sensor and a low liquid level measurement sensor; the cold exchange assembly is fixed in the liquid nitrogen storage tank through a cold exchange core supporting assembly, and the liquid nitrogen storage tank is provided with a liquid nitrogen inlet, a liquid nitrogen outlet and a nitrogen gas discharge port; the cold exchange assembly comprises a cold exchange core, a liquid oxygen input pipe and a liquid oxygen output pipe, and the liquid oxygen input pipe and the liquid oxygen output pipe are communicated with the cold exchange core; the high liquid level measurement sensor is fixed to the high liquid level of the liquid nitrogen storage tank, and the low liquid level measurement sensor is fixed to the low liquid level of the liquid nitrogen storage tank. According to the invention, the common liquid oxygen with the temperature being minus 183 DEG C can be fast cooled to minus 194 DEG C.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

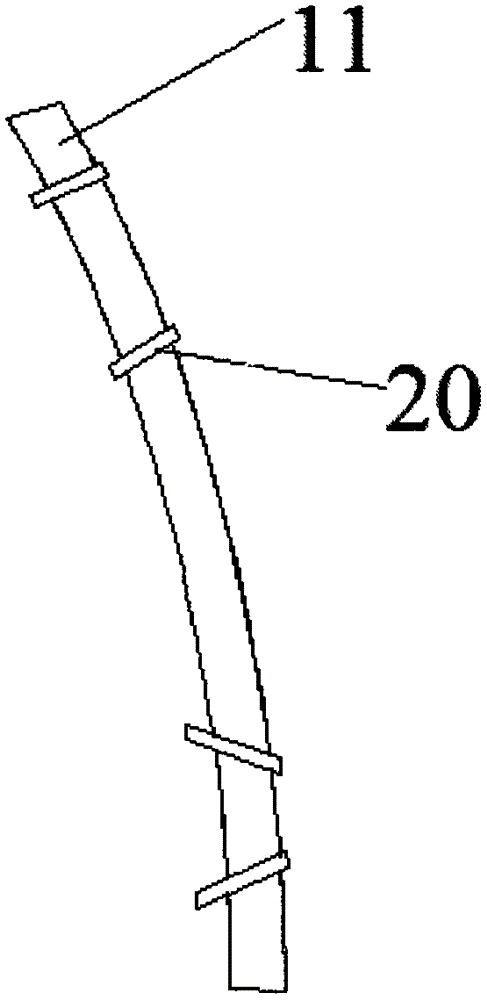

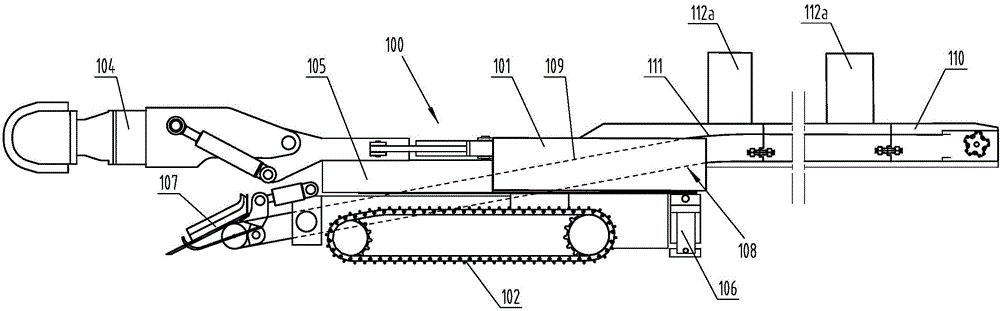

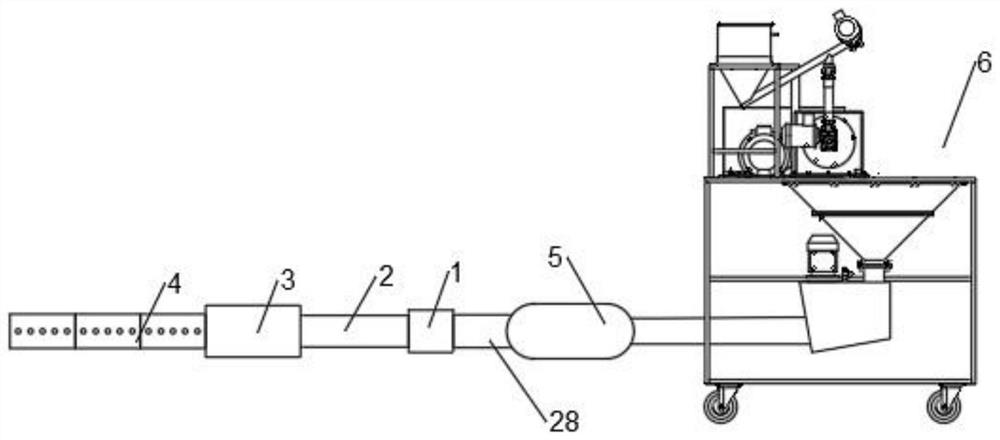

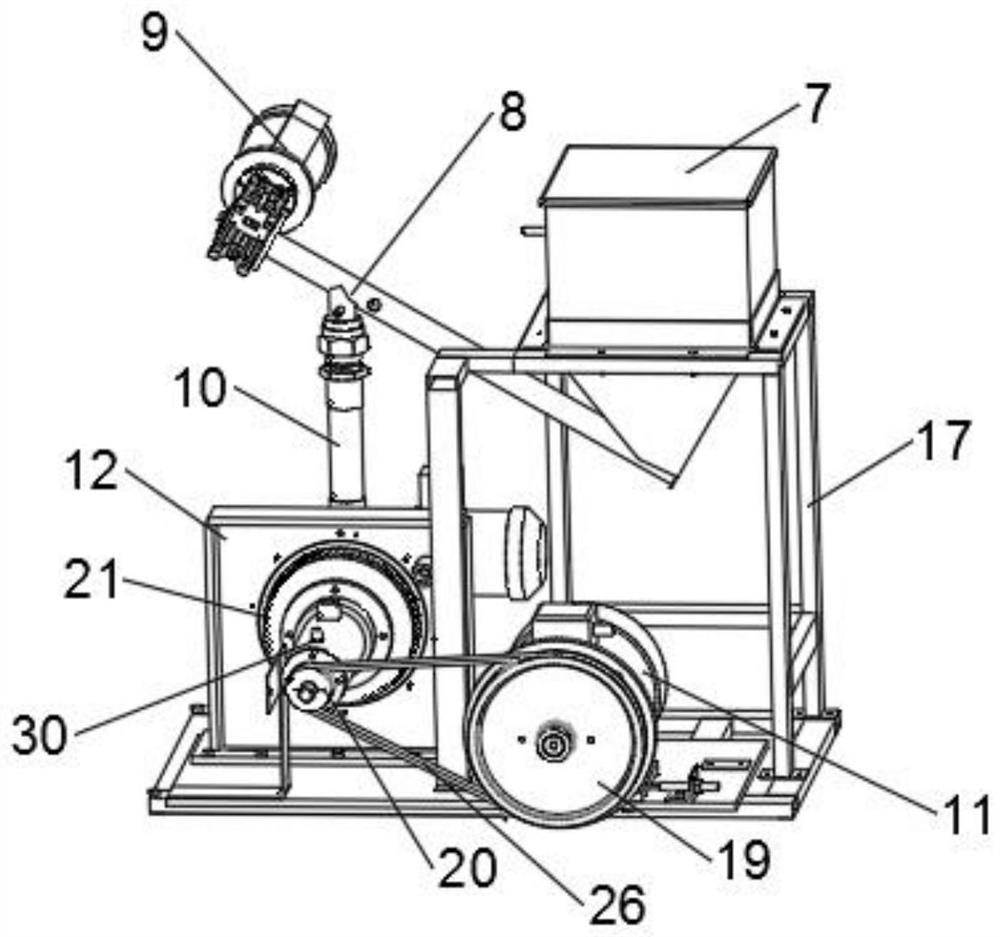

Cantilever type longitudinal axis digging and anchoring machine and step-by-step construction stage coal tunnel forming construction process

The present invention belongs to the technical field of coal mine coal tunnel digging construction equipment, and particularly relates to a cantilever type longitudinal axis digging and anchoring machine, which comprises a rack body, a left walking part, a right walking part, a cutting part, a rotation body, a rear support body, a loading mechanism, a first scraping plate conveyor, an electric control system, a hydraulic system, a spraying system and a cooling system, wherein the first scraping plate conveyor comprises a machine tail portion arranged on the rack body and a machine head portion extending out of the rack body rear portion, and the machine head portion is provided with a plurality of airborne anchor rod drillers. According to the present invention, during the use, when the cantilever type longitudinal axis digging and anchoring machine digs, the coal tunnel is subjected to anchoring fixation support by using the airborne anchor rod drillers, such that the parallel operations of digging and anchoring can be achieved, the time consumption problem caused by the frequent switching between the two processes such as digging and anchoring can be solved, the construction efficiency and the construction speed can be improved, and the puking phenomenon can be prevented.

Owner:内蒙古维维能源有限公司

Inorganic material for reinforcement

The inorganic material is prepared from, by weight, 30-90 parts of specially-made cement, 0.1-20 parts of an accelerator, 6-35 parts of stone powder, 0.4-26 part of bentonite, 0.2-10 parts of sulfate,0.1-15 parts of a water reducing agent, 0.1-18 parts of silicon-calcium powder, 0.1-17 parts of an early strength agent, 0-10 parts of fine powder, 0-5 parts of iron powder, 0.2-20 parts of fly ash and 0.3-11 parts of gypsum. A vertical anchor rod hole is drilled in a coal-rock mass by using an anchor rod drilling machine, an anchor rod is inserted into the anchor rod hole, inorganic materials are mixed according to a water-cement ratio of (0.28-0.4): 1, and grouting is performed by using the anchor rod to reinforce the coal-rock mass. The inorganic material has the effects of preventing fireand ensuring safe production of a coal mine and roadway utilization; repeated roadway repair is completely eradicated, slope deviation and roof fall are prevented, operation is easy, and safety and reliability are achieved; and the inorganic material is economical and applicable.

Owner:SUZHOU JINDING SAFETY TECH CO LTD

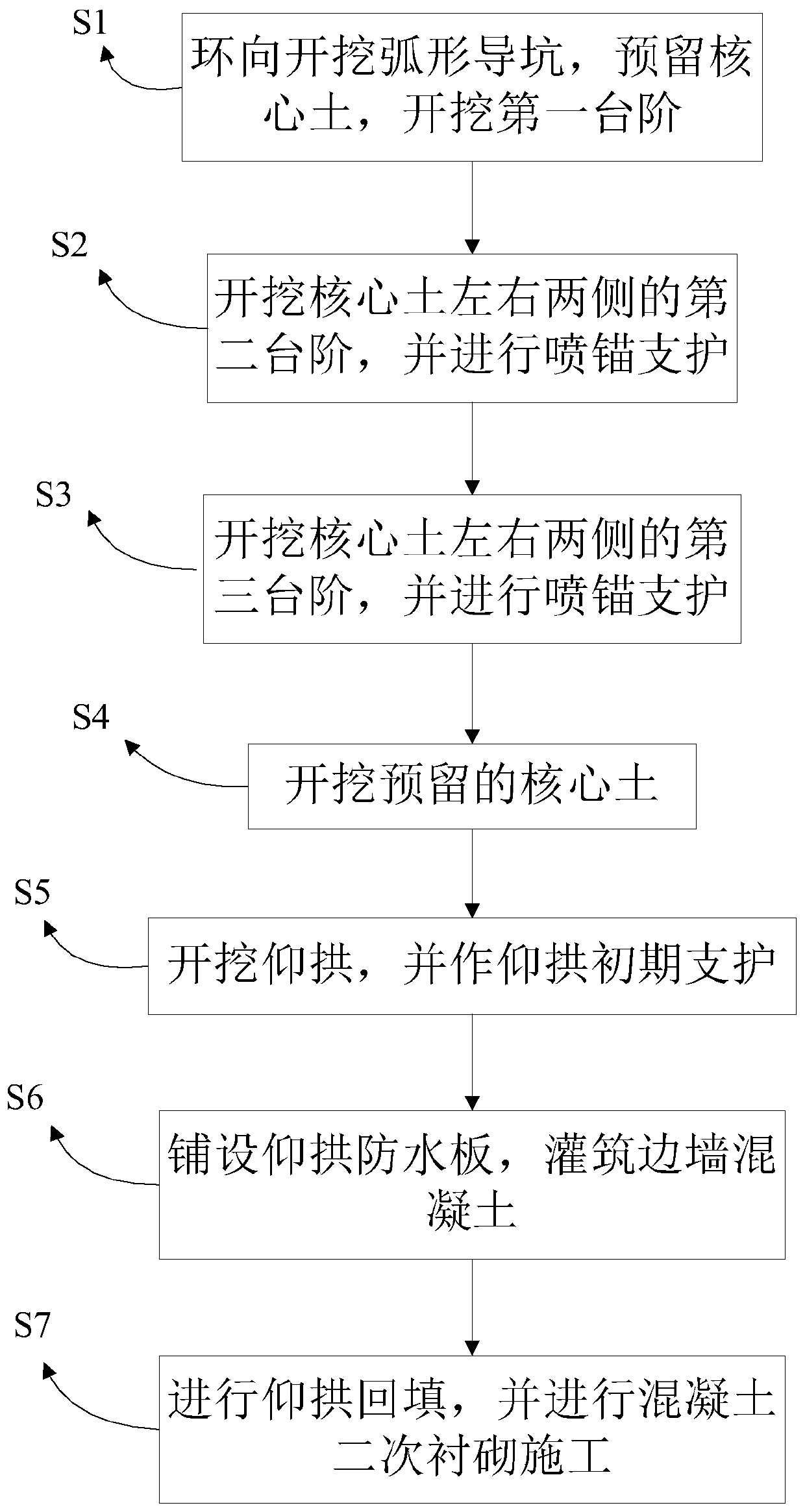

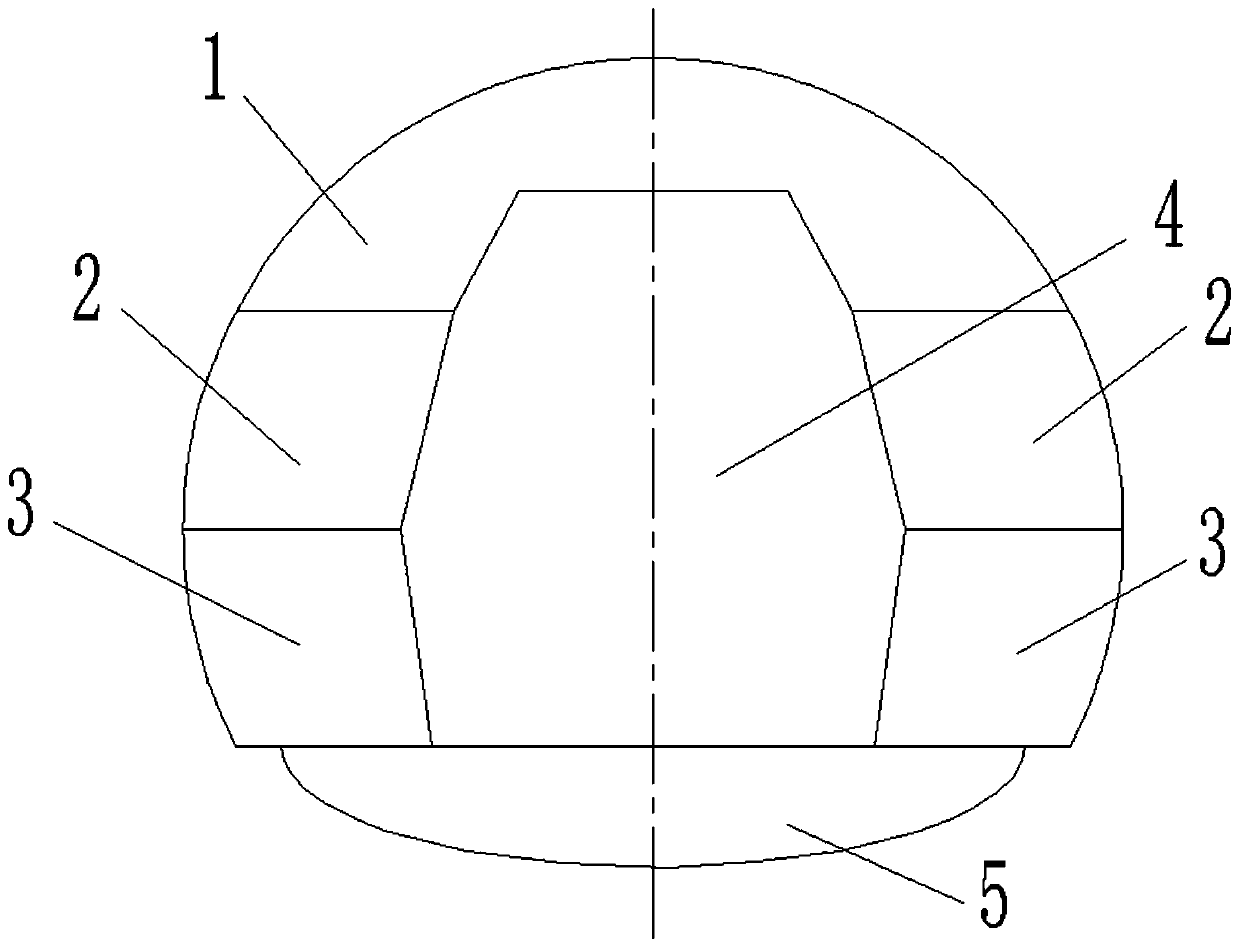

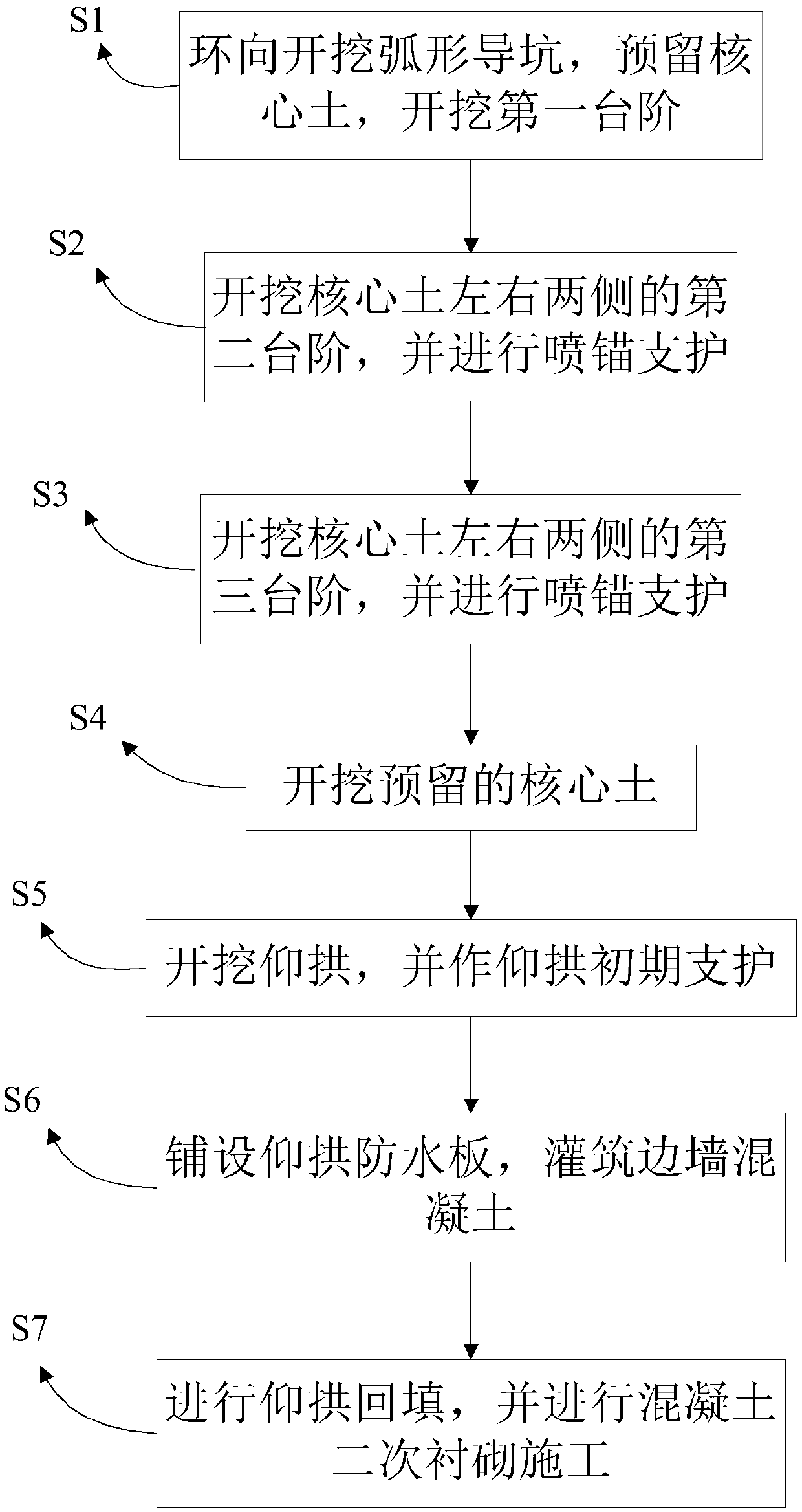

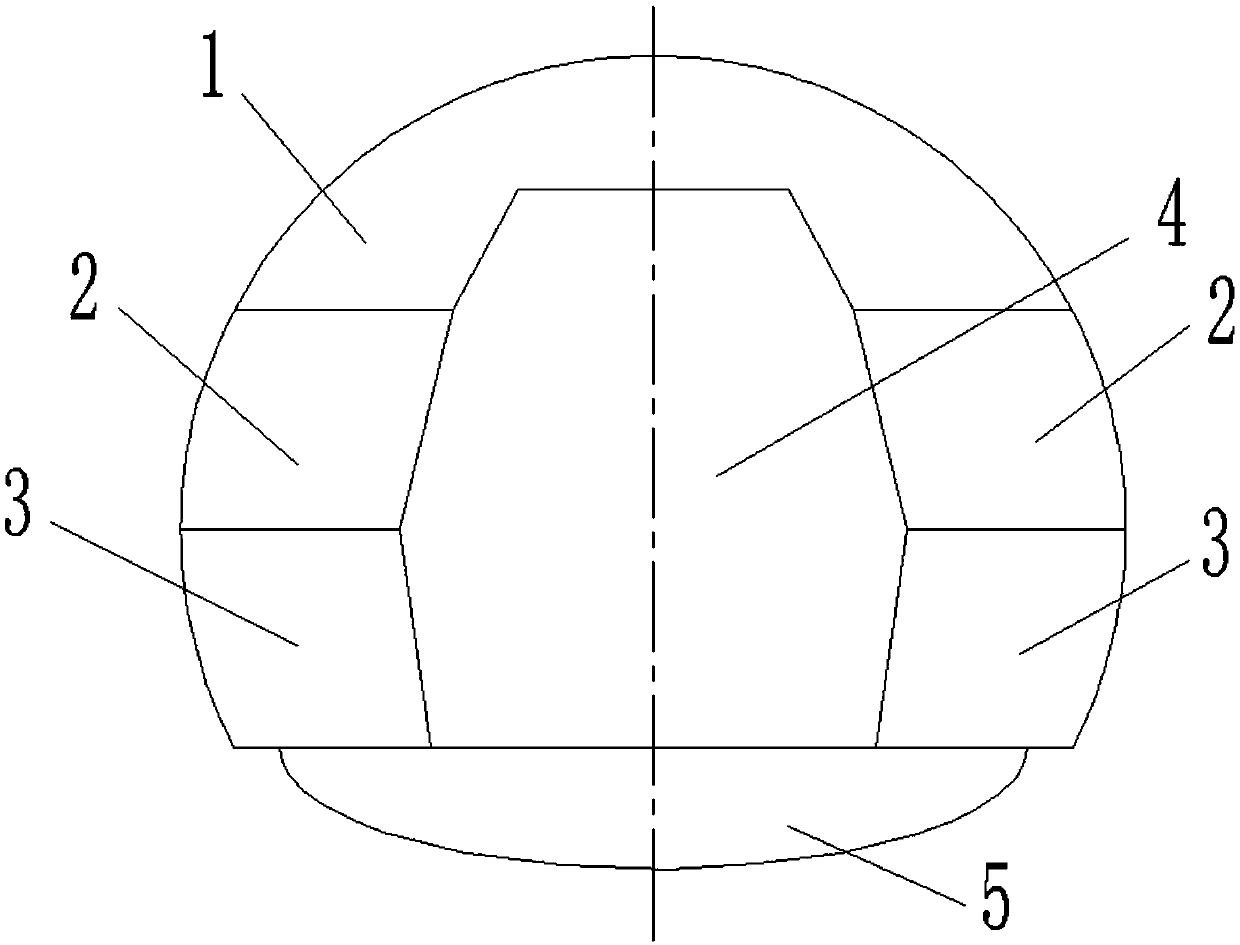

Construction Method of Reversed Slope Tunnel

ActiveCN108678753BAvoid falling blocksPrevent roof fallUnderground chambersDrainageShotcreteWater level

The invention discloses a construction method of a reverse slope tunnel, which comprises the following steps: an arc-shaped heading is excavated in a circular shape, a core soil is reserved, and a first step is excavated; two second steps and two third steps reserved on the left and right sides of the core soil are respectively excavated, and the shotcrete and anchor support is carried out; the reserved core soil is excavated; an inverted arch is excavated and the initial support of the inverted arch is made; a waterproofing plate of the inverted arch is laid, and the side wall concrete is poured; after the pouring of the inverted arch concrete is completed, the inverted arch shall be backfilled in time, and the construction of secondary lining of the concrete shall be carried out. According to the invention, the construction of the reverse slope tunnel under the water level line of the adjacent reservoir is carried out, and the reverse slope is being made positive, so that the water seepage and the water inflow of the first step and the second step tunnel face can be timely discharged to the temporary water collecting pit of a third step to prevent the tunnel surrounding rock fromfalling out of the block, roof falling, landsliding or water inflowing. The integrity of the tunnel surrounding rock can be ensured, and the adverse effect on the reservoir and the surrounding environment can be reduced.

Owner:CHINA COMM NORTH ROAD & BRIDGE

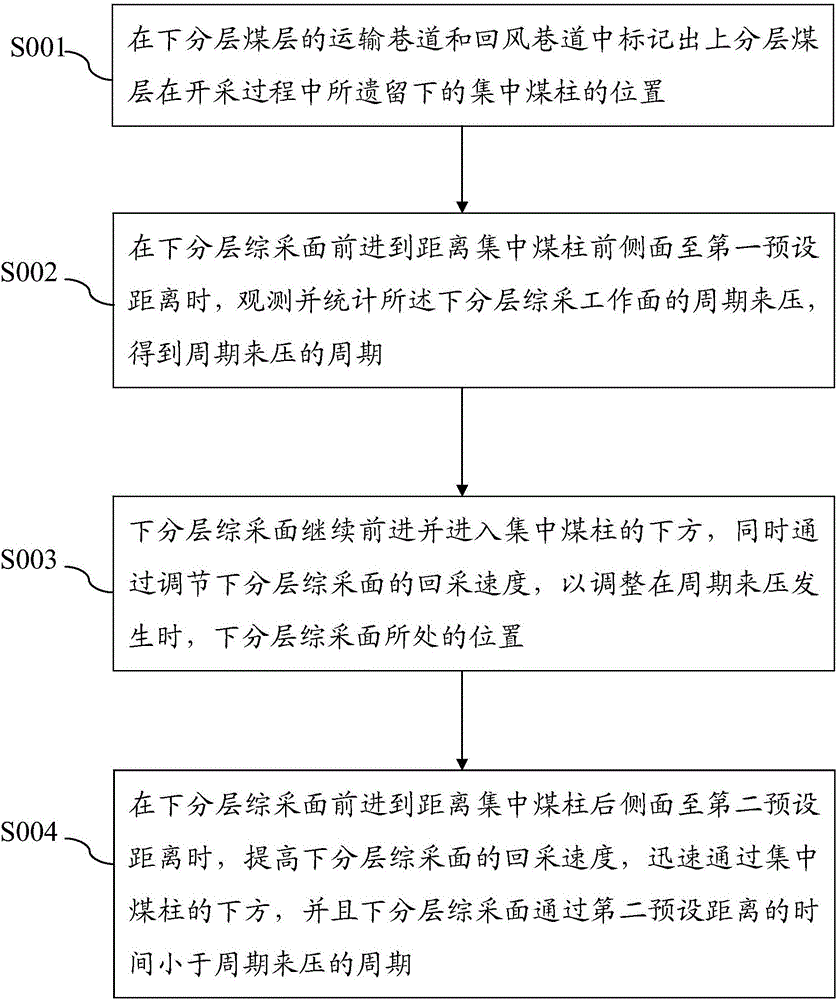

Mining technology for lower slice fully-mechanized coal mining face passing through concentrated coal pillar of higher slice coal seam

InactiveCN106522951AImprove securityAvoid roof fallUnderground miningSurface miningCoal pillarMineralogy

The invention discloses a mining technology for a lower slice fully-mechanized coal mining face passing through a concentrated coal pillar of a higher slice coal seam. The mining technology includes the following steps that S001, the position of the concentrated coal pillar is marked in a haulage roadway and a ventilation roadway of a lower slice coal seam; S002, when the lower slice fully-mechanized coal mining face moves forwards to a first preset distance away from the front side face of the coal pillar, observation and statistics of periodic weighting of the lower slice fully-mechanized coal mining face are carried out; S003, by regulating the mining speed of the lower slice fully-mechanized coal mining face, the position of the lower slice fully-mechanized coal mining face is adjusted when periodic weighting occurs; and S004, when the lower slice fully-mechanized coal mining face moves forwards to a second preset distance away from the back side face of the coal pillar, the mining speed of the lower slice fully-mechanized coal mining face is increased, the lower slice fully-mechanized coal mining face rapidly passes through the lower side of the coal pillar, and the time for the lower slice fully-mechanized coal mining face passing through the second preset distance is shorter than the period of periodic weighting. The lower slice fully-mechanized coal mining face can safely pass through the area of the concentrated coal pillar of the higher slice coal seam, roof caving or support crushing is avoided, and the safety of coal production is improved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

A liquid pressure monitoring device and monitoring method

InactiveCN106768599BEnsure safe productionPreventing Slump AccidentsProps/chocksFluid pressure measurement by optical meansEngineeringIrradiation

Owner:TAIYUAN UNIV OF TECH

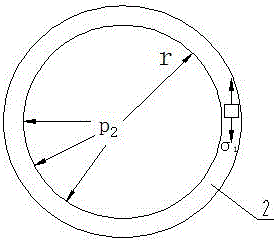

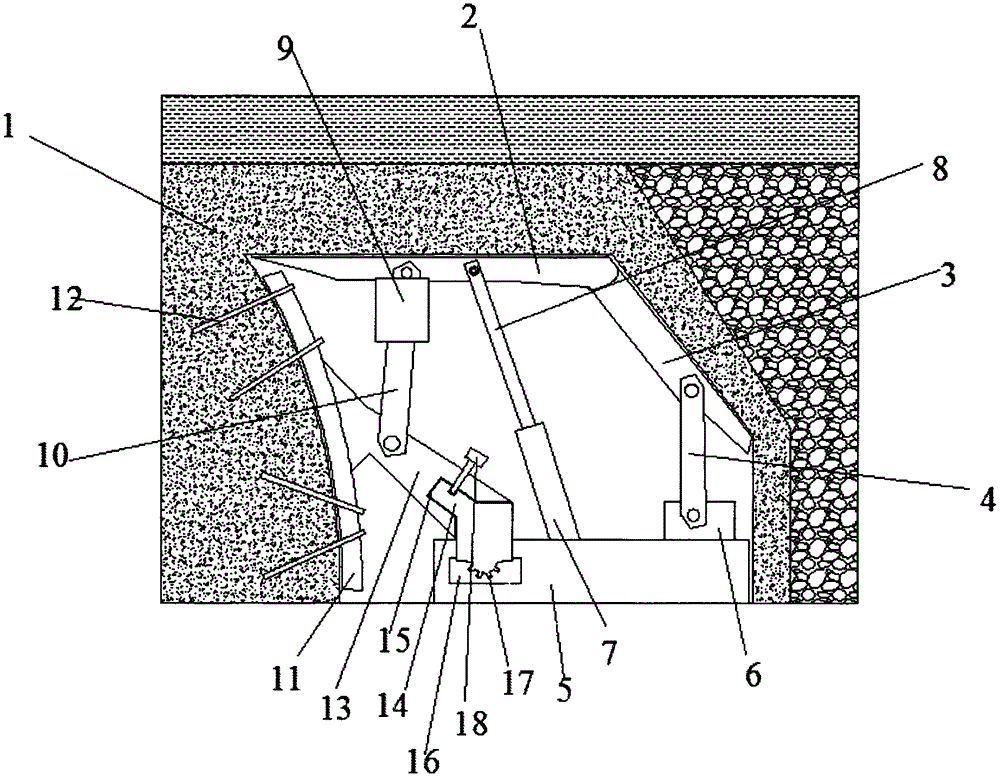

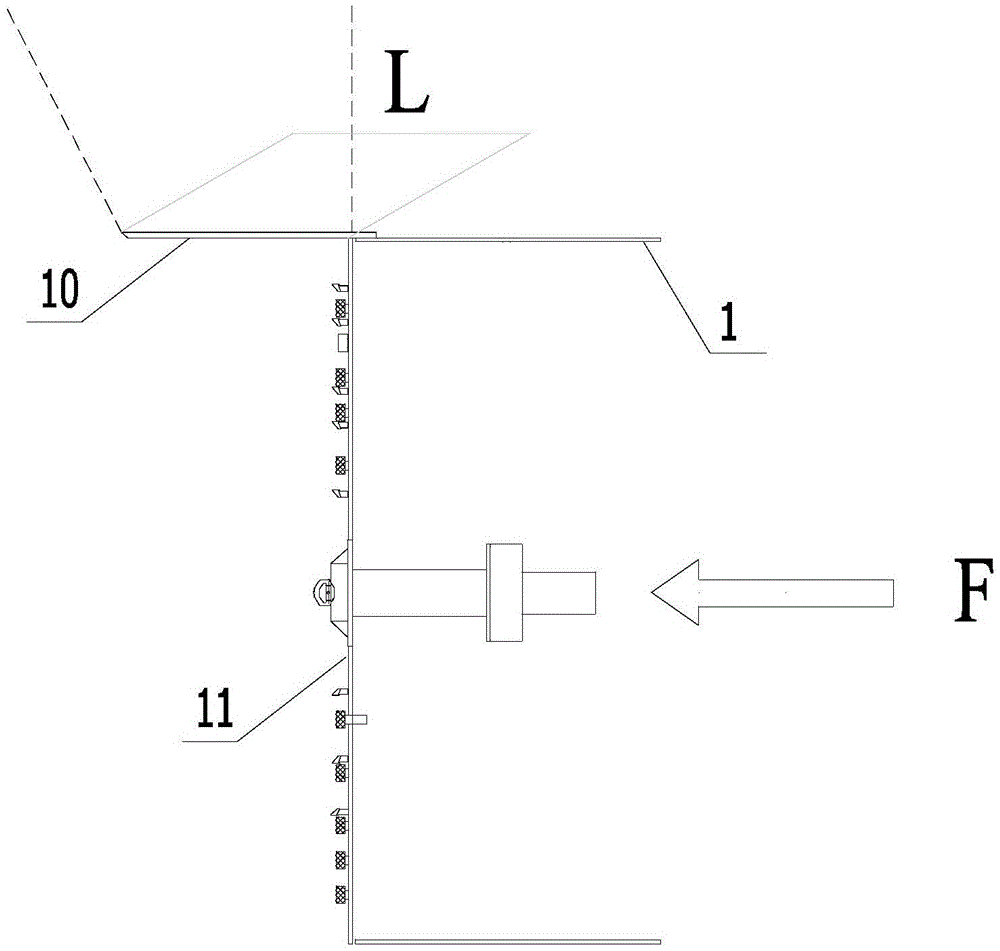

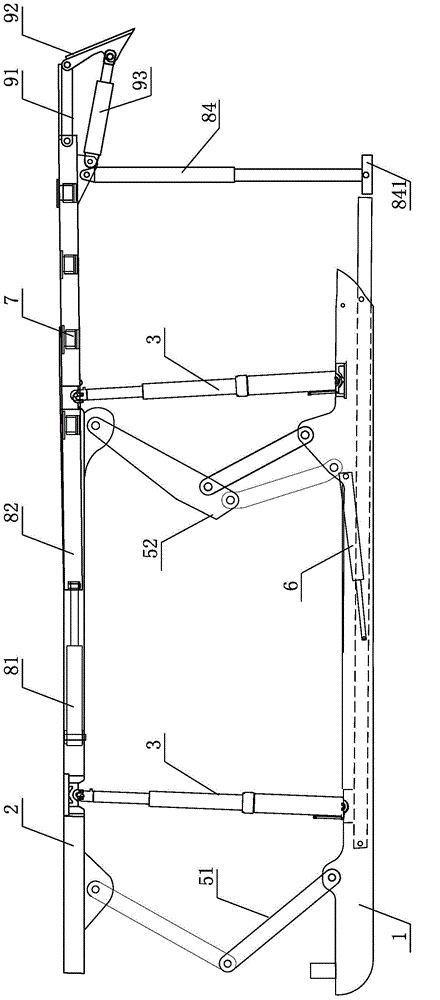

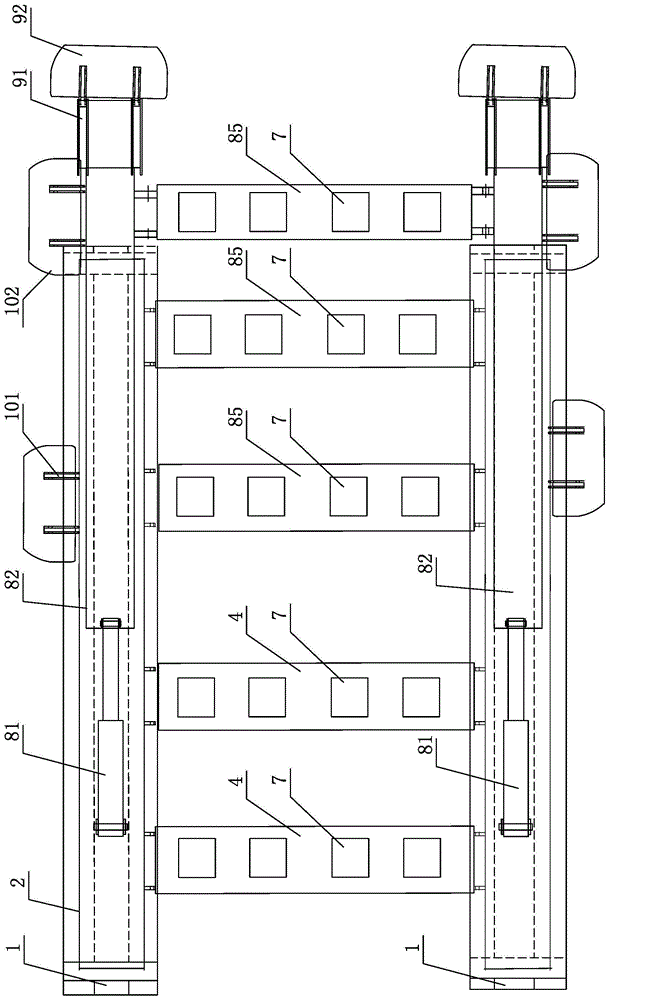

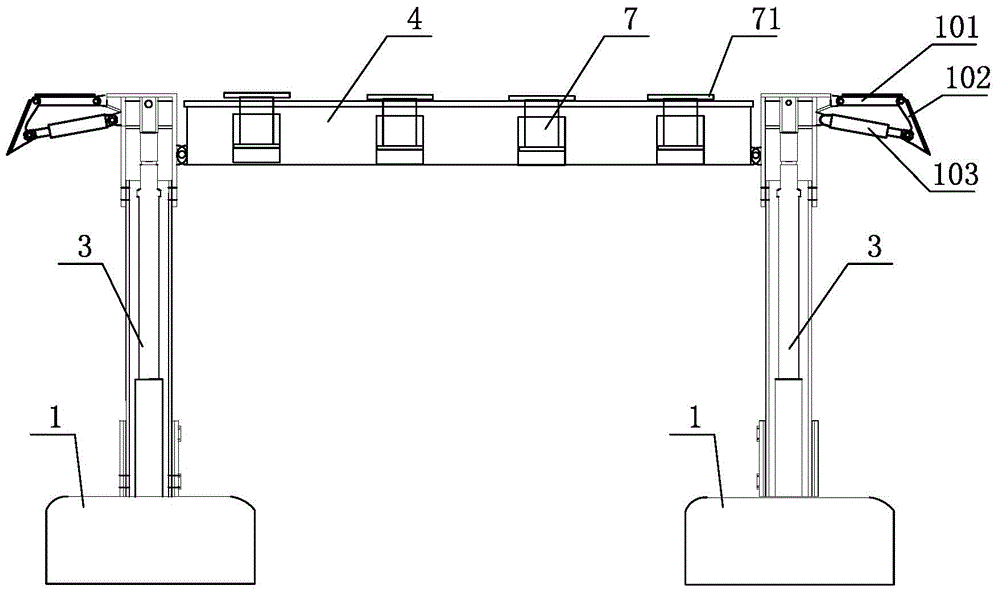

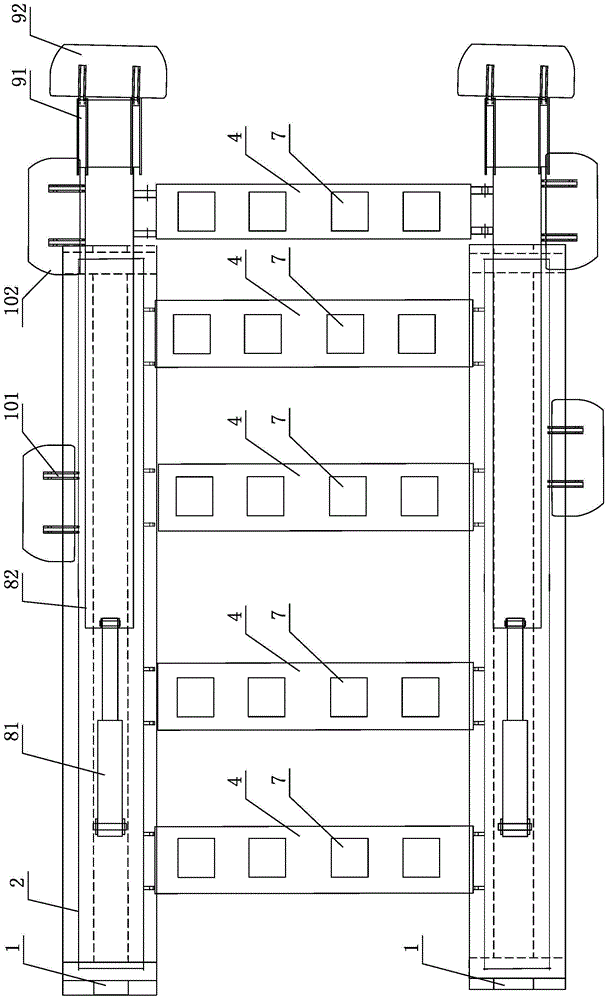

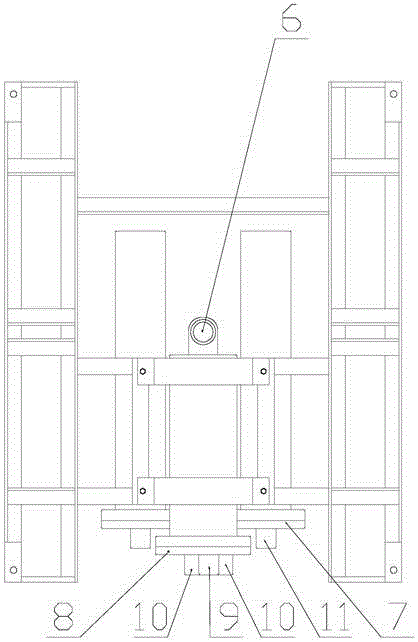

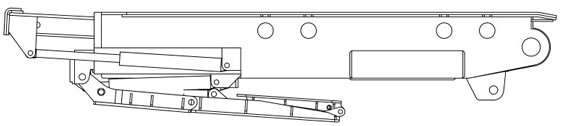

Temporary supporting hydraulic support of tunneling working face

The invention discloses a temporary supporting hydraulic support of a tunneling working face. The temporary supporting hydraulic support of the tunneling working face comprises protective top beams and two longitudinal bearing structural bodies; each longitudinal bearing structural body comprises a longitudinal bearing top beam, a base and a support stand column; telescopic top beams are arranged on the longitudinal bearing top beams or the protective top beams, telescopic top beam support devices are arranged on the telescopic top beams, each telescopic top beam support device comprises a support oil cylinder and a displacement control oil cylinder, one end of each support oil cylinder and one end of each displacement control oil cylinder are each in hinged connection with each telescopic top beam, and the other end of each displacement control oil cylinder is connected with each support oil cylinder; protective top beams of the telescopic top beam are arranged on the telescopic top beams, supporting load cylinders are arranged on the protective top beams of the telescopic top beam and the protective top beams, and one end of each supporting load cylinder points to a roadway roof. The temporary supporting hydraulic support of the tunneling working face has the advantages of being strong in supporting and protective abilities for the roof, and capable of flexibly controlling the supporting points of the roof, creating a safe working environment for operating workers and improving the tunneling construction efficiency and footage level.

Owner:CHINA COAL PANJIANG HEAVY IND CO LTD

Reverse slope tunnel construction method

ActiveCN108678753AAvoid falling blocksPrevent roof fallUnderground chambersDrainageShotcreteWater level

The invention discloses a construction method of a reverse slope tunnel, which comprises the following steps: an arc-shaped heading is excavated in a circular shape, a core soil is reserved, and a first step is excavated; two second steps and two third steps reserved on the left and right sides of the core soil are respectively excavated, and the shotcrete and anchor support is carried out; the reserved core soil is excavated; an inverted arch is excavated and the initial support of the inverted arch is made; a waterproofing plate of the inverted arch is laid, and the side wall concrete is poured; after the pouring of the inverted arch concrete is completed, the inverted arch shall be backfilled in time, and the construction of secondary lining of the concrete shall be carried out. According to the invention, the construction of the reverse slope tunnel under the water level line of the adjacent reservoir is carried out, and the reverse slope is being made positive, so that the water seepage and the water inflow of the first step and the second step tunnel face can be timely discharged to the temporary water collecting pit of a third step to prevent the tunnel surrounding rock fromfalling out of the block, roof falling, landsliding or water inflowing. The integrity of the tunnel surrounding rock can be ensured, and the adverse effect on the reservoir and the surrounding environment can be reduced.

Owner:CHINA COMM NORTH ROAD & BRIDGE

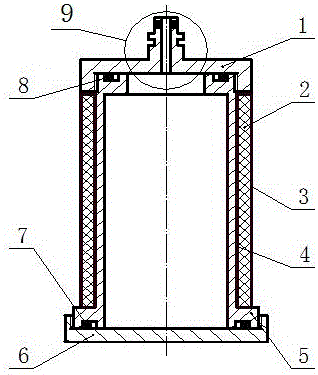

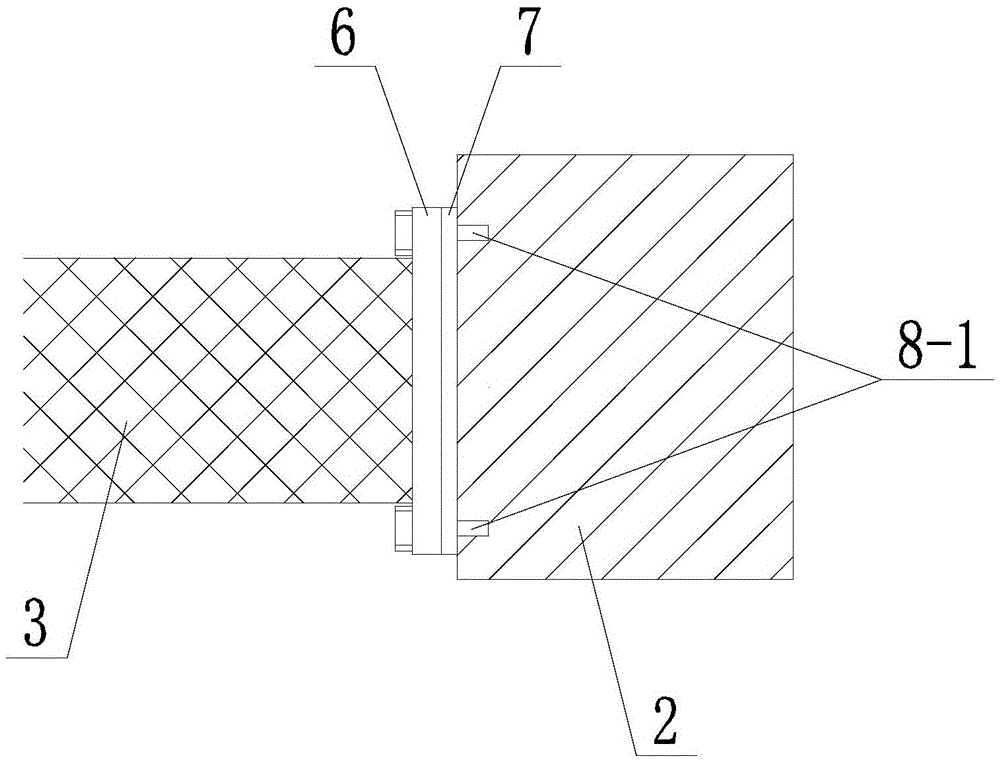

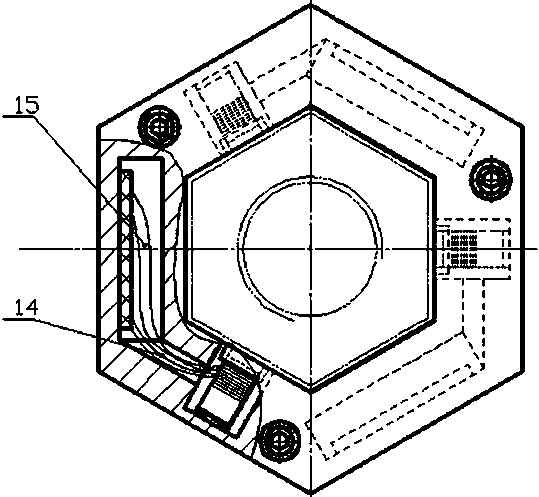

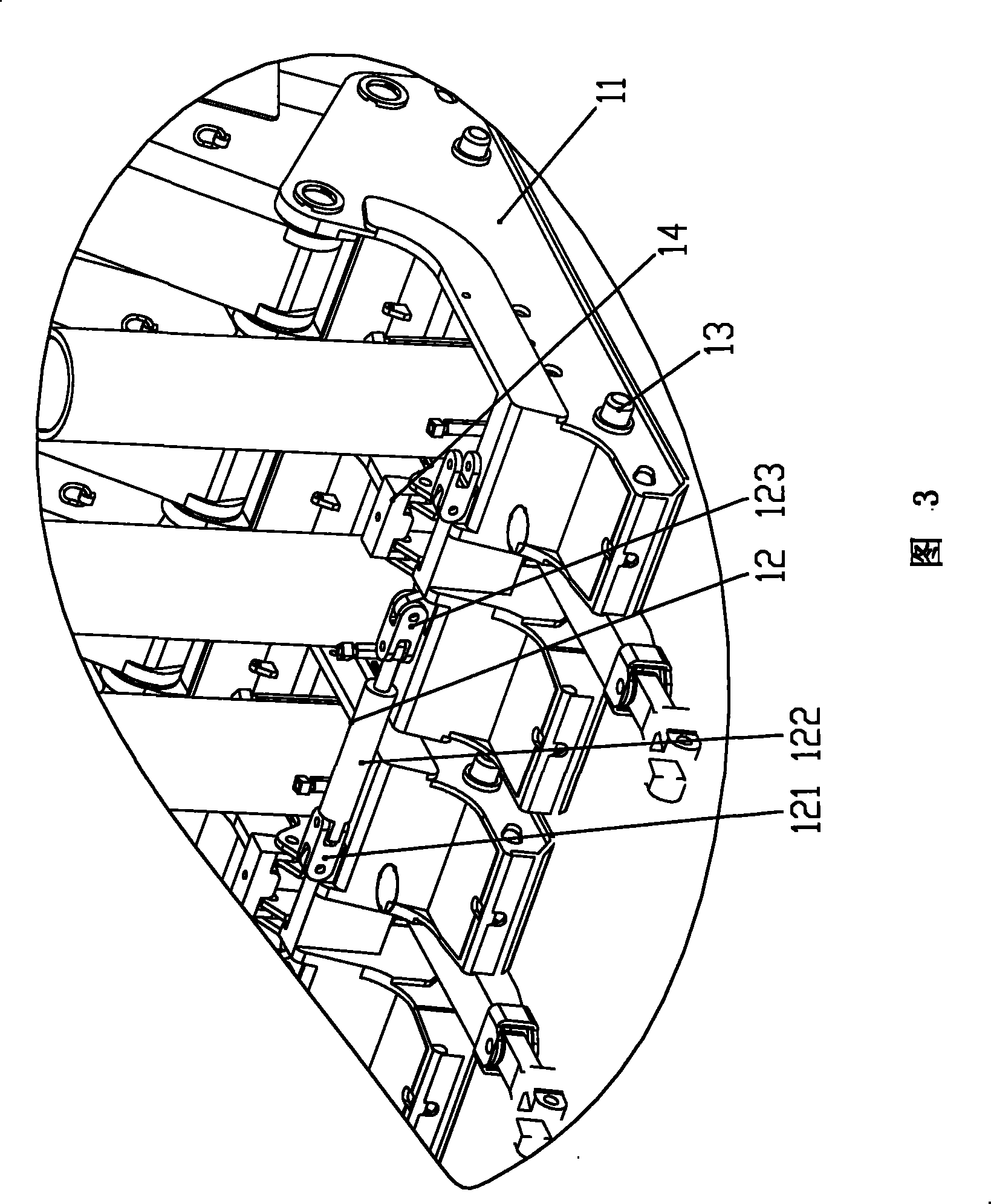

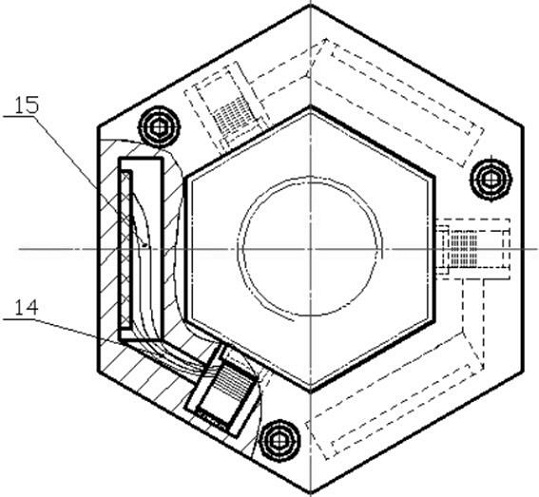

Detection device and detection method for axial force of anchor rod

InactiveCN109238517APrevent landslidesPrevent roof fallForce measurement by measuring magnetic property varationAxial forceEngineering

The invention discloses a detection device and a detection method for the axial force of an anchor rod. An integrated structure of the device is a regular hexagonal prism; an upper end cover and a lower end cover are respectively connected with a protective shell through fastening screws; a plurality of two-pole U-shaped magnetic cores are uniformly disposed at an outer side of an anchor rod fastening nut; the two-pole U-shaped magnetic cores are located in a space encircled by the upper end cover, the lower end cover and the protective shell; silicon rubber sleeves are sleeved on two magneticpoles of the two-pole U-shaped magnetic cores; a magnetic fluid is filled in each of the silicon rubber sleeves; a circuit slot is disposed in the space encircled by the upper end cover, the lower end cover and the protective shell; a control circuit is disposed in the circuit slot; a wire led from the control circuit passes through the circuit slot to wind an excitation coil and a detection coilto upper and lower ends of the two-pole U-shaped magnetic cores; elastic sheets are disposed at outer sides of the two-pole U-shaped magnetic cores; and the elastic sheets are fixed on an inner wallof the protective shell. The detection device and the detection method for the axial force of the anchor rod are used for detecting the axial force of the anchor rod, the collapse and cave-in of a topplate are avoided, a top plate support parameter is provided, and a reliable technical parameter is provided for support design of a laneway layout and safety monitoring of the top plate.

Owner:TAIYUAN UNIV OF TECH

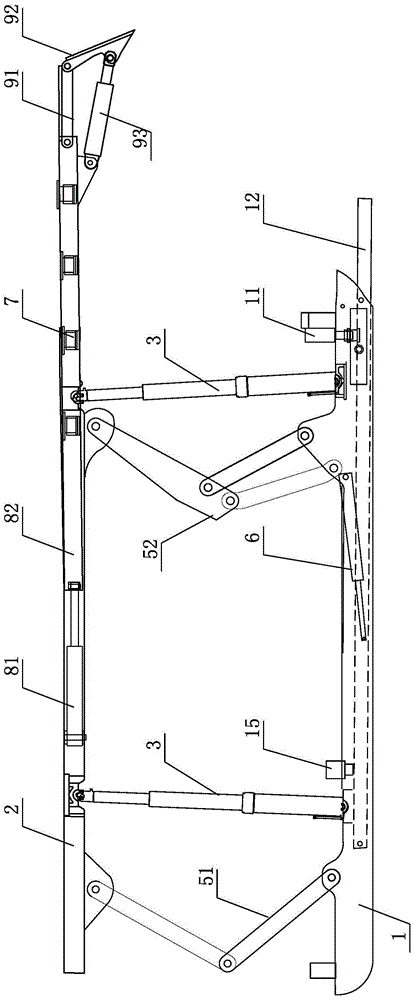

Overlarge mining height hydraulic support

The invention relates to a super large mining height hydraulic support which comprises an opened rigid integrated base, wherein, two double-telescopic hydraulic upright posts are arranged on the base, and the upper ends of the upright posts are connected with a top beam; the rear of the top beam is connected with a screening beam; an edge protection device is connected with the telescopic beams which are in inner extension connection with the top beam; a balance jack is arranged between the top beam and the screening beam; the screening beam and the base are respectively connected with the front and rear connecting rods; a push jack is arranged on the base and is connected with a push rod; the front part of the top beam is provided with the telescopic beams, the middle part of the top beam is provided with a falling prevention device for the support, and bottom lifting, skid prevention and support regulation devices are arranged on the base; and a levelling device is arranged on a cross binding head on the front end of the push rod; the support adopts 2-meter width between centers, the maximum height ranges from 6.3 meters to 7.5 meters, and the front end of the telescopic beam isprovided with a third-stage edge protection device which is not lower than half of the mining height. The support has obvious effects of controlling the wall caving of the coal wall of a super thick coalseam, the roof fall of the ceiling, and the stability of the hydraulic support.

Owner:CCTEG COAL MINING RES INST

Temporary support of hydraulic supports in excavation work

ActiveCN104612735BRealize self-movingPrevent roof fallMine roof supportsWorking environmentArchitectural engineering

The invention discloses a temporary support hydraulic support for a tunneling working face. The temporary support hydraulic support for the tunneling working face comprises a protective ejection beam, two longitudinal bearing structural bodies arranged on the left side and the right side of the protective ejection beam, a front protective device and a side protective device. Each longitudinal bearing structure body comprises a longitudinal bearing top beam, a base and supporting stand columns. The cross section of each base is in the shape of a groove with a downward opening. Each base is provided with a base lifting device. Each base lifting device comprises a base lifting oil cylinder and a base lifting supporting plate. Each base lifting oil cylinder is vertically installed on the front portion of the corresponding base. Each base lifting supporting plate is arranged in the groove of the corresponding base. A pushing oil cylinder is arranged between each base lifting supporting plate and the base. The protective top beam is provided with a supporting and loading oil cylinder pointing to a tunnel roof. By the adoption of the temporary support hydraulic support for the tunneling working face, base lifting and self movement of the hydraulic support are achieved, the roof supporting capacity is high, all-directional safety protection is achieved, a safe working environment is created for mine coal roadway fully-mechanized tunneling construction personnel, and the tunneling efficiency and the footage level are improved.

Owner:安徽恒源煤电股份有限公司

A Construction Method for Preventing Shield Tunnel from Roof Falling During Construction

ActiveCN105649640BPrevent roof fallQuality is easy to controlUsing mechanical meansTunnelsControl qualityShield tunneling

The invention provides a construction method for preventing roof caving of a shield in construction. The construction method comprises the steps that 1, stratum investigation is performed along a shield path; 2, a cap peak device is installed on a shield tunneling machine; 4, the cap peak device is applied to shield construction. When the cap peak device is not adopted, the cap peak device is retracted into a cutterhead face through a hydraulic oil cylinder; when the shield enters the roof caving stratum, the cap peak device can stretch out by means of the hydraulic oil cylinder, the stretching-out length can be determined according to the condition of the stratum, and roof caving is prevented according to the stretching-out length of the cap peak. By adopting the construction method, roof caving of the shield on various geological conditions is prevented more easily and conveniently, the axis control quality is improved, and soil body disturbance and ground deformation are reduced.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +2

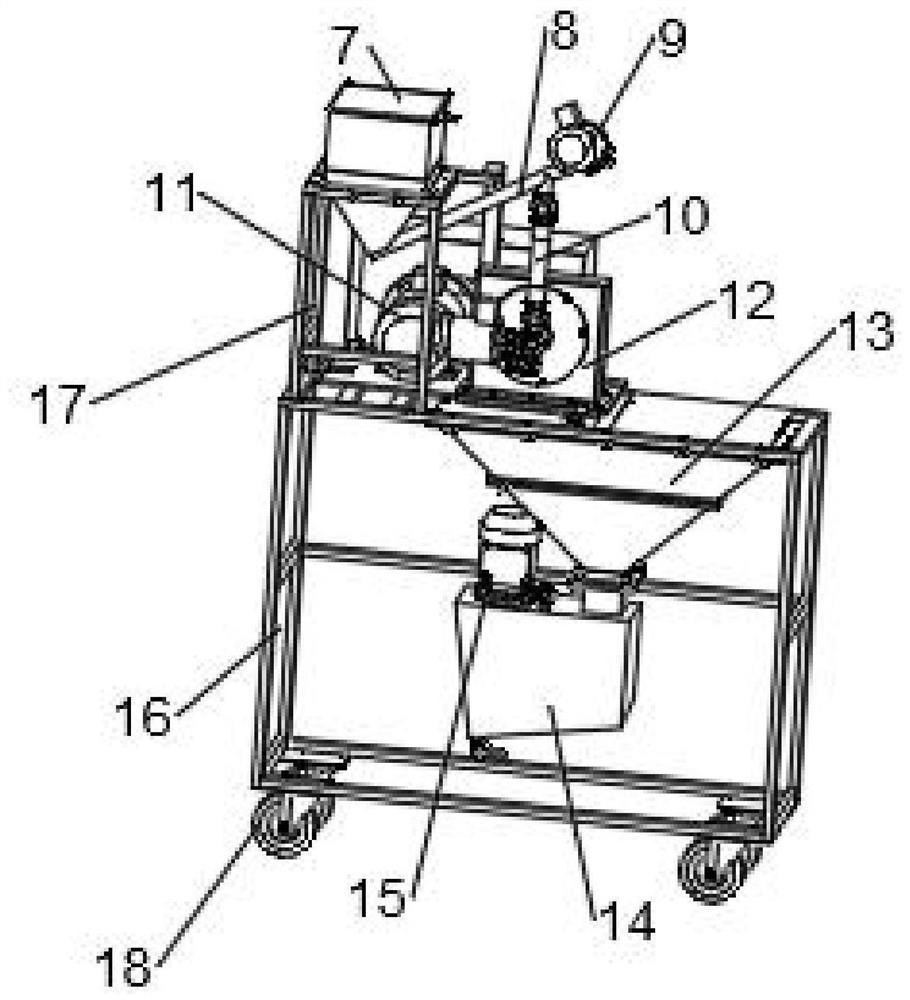

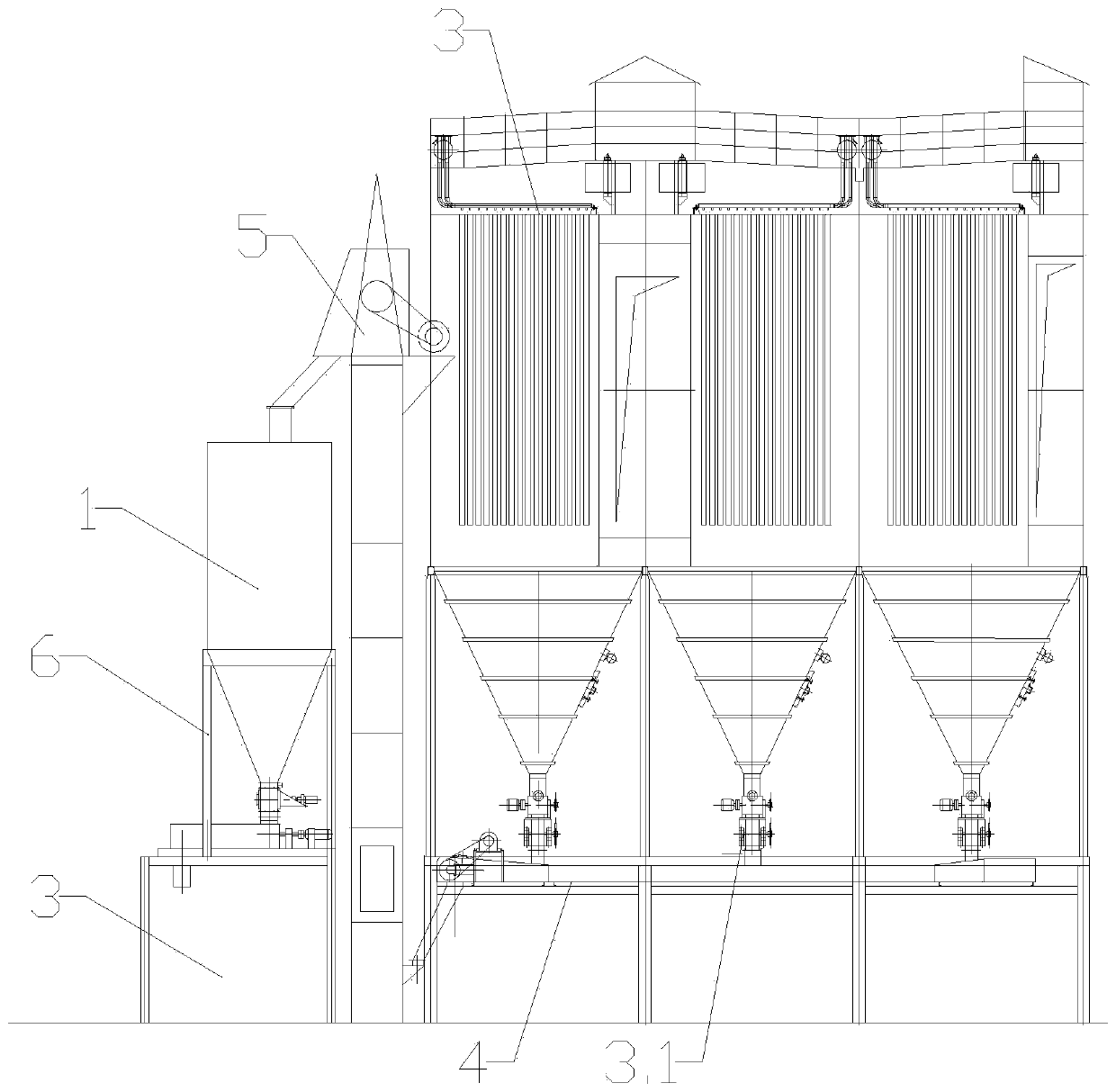

Blast furnace front dedusting system

InactiveCN110042185AImproving the Casthouse EnvironmentImprove the environmentProcess efficiency improvementDust arrestersBucket elevatorDust emission

The invention relates to a blast furnace front dedusting system. The system comprises an ash storage bin, a bin top dust remover, pulse dust collectors, a buried scraper conveyor, a bucket elevator and an ash discharging chamber. Discharge valves are arranged at the lower ends of the pulse dust collectors correspondingly. The buried scraper conveyor is arranged below the discharge valves of the pulse dust collectors. An outlet of the buried scarper conveyor is connected with an inlet of the bucket elevator. An outlet of the bucket elevator is connected with an inlet of the bin top dust remover. An outlet of the bin top dust remover is connected with an ash falling hole of the ash storage bin. The ash discharging chamber is located below a discharge outlet of the ash storage bin. Accordingto the blast furnace front dedusting system, the pulse dust collectors are adopted and matched with the buried scraper conveyor, the bucket elevator, the bin top dust remover and the ash storage bin,the system is made to operate stably, the casting house environment is further improved, dust emission reaches emission requirements of new standards, the emission amount is smaller than or equal to 8mg / Nm<3>, and emission is stable.

Owner:无锡澄天环境科技有限公司

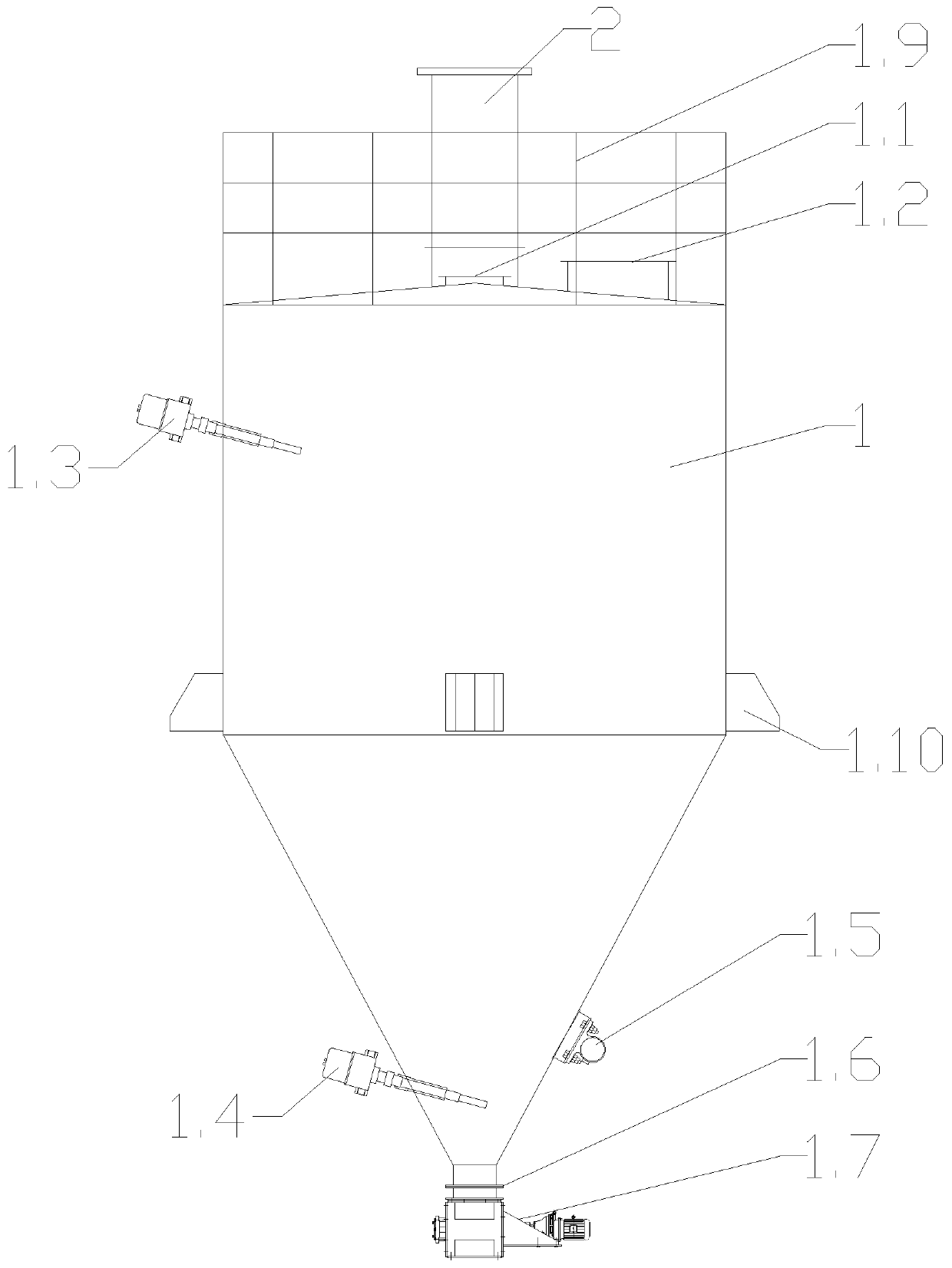

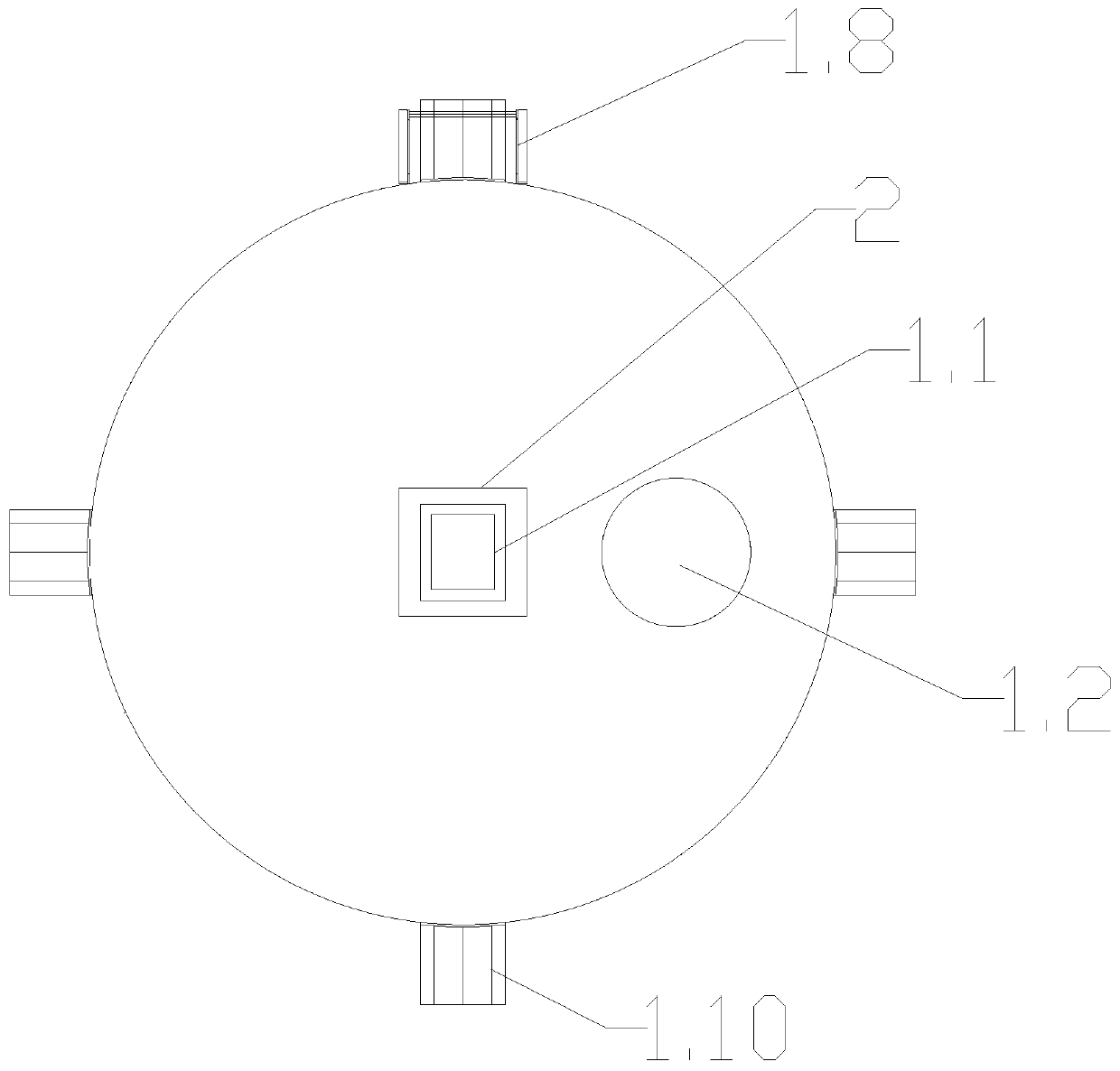

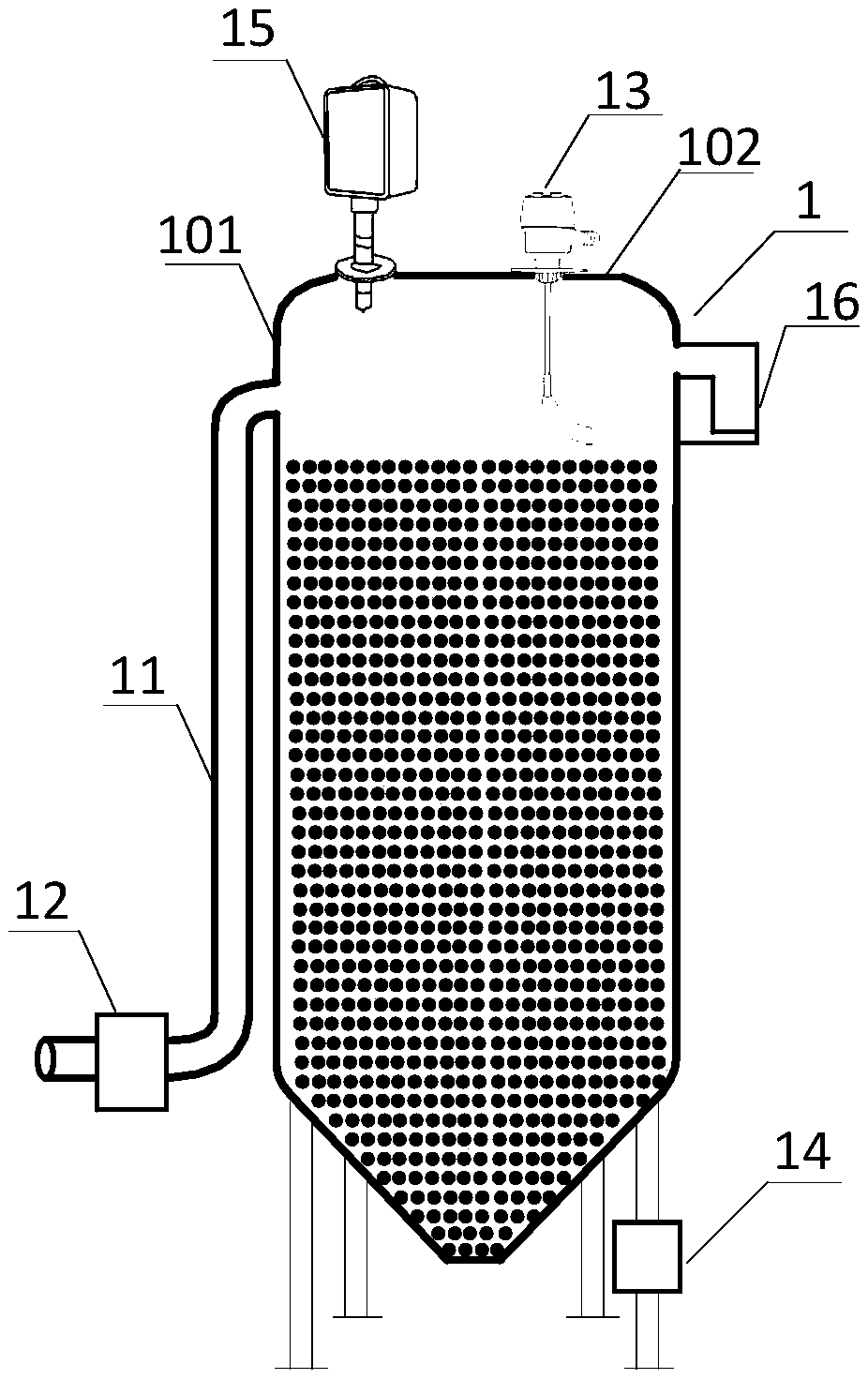

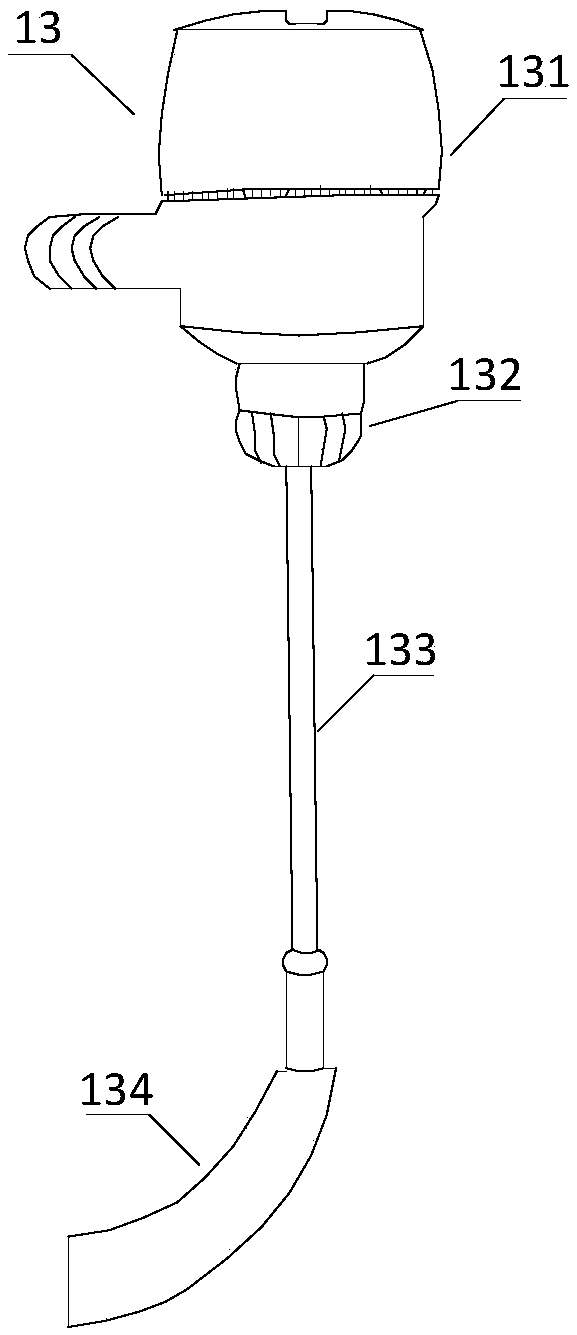

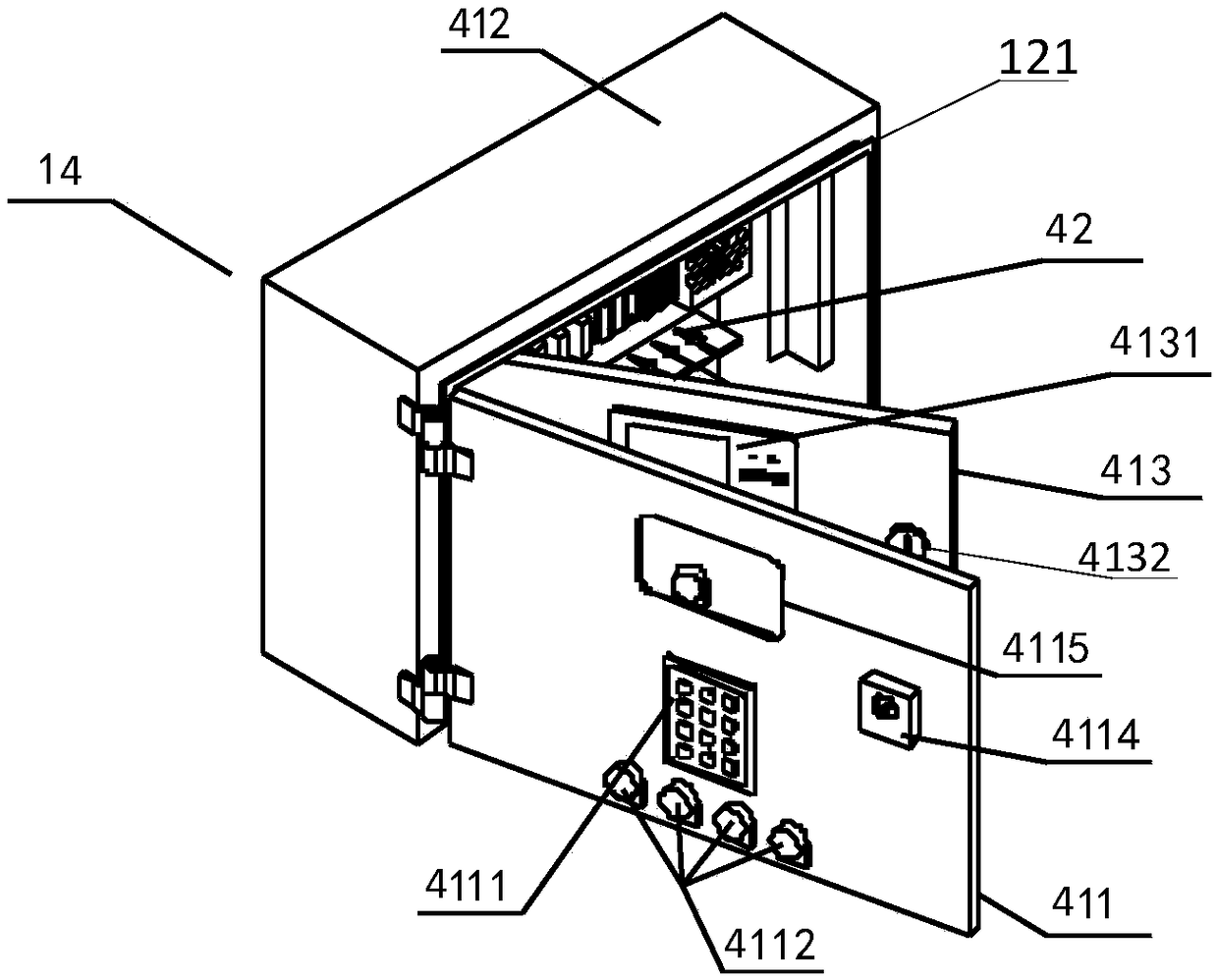

Safety monitoring system for powdery material bin

The invention discloses a safety monitoring system for a powdery material bin. The safety monitoring system comprises a feeding pipe which is arranged on the upper part of a side wall of the airtightpowdery material bin, a feeding control valve which is arranged at the bottom end of the feeding pipe, and a charge level indicator which is arranged on the top of the side wall of the airtight powdery material bin; the charge level indicator comprises a damped rotation type charge level indicator and a heavy hammer type charge level indicator; the feeding control valve can be controlled through asafety charging control terminal; multiple safety control measures such as password input and two-stage box covers are configured in the terminal, and the feeding situations in the material bin can be monitored through the damped rotation type charge level indicator and the heavy hammer type charge level indicator so as to prevent roof collapse; powdery materials in the bin can be accurately measured; moreover, through arrangement of a bag type dust remover, explosion caused by dust in a feeding process is avoided, so that the safe reliability is further enhanced.

Owner:HENAN QIANHE AUTOMATION TECH

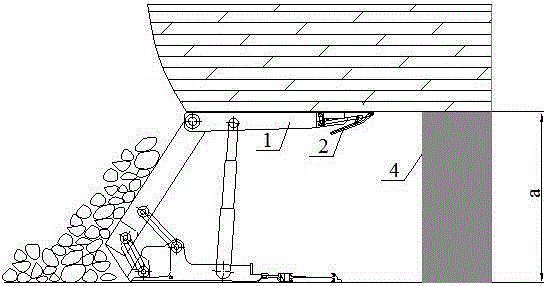

Rapid Coal Mining Technology in Fully Mechanized Mining Face with Large Mining Height

A large-mining-height fully-mechanized-face fast coal mining technology is suitable for large-mining-height fully-mechanized-face fast coal mining with a roof of a coal seam higher than medium hard level and firmness coefficient of the coal seam more than 1.0. Coal is first cut in the middle part of the coal seam, a front roller of a coal mining machine is then used for cutting top coal, a rear roller of the coal mining machine is used for cutting bottom coal, and simultaneously a hydraulic support of a coal cutting achieving part is moved, after the hydraulic support is moved, a face guard of the hydraulic support is opened to enable the face guard to be tightly attached to a coal wall. Every cycle operation goes on sequentially in a cycling mode according to the working procedures, the middle part of the coal seam is cut first, and the top coal at the upper part depends on the face guard to support so that wall caving of the coal wall and roof fall of the end face can be effectively prevented. Due to the fact that a coal cutting height is reduced, coal cutting speed is remarkably improved, and simultaneously coal of large sizes cannot be produced. Therefore, the large-mining-height fully-mechanized-face fast coal mining technology fundamentally resolves the problem that large-mining-height fully-mechanized-face large-sized coal hinders working-face coal cutting, coal charging and coal carrying, removes potential dangers of manually breaking large-sized coal, and is simple in technological operation, safe, reliable and high in efficiency.

Owner:CHINA UNIV OF MINING & TECH

Neutron material level meter and delayed coking liquid level analysis system

ActiveCN106645246AIntuitive display statusIntuitive display densityMaterial analysis using wave/particle radiationNuclear energy generationHydrogenEngineering

The invention discloses a neutron material level meter and a delayed coking liquid level analysis system. The neutron material level meter comprises a shell body, wherein an opening is formed in the front side of the shell body; a baffle with an air vent is formed in the rear side of the shell body; a supporting frame is arranged on the inner side of the shell body; a transmitter explosion-proof shell is arranged at the top of the supporting frame; a transmitter connected with a neutron material level meter main engine is arranged in the transmitter explosion-proof shell; two neutron detector explosion-proof shells are arranged below the transmitter explosion-proof shell, wherein at least one neutron detector explosion-proof shell is internally provided with a helium-3 pipe connected with the transmitter; a neutron radioactive source mounting shell is arranged between the two neutron detector explosion-proof shells; a neutron radioactive source mounting hole is formed in the top of the shell body; a hole cover capable of being opened and closed is arranged on the neutron radioactive source mounting hole. According to the neutron material level meter disclosed by the invention, a scattering and moderation principle of neutrons in a hydrogen-containing medium is used for distinguishing a dynamic distribution rule of states of all materials in a tower; an upper-layer real-time height indication value of a coke layer is given under the matching of a tower-bottom oil injection starting signal.

Owner:北京华科拓普电子仪器有限公司

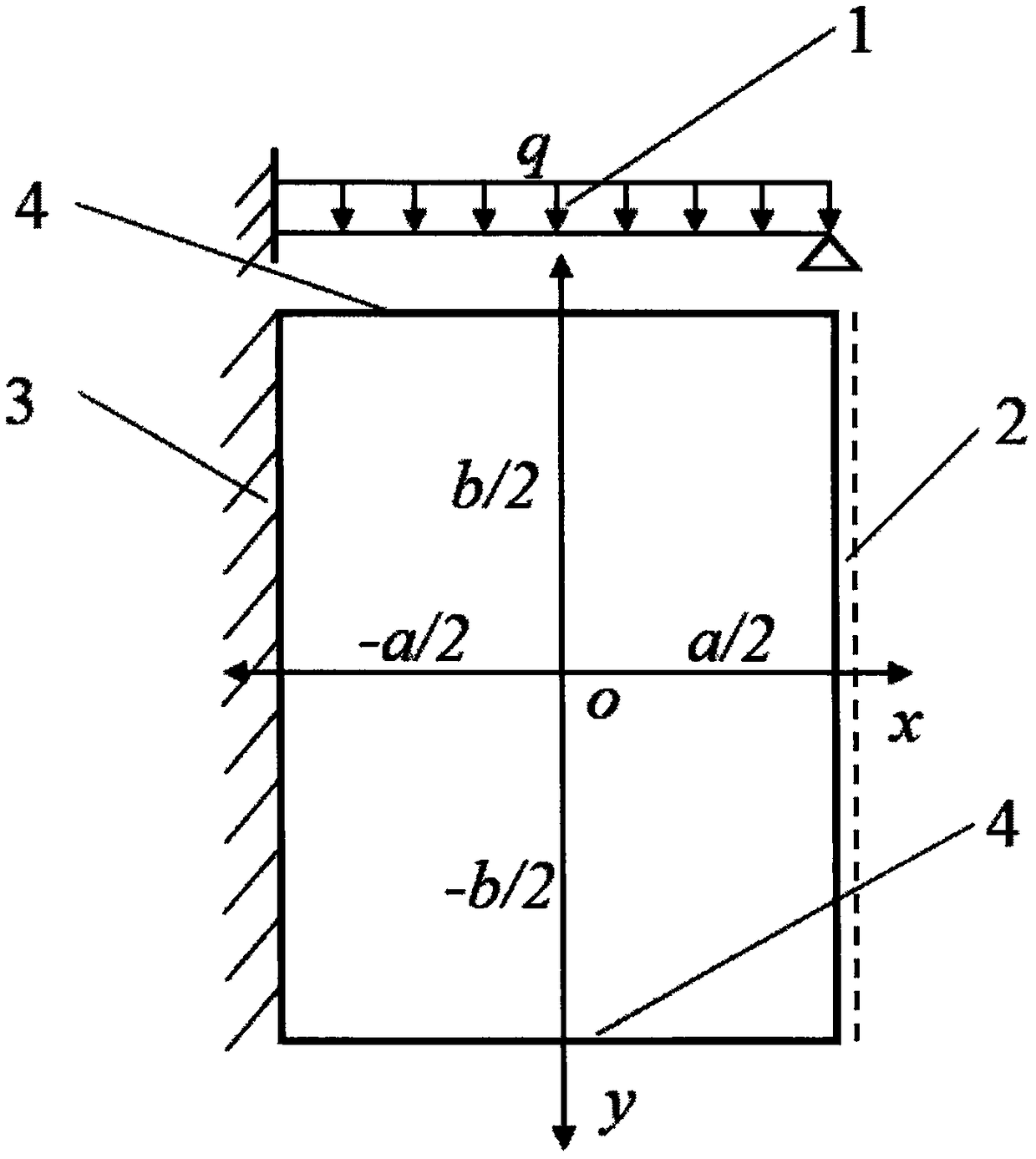

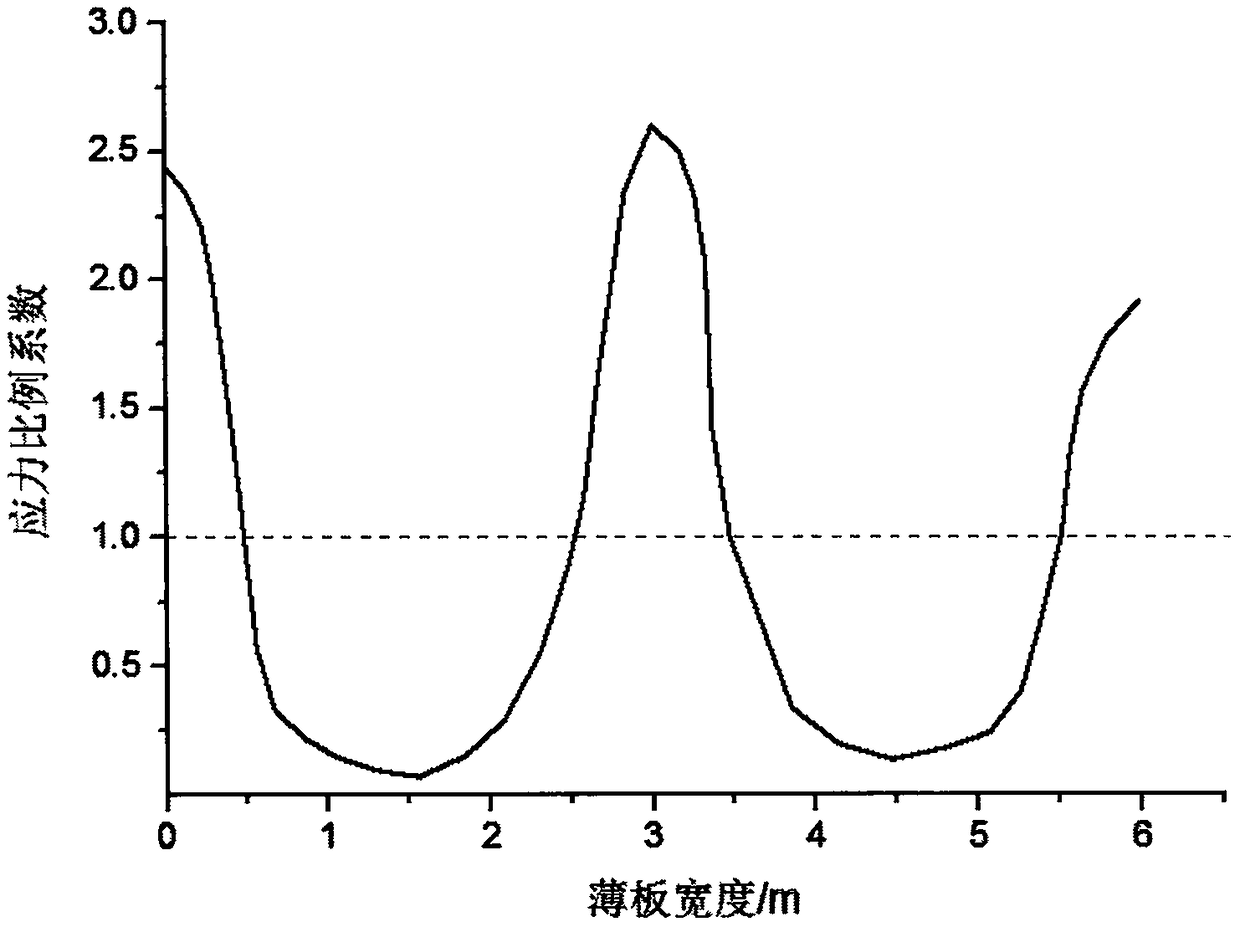

Determining method for positions of reinforcing of gob-side entry roofs through cable-stayed anchor cables

ActiveCN108266211ASafe and Efficient MiningPrevent roof fallDesign optimisation/simulationSpecial data processing applicationsStress ratioCable stayed

The invention relates to a determining method for the positions of reinforcing of gob-side entry roofs through cable-stayed anchor cables. As for traditional reinforcing of the gob-side entry roofs, anchor cables inclining towards entity coal sides are driven nearby roadway filled bodies to protect the stability of retained roadways, but the actual effect is very poor. The method is particularly suitable for determining of arrangement of the cable-stayed anchor cables of the gob-side entry roofs. According to the method, the poor effect of reinforcing of the roofs through the roof cable-stayedanchor cables is mainly caused by the unreasonable designed and arranged positions of the retained roadway roof cable-stayed anchor cables, thus in the method, the retained roadway roofs are regardedas thin plates each with one pair of opposite edges being fixedly and simply supported and the other pair of opposite edges being free, maximum and minimum main stress expressions of the thin platesare obtained through calculation, the maximum main stress of the thin plates is compared with the rock tensile strength, thus the stress ratio coefficient of the thin plates is obtained, when the stress ratio coefficient is larger than 1, rock plates are damaged, and the position needs to be reinforced by driving the cable-stayed anchor cables. According to the method, calculation is easy, achievement is easy, and safety and reliability are achieved.

Owner:河北充填采矿技术有限公司

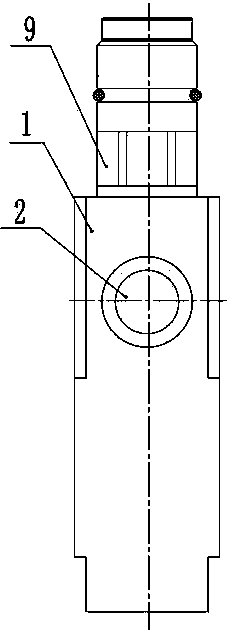

Roof brushed frame moving valve of hydraulic support for coal mine

The invention discloses a roof brushed frame moving valve of a hydraulic support for a coal mine. The roof brushed frame moving valve comprises a valve body, a high-pressure liquid inlet, a liquid returning opening and a control liquid opening, wherein the high-pressure liquid inlet, the liquid returning opening and the control liquid opening are formed in the valve body; the valve body is internally provided with a hydraulic control one-way valve and a one-way valve; a working cavity of the hydraulic control one-way valve is communicated with the high-pressure liquid inlet; an unloading cavity of the hydraulic control one-way valve is communicated with a liquid inlet of the one-way valve; a liquid outlet of the one-way valve is communicated with the liquid returning opening; the control liquid opening is communicated with the lower end face of an ejection rod of the hydraulic control one-way valve. The roof brushed frame moving valve disclosed by the invention has the advantages that a frame can be moved under pressure when the hydraulic support works under a well, that is, a roof beam and a roof plate can contact mutually all the time when the hydraulic support is moved and the hydraulic support also has certain supporting force on the roof plate when the hydraulic support is removed, so as to prevent an unstable direct roof, a false roof or a crushed roof from caving and puking. Meanwhile, when the hydraulic support is moved, a column does not need to be descended and only pressure in a stand column of the hydraulic bracket needs to be reduced to a pre-set value to carry out frame moving operation.

Owner:郑州煤机液压电控有限公司

A Supporting Method for Anti-Caution Roof Side

ActiveCN103266903BDoes not affect normal recovery workReduce the amount of helpProtective coversJoistEngineering

Provided is a supporting method capable of preventing roof and wall falling accidents. By means of the supporting method, joist steel, metal nets and a hydraulic support are adopted for supporting a broken roof plate of a working surface in an auxiliary mode. When an opening is cut in the working surface, metal nets with certain specifications are overlaid on a section of a cut opening on the whole working surface are fixedly connected onto the section of the cut opening, and certain pitches among the metal nets are connected through iron wires. Afterwards, the hydraulic support is installed in the cut opening, a top beam of the hydraulic support butts against a direct top, so that the connected metal nets can droop in front of the hydraulic support and butts against a coal mine wall through a face guard plate. The joist steel is horizontally bundled on the metal nets before the hydraulic support through iron wires. In coal mining, the face guard plate is drawn back, and the metal nets in front of the hydraulic support are bundled on a column through iron wires. When coal mining is not performed, the metal nets are put down, the face guard plate butts against the coal mine wall, the support moves frontward, the metal nets are connected with the joist steel and moves to cover on the roof plate relative to the support, then work for connecting the metal wires and bundling the joist steel can be performed uninterruptedly and repeatedly until actual mining on the working surface is finished.

Owner:ANHUI UNIV OF SCI & TECH

A super large mining height hydraulic support

ActiveCN111706377BGuaranteed response speedSolve the problem of helpMine roof supportsStructural engineeringMechanical engineering

The invention discloses a hydraulic support for super-large mining height, which includes a top beam and a double-layer roof protection and side protection mechanism installed on the top beam. The top beam includes an upper slideway cavity and a lower slideway cavity. The roof protection mechanism includes an upper telescopic beam roof protection mechanism and a three-stage side protection mechanism. The upper telescopic beam roof protection mechanism includes an upper telescopic beam slidably installed in the upper slideway cavity and an upper telescopic beam matched with the upper telescopic beam. Beam jack, the three-stage protection mechanism includes a lower telescopic beam slidably installed in the lower slideway cavity, a lower telescopic beam jack matched with the lower telescopic beam, and a three-stage apron installed at the front end of the lower telescopic beam ontology. The ultra-large mining height hydraulic support obtained by the present invention can cope with the side protection problem caused by the increasing mining height of the working face, and is suitable for full-height mining in one-time mining of extra-thick coal seams.

Owner:CCTEG COAL MINING RES INST +1

A stope coal wall slab control device

The invention provides a stope coal wall caving control device. The stope coal wall caving control device is characterized in that a hydraulic support device and a caving protection device are integrally arranged on the same support base, a hydraulic support top plate and a hydraulic support auxiliary plate of the hydraulic support device are arranged on the top of a coal seam, the caving protection device is arranged on a stope coal wall, and support protection angles of a caving protection plate of the caving protection device can be adjusted. The stope coal wall caving control device has the advantages that the hydraulic support device and the caving protection device are integrally arranged, the support protection angles of the caving protection plate can be adjusted, and accordingly the caving protection fastening property and safety can be greatly improved; the stope coal wall caving control device is provided with angle adjusting teeth, accordingly, angles of the caving protection plate can be conveniently adjusted, and the caving protection plate can be conveniently mounted; anchor rods are arranged on the protection plate, accordingly, the coal wall caving fastening property can be effectively improved under joint effects of the protection plate and the anchor rods, and roof collapse can be prevented; positioning protrusions are arranged on anchor rod holes, and accordingly the supporting convenience and accuracy of the anchor rods can be improved.

Owner:NORTH CHINA INST OF SCI & TECH

A detection device and detection method for the axial force of a bolt

InactiveCN109238517BPrevent landslidesPrevent roof fallForce measurement by measuring magnetic property varationMagnetic polesHemt circuits

The invention discloses a detection device and a detection method for the axial force of an anchor rod. An integrated structure of the device is a regular hexagonal prism; an upper end cover and a lower end cover are respectively connected with a protective shell through fastening screws; a plurality of two-pole U-shaped magnetic cores are uniformly disposed at an outer side of an anchor rod fastening nut; the two-pole U-shaped magnetic cores are located in a space encircled by the upper end cover, the lower end cover and the protective shell; silicon rubber sleeves are sleeved on two magneticpoles of the two-pole U-shaped magnetic cores; a magnetic fluid is filled in each of the silicon rubber sleeves; a circuit slot is disposed in the space encircled by the upper end cover, the lower end cover and the protective shell; a control circuit is disposed in the circuit slot; a wire led from the control circuit passes through the circuit slot to wind an excitation coil and a detection coilto upper and lower ends of the two-pole U-shaped magnetic cores; elastic sheets are disposed at outer sides of the two-pole U-shaped magnetic cores; and the elastic sheets are fixed on an inner wallof the protective shell. The detection device and the detection method for the axial force of the anchor rod are used for detecting the axial force of the anchor rod, the collapse and cave-in of a topplate are avoided, a top plate support parameter is provided, and a reliable technical parameter is provided for support design of a laneway layout and safety monitoring of the top plate.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com