A Supporting Method for Anti-Caution Roof Side

A technology of side and roof, which is applied in earthwork drilling, temporary shields, mining equipment, etc., can solve problems such as roof fall accidents, uncertainty of sides, and influence on conventional mining of working faces, so as to prevent roof fall and reduce sides volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following is a further description of an embodiment of the present invention:

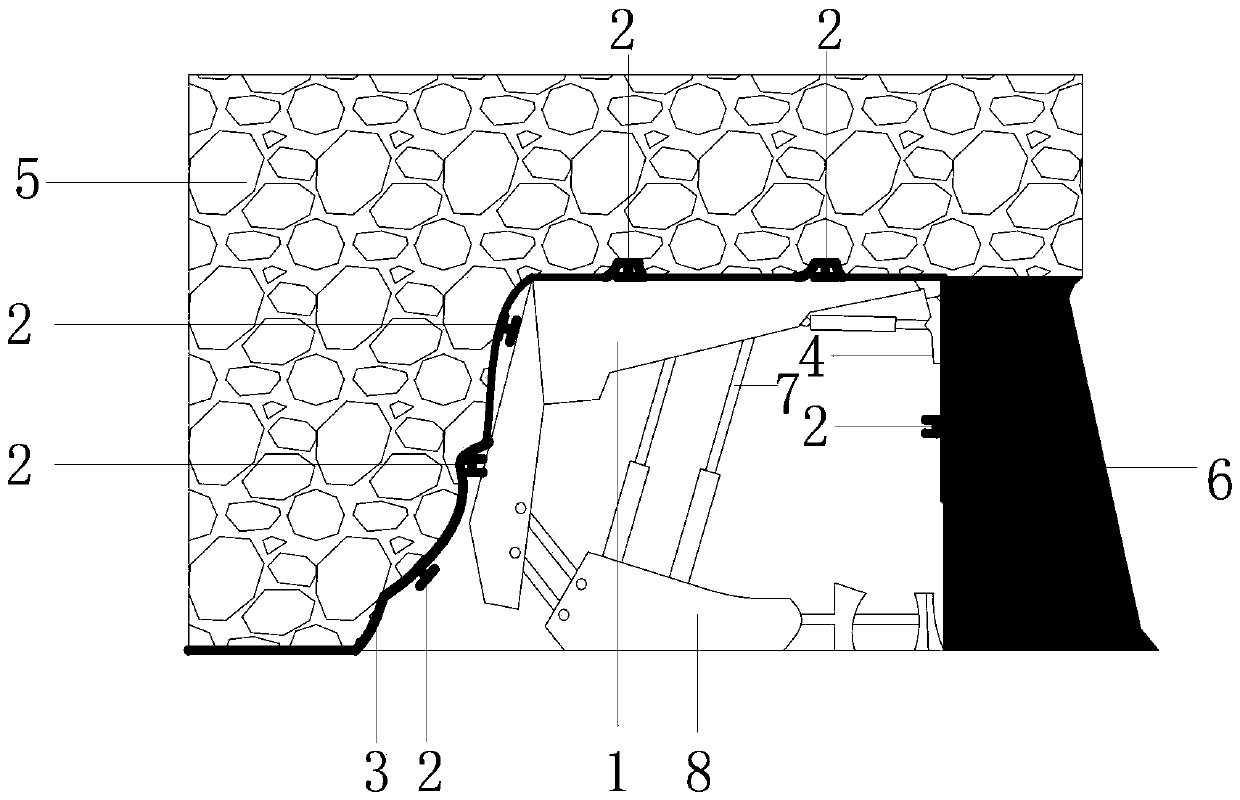

[0013] The present invention is a method for supporting the anti-collapse roof panel. First, when the cut hole is opened in the working face, the cut cut section roof of the entire working face is pre-laid and connected with a metal net with a fixed specification of 5.0m×1.0m. The net material is 10# iron wire, the mesh is diamond-shaped braided holes, the mesh is 0.04m×0.04m, and then the hydraulic support is installed in the cut hole, and the hydraulic support top beam is against the direct roof to ensure that the length of the connected metal mesh can hang in front of the support coal wall. And use the hydraulic support protection board against the coal wall; when laying the net, first unfold the net along the working surface, and then connect with the front net of the hydraulic support in turn. The overlap of the metal net shall not be less than 200mm, and the double strand 16# iron wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com