A self-moving drilling site gangue extraction device

A self-moving, drilling field technology, used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of low labor efficiency, high labor intensity of employees, and high labor consumption, and achieve simple installation procedures and improve gangue efficiency. , the effect of reducing the intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

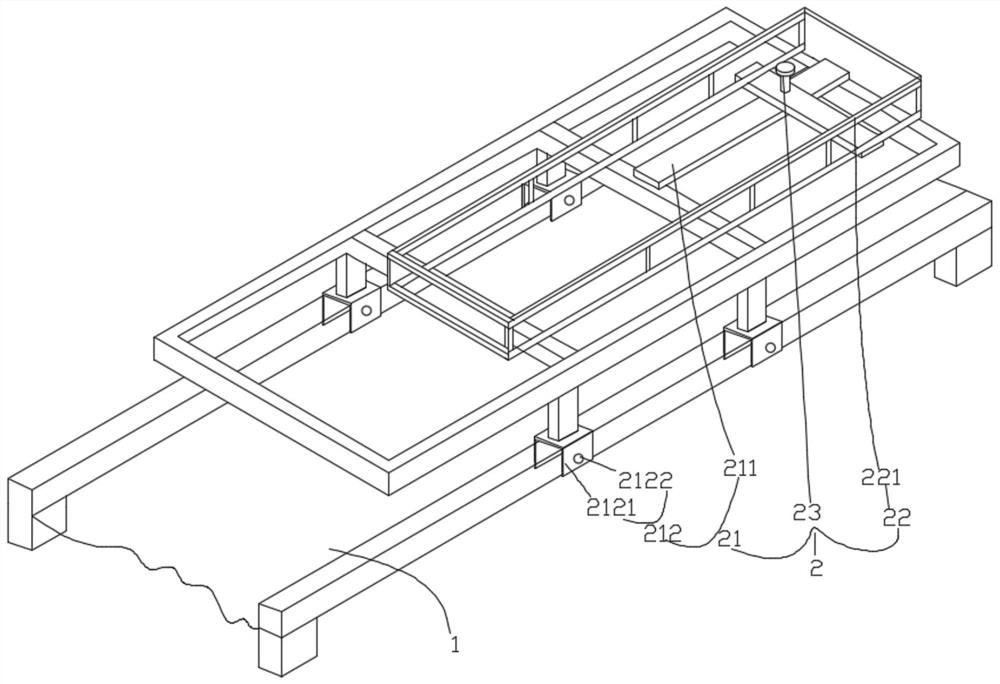

[0047] Such as figure 1 As shown, a self-moving drilling site gangue extraction device includes a belt conveyor 1 and a gangue extraction device 2, and the gangue extraction device 2 is arranged at the tail of the belt conveyor 1;

[0048] The gangue-discharging device 2 includes a mounting bracket 21, a gangue-discharging conveyor 22 and a connector 23. The mounting bracket 21 is erected at the tail of the belt conveyor 1, and the gangue-discharging conveyor 22 is installed on the mounting bracket 21 through the connector 23, and the gangue-discharging conveying The width of the machine 22 is less than or equal to the width of the mounting bracket 21 . The gangue conveyor 22 includes a frame 221 and a gangue belt, and the gangue belt is arranged above the frame 221 .

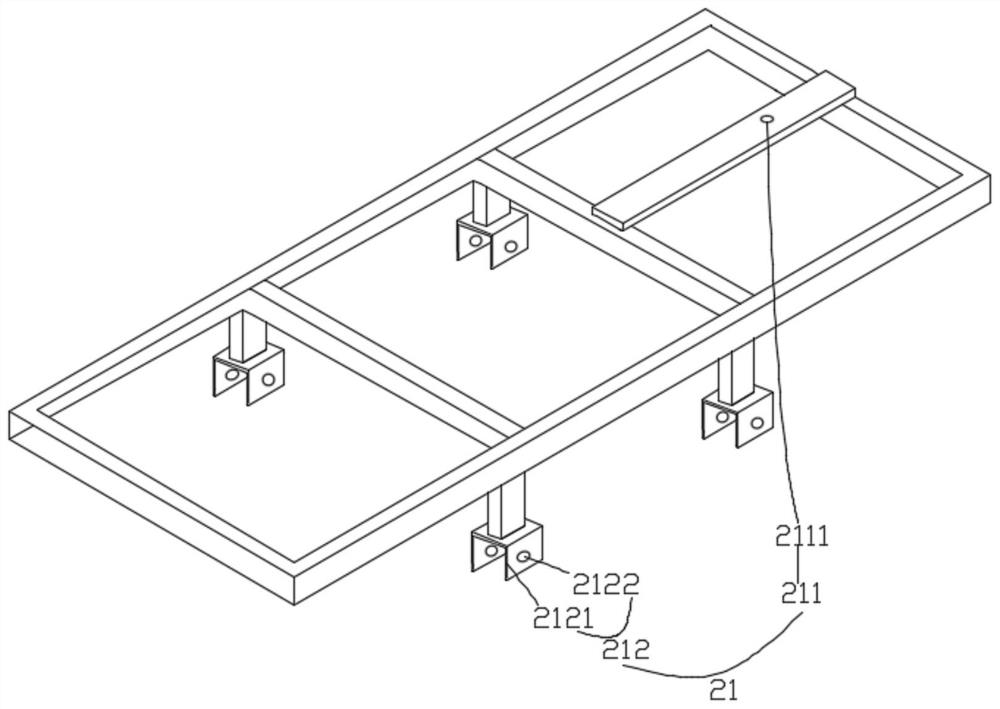

[0049] Such as figure 2 As shown, the mounting bracket 21 is a frame hollow structure, the bottom of the mounting bracket 21 is provided with a mounting leg 212, and the bottom of the mounting leg 212 is pro...

Embodiment 2

[0056] On the basis of Example 1, through 10cm

[0057] Further, L2=L3, that is, the connecting piece 23 is arranged on the horizontal midline of the installation bracket 21 .

Embodiment 3

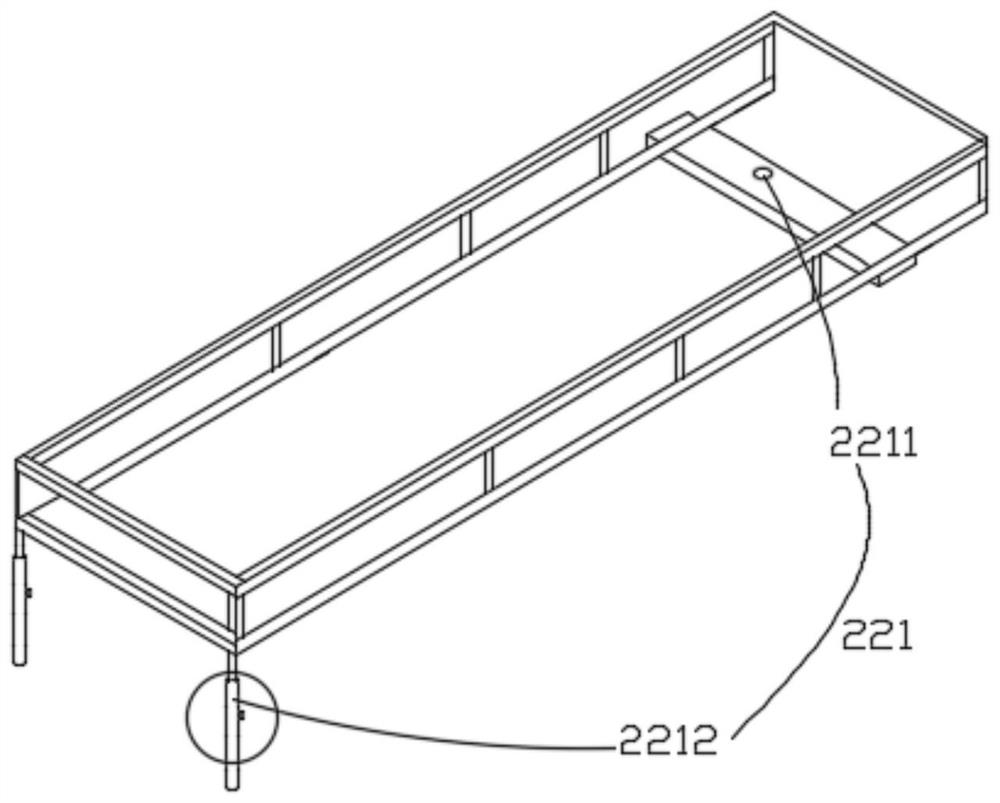

[0059] Such as image 3 with Figure 7 As shown, the frame 1 is provided with a foldable support leg 2212 near the bottom, and the bottom of the frame 221 is provided with a support leg placement groove 2213, and the support leg placement groove 2213 is used to place the folded support leg 2212. When discharging gangue, the gangue conveyor 21 is rotated to a suitable position by adjusting the connecting piece 23, and the supporting leg 2212 in the supporting leg placement groove 2213 is taken out, and the frame 221 not only fixes and supports the output end through the connecting piece 23 in the installation On the support 21, the input end of the frame 221 is supported by the supporting legs 2212 at the same time, so as to improve the stability of the gangue-discharging device. When the use of the gangue-discharging device is finished, the supporting legs 2212 are folded and placed in the supporting-leg placement groove 2213, so as to reduce the occupied space of the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com