Installation of hydraulic support and frame adjustment device for eye cutting in fully mechanized fully mechanized caving coal mining face

A technology for coal mining face and hydraulic support, which is applied to pillars/supports, mining equipment, earth-moving drilling, etc., can solve the problems of low work efficiency and restricting the installation progress of the working face, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

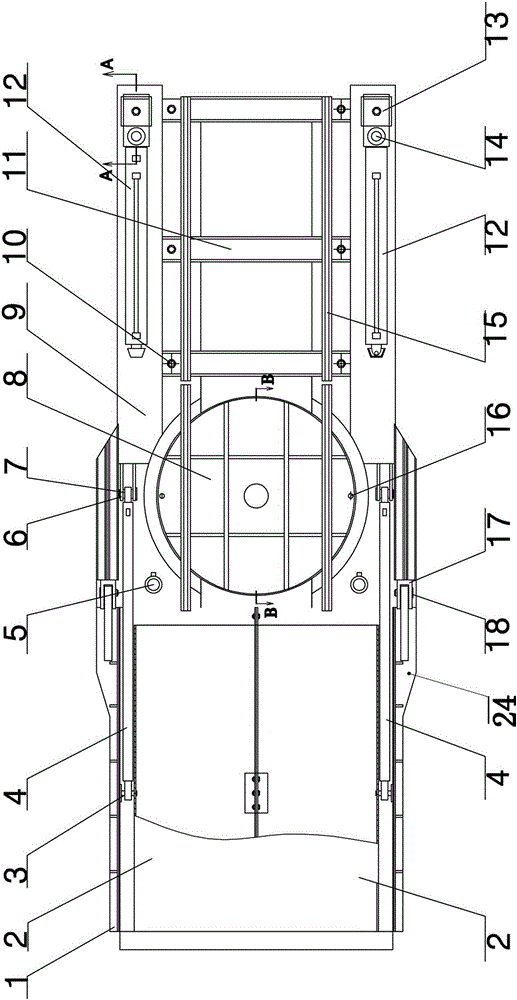

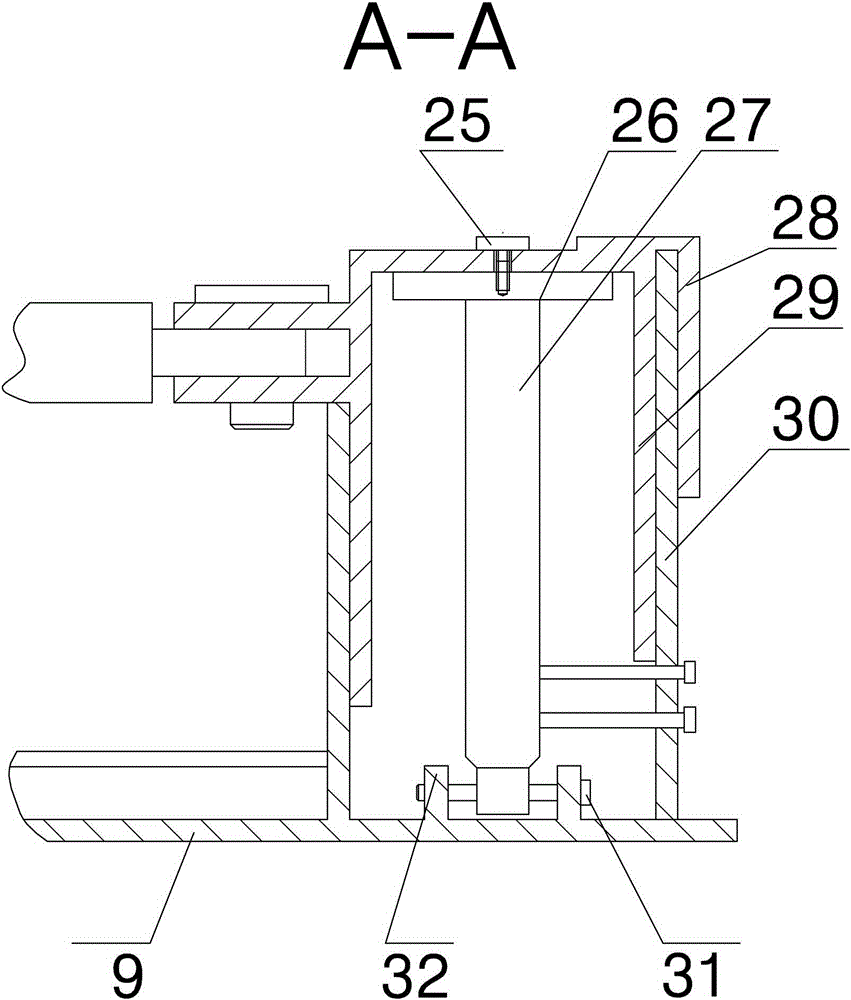

[0034] Embodiment 1: The design diameter of the turntable 8 is 1.5m, which meets the requirement of a wheelbase of 1.1m for a flatbed truck. The ball rolling elements are arranged in a dispersed manner and have a large load-carrying capacity. 8 is hugged tightly by chassis 9, easy to install, accurate in positioning.

Embodiment 2

[0035] Embodiment 2: The pushing seat 13 is telescopic, and the minimum height does not exceed the flatbed car. The connecting jack can be rotated 45 degrees outward horizontally to avoid interference with the support when it rotates;

Embodiment 3

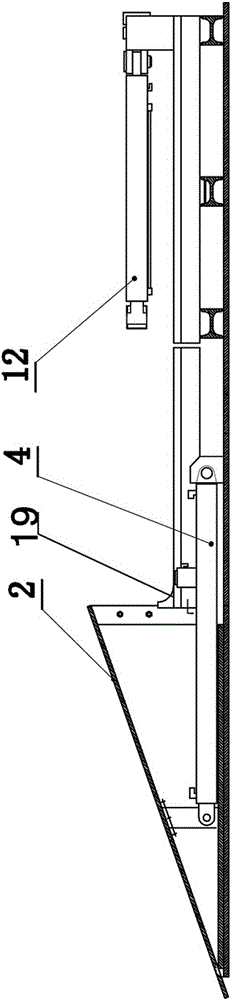

[0036] Embodiment 3: Transition platform 2 and transition platform guide groove 1: Transition platform 2 is 2.1m long, 2m wide, and 0.55m high. It has a split structure and can be disassembled into two parts to facilitate going into the well. The jack 4 is pushed through the transition table to realize expansion and contraction in the guide groove 1 of the transition table, which meets the requirements of the support entering the turntable and unloading, and at the same time can adjust the support to realize the self-moving function of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com