A super large mining height hydraulic support

A hydraulic support and mining height technology, which is applied to mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of increased difficulty in controlling the stability of the surrounding rock of the working face, low system reliability, slow response speed of the hydraulic system, etc. Achieve effective coal wall stability control measures, ensure response speed, and prevent coal wall fragmentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

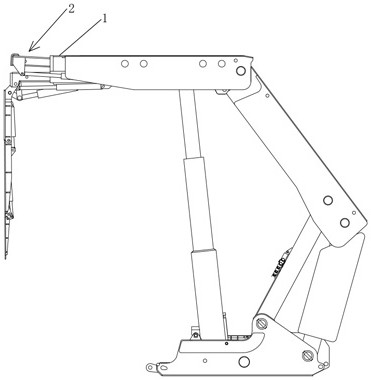

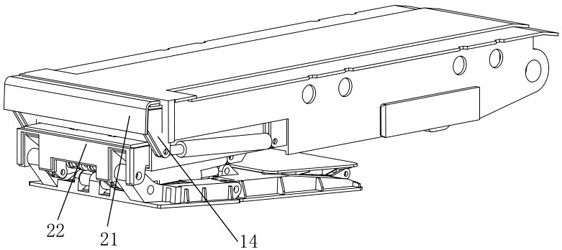

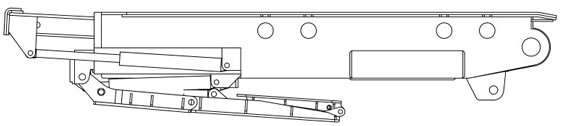

[0022] Please refer to Figure 1 to Figure 8 As shown, it is a hydraulic support for super-large mining height of the present invention, which includes a top beam 1 and a double-layer roof protection and side protection mechanism 2 installed on the top beam 1. The top beam 1 includes an upper slideway cavity 11 and a lower floor Slideway cavity 12, the upper slideway cavity 11 is several upper small cavities side by side, preferably three, and the lower slideway cavity 12 is several spaced lower small cavities, preferably two; the double-layer roof protection side Mechanism 2 includes an upper telescopic beam roof protection mechanism 21 and a three-stage side protection mechanism 22. The upper telescopic beam roof protection mechanism 21 includes an upper telescopic beam 211 slidably installed in the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com