Temporary support of hydraulic supports in excavation work

A technology of excavation work and hydraulic support, which is applied in the field of excavation construction work, timely support hydraulic support for excavation work, and coal mine machinery and equipment to achieve the effect of facilitating smooth frame removal, strengthening protection, and preventing roof caving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

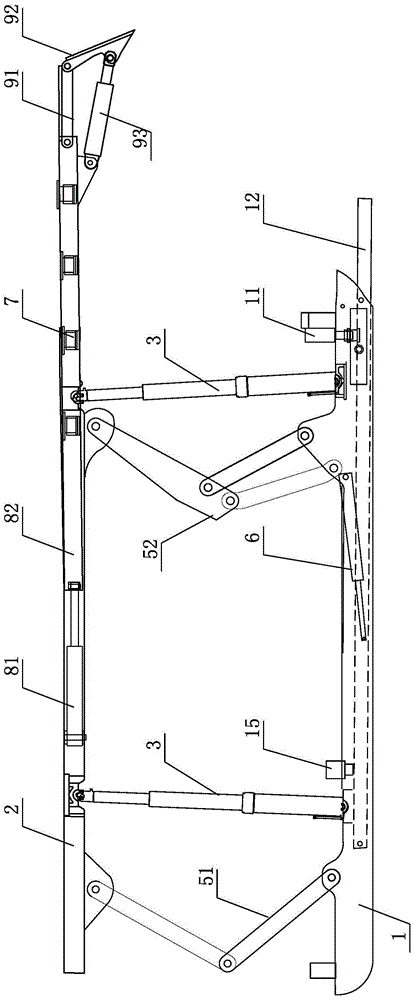

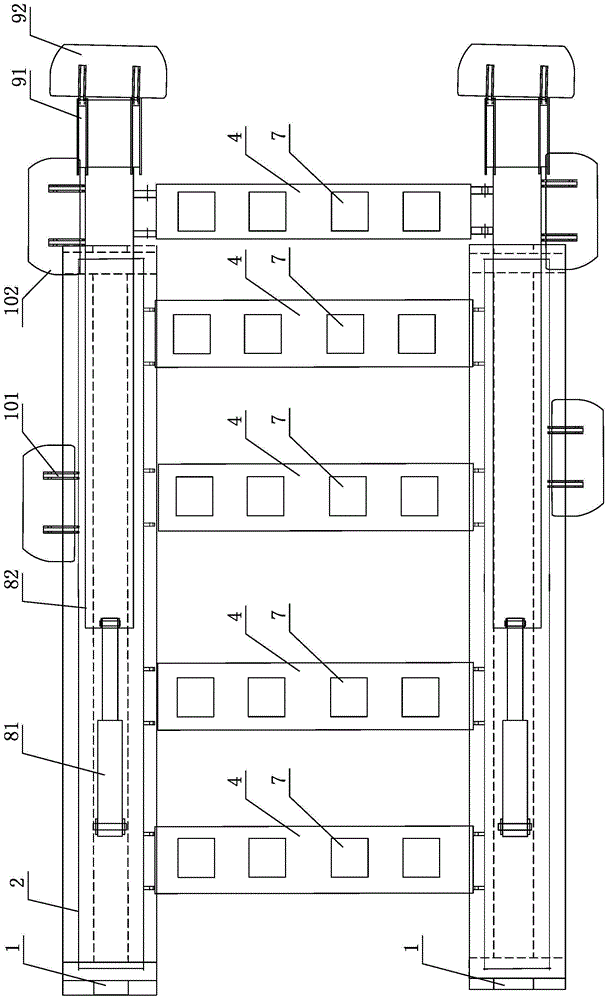

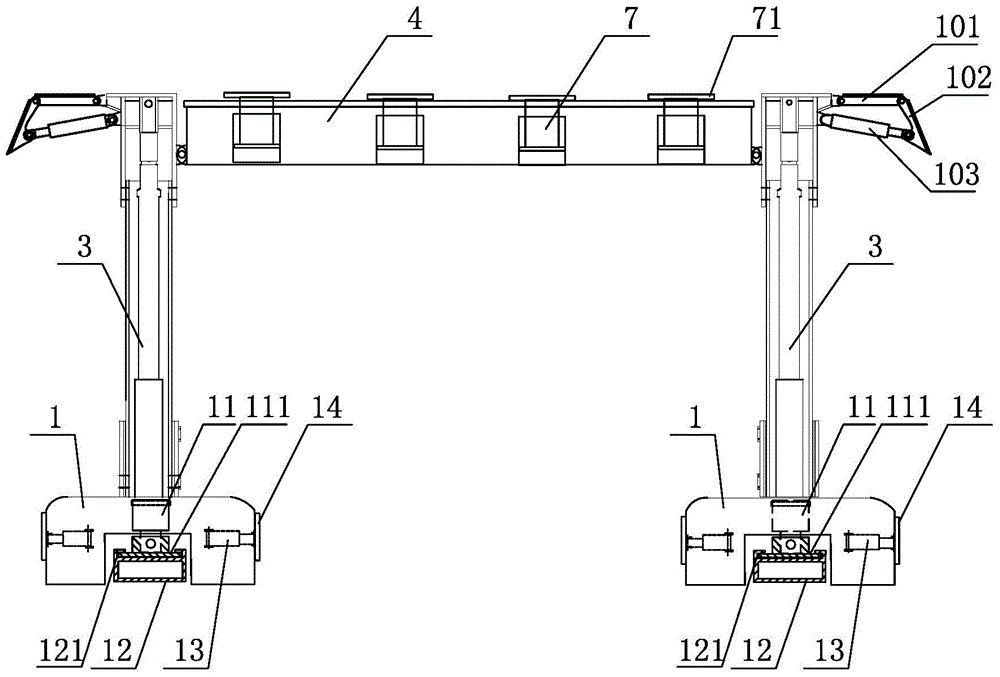

[0028] Such as figure 1 , figure 2 and image 3 As shown, the excavation working face of the present embodiment supports the hydraulic support in time and includes a protective top beam 4 and two longitudinal load-bearing structures respectively arranged on the left and right sides of the protective top beam 4; each longitudinal load-bearing structure includes a longitudinal load-bearing top beam 2. The base 1, the hydraulic support column 3 connecting the longitudinal load-bearing top beam 2 and the base 1 and the load-bearing top beam stabilization mechanism, that is, the two-bar mechanism 51 and the four-bar linkage mechanism 52; the protective top beam 4 is connected to the longitudinal load-bearing top beam 2 And fix the relative position between the two longitudinal bearing structures. Such as image 3 and Figure 4 As shown, wherein, the cross-section of the base 1 is in the shape of a groove opening downwards, and when the excavation work is being carried out, the...

Embodiment 2

[0048] The second embodiment is basically on the basis of the first embodiment, and the excavation work face is set up in groups at the front and rear of the temporary support hydraulic supports.

[0049] The first setting method of Embodiment 2: each excavation working face set at the front and back is independent of the temporary support hydraulic supports, that is, the lifting base device and the pushing cylinder of each hydraulic support are independent, and the lifting base and moving cylinder of each hydraulic support are independent. The racking process is the same as that in Embodiment 1, and will not be illustrated or described in detail here.

[0050] The second setting method of Embodiment 2: such as Figure 5 and Figure 6 As shown, the rear end of the bottom-lifting support plate 12 of the previous excavation work face and the time-supporting hydraulic support is hingedly connected with the front end of the bottom-lift support plate 12 of the back excavation work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com