Temporary supporting hydraulic support of tunneling working face

A technology for excavation work and hydraulic support, which is applied in coal mine machinery and equipment, and in the field of excavation work to support hydraulic supports when faced with excavation work. It can solve the problems of small support capacity, broken roof, and unsatisfactory roof support effect, etc., to improve the cantilever status, enhanced support strength, and the effect of enhanced protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

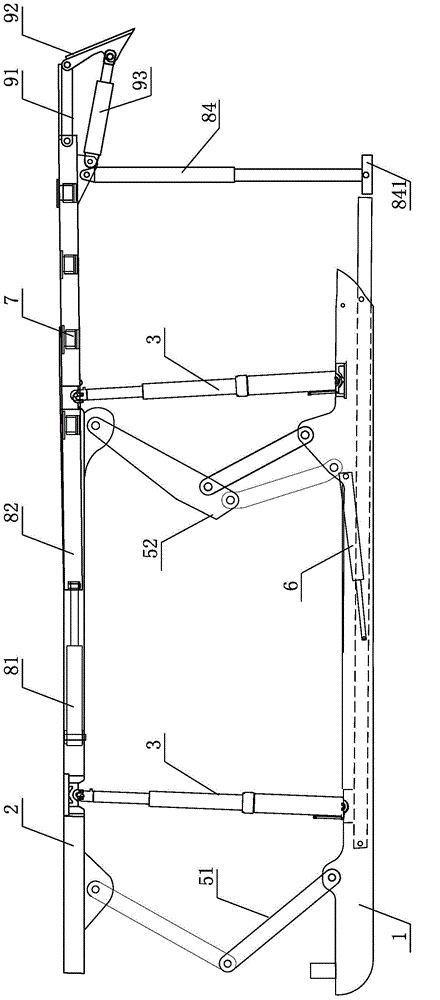

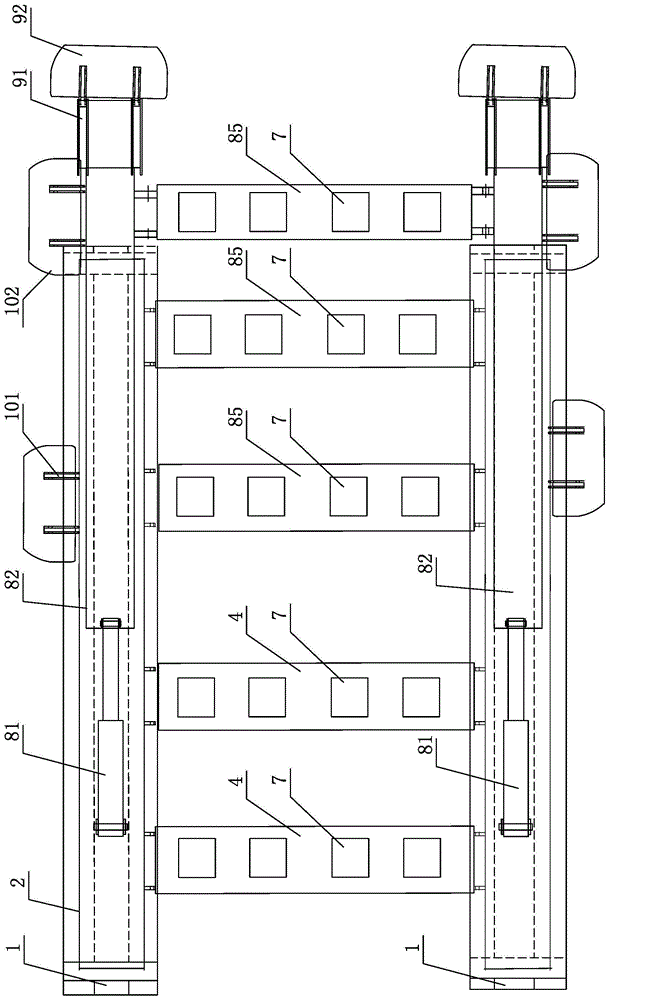

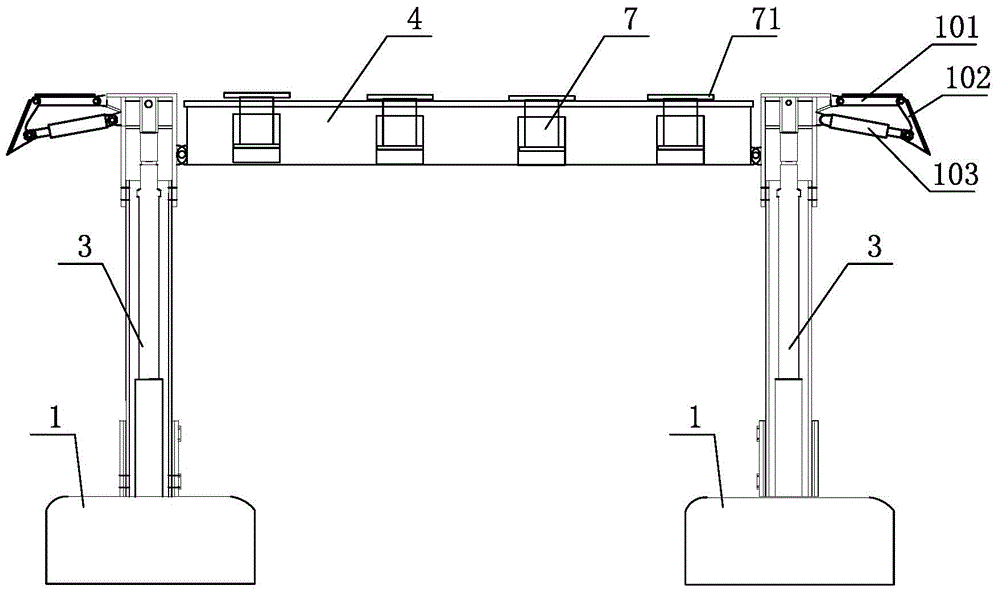

[0022] Such as figure 1 , figure 2 with image 3 As shown, the excavation work face of the first embodiment supports the hydraulic support in time, including the protective roof beam 4 and two longitudinal load-bearing structures respectively arranged on the left and right sides of the protective roof beam 4; wherein, each longitudinal load-bearing structure includes a vertical The load-bearing top beam 2, the base 1, the hydraulic support column 3 connecting the longitudinal load-bearing top beam 2 and the base 1, and the load-bearing top beam stabilizing mechanism are the two-bar linkage mechanism 51 and the four-bar linkage mechanism 52; the protective top beam 4 and the longitudinal load-bearing top beam The beam 2 connects and fixes the relative position between the two longitudinal bearing structures. Wherein, the telescopic top beam 82 driven by the telescopic top beam jack 81 is arranged on the longitudinal load-bearing top beam 2, and the telescopic top beam jack 8...

Embodiment 2

[0030] Such as Figure 4 with Figure 5As shown, the excavation work face temporary support hydraulic support of embodiment two is basically the same structure as the excavation work face temporary support hydraulic support support structure of embodiment one, the difference is that the telescopic top beam support device in embodiment two also includes variable Position control oil cylinder 83, wherein, one end of the displacement control oil cylinder 83 is hinged to the telescopic roof beam 82, the other end of the displacement control oil cylinder 83 is hinged to the support cylinder 84 or connected by a stay rope, and the support cylinder 84 is hinged to the telescopic roof beam 82 , the angle between the support cylinder 84 and the telescopic top beam 82 is adjusted by the expansion and contraction of the displacement control cylinder 83. When the support cylinder 84 is unloaded and separated from the bottom plate of the roadway under construction, the displacement control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com