Patents

Literature

78results about How to "Reduce the number of repetitions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

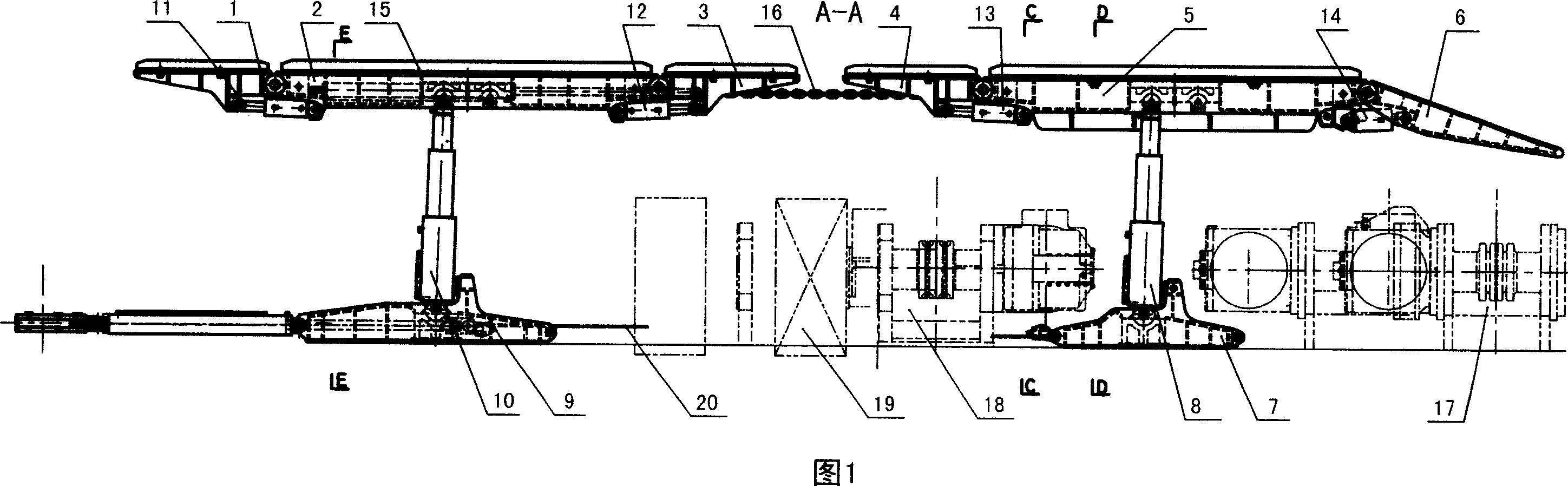

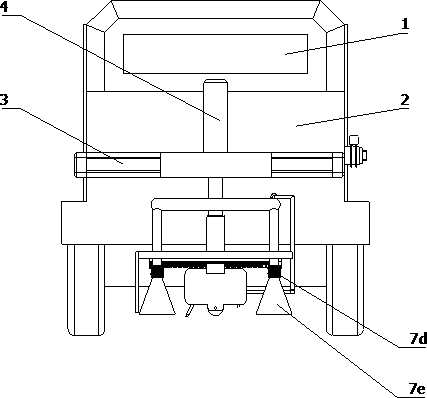

Fully mechanized working faces along conveying end head bracket

InactiveCN101096911AImprove stabilityImprove support strengthMine roof supportsEngineeringTrailing edge

The invention discloses a working face transferring end fluid pressure brace, which is characterized by the following: comprising with front brace support and back brace support to front back two braces as one group type; setting the front brace and the back brace as left right asymmetric structure and nearly same; setting the working face side as short chassis and single stud; setting another side as long chassis, multiple stud and four joint rod device; connecting the top beam on the back brace working face side and the chassis through cable or ring chain, draw top beam or draw shift jack to the front brace or transfer machine; adapting the front and back space of the back brace single stud to the width between the rear edge transferring machine head and the coal getting machine roller front end face; setting anchor bar tendon avoiding protection device at the top beam and front back beam. This brace can increase protection strength and stability.

Owner:兖矿能源集团股份有限公司

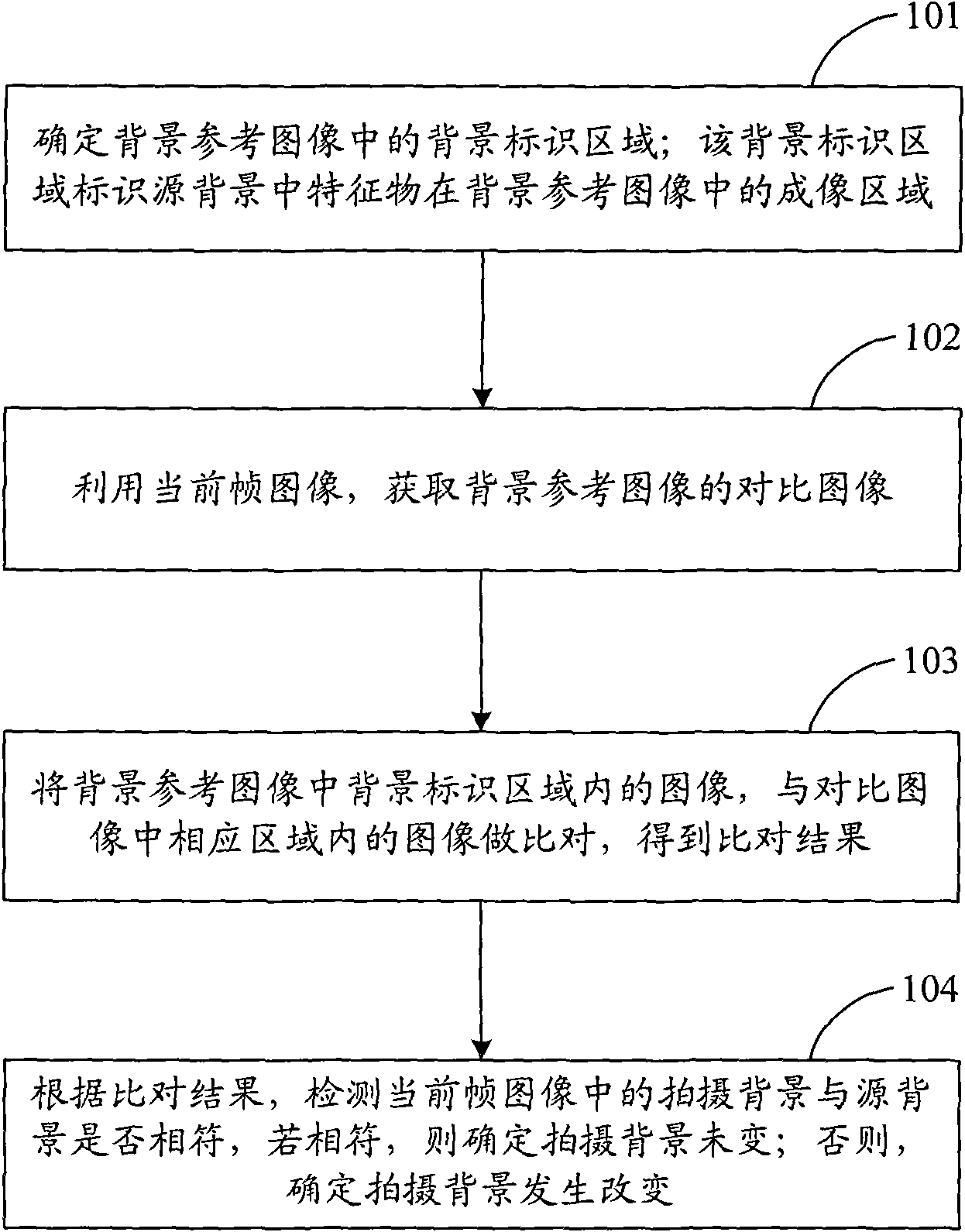

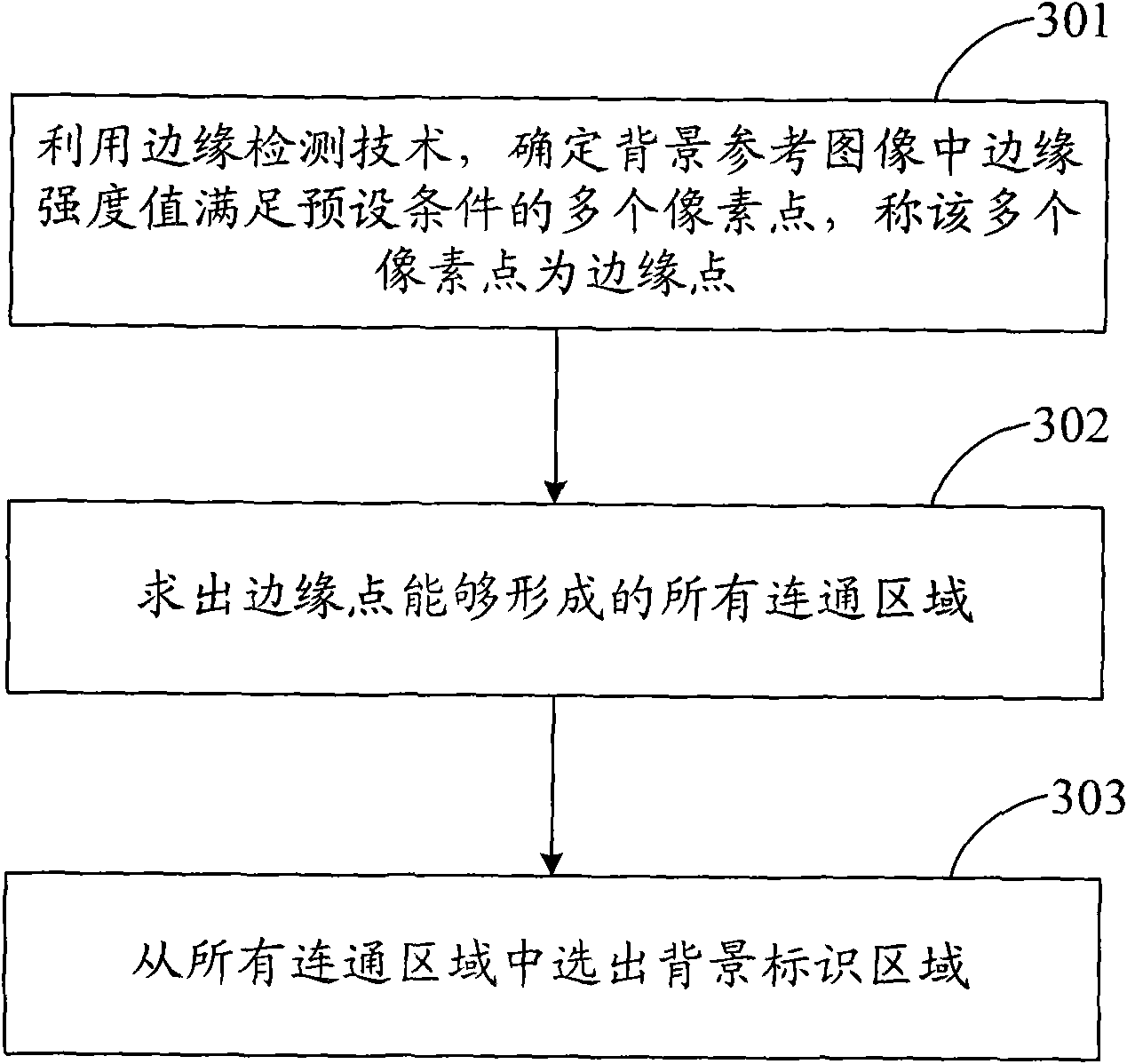

Detection method for determining alteration of shooting background and image processing device

ActiveCN101599175AHigh precisionImprove accuracyTelevision system detailsImage analysisImaging processingReference image

The invention provides a detection method for determining alteration of shooting background and an image processing device; wherein the method comprises the following steps: determining a background identification area in a background reference image; identifying an imaging area of a feature in source background in the background reference image by the background identification area; using the current frame image to obtain a contrast image of the background reference image; contrasting an image in the background identification area in the background reference image with the image in corresponding area in the contrast image to obtain a contrast result; according to the contrast result, detecting whether the shooting background in the current frame image conforms to the source background, if yes, determining the shooting background unaltered; otherwise, determining the shooting background altered. The technical proposal provided by the embodiment of the invention can effectively reduce the false detection probability on whether the shooting background is alters or not.

Owner:VIMICRO ELECTRONICS CORP

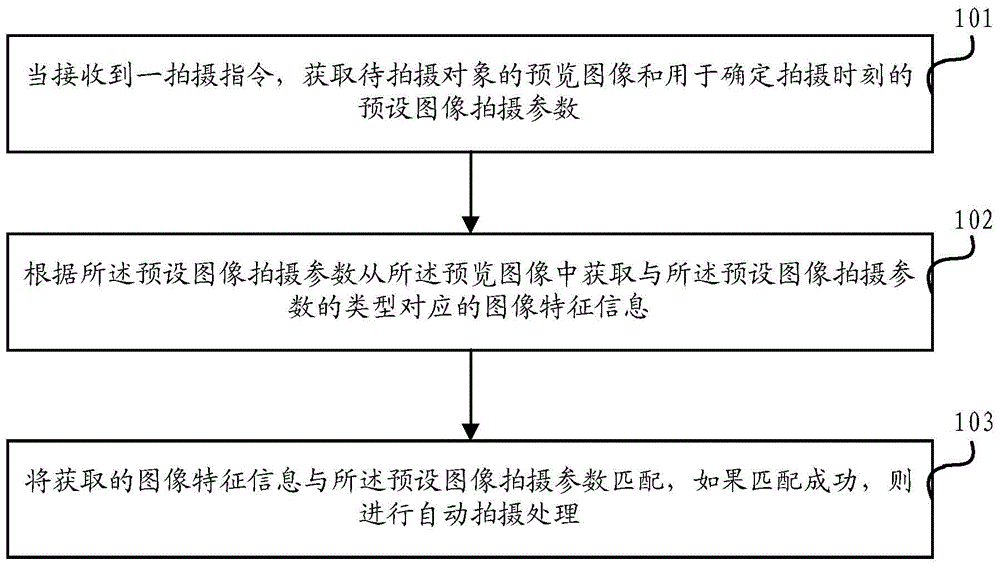

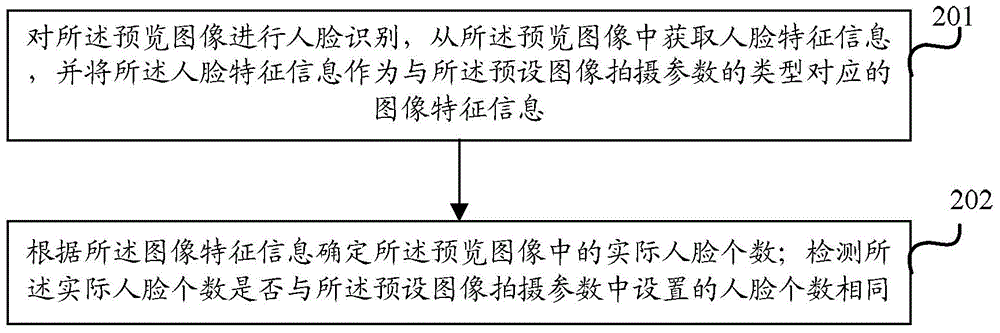

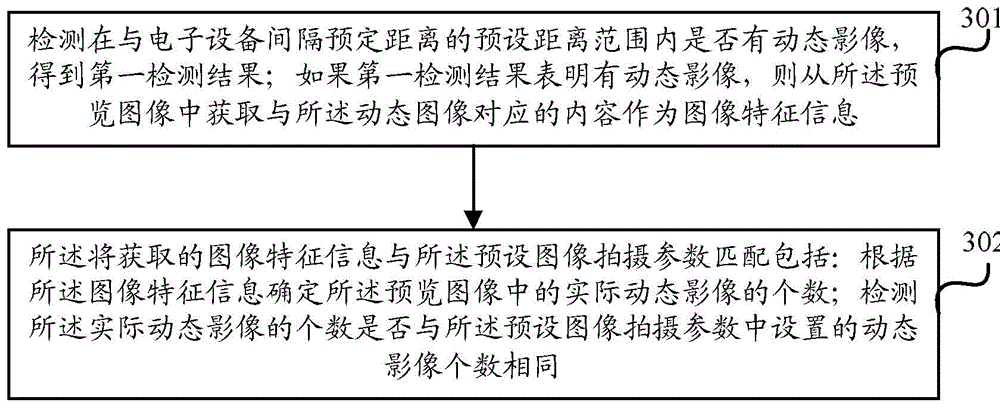

Information processing method and electronic device

InactiveCN104427238AReduce the number of repetitionsReduce energy consumptionTelevision system detailsColor television detailsComputer visionComputer graphics (images)

The invention discloses an information processing method and an electronic device. The method comprises the steps of acquiring a preview image of a target to be photographed by the electronic device and a preset image photographing parameter for determining a photogram time when a photographing instruction is received; acquiring image characteristic information corresponding to a type of the preset image photographing parameter from the preview image according to the preset image photographing parameter; matching the acquired image characteristic information with the preset image photographing parameter, and carrying out the automatic photography if the acquired image characteristic information is successfully matched with the preset image photographing parameter. According to the method and device, the automatic photographing time is determined according to the characteristic information in the preview image, so that the current situation of the photographed target can be more intelligently adapted, and the repeated operating times of the automatic photographing can be reduced.

Owner:LENOVO (BEIJING) CO LTD

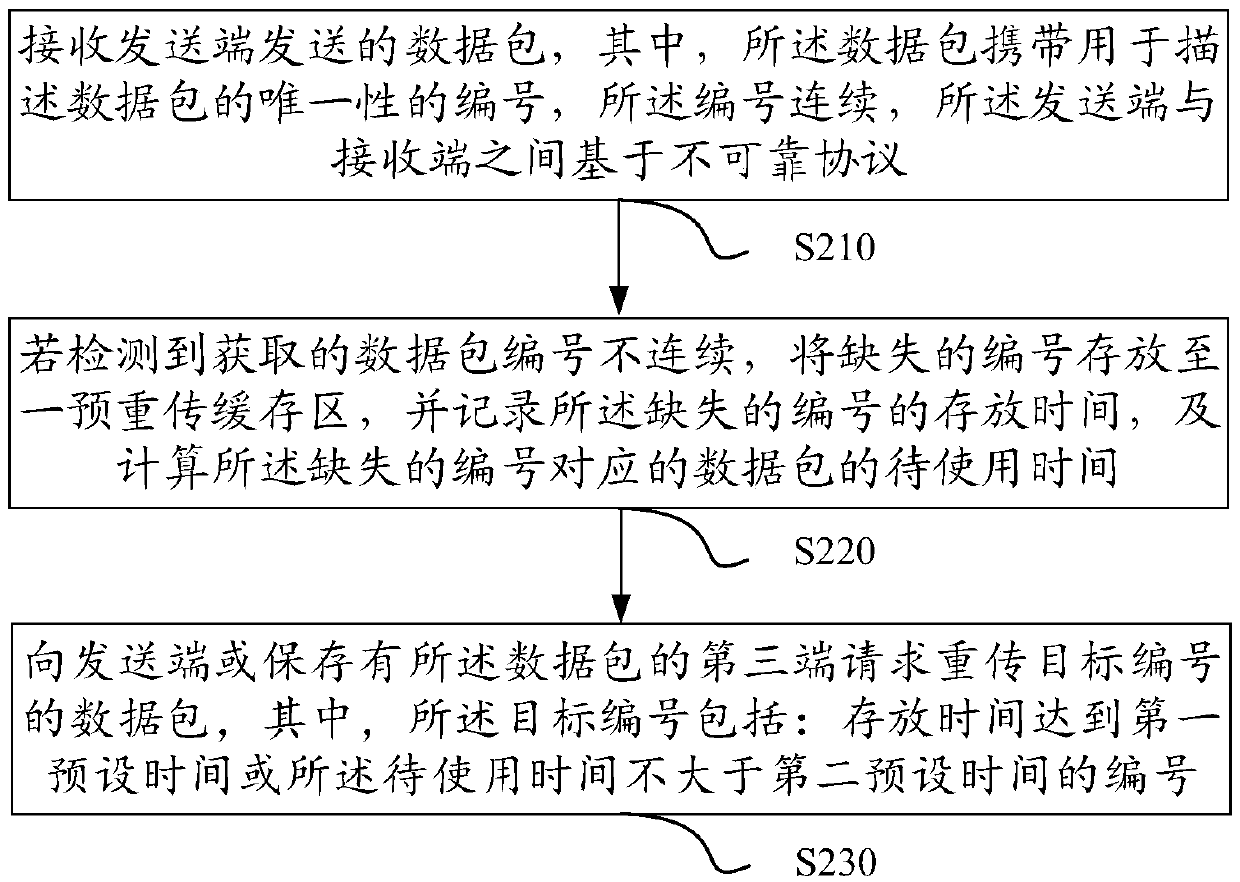

Data retransmission method and device, terminal equipment and storage medium

ActiveCN109560901AUse impactReduce the number of repetitionsError prevention/detection by using return channelNetwork packetSerial code

The invention discloses a data retransmission method, a data retransmission device, terminal equipment and a storage medium. The data retransmission method is applied to a receiving end, and comprisesthe steps of: receiving data packets transmitted by a transmitting end, wherein each data packet carries a serial number used for describing the uniqueness of the data packet, the serial numbers areconsecutive, and the receiving end and the transmitting end are based on an unreliable protocol; storing a missed serial number in a pre-retransmission cache region when detecting that the serial numbers of the acquired data packets are not consecutive, recording storage time of the missed serial number and calculating to-be-used time of the data packet corresponding to the missed serial number; and requesting for retransmission of the data packet of a target serial number to the transmission end or a third end storing the data packet corresponding to the missed serial number, wherein the target serial number comprises a serial number with the storage time reaching first preset time or the to-be-used time not longer than second preset time. The data retransmission method, the data retransmission device, the terminal equipment and the storage medium aim to solve the problem of data retransmission redundancy or influence on data usage in the existing data retransmission technology.

Owner:GUANGZHOU HUYA INFORMATION TECH CO LTD

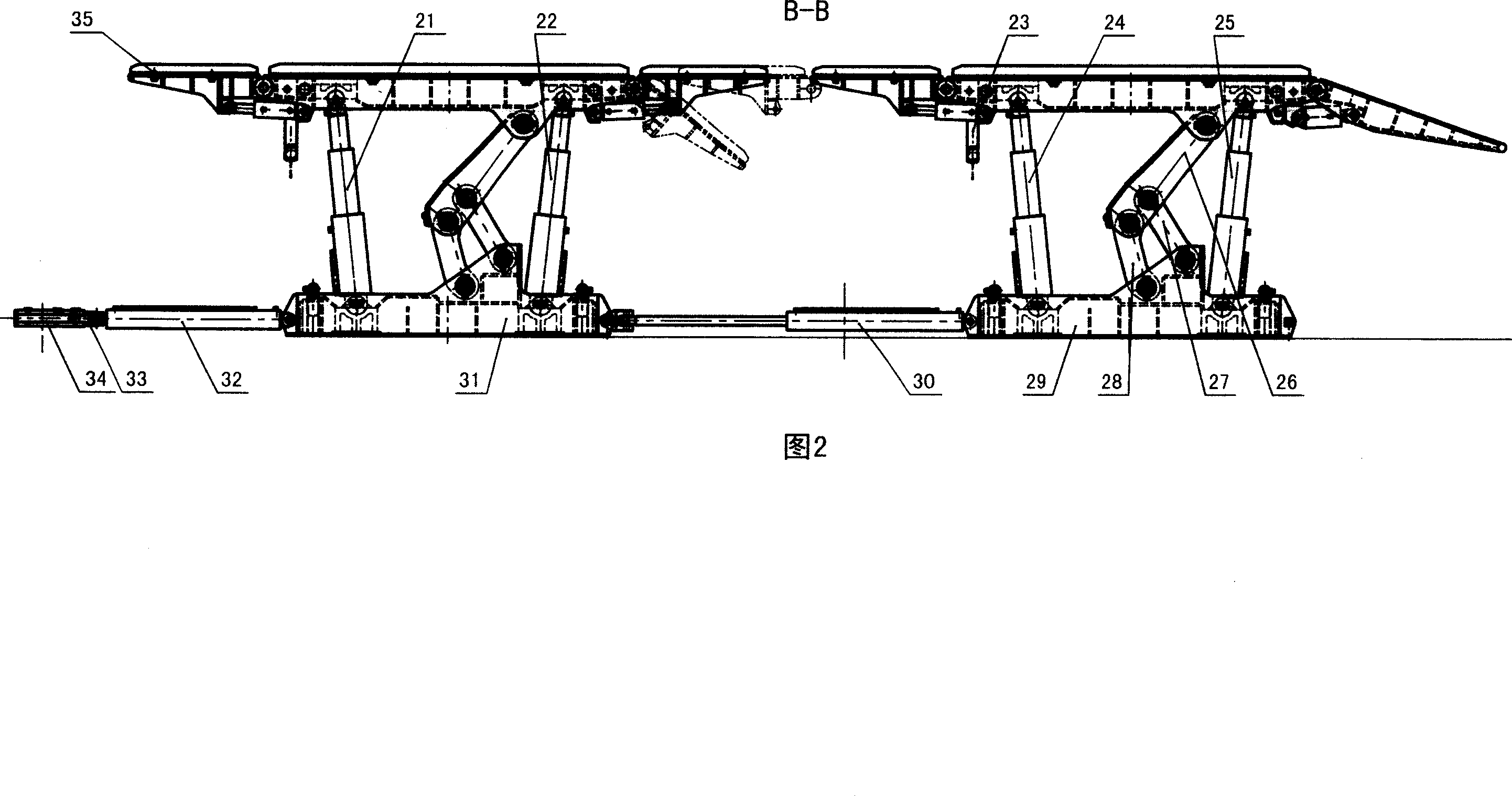

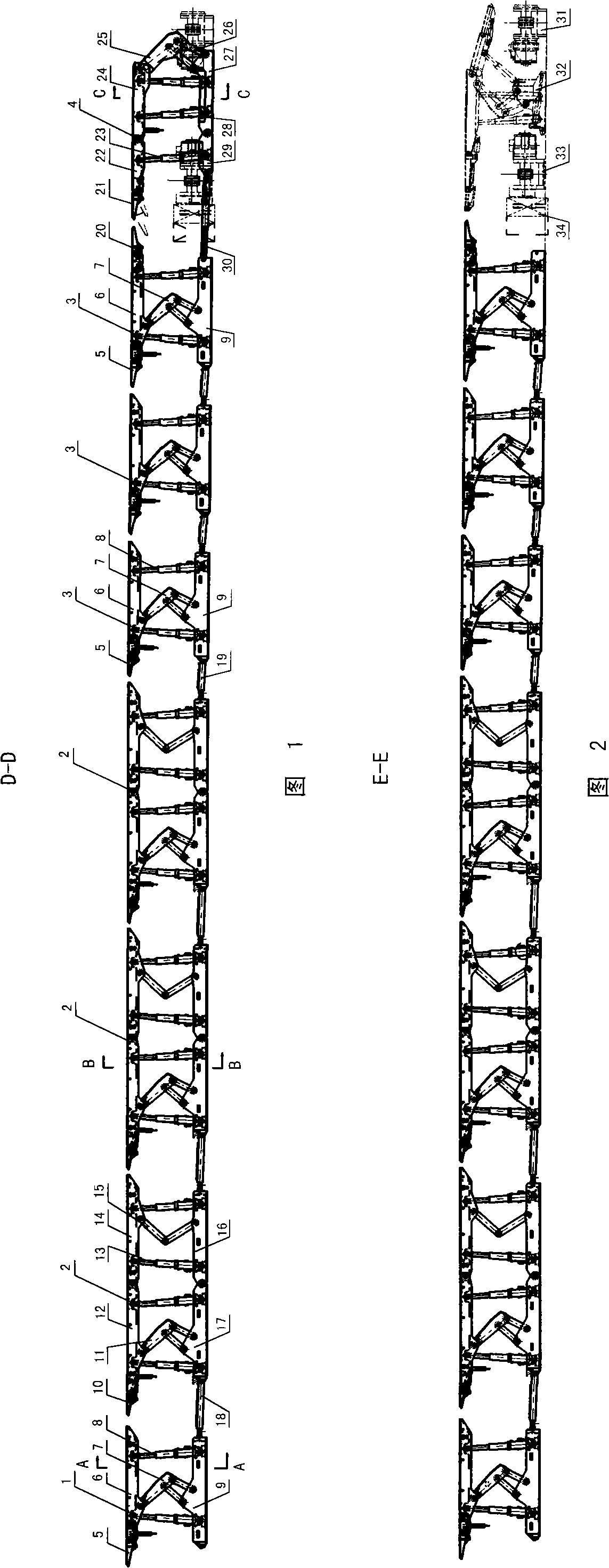

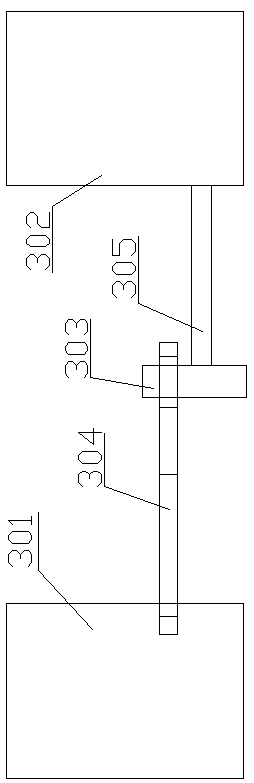

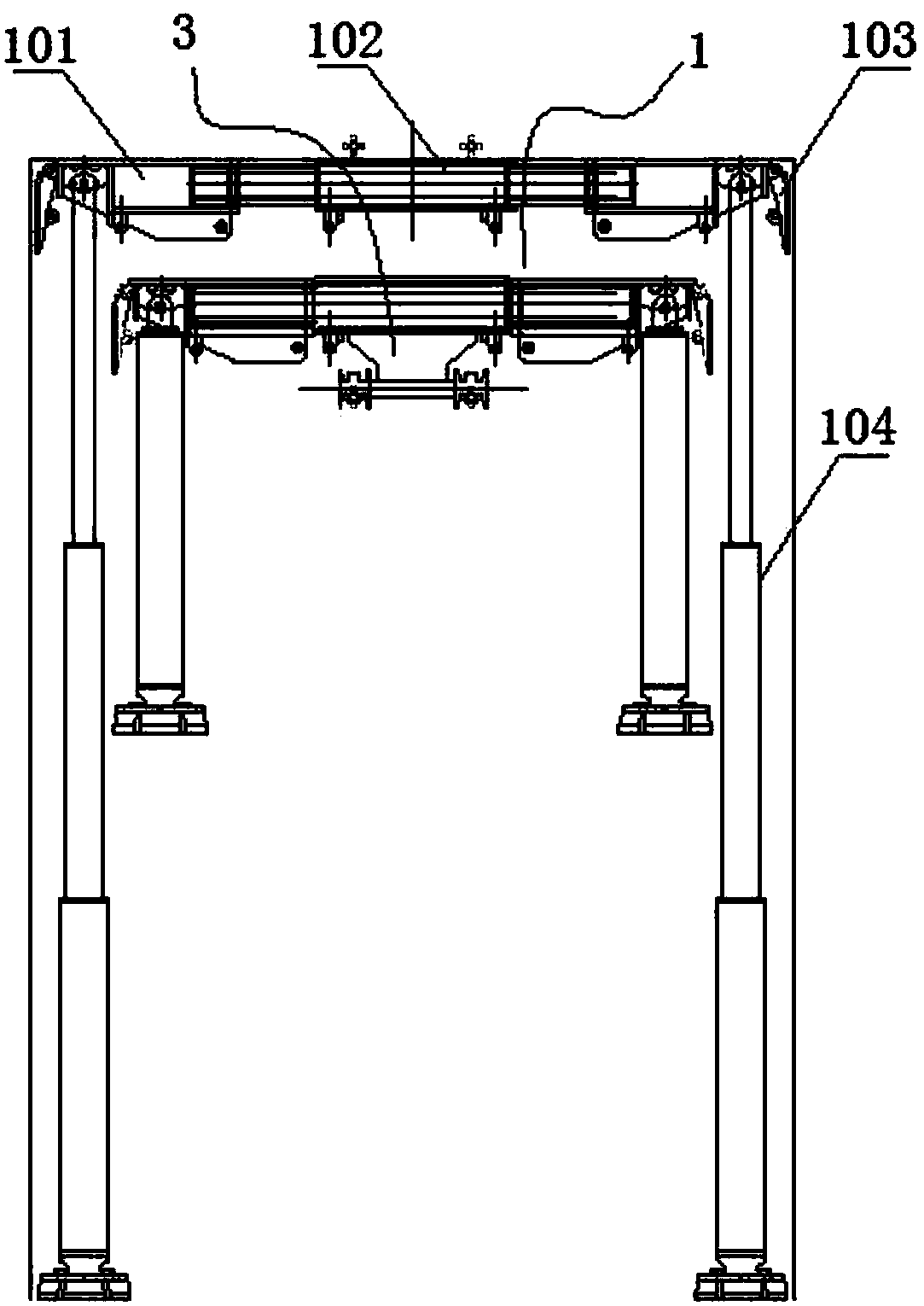

Fully mechanized caving face along-track end bracket

InactiveCN101315031AOvercoming the difficulty of changing the columnOvercome the problem of unbearable partial loadMine roof supportsSpelunkingEngineering

A face-end support for the track channel of a fully-mechanized caving face is composed of an anchor support (1), a fore support (2), a face-end support (3), and a tail-end support (4). The anchor support has a four-pillar and four-connection-rod structure and includes an internal and an external supports, wherein both the internal and the external supports are composed of a top beam, a pedestal, two pillars and a four-connection-rod mechanisms. The fore support includes 3 to 5 groups, and each group has an eight-pillar structure and includes an internal and an external supports, wherein both the internal and the external supports are composed of a hinged top beam, a hinged pedestal, four pillars, a four-connection-rod and single-swing-rod mechanism, and a forepoling beam. The face-end support includes 1 to 3 groups, and each group has a four-pillar and four-connection-rod structure and includes an internal and an external supports. The tail-end support has a six-pillar hinge beam structure. An adjusting jack is arranged between the top beams of the internal and the external supports and the pedestal of each support. The face-end support solves the problems that the anchor support has difficulty in changing the pillars and is not easy to bear offset loads and that the distance between pedestals of the internal and the external supports is not easy to be adjusted. Accordingly, the face-end support has more reasonable force bearing capacity, and can improve the support ability and the stability of the support. Two kinds of step pitch moving supports reduce repeatedly supporting. The face-end support is suitable for channels with large pressure and large deformation along hollow tracks.

Owner:兖矿能源集团股份有限公司

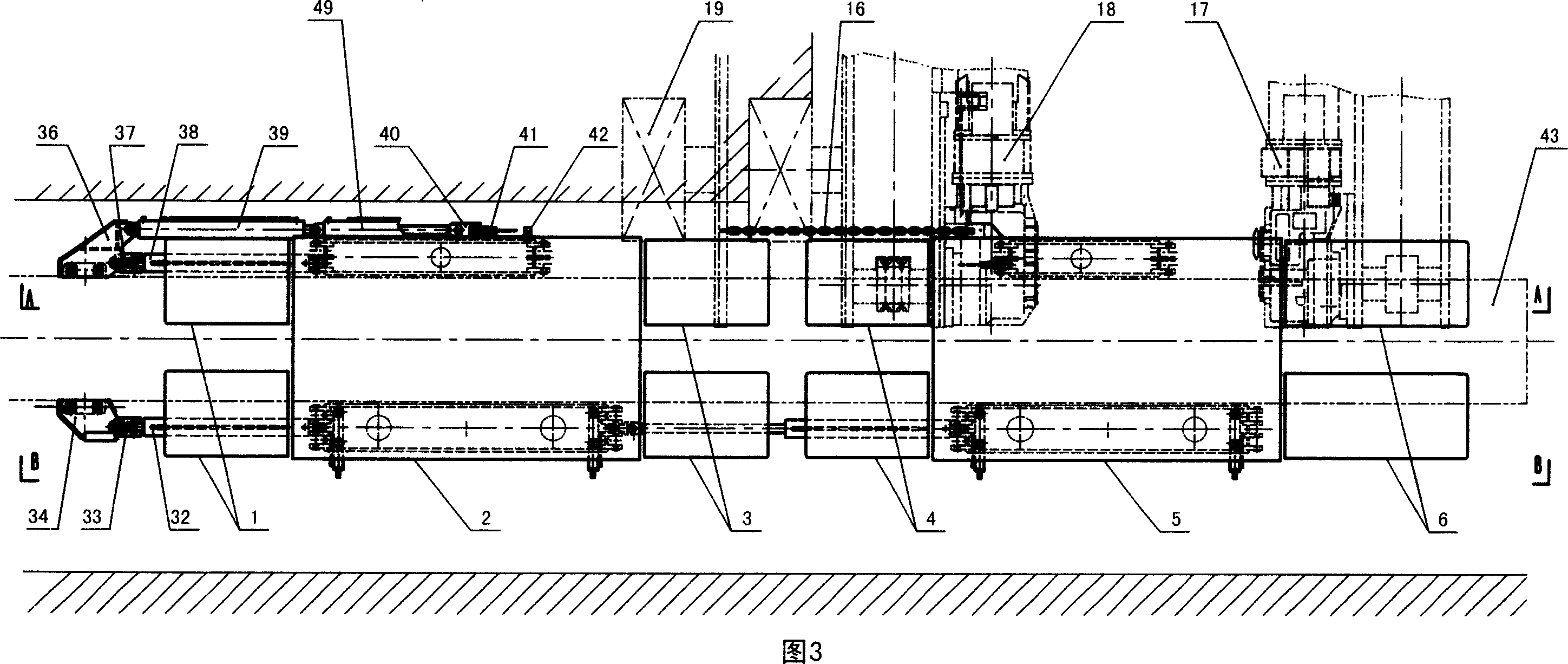

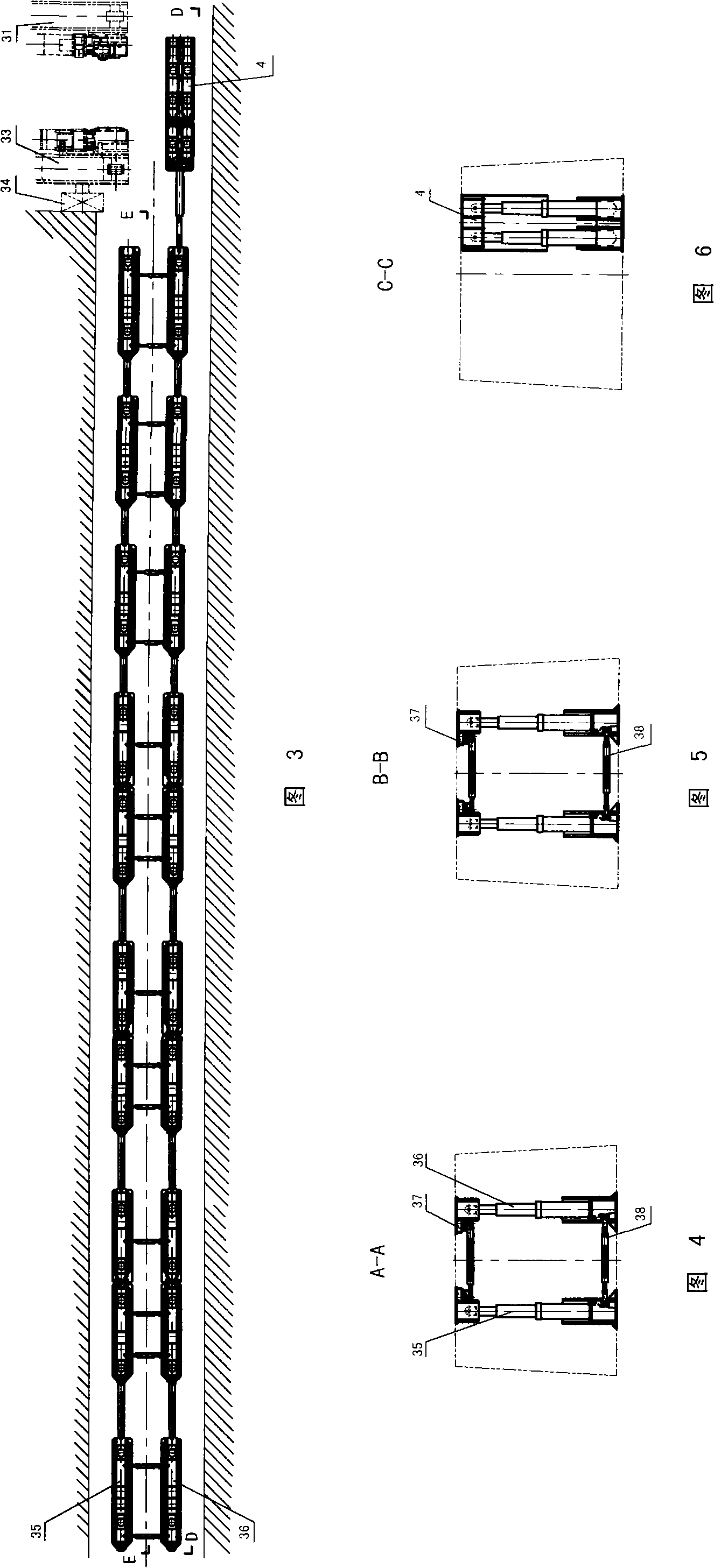

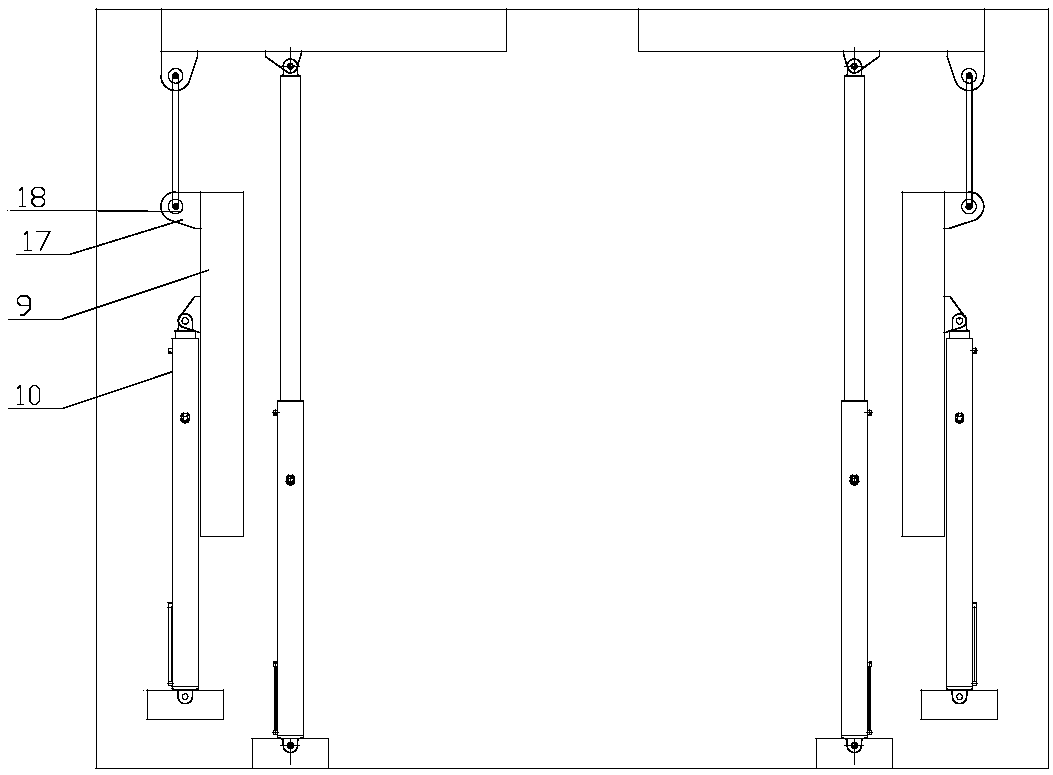

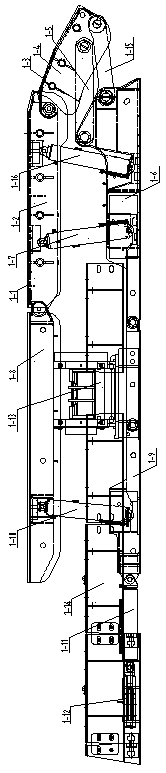

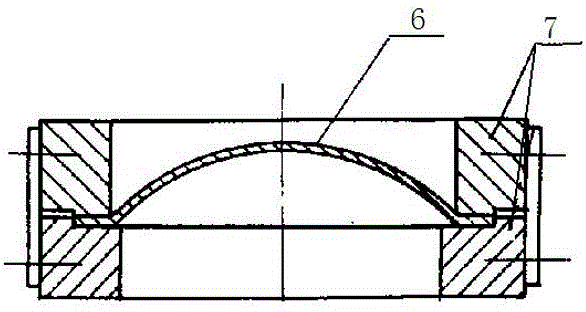

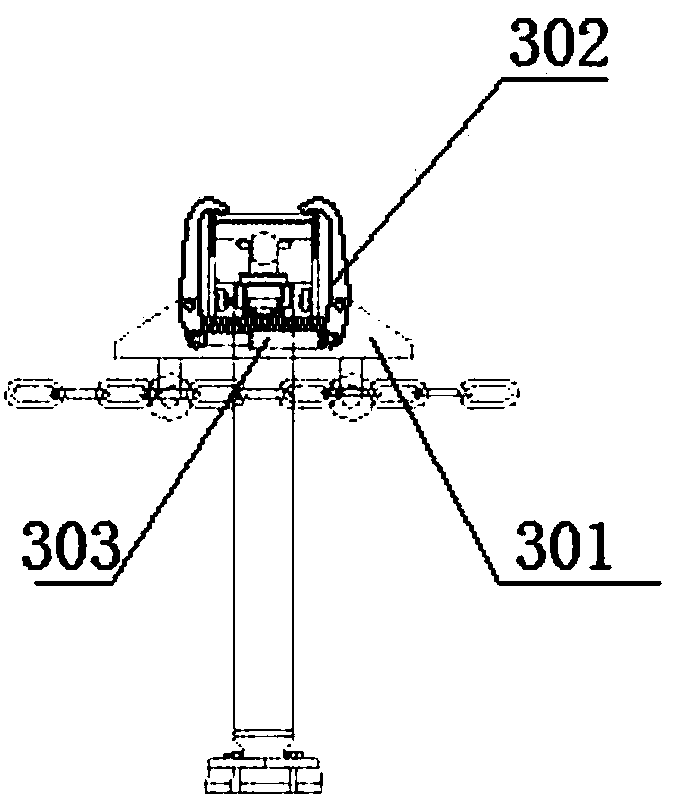

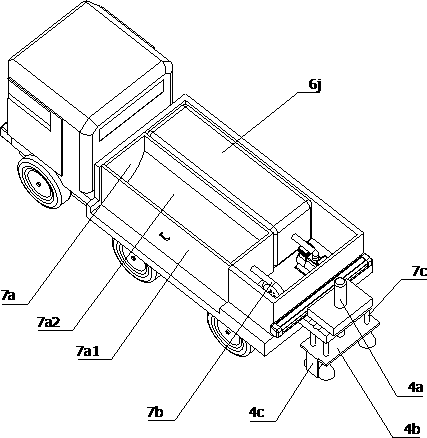

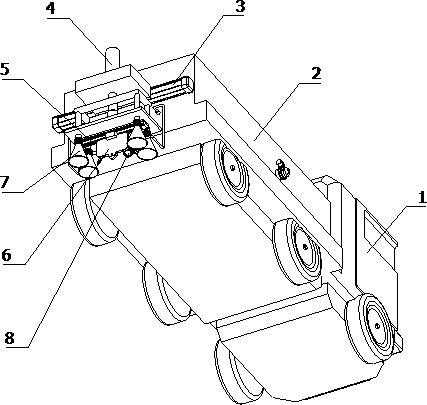

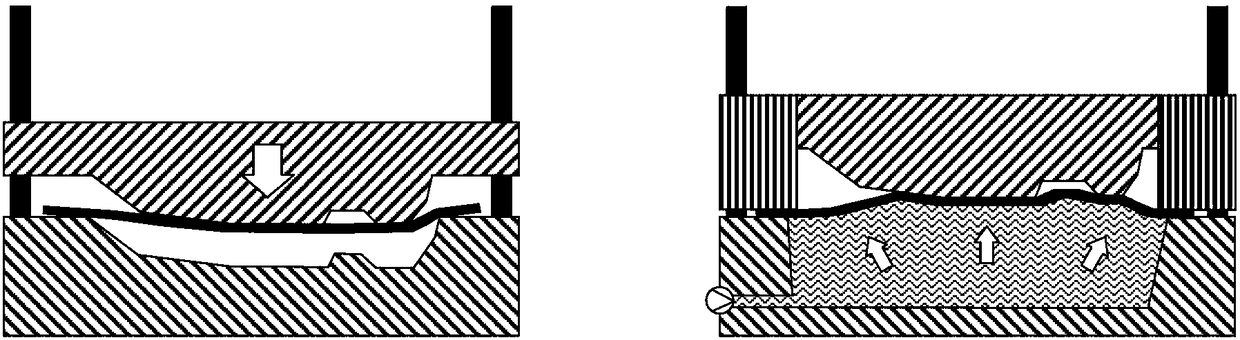

Circular self-movement type tunnel advance support hydraulic holder

ActiveCN108506034AEasy maintenanceReduce the number of repetitionsMine roof supportsEngineeringMechanical engineering

The invention discloses a circular self-movement type tunnel advance support hydraulic holder which comprises an auxiliary suspended holder, an end head hydraulic holder, supporting beam assemblies and a flexible transmission device, wherein the auxiliary suspended holder and the end head hydraulic holder are oppositely arranged, the supporting beam assembly is leveled with the auxiliary suspendedholder and the end head hydraulic holder, and the flexible transmission device is used for moving the supporting beam assemblies. The flexible transmission device comprises flexible elements, an initiative wheel and a passive wheel, wherein the initiative wheel and the passive wheel are used for driving the flexible elements. The supporting beam assemblies comprise bases, supporting beams for supporting a top plate and stand columns, wherein the stand columns are arranged on the bases and are used for lifting the supporting beams, and the stand columns are hinged with the supporting beams. Lifting lugs are arranged on the supporting beams and are matched with the flexible elements. Grooves matched with the lifting lugs for transferring the supporting beam assemblies are formed in the initiative wheel and the passive wheel. The circular self-movement type tunnel advance support hydraulic holder is fast in moving speed and convenient to operate, repeat supporting is not carried out on the top plate, practical using requirements of the tunnel can be adapted, and safe and efficient production of coal miningworking faces can be achieved.

Owner:河南国新智能科技研究院有限公司

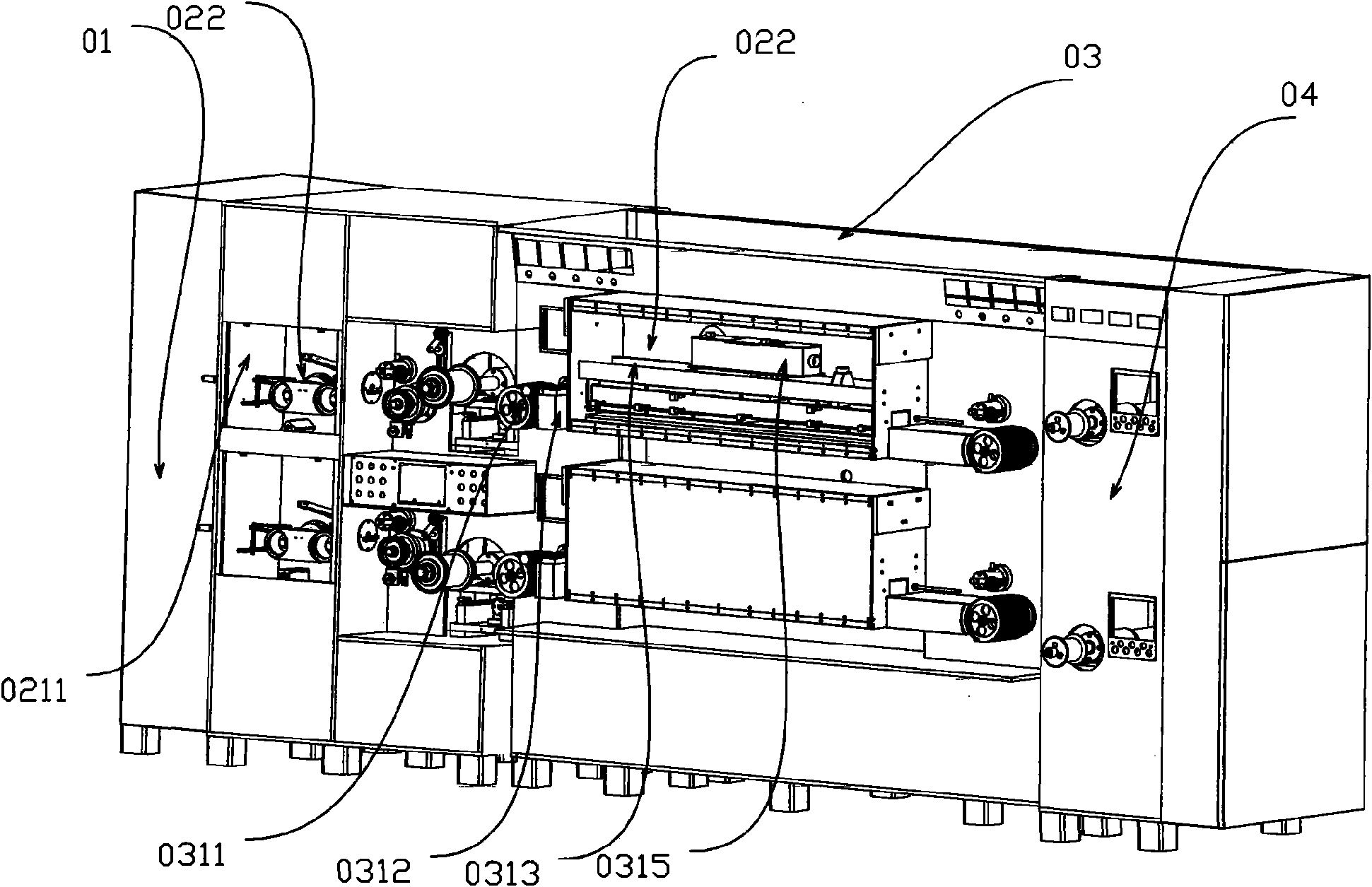

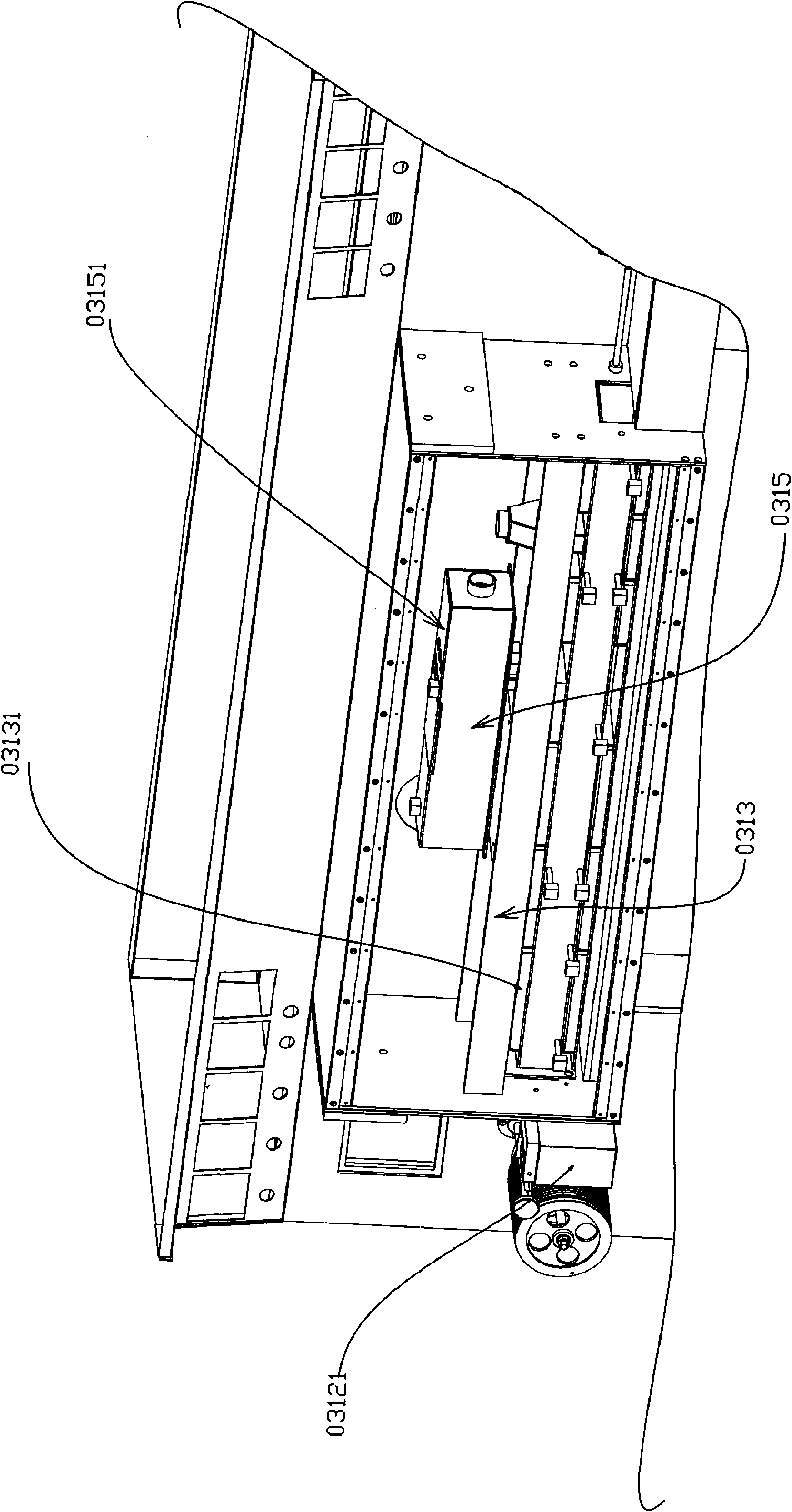

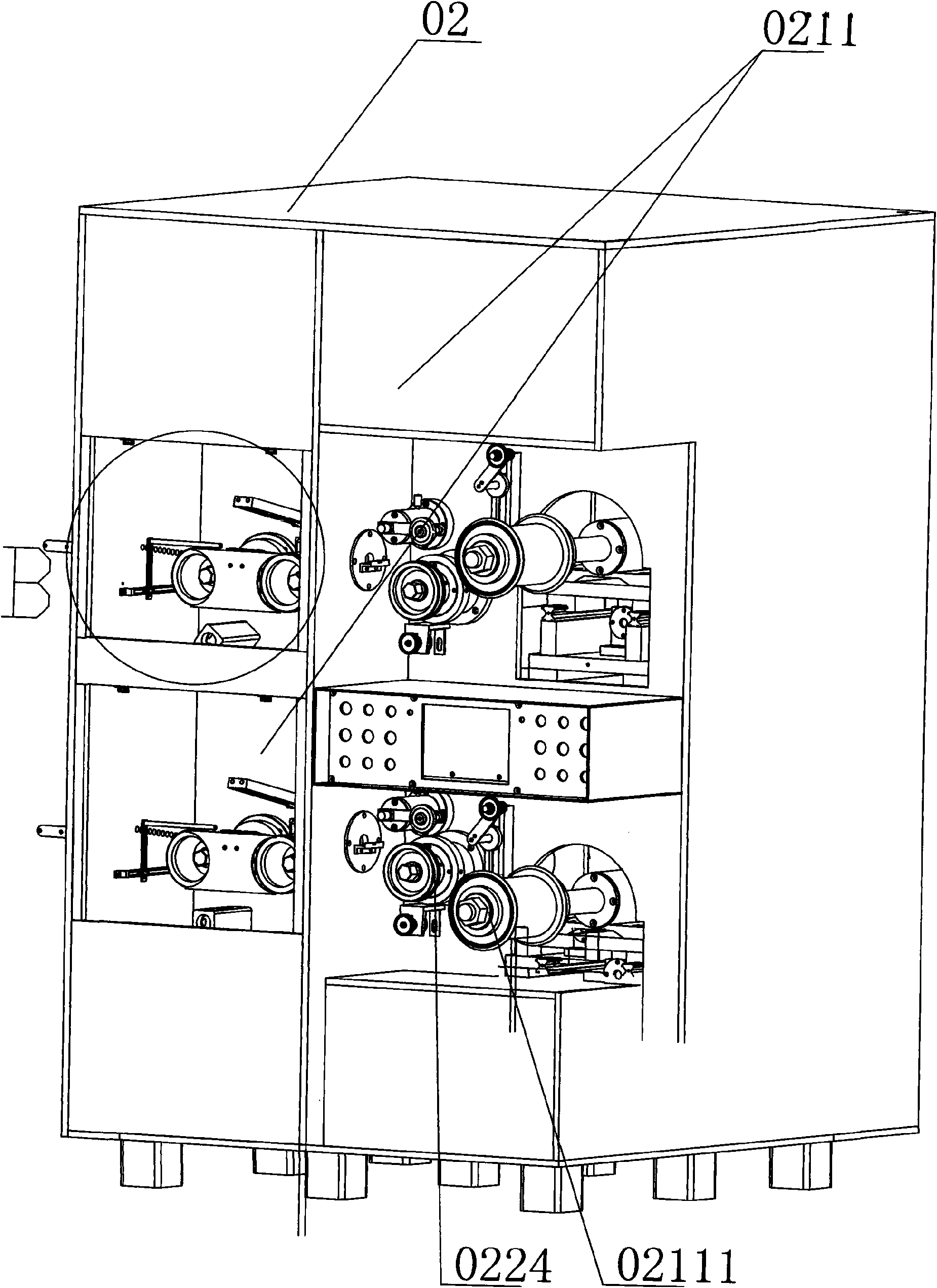

Equipment for producing bonding wire for packaging semiconductor

InactiveCN101572135AReduce volumeCompact structureLine/current collector detailsSemiconductor/solid-state device manufacturingThin metalSemiconductor package

The invention discloses equipment for producing a bonding wire for packaging a semiconductor, which comprises a wire releasing device, a wire-drawing machine, a quenching and tempering device and a take-up device, wherein a metal wire in the wire releasing device is sent to the wire-drawing machine through a leading mechanism; the wire-drawing machine is arranged on one side of a wire outlet of the wire releasing device and comprises a wire-drawing component; the metal wire led out of the leading mechanism of the wire releasing device is connected to a wire-drawing component capable of gradually drawing the outer diameter of the metal wire small; the quenching and tempering device is arranged on one side of a wire outlet of the wire-drawing machine and comprises a wire sending device, a washing device, a coating device, an annealing device and a roasting oven; a thin metal wire conforming to specifications and pulling out of the wire-drawing machine is sent to the washing device through the wire sending device; the washed metal wire enters the annealing device for annealing; the annealed metal wire enters the coating device for coating; the coated metal wire enters the roasting oven for drying and then enters a cooling device for cooling; the wire take-up device is provided with a wire containing tray for collecting a finished wire, and the wire containing tray is connected with a driving device and driven by the driving device.

Owner:袁毅

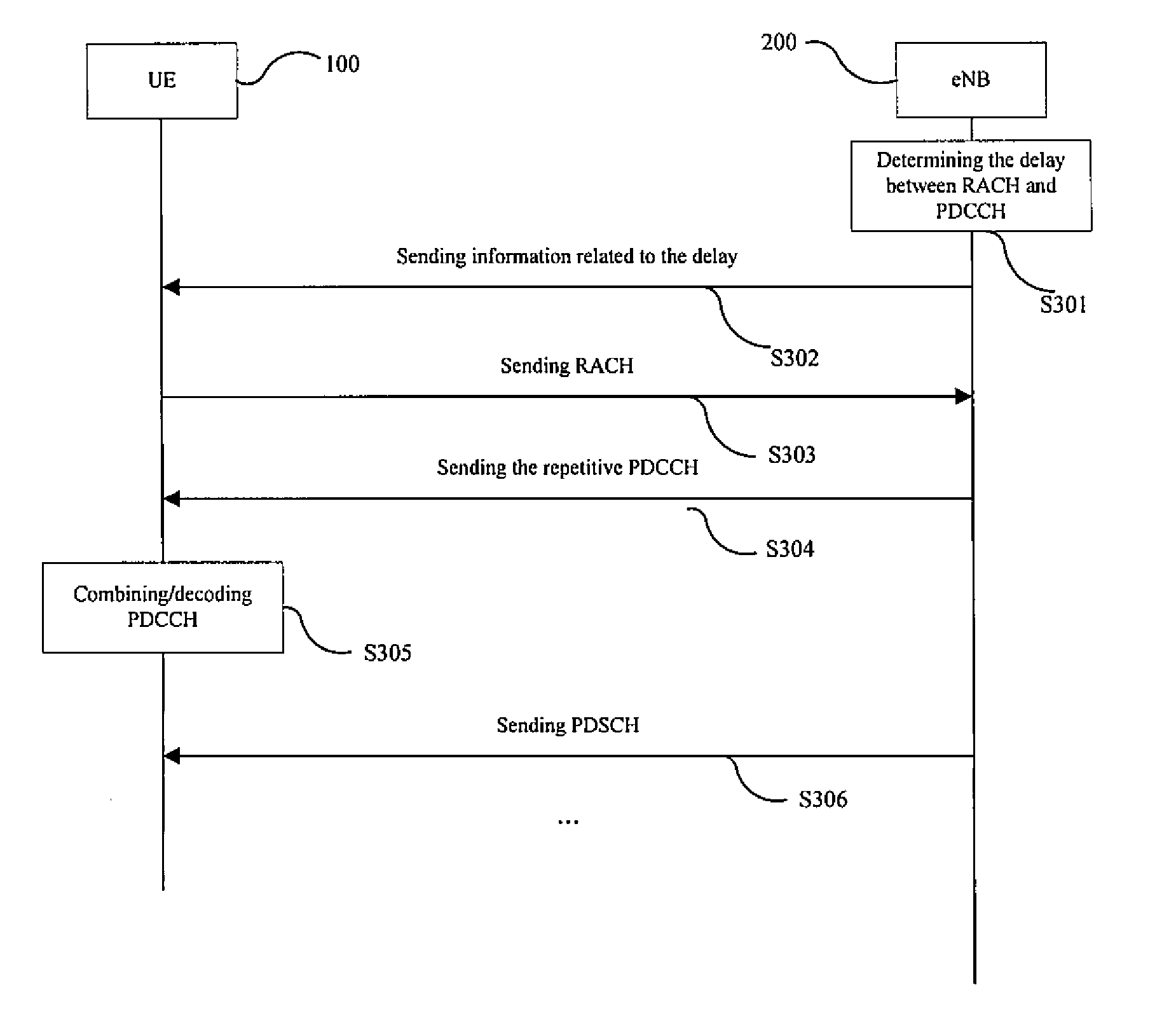

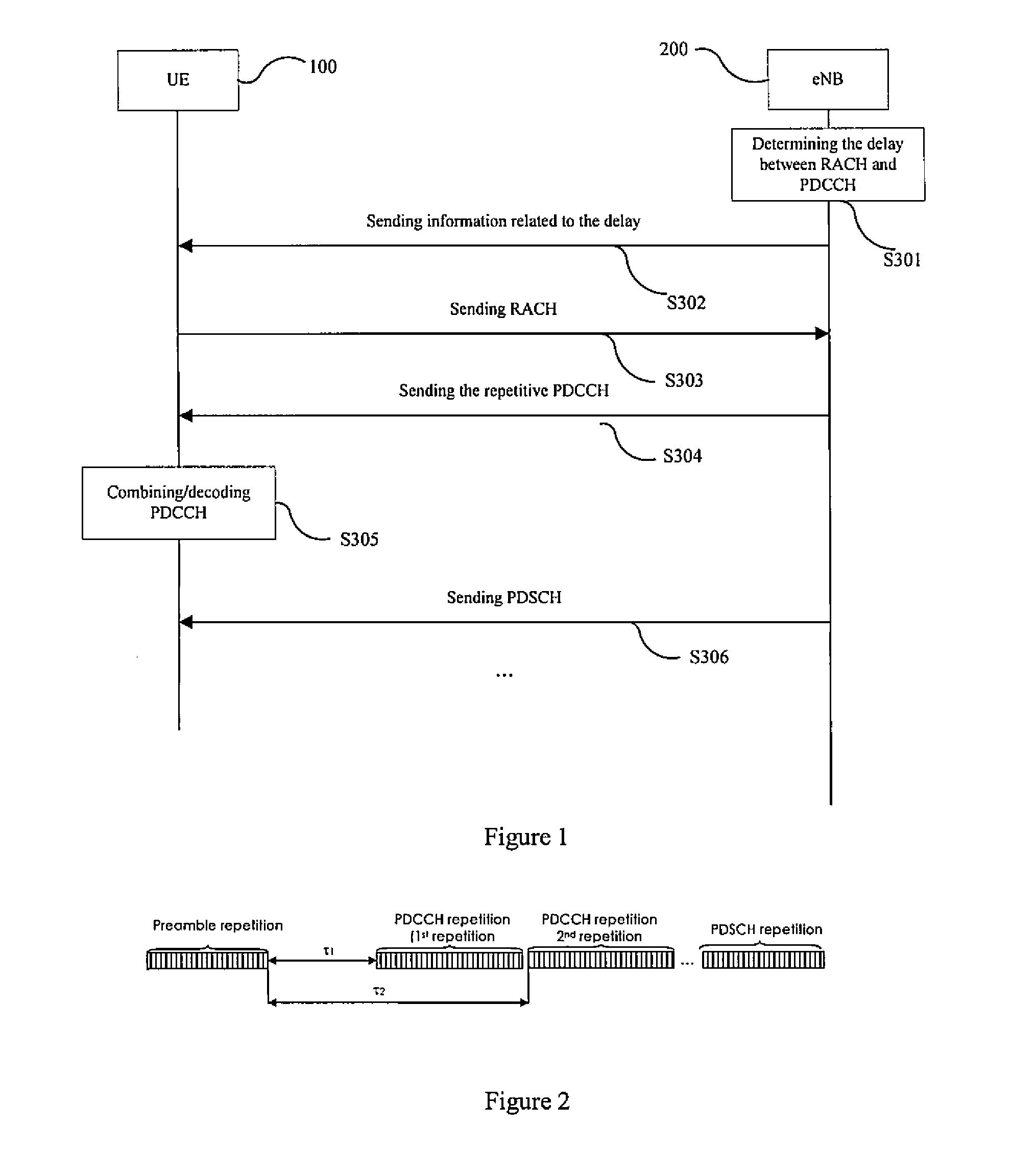

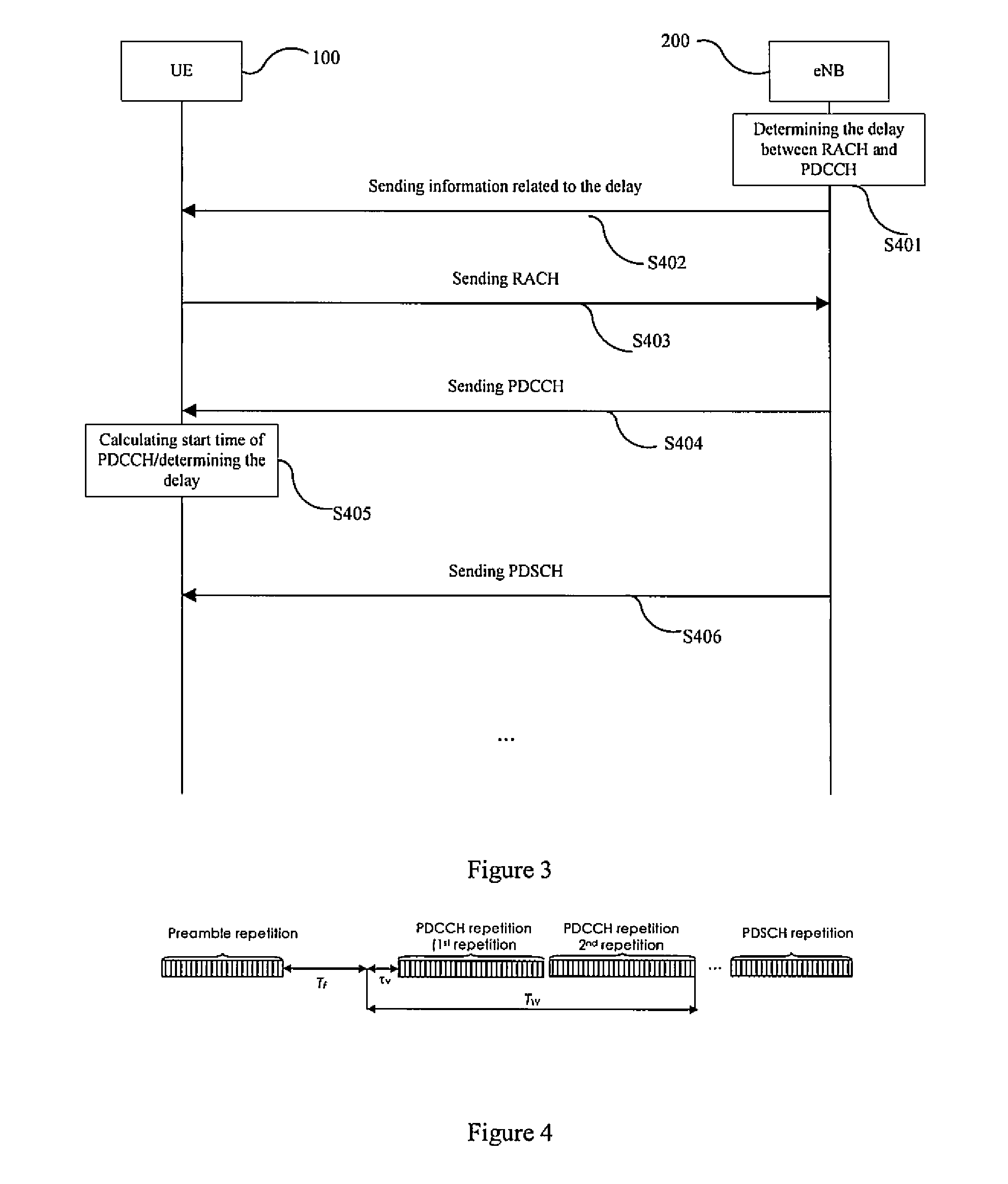

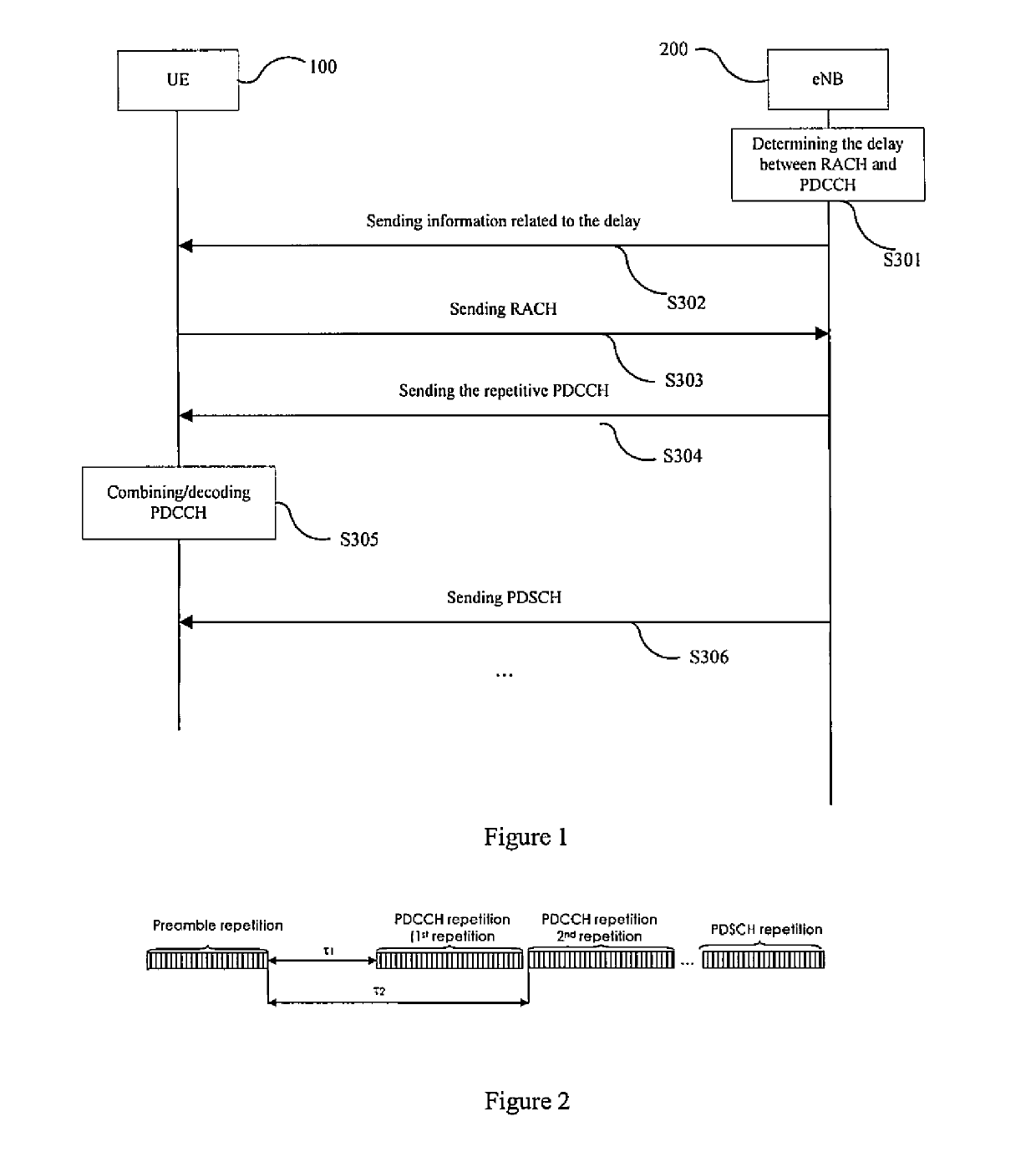

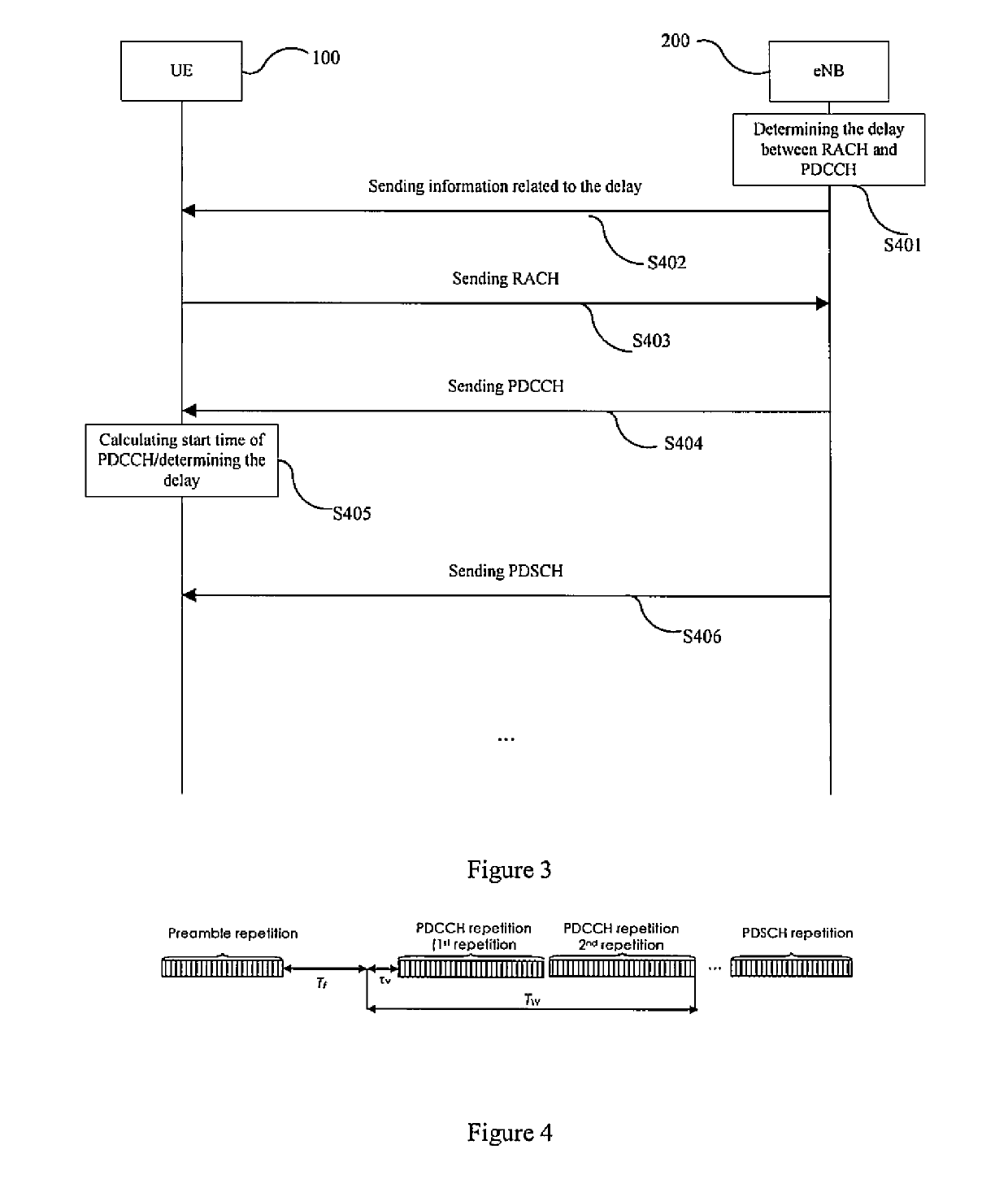

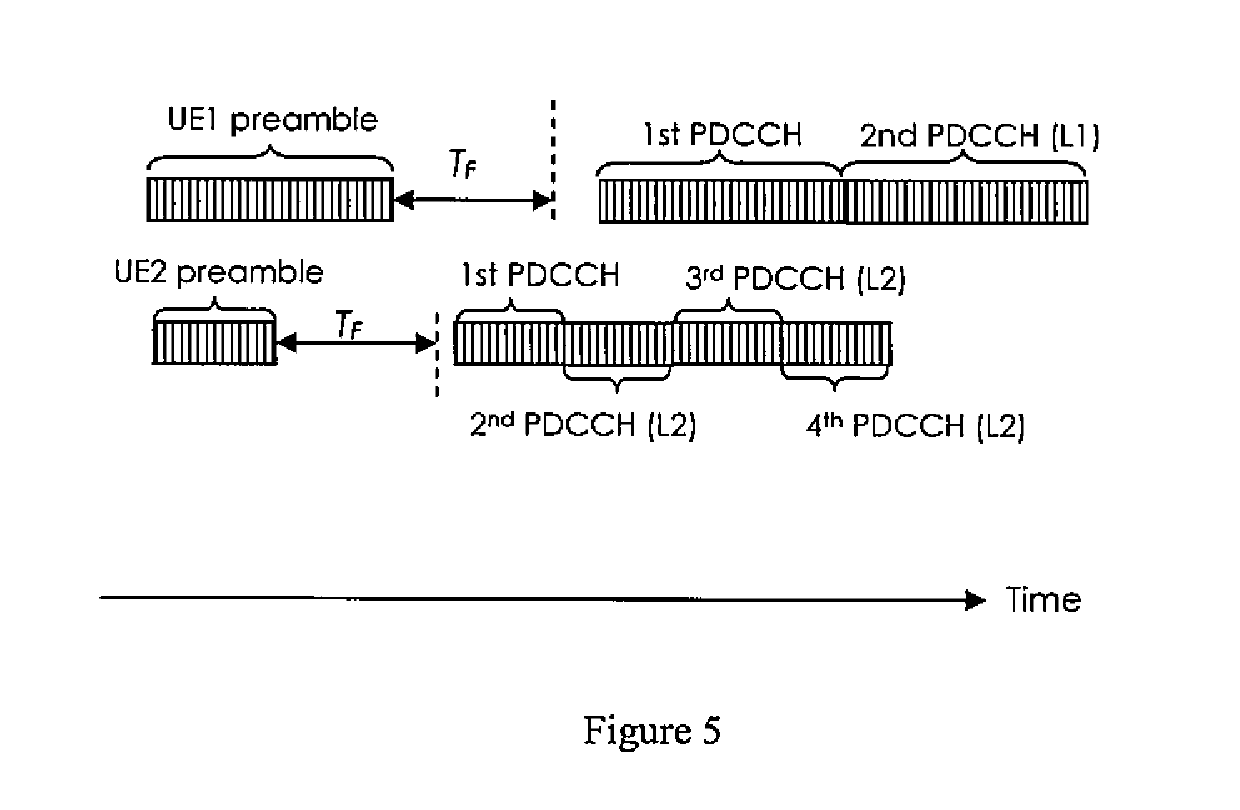

Method and apparatus for determining delay between random access channel and downlink control channel

ActiveUS20160234700A1Save time and system resourcesMore flexibilityAssess restrictionSignal allocationControl channelRandom access

A method is provided for determining delay between random access channel and downlink control channel in random access procedures. The method comprises receiving from a base station, by a user equipment, information related to one or more delay(s) between a random access channel and one or more repetition period(s) of a downlink control channel for the user equipment; sending to the base station, by the user equipment, the random access channel transmitted in a repetitive form; receiving, by the user equipment, the one or more repetition period(s) of the downlink control channel, wherein each of the one or more repetition period(s) of the downlink control channel is transmitted according to a corresponding one of the delay(s); and determining, by the user equipment, the one or more delay(s) based at least on the information related to the delay(s).

Owner:NOKIA TECHNOLOGLES OY

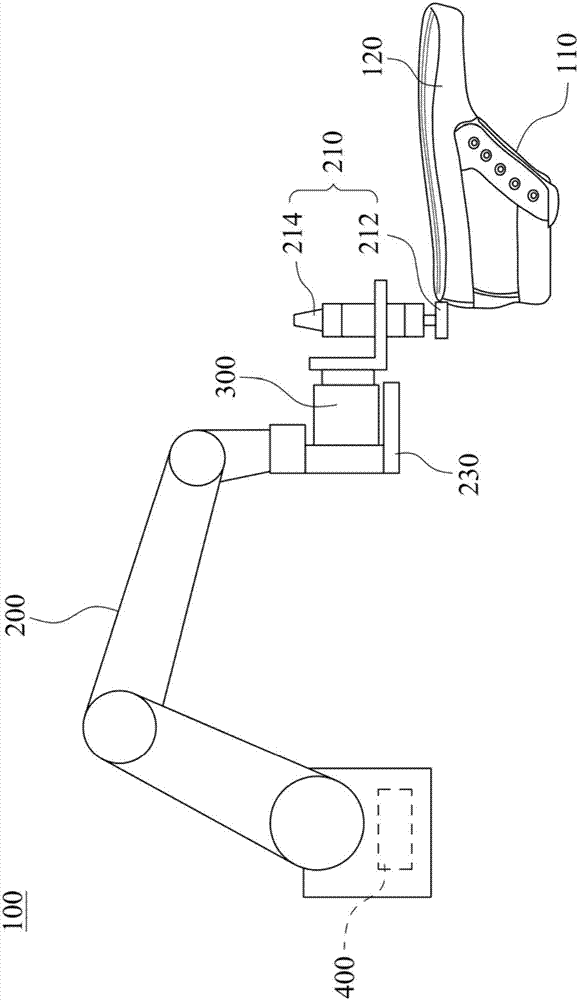

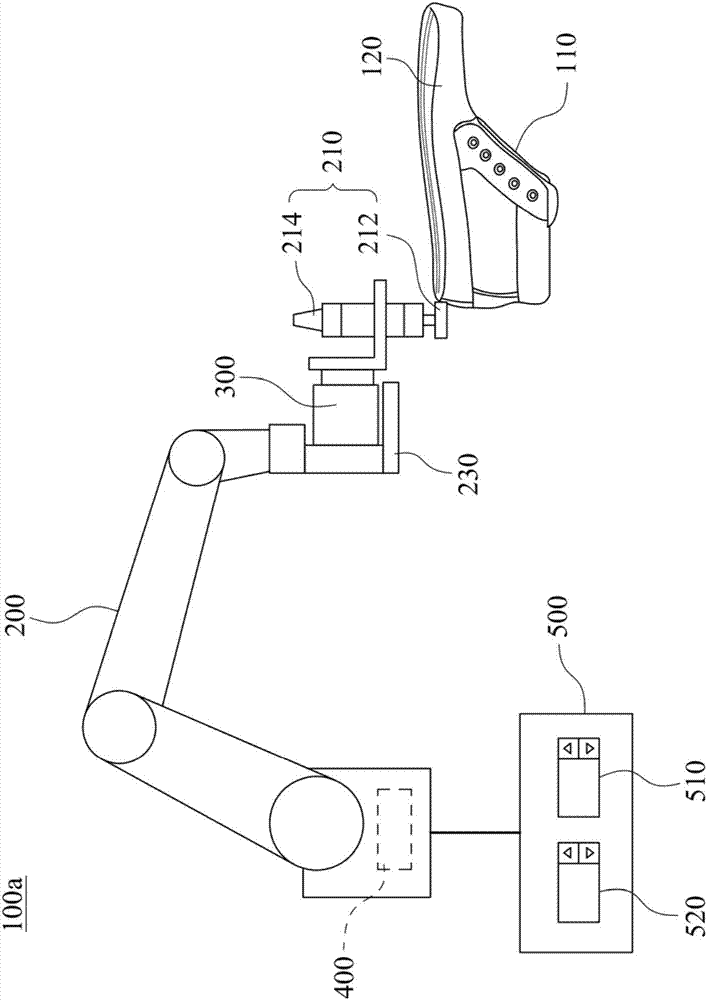

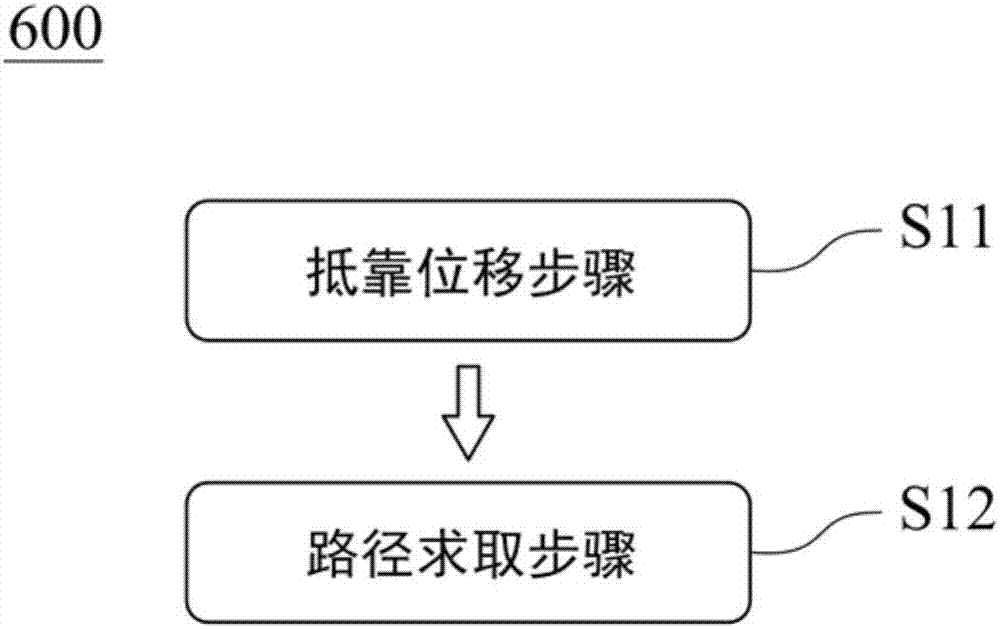

Outline measuring device and control method thereof

The invention provides an outline measuring device and a control method thereof. The outline measuring device is used for measuring an outline of a shoe upper, and the device comprises a mechanical arm, a feedback sensor, an outline path adjusting module. A measuring unit of the mechanical arm abuts against the shoe upper along an original outline path to shift, so that the shoe upper correspondingly generates displacement. The feedback sensor is connected with the measuring unit, and senses and records the displacement. The outline path adjusting module is connected with the mechanical arm and the feedback sensor, and the outline path adjusting module calculates and corrects the original outline path and generates a preset outline path according to the displacement, so that the measuring unit shifts along the preset outline path. Firstly the displacement of the shoe upper is read through the mechanical arm by combining with the feedback sensor, then the operation is conducted by using the displacement, the preset outline path is obtained, the different material is judged, and then the accuracy and efficiency of roughing are improved.

Owner:POU CHEN CORPORATION

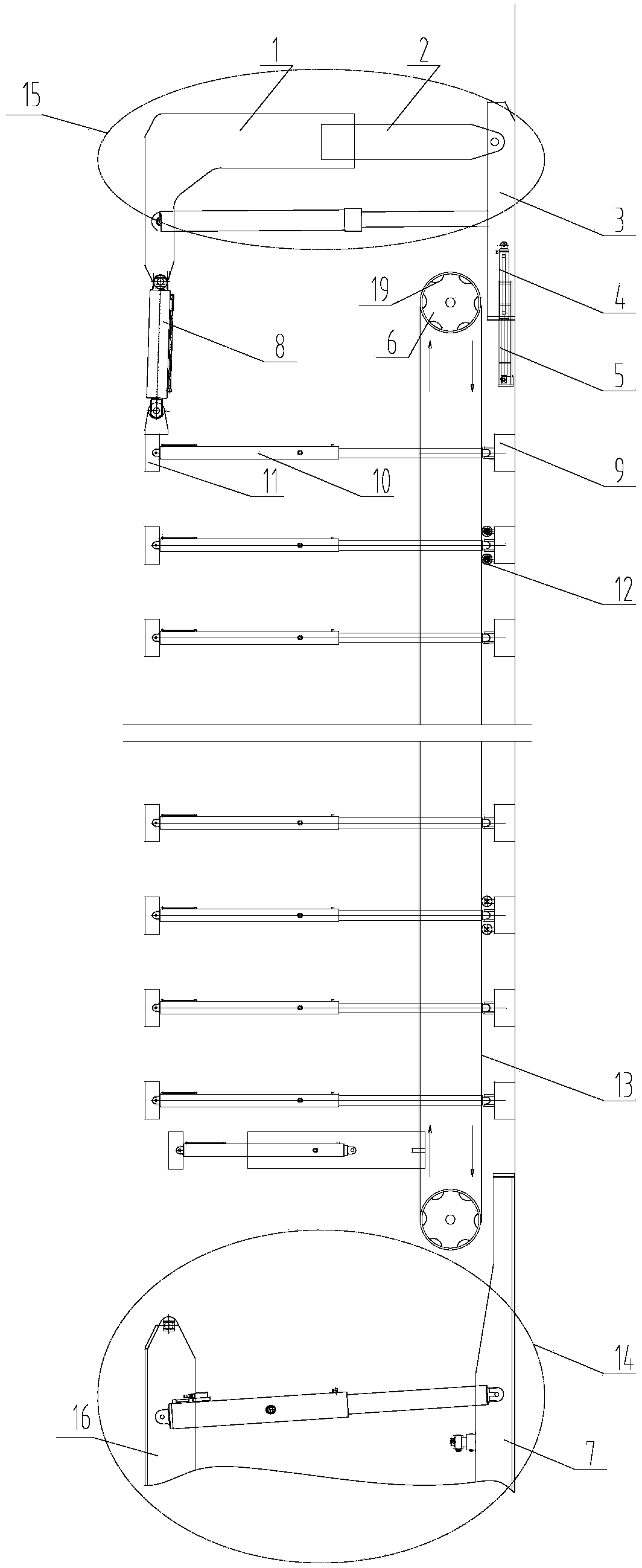

Hydraulic support device and supporting method based on extending in roadway

Owner:山东塔高矿业机械装备制造有限公司

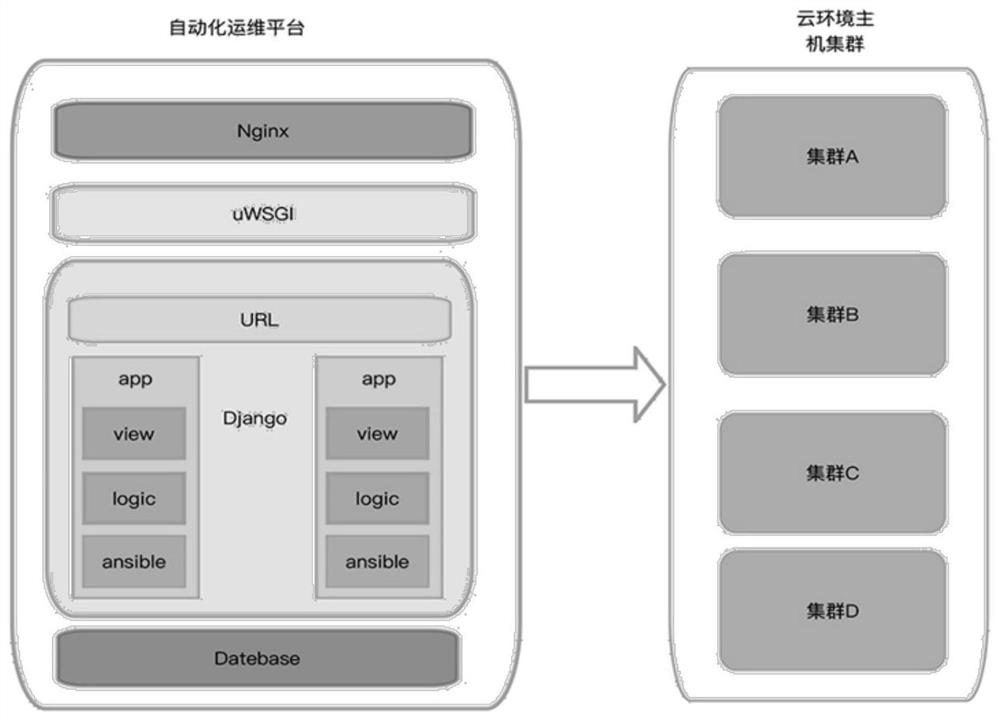

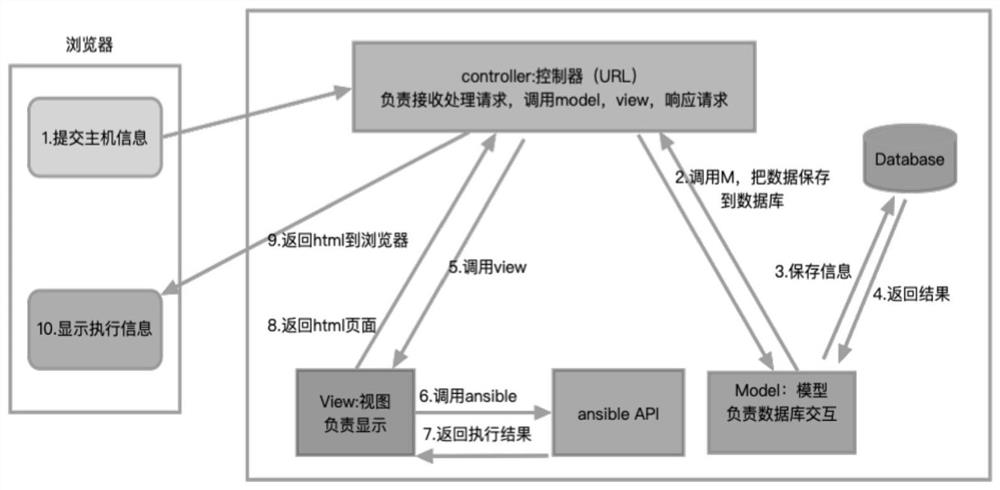

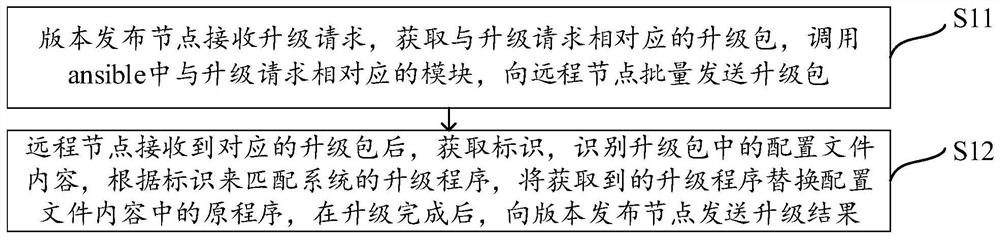

Upgrading method and device of distributed system and computer system

PendingCN111752581AReduce the difficulty of operationEasy to useVersion controlSoftware deploymentService modeReliability engineering

The embodiment of the invention discloses an upgrading method and device of a distributed system and a computer system. The method comprises the following steps: a version release node receives an upgrading request, acquires an upgrading packet corresponding to the upgrading request, calls a module corresponding to the upgrading request in the ansible and sends the upgrading packet to the remote node in batches, the upgrading packet comprises a configuration file, and the configuration file carries an identifier corresponding to an upgrading program required by the remote node; and after receiving the corresponding upgrade package, the remote node obtains the identifier, identifies the configuration file content in the upgrade package, matches the upgrade program of the system according tothe identifier, replaces the original program in the configuration file content with the obtained upgrade program, and sends an upgrade result to the version release node after the upgrade is completed. The high-cost operation and maintenance service mode of traditional operation and maintenance is changed, the standardized upgrading process of the system is customized according to requirements,manual intervention upgrading is not needed, the number of repeated operation times is reduced, upgrading problems are avoided, and the possibility of misoperation is reduced.

Owner:POSBANK

Method for preparing graphene

ActiveCN102765717BEfficient strippingQuality improvementGrapheneBulk chemical productionPresent methodSolvent

Disclosed is a method for preparing graphene. In particular, the method comprises: using n-hexane or propane as a supercritical solvent, filling graphite powder or graphite powder and a cosolvent into an autoclave, sealing the autoclave by selecting an appropriate rupture disk, adding n-hexane or propane after the autoclave is vacuumized, keeping in a supercritical state for a period of time at a temperature and a pressure, then increasing the temperature and the pressure slightly or increasing the pressure alone,, and a collector collecting rushed-out materials instantly for treatment to prepare a graphene product after the rupture disk bursts when the pressure exceeds the pressure which the rupture disk can bear. In the present method, pressure relief occurs in milliseconds, and thereby efficient strip of graphite can be achieved. The method belongs to a physical process, does not cause large damage on the structure of graphene, is simple in the preparation process, does not require a large quantity of inorganic acids and oxidants, and is free of "three wastes". The prepared graphene crystal is intact in structure, good in quality, and capable of achieving large-scale industrial production of graphene.

Owner:余美群

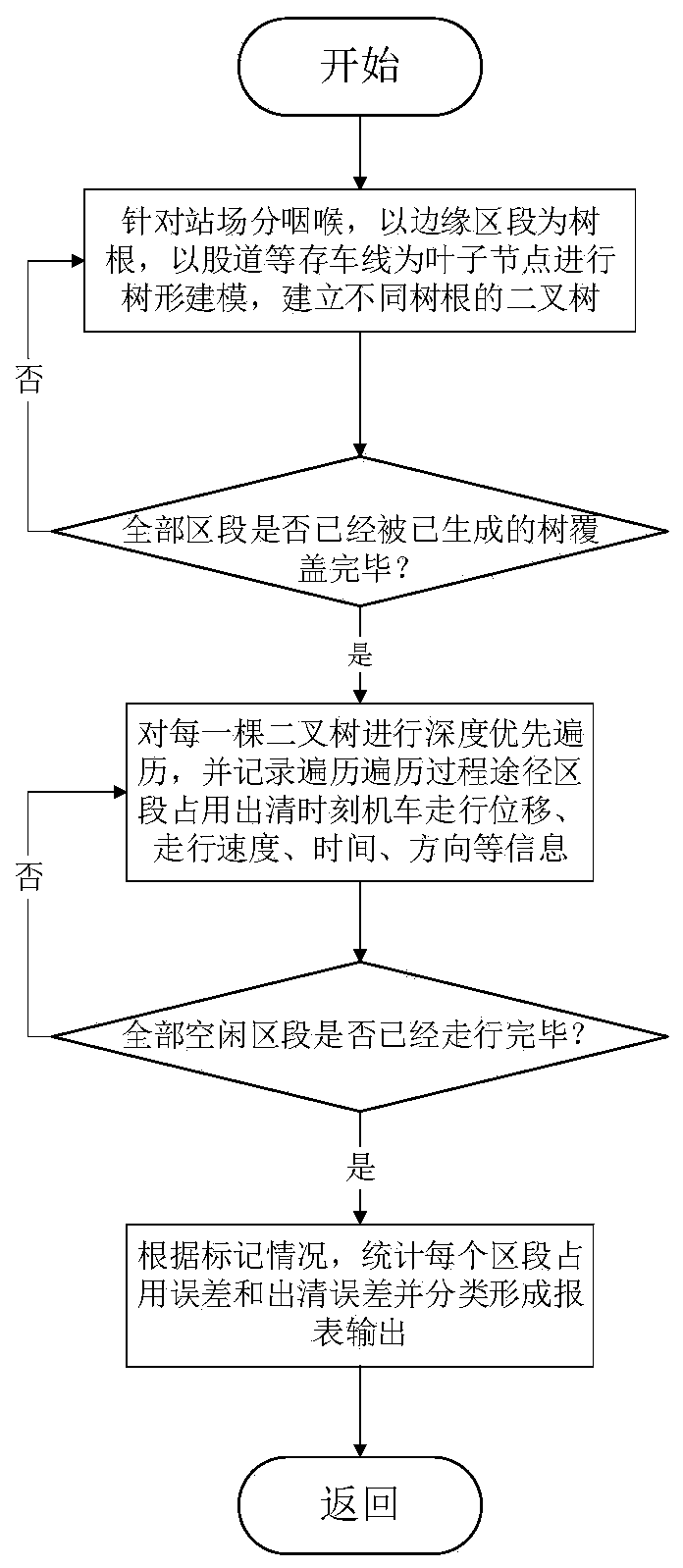

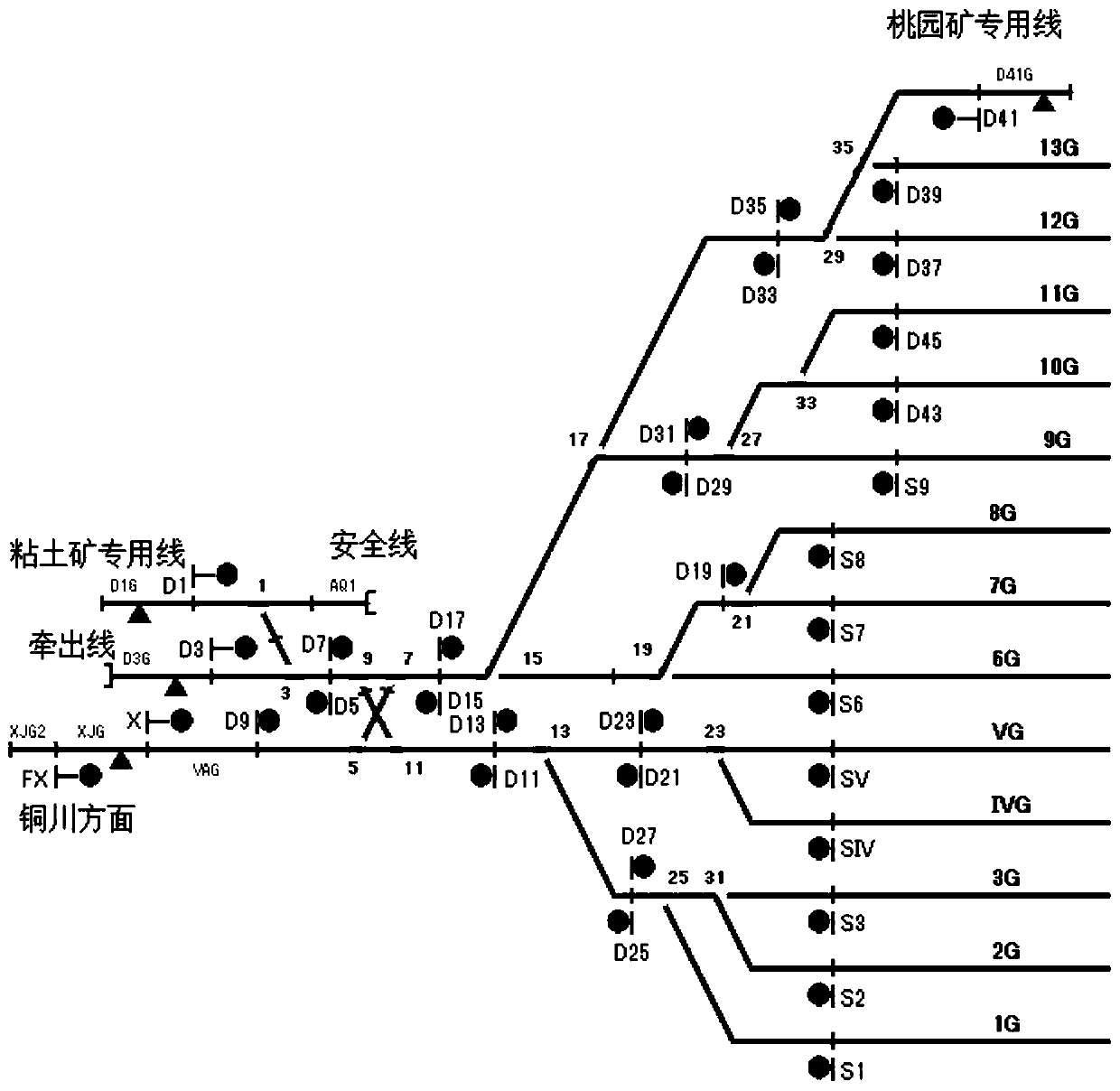

Operation sequence selecting method suitable for STP operation test

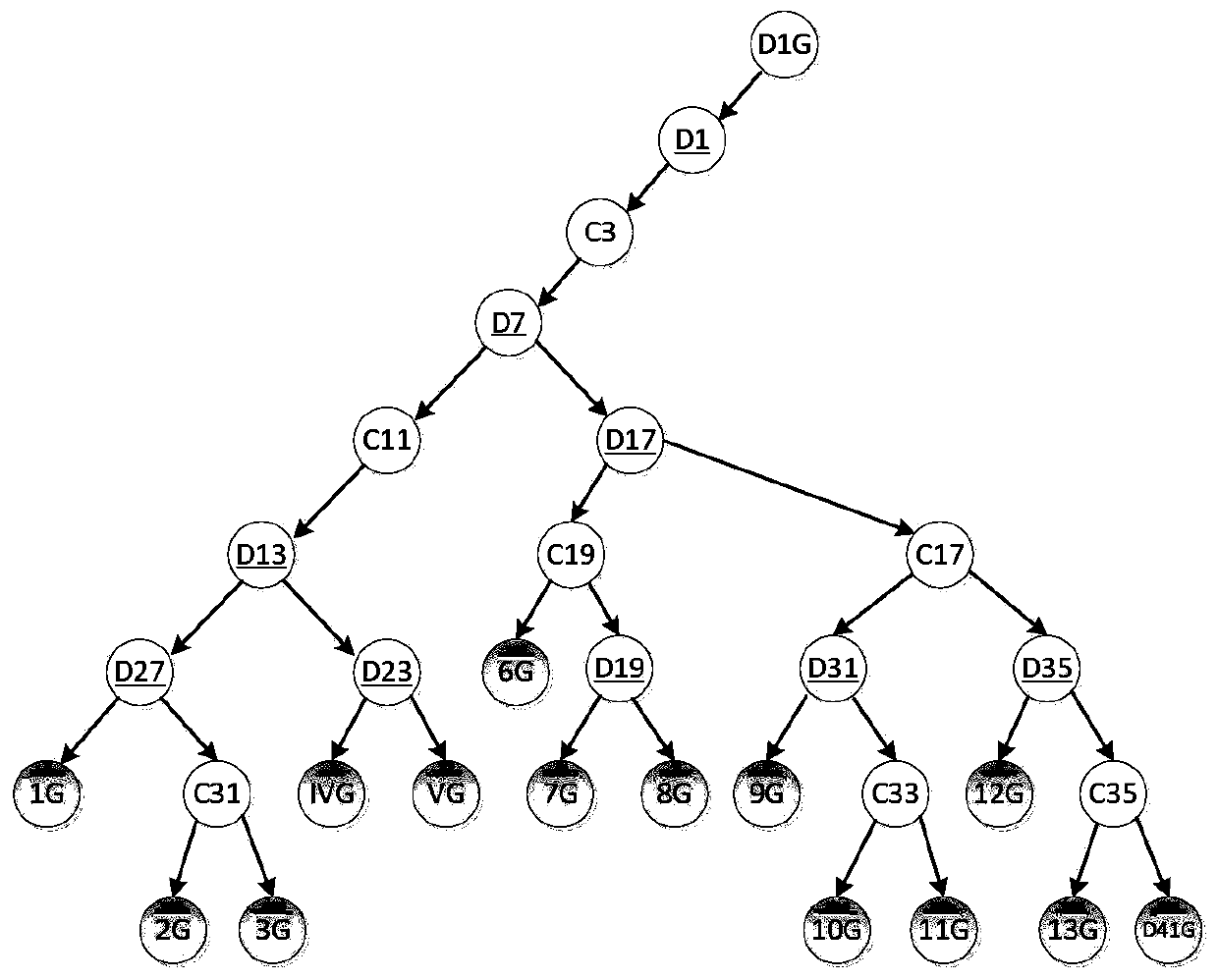

ActiveCN110509963AReduce the number of repetitionsReduce omission rateAutomatic systemsOther databases indexingTree rootNODAL

The invention discloses an operation sequence selecting method suitable for an STP operation test. The operation sequence selecting method suitable for the STP operation test comprises the steps of abstracting a whole railway yard into binary tree representations of different tree roots according to throats by using station tracks as boundaries, yard edge segments as root nodes, station tracks asleaf nodes and equipment on a path as other nodes of a binary tree; carrying out depth-first search on each tree and intensively marking passing segments; and after all searches are finished, using marked information to calculate an occupation error and a clearance error of each segment. According to the operation sequence selecting method suitable for the STP operation test, through tree form modeling, depth-first search and undetected segment statistics, the coverage of operation segments is guaranteed, and the omission probability of completely depending on manually following a vehicle to review the lengths of segments is effectively reduced. Through statistics of operation conditions and results of different segments, statistical analysis of the segment length error is automatically output so that the working intensity of manually following and watching the vehicle is effectively reduced, and the statistical accuracy is improved.

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

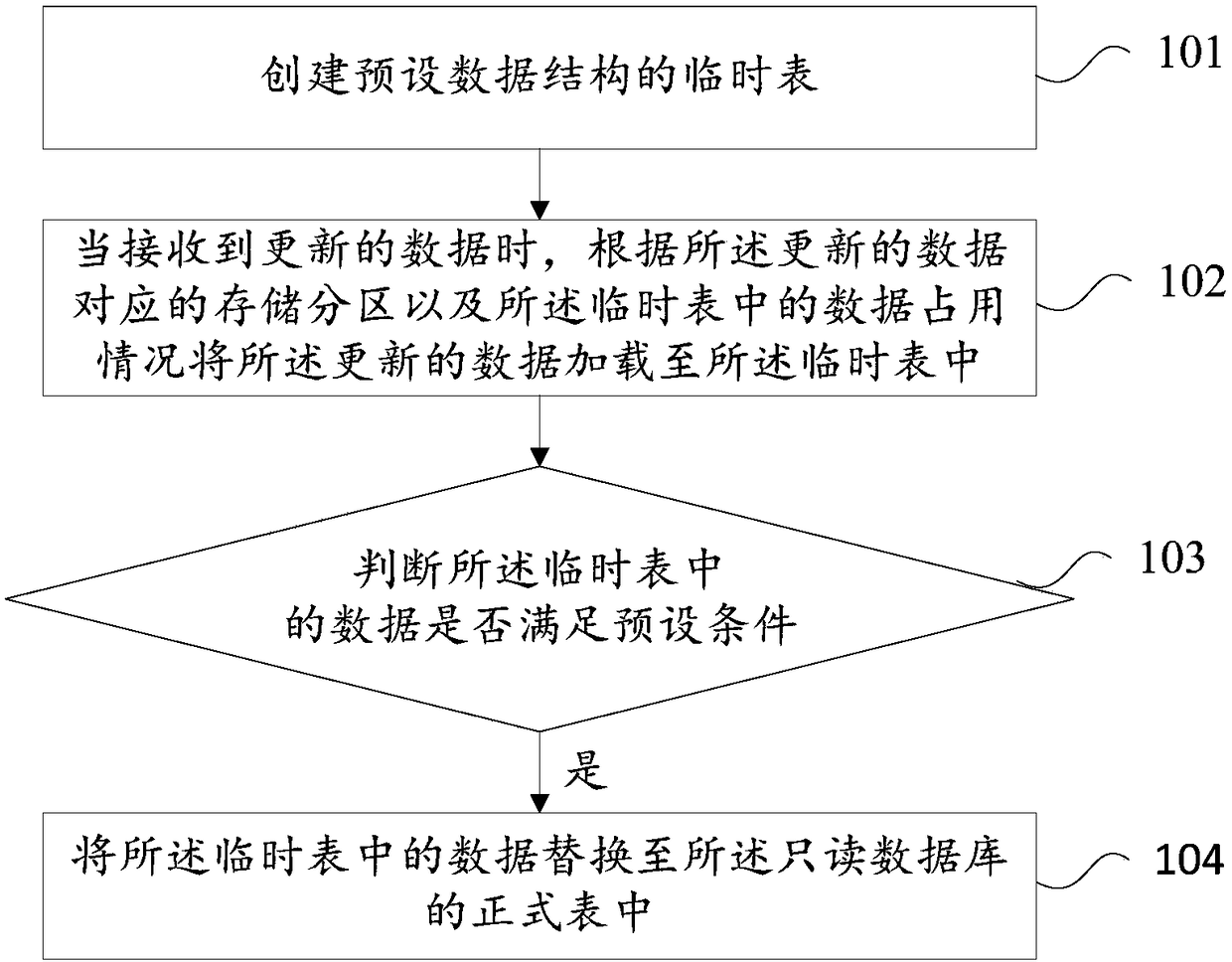

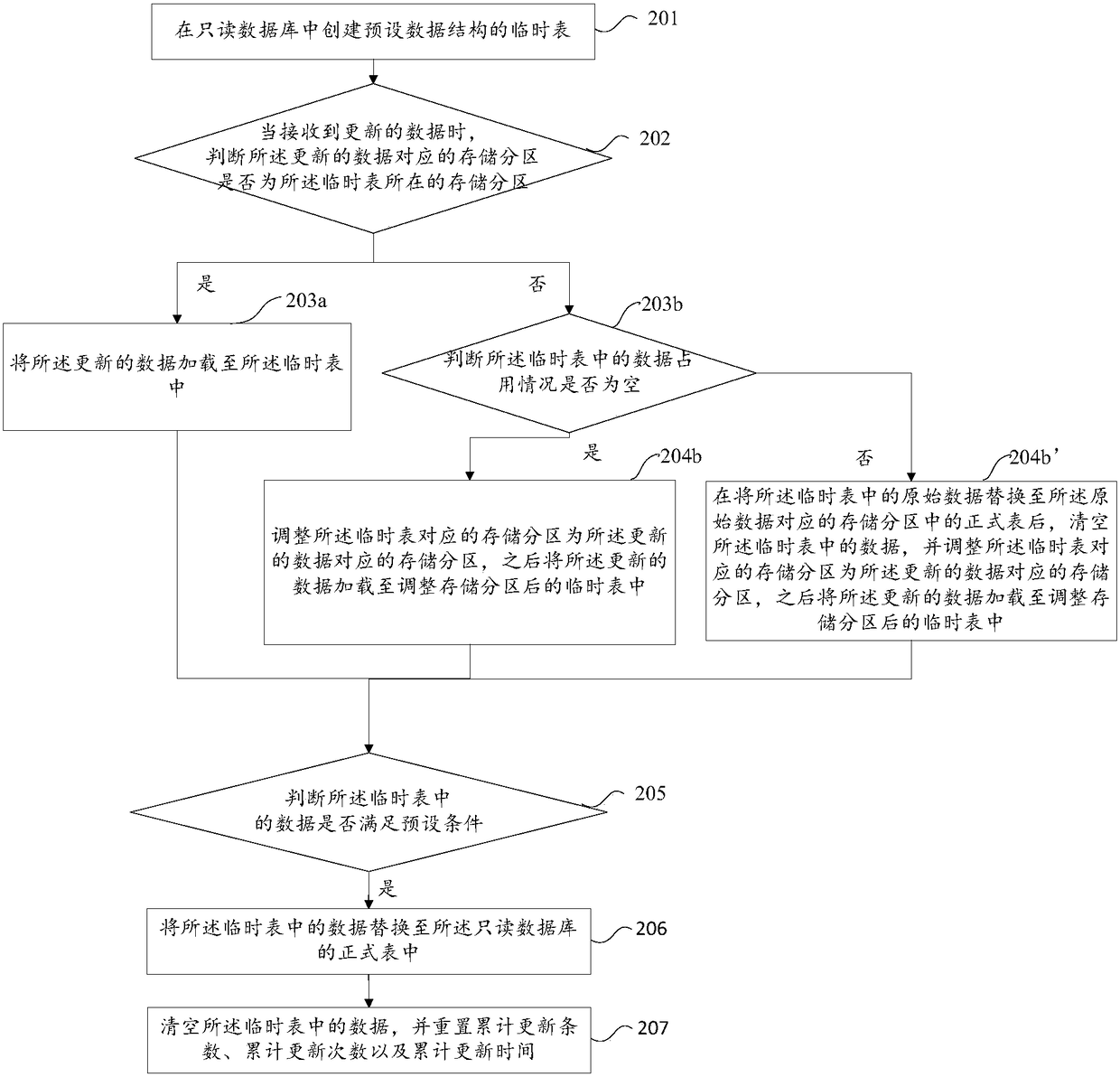

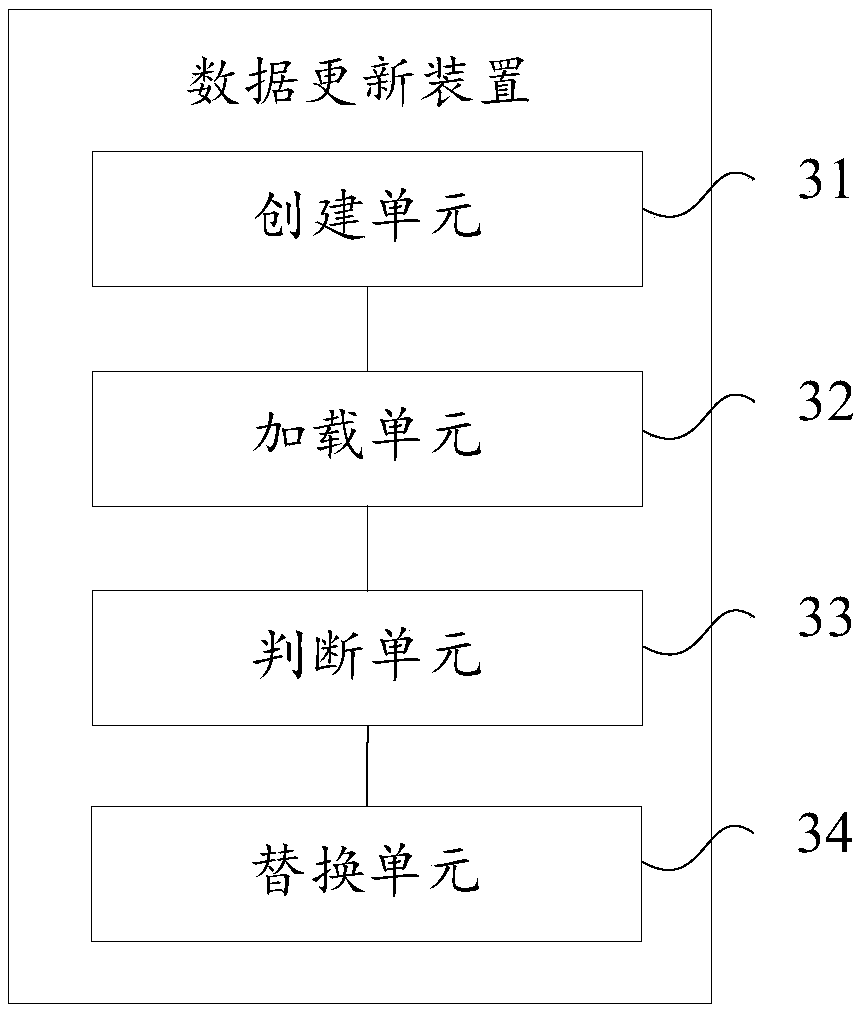

A method and apparatus for updating data

ActiveCN109388644ALoad accuratelyReduce data volumeDatabase updatingDatabase indexingAccess timeData structure

A method and apparatus for updating data, relating to the technical field of data processing, which mainly aims at reducing the data updating time and the inaccessible time of the read-only database.The main technical scheme of the invention is as follows: creating a temporary table with a preset data structure; the data structure of the temporary table is the same as that of the formal table inthe read-only database; When the updated data is received, loading the updated data into the temporary table according to the storage partition corresponding to the updated data and the data occupancyin the temporary table; Judging whether the data in the temporary table satisfies a preset condition; If so, replacing the data in the temporary table with an official table of the read-only database. The invention is mainly used for updating data.

Owner:BEIJING GRIDSUM TECH CO LTD

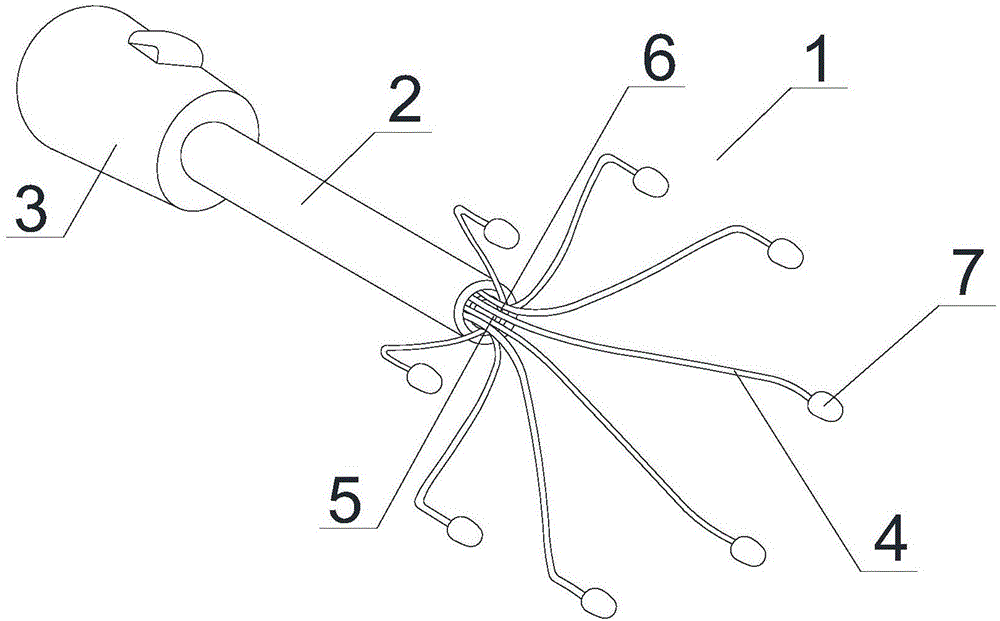

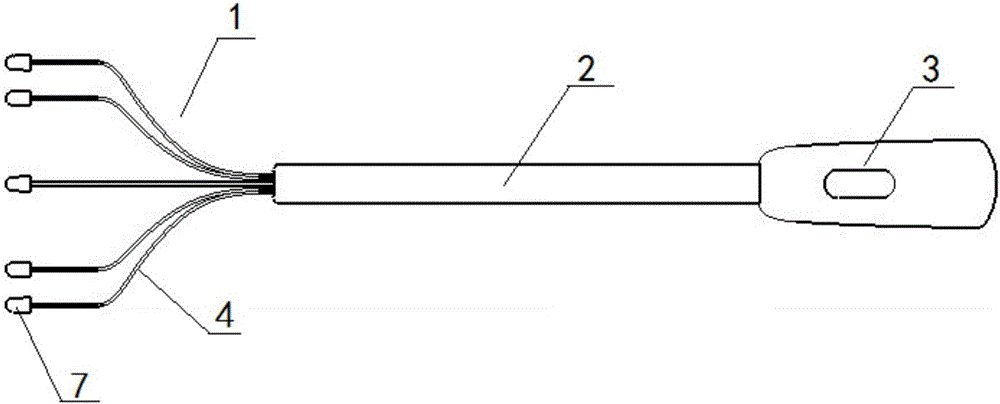

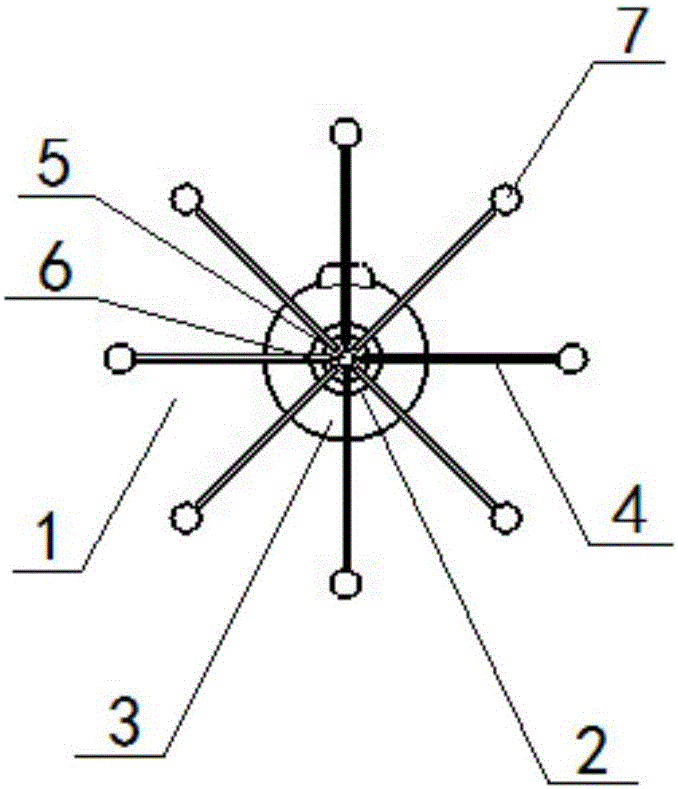

Vascular radio-frequency ablation electrode catheter provided with claw-shaped catheter branches

The invention relates to the technical field of medical apparatuses, and in particular to a vascular radio-frequency ablation electrode catheter provided with claw-shaped catheter branches; a radio-frequency ablation working section is arranged on the front section of the vascular radio-frequency ablation electrode catheter , a catheter body section is arranged on the middle section of the vascular radio-frequency ablation electrode catheter and a control handle section is arranged on the rear section of the vascular radio-frequency ablation electrode catheter; the eight radio-frequency catheter branches extend from a peripheral direction of the radio-frequency ablation working section; the eight radio-frequency catheter branches are integrally represented as claw-shaped structures; and at least one ablation electrode is connected to the head end of each radio-frequency catheter branch. The vascular radio-frequency ablation electrode catheter provided by the invention has the beneficial effects that in practical clinical treatment, the vascular radio-frequency ablation electrode catheter provided with the claw-shaped catheter branches provided by the invention can be applied to various blood vessels differing in diameter and can be used for conducting radio-frequency ablation therapy on cardiac muscle tissues in a complex part, such as for vascular ablation of such diseases as paroxysmal atrial tachycardia, supraventricular tachycardia, atrial flutter, atrial fibrillation, resistant hypertension and the like.

Owner:汤敬东 +2

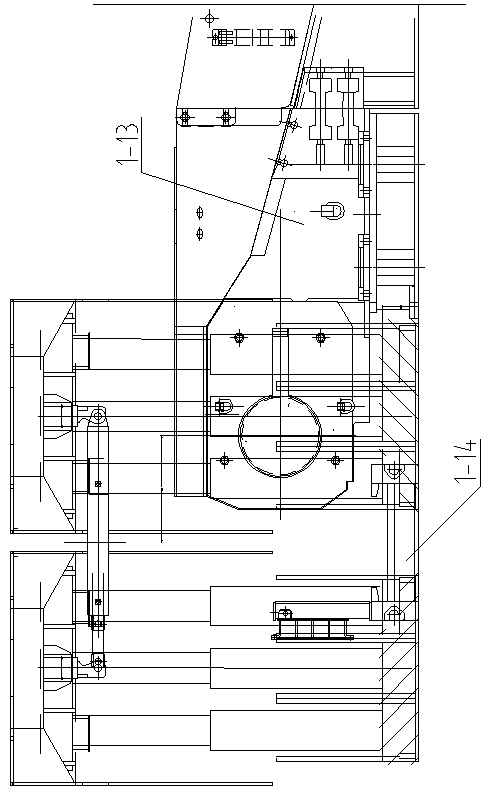

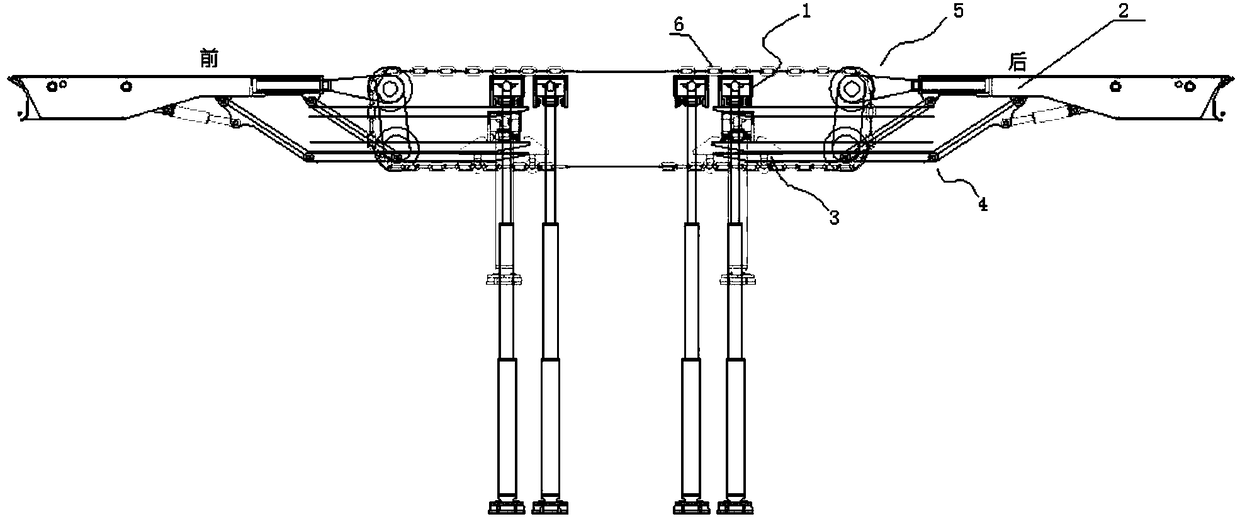

Circulating self-moving type roadway advanced-support hydraulic support

PendingCN108442952AChange frameChange the rack moving methodMine roof supportsProps/chocksDrive wheelEngineering

The invention discloses a circulating self-moving type roadway advanced-support hydraulic support. The circulating self-moving type roadway advanced-support hydraulic support comprises auxiliary suspension frames, face-end supports and a retractable supporting and protecting assemblies, wherein the auxiliary suspension frames and the face-end supports are arranged oppositely, and the retractable supporting and protecting assemblies are arranged side by side with the auxiliary suspension frames and the face-end supports; the circulating self-moving type roadway advanced-support hydraulic support further comprises flexible gearings which are used for moving the retractable supporting and protecting assemblies, and the flexible gearings comprise flexible tracks, driving wheels and driven wheels for driving the flexible tracks; the retractable supporting and protecting assemblies comprise bases, supporting beams for supporting a top plate and upright posts for lifting the supporting beams,wherein the upright posts are arranged on the bases and hinged to the supporting beams; and the supporting beams are provided with lifting lugs matched with the flexible tracks, and the driving wheels and the driven wheels are both provided with grooves matched with the lifting lugs for conveying the retractable supporting and protecting assemblies. The circulating self-moving type roadway advanced-support hydraulic support has fast moving speed and convenient operation, a roof of a roadway cannot be repeatedly supported, the actual use needs of the roadway can be met, and the safe and efficient production of a coalface is facilitated.

Owner:河南国新智能科技研究院有限公司

Bridge cleaning machineshop truck and implementation method

ActiveCN110725249AAvoid secondary pollutionEasy to use for cleaning operationsRoad cleaningDust controlTruck

The invention relates to the field of bridge maintenance equipment, in particular to a bridge cleaning machineshop truck and an implementation method. The bridge cleaning machineshop truck comprises amachineshop truck body, a carriage, a first linear displacement mechanism, a second linear displacement mechanism, a third linear displacement mechanism, a telescopic seam cleaning mechanism, a dedusting mechanism, a positioning mechanism, a storage battery and a controller, wherein the carriage is fixedly connected with the machineshop truck body; the first linear displacement mechanism is fixedly mounted on the outer wall of the rear side of the carriage; the second linear displacement mechanism is fixedly mounted on the movable part of the first linear displacement mechanism; the third linear displacement mechanism is fixedly mounted on the movable part of the second linear displacement mechanism; the moving direction of the movable part of the third linear displacement mechanism is consistent with that of the movable part of the first linear displacement mechanism; and the telescopic seam cleaning mechanism is fixedly mounted on the movable part of the third linear displacement mechanism. According to the scheme, multiple impurities in a bridge telescopic seam are automatically cleaned to save the human cost, the cleaning effect is thorough, the working efficiency is high, thecruising ability is high, and the safety is high.

Owner:郭云美

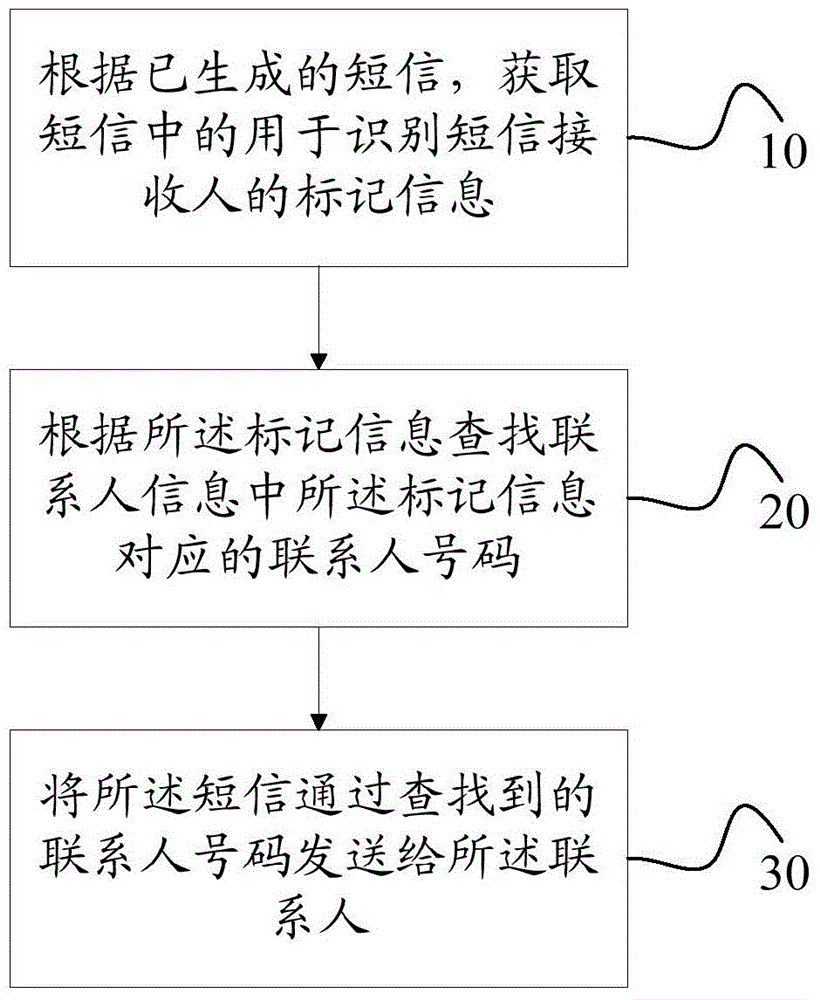

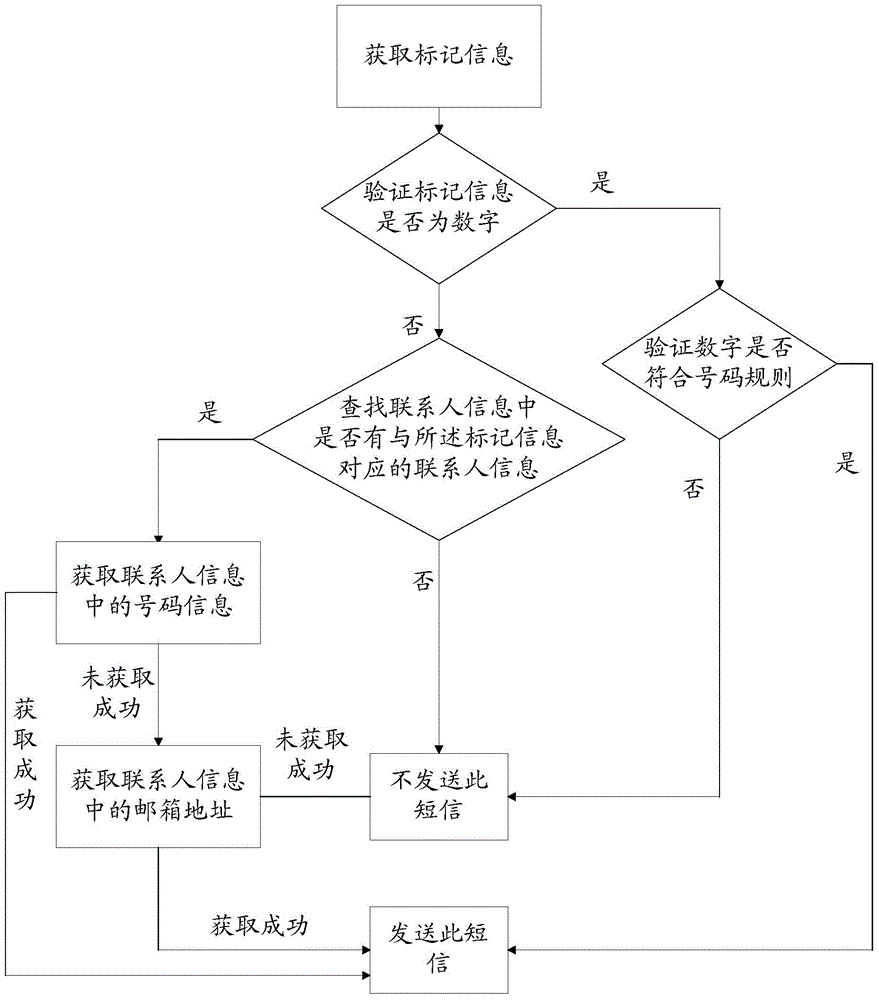

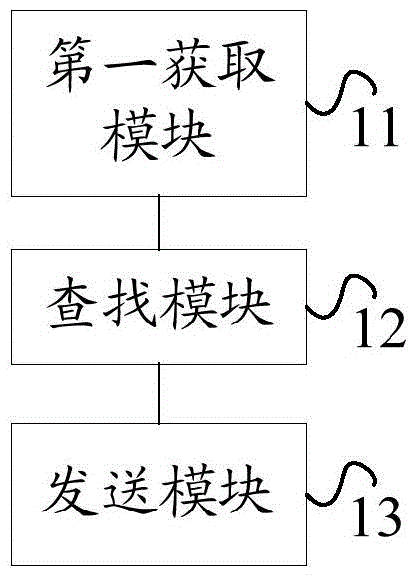

Short message transmission method, device and terminal

ActiveCN104954541AEasy to operateReduce the number of repetitionsSubstation equipmentAddress bookComputer science

The invention provides a short message transmission method, device and terminal. The method comprises the steps: obtaining marking information, for recognizing a short message receiving person, in the short message according to a generated short message; searching a contact person number, corresponding to the marking information, in the contact person information according to the marking information; and transmitting the short message to a contact person through the searched contact person number. According to the above scheme, the problems, caused by that a user usually needs to select and add senders to an editing interface from an address book, of complex operation and time waste are solved when the user carries out group transmission of a short message. The information of a short message receiving person is directly inputted in the short message, and the automatic matching of a corresponding contact person number can be achieved during the transmission of the short message. The information is transmitted to the contact person number, thereby facilitating the user operation, and reducing the number of repeated operation.

Owner:摩托罗拉移动通信软件(武汉)有限公司

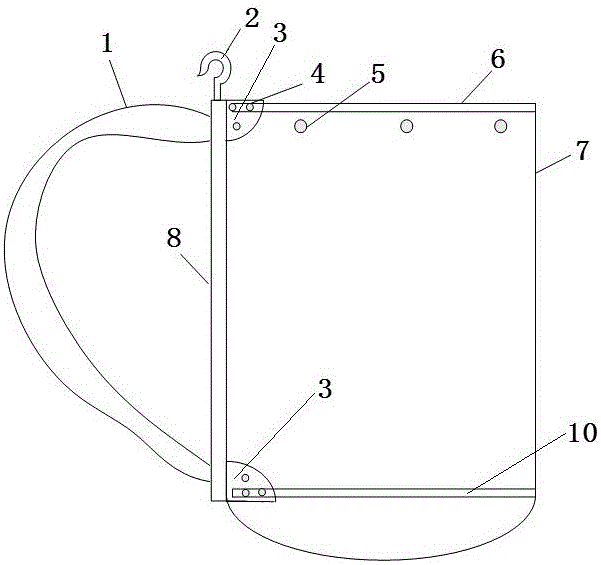

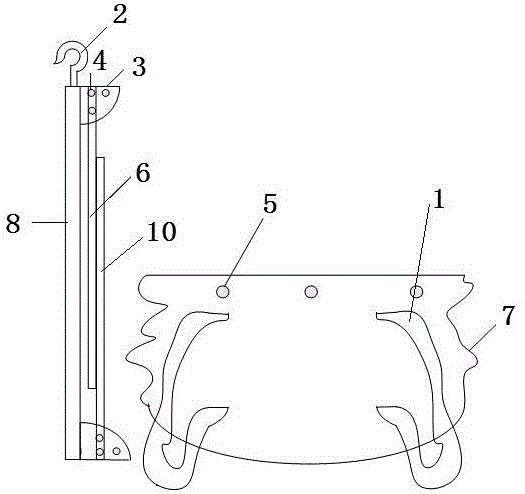

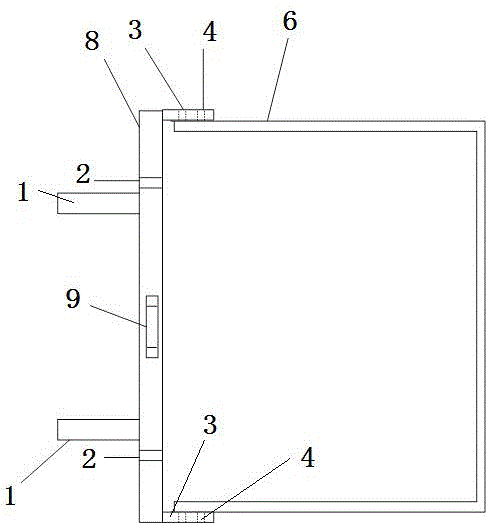

Nest cleaning auxiliary tool

InactiveCN105703267AEasy to clean and transportImprove cleaning efficiencyApparatus for overhead lines/cablesEngineeringNest

The invention discloses a nest cleaning auxiliary tool, characterized by comprising a support body (8). The support body (8) is movably connected to an upper movable support pole (6) and a lower movable support pole (10) through movable support pole fixing bracket joints (3), and spring pins (4). An upper end of the support body (8) is connected to two hooks (2) and a suspension ring (9). A bag (7) sleeves the support body (8), the upper movable support pole (6), and the lower movable support pole (10). An upper end of the bag (7) is folded at the upper movable support pole (6) and is fixed through an upper row of fixing holes (5) and a lower row of fixing holes (5) on the bag. The nest cleaning auxiliary tool has simple structure, convenient carrying, high safety, and low cost, is repeatedly usable and convenient for the work personnel to clean the nest on the pole, store foreign materials and transport materials up and down, and raises the nest cleaning efficiency.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

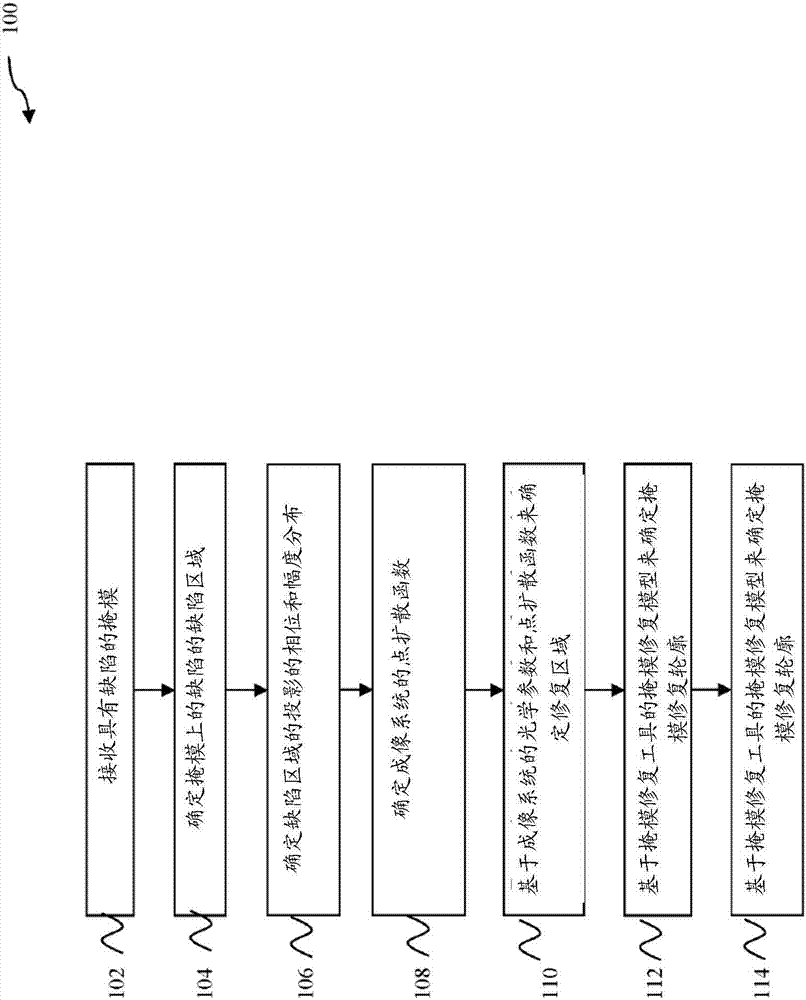

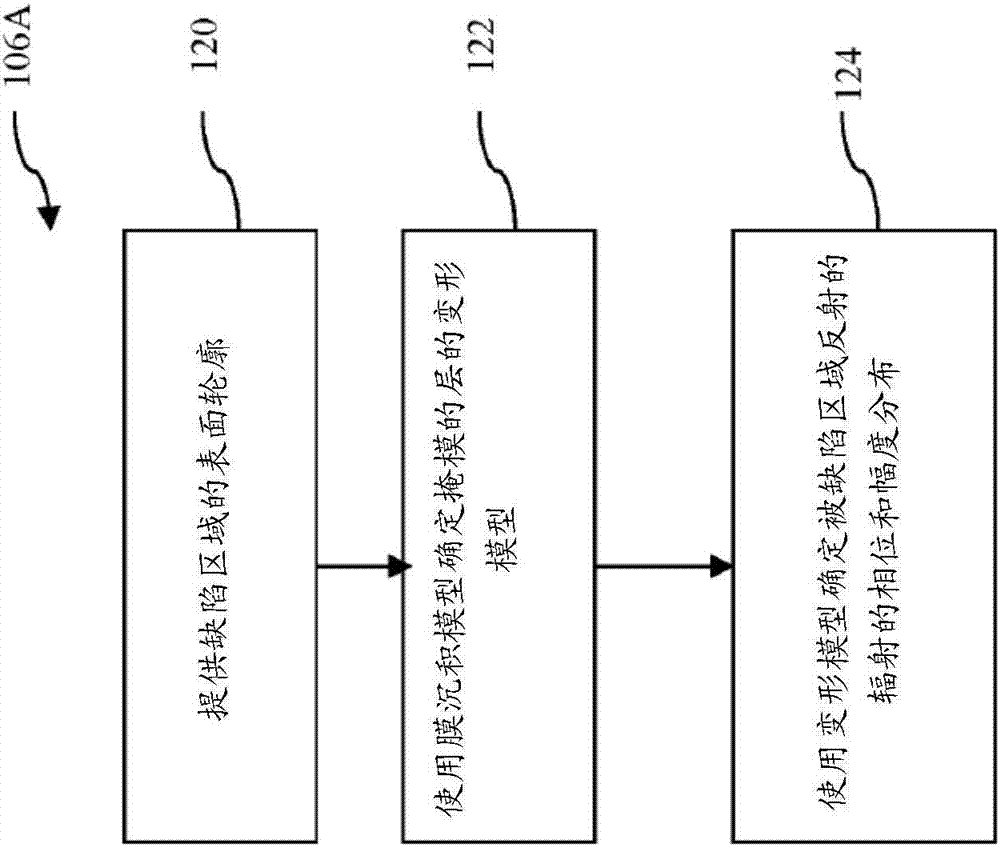

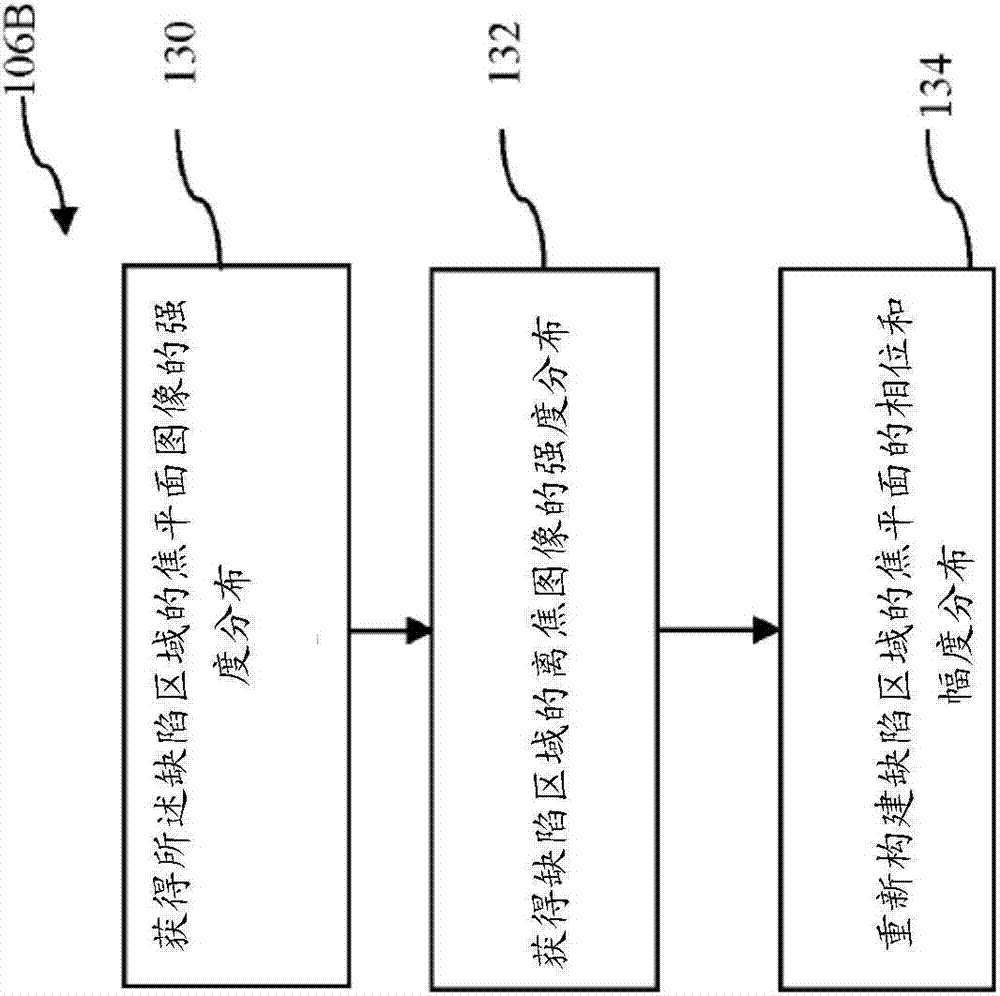

Method for repairing a mask

InactiveCN107463065AReduce the number of repetitionsImage enhancementImage analysisPoint spread functionEngineering

A method includes inspecting a mask to locate a defect region for a defect of the mask. A phase distribution of an aerial image of the defect region is acquired. A point spread function of an imaging system is determined. One or more repair regions of the mask are identified based on the phase distribution of the aerial image of the defect region and the point spread function. A repair process is performed to the one or more repair regions of the mask to form one or more repair features.

Owner:TAIWAN SEMICON MFG CO LTD

Method and apparatus for determining delay between random access channel and downlink control channel

ActiveUS10492083B2Much resourceMany timesAssess restrictionSignal allocationControl channelRandom-access channel

A method is provided for determining delay between random access channel and downlink control channel in random access procedures. The method comprises receiving from a base station, by a user equipment, information related to one or more delay(s) between a random access channel and one or more repetition period(s) of a downlink control channel for the user equipment; sending to the base station, by the user equipment, the random access channel transmitted in a repetitive form; receiving, by the user equipment, the one or more repetition period(s) of the downlink control channel, wherein each of the one or more repetition period(s) of the downlink control channel is transmitted according to a corresponding one of the delay(s); and determining, by the user equipment, the one or more delay(s) based at least on the information related to the delay(s).

Owner:NOKIA TECH OY

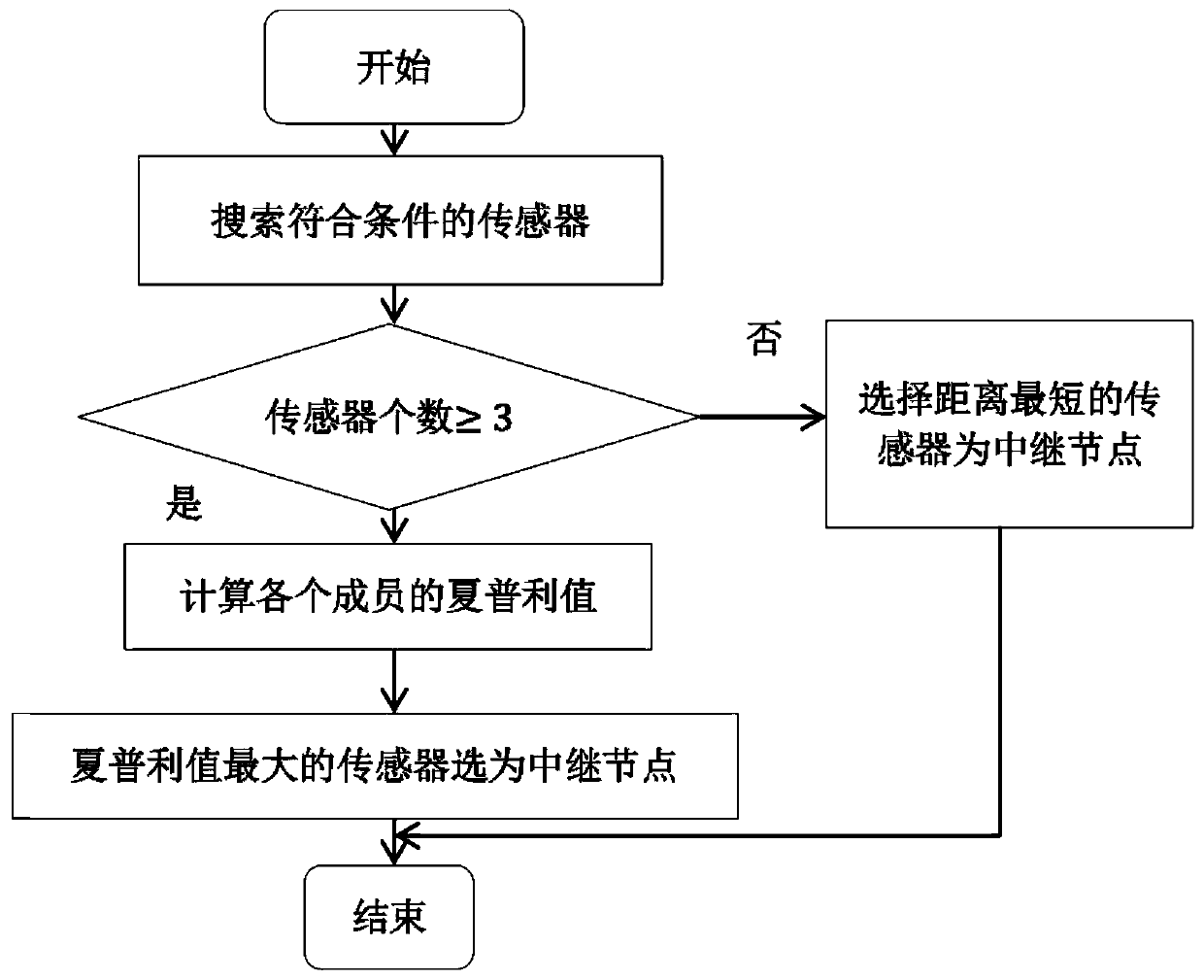

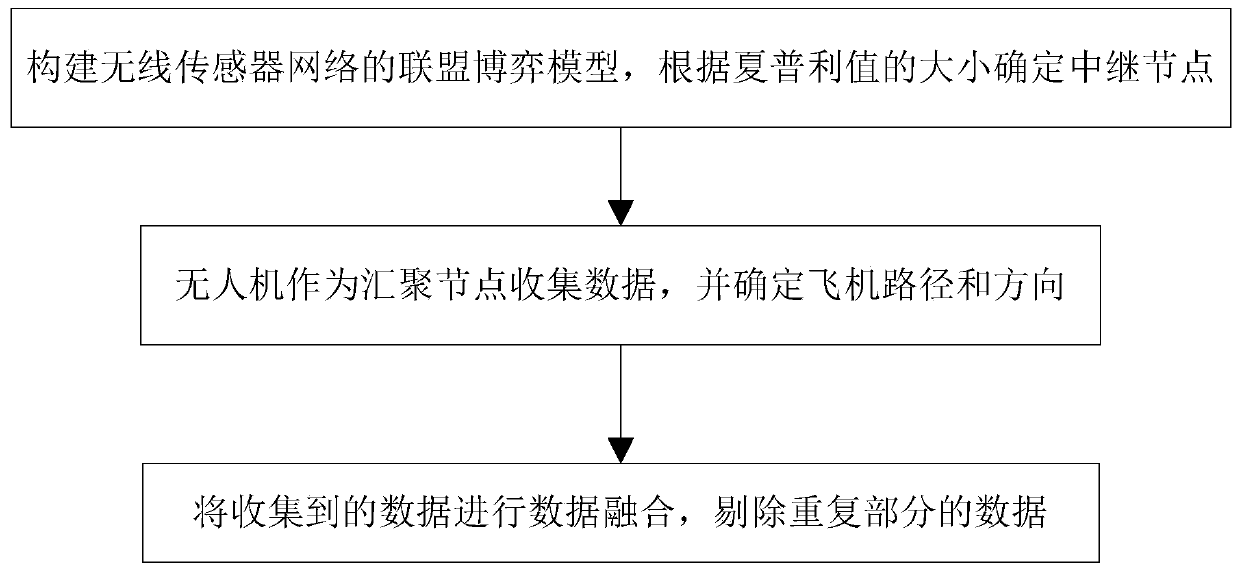

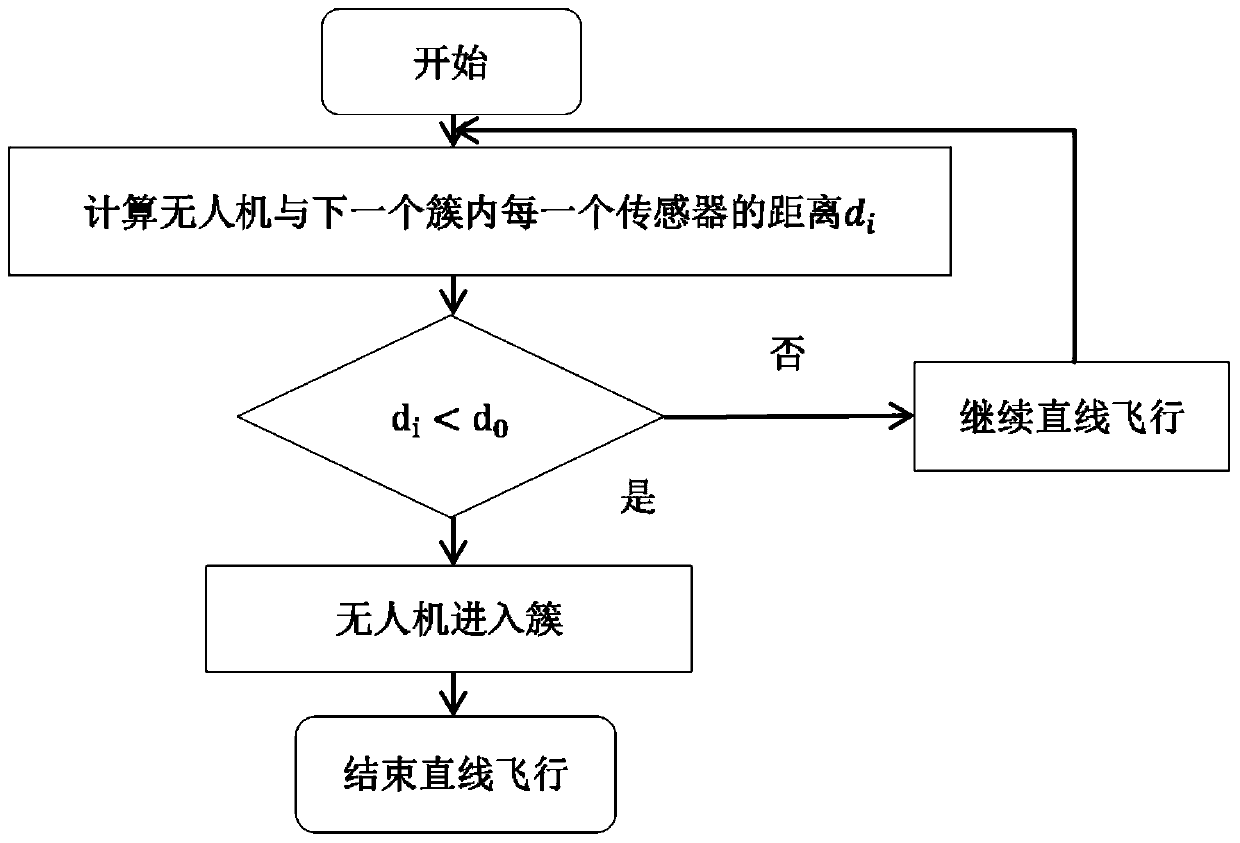

Data fusion alliance game method and system for wireless sensor network

ActiveCN110493844ABalanced energy consumptionEfficient use ofPower managementNetwork topologiesFlight directionWireless sensor networking

The invention discloses a data fusion alliance game method and a data fusion alliance game system for a wireless sensor network. The method comprises the following steps: building an alliance game model based on the wireless sensor network, taking a Shapeland value as a solution of alliance income distribution, and determining a relay node according to the size of the Shapeland value; taking the unmanned aerial vehicle as an aggregation node in the wireless sensor network to collect data, and determining a flight path and a flight direction of the unmanned aerial vehicle; and the unmanned aerial vehicle performs preliminary data fusion on the collected data, and removes repeated parts in the collected data. According to the invention, the unmanned aerial vehicle is used as a mobile aggregation node in the wireless sensor network; a proper sensor data transmission path is selected according to the Shapley value, so that the energy consumption of the sensor is more uniform, more reasonable and more efficient, the life cycle and the working efficiency of the wireless sensor network are improved, the data storage amount of the unmanned aerial vehicle is reduced by adopting data fusion,and the working time of the unmanned aerial vehicle is prolonged.

Owner:GUANGZHOU UNIVERSITY

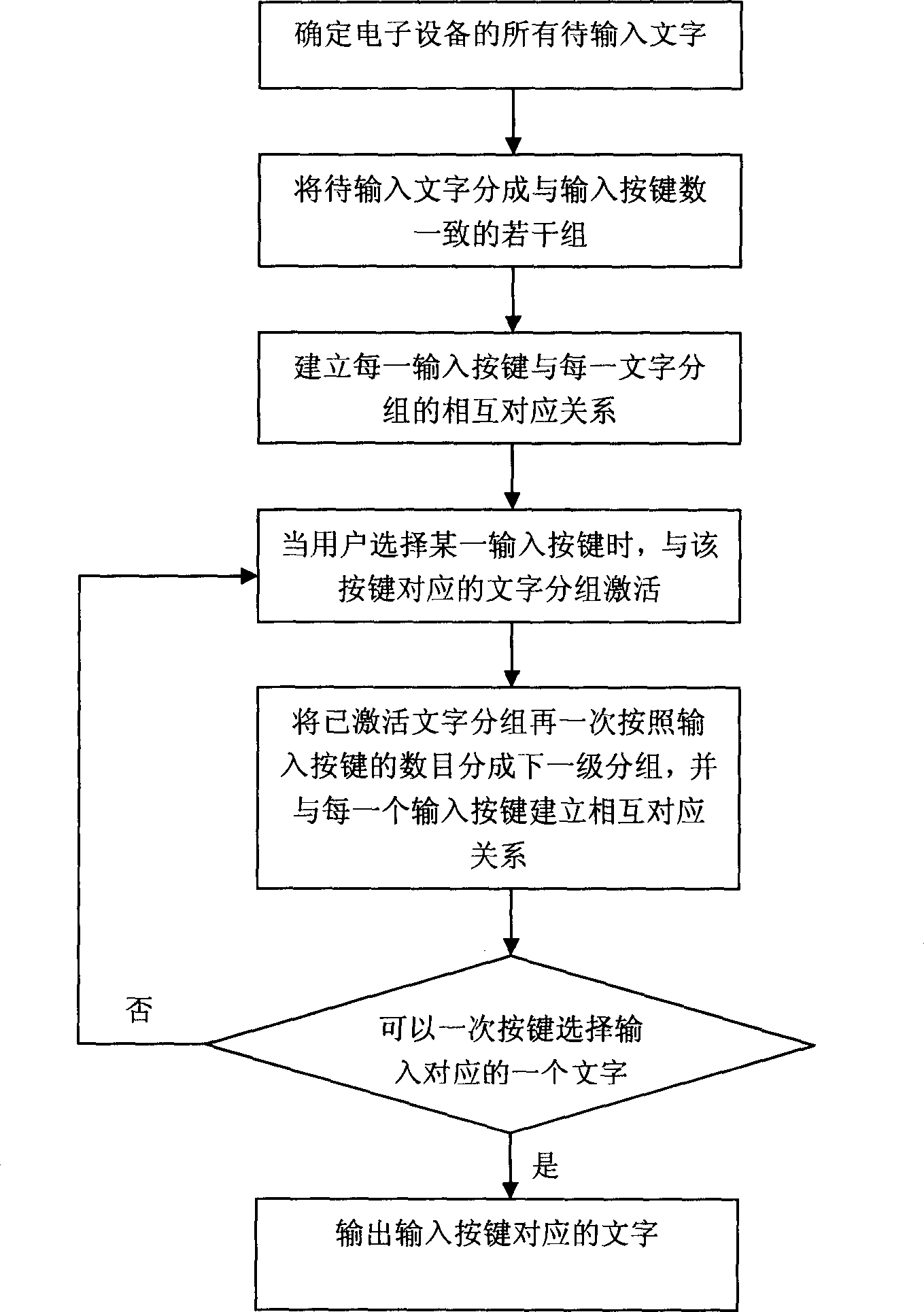

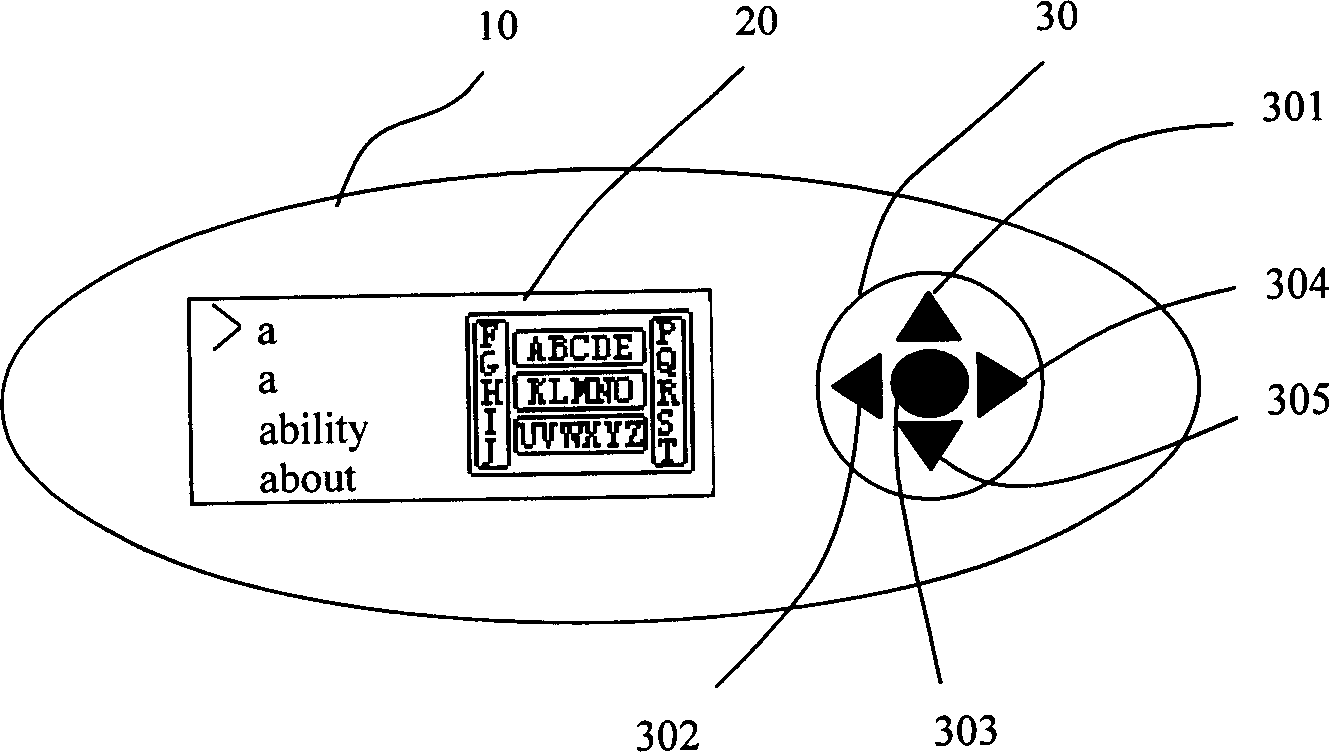

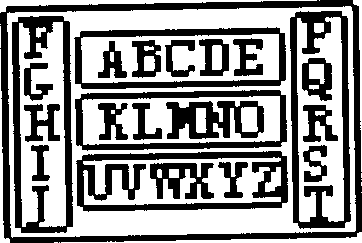

Grading character input method for portable electronic equipment

InactiveCN1821939AReduce the number of keysSolve appearance structureTelephone set constructionsInput/output processes for data processingKey pressingComputer hardware

This invention provides a hierarchical word-input method for portable electronic devices, which divides words to be input into several groups in the same number with the input keys and sets up corresponding relation between the input keys and the word groups then divides the activated groups into the next stage word groups according to the number of the keys till the word of the next stage word group corresponding to an input key can be input by one key, which can input words in less times to reduce the key number.

Owner:深圳市华普教育科技有限公司

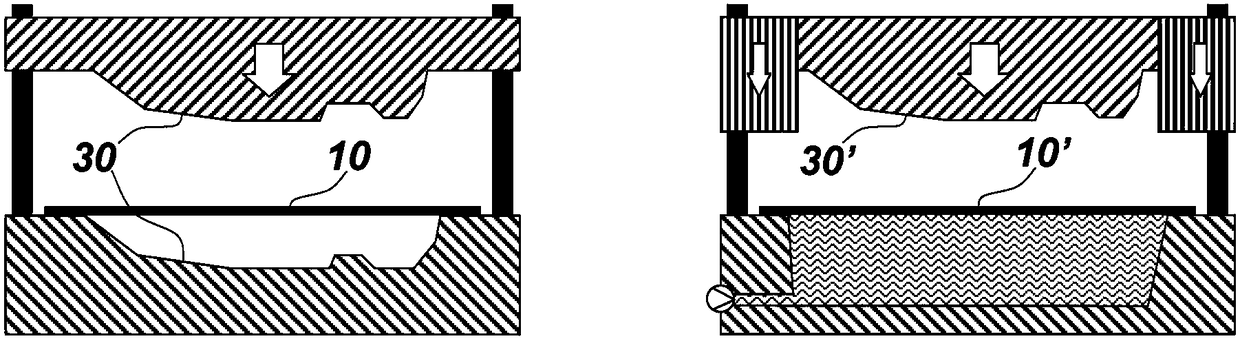

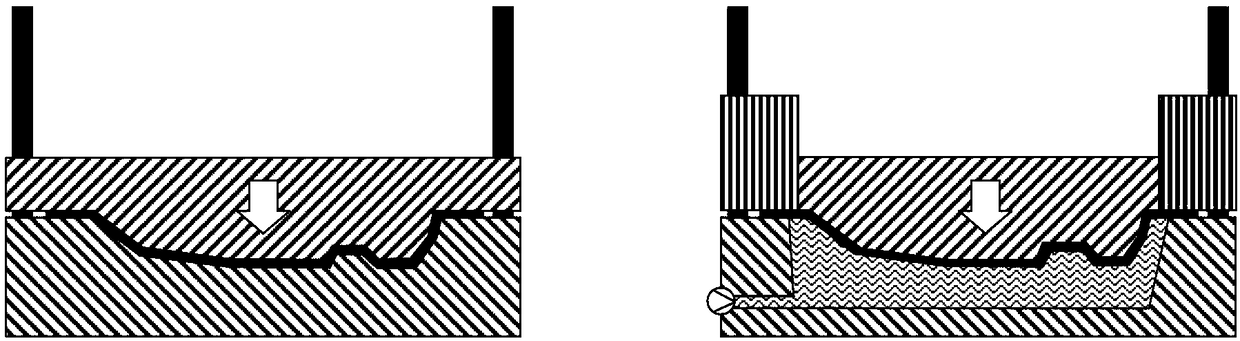

Method for designing a die surface

ActiveCN108664686AReduce the number of repetitionsShorten the timeGeometric CADShaping toolsEngineeringMockup

The invention relates to a method for designing a die surface of a die, comprising generating a workpiece simulation-model corresponding to a workpiece, generating a target simulation-model corresponding to a target formed part, determining an initial die surface, which an initial numerical simulation predicts as forming the workpiece simulation-model into the target simulation-model, determiningresidual stresses resulting from forming the workpiece simulation-model into the target simulation-model, with a die having the initial die surface, forming the workpiece into an actual formed part, by measuring the actual formed part, generating a numerical representation of the actual formed part, based on the numerical representation of the actual formed part, generating an actual simulation-model, based on the residual stresses, matching the actual simulation-model and the target simulation-model, based on deviations between the matched target simulation-model and actual simulation-model,modifying the initial numerical simulation to provide a modified numerical simulation, and determining a corrected die surface, which the modified numerical simulation predicts as forming the workpiece simulation-model into the target simulation-model.

Owner:HEXAGON TECH CENT GMBH

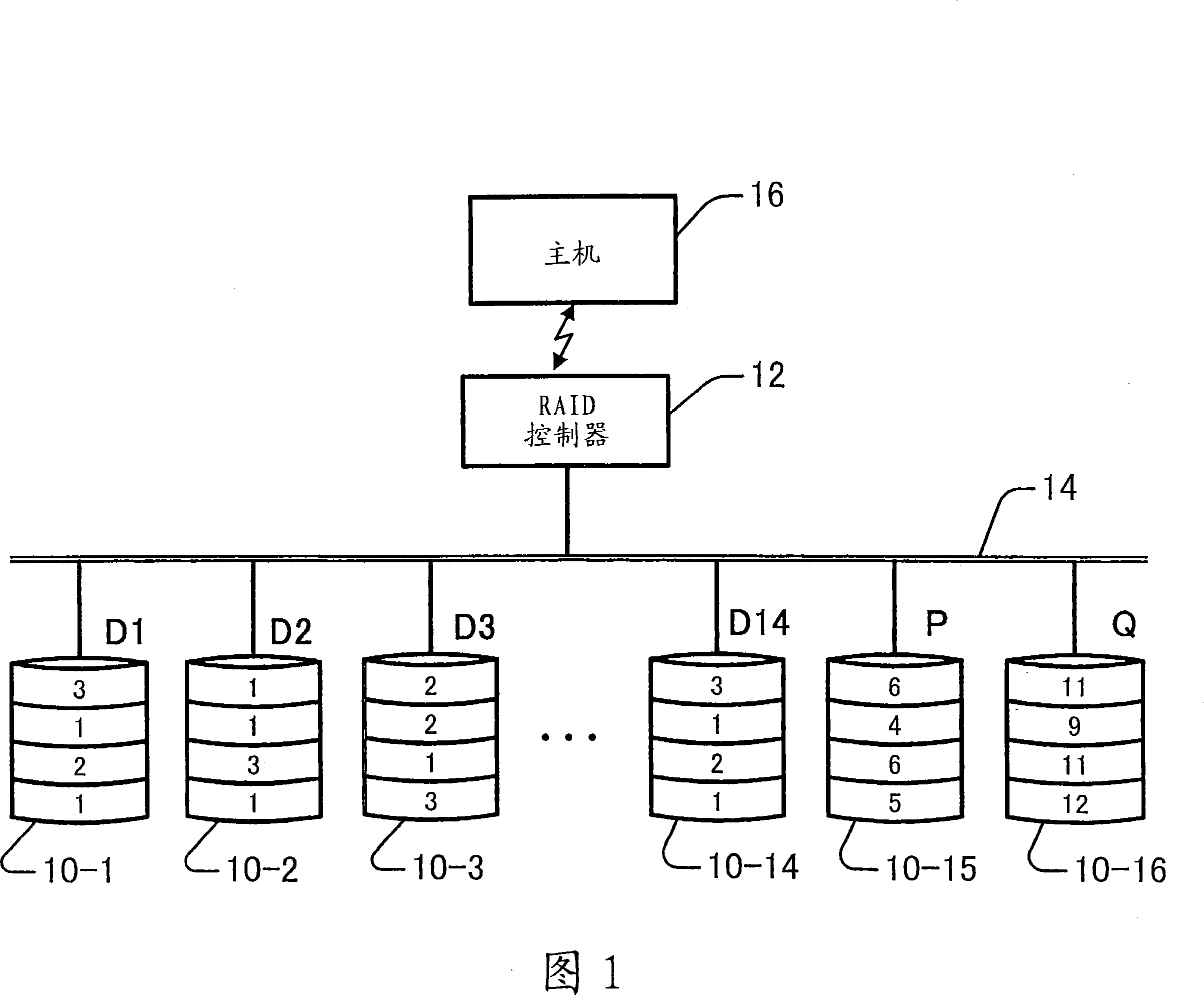

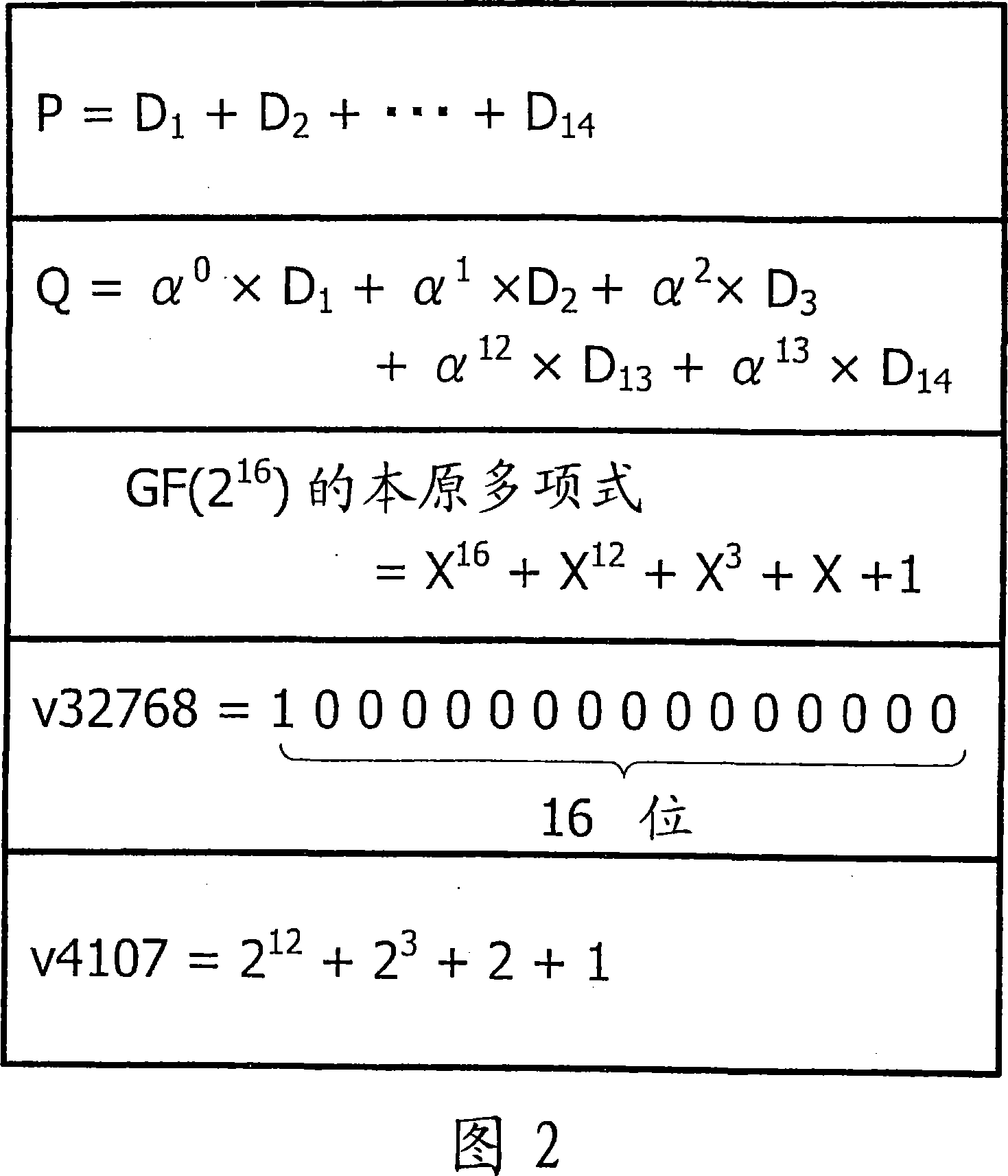

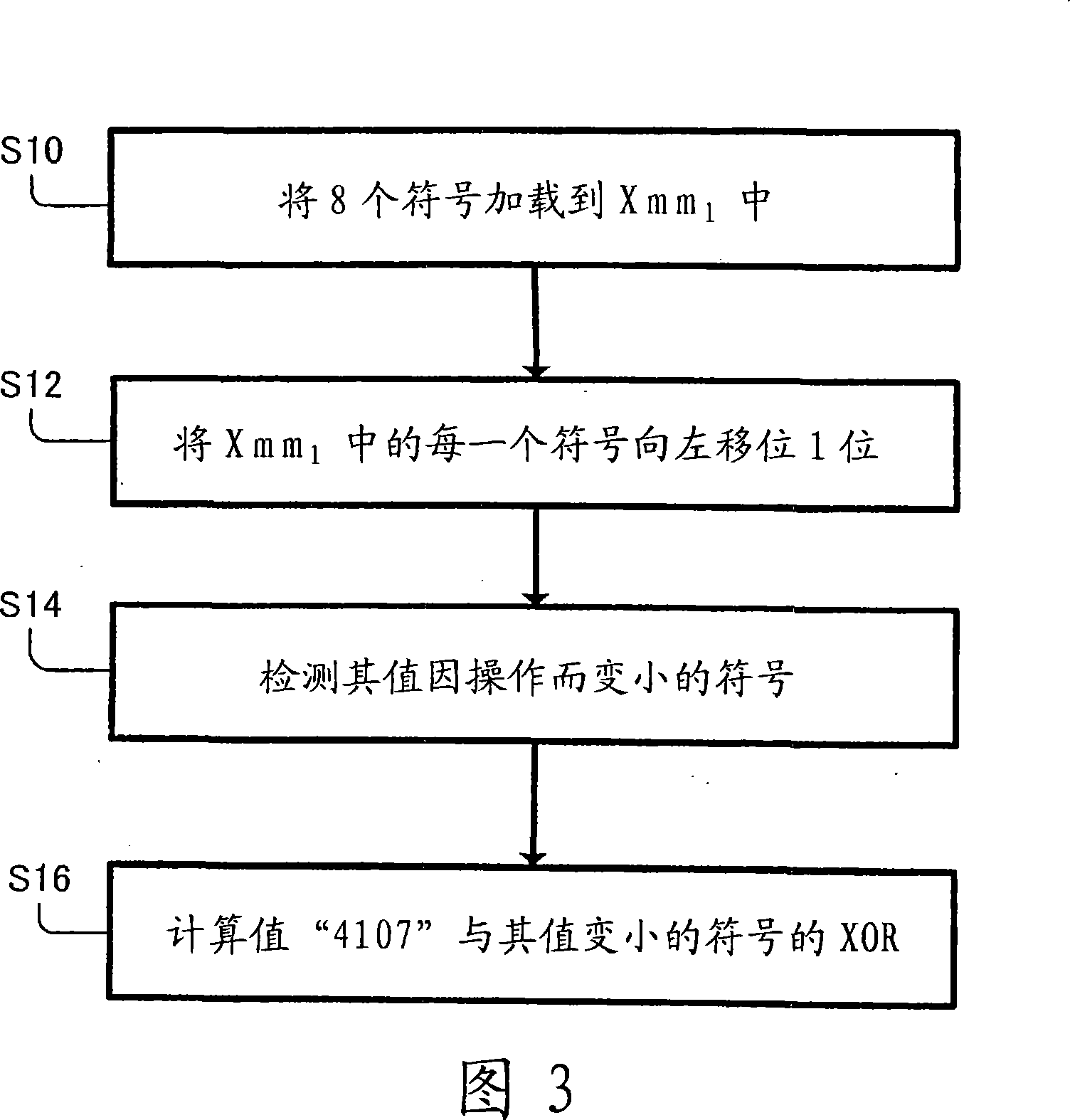

RAID system and galois field product computation method

ActiveCN101226492AReduce processing timeReduce the number of repetitionsComputation using non-contact making devicesError detection onlyRAIDTheoretical computer science

Described is an apparatus for performing a Galois field product computation on data. A first symbol data includes a plurality of symbols each being a bit sequence on which a product operation by a factor alpha is to be performed in a Galois field, where alpha is a primitive element of the Galois field, is acquired. A factor alpha computation is performed on the first symbol data by performing a bit shift operation on the first symbol data toward high-order bit position, generating first mask data from the first symbol data, generating first correction data by computing a logical AND of the first mask data and a first symbol correction value, generating a factor alpha computation result by computing a XOR of the second symbol data and the first correction data.

Owner:FUJITSU LTD

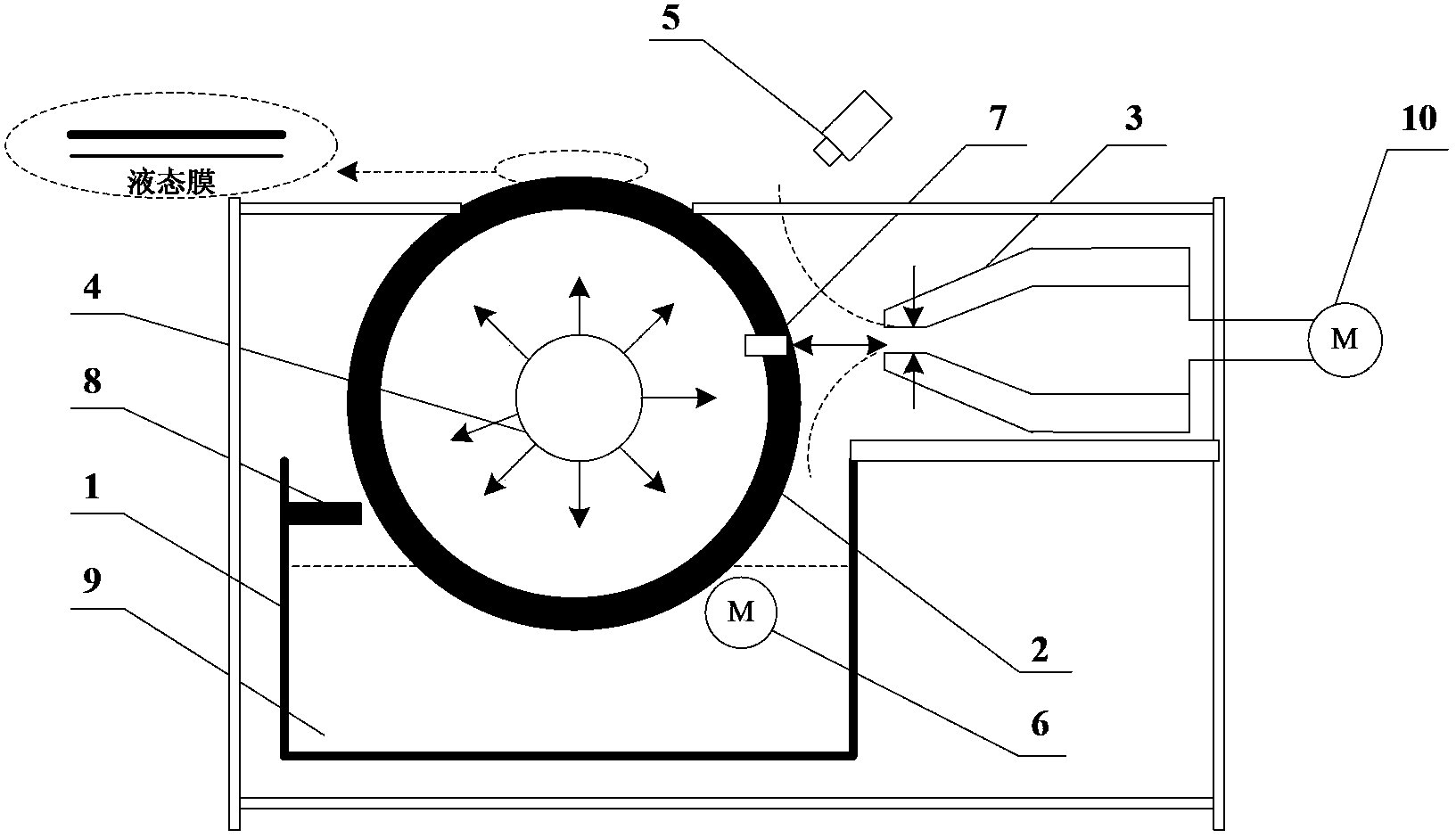

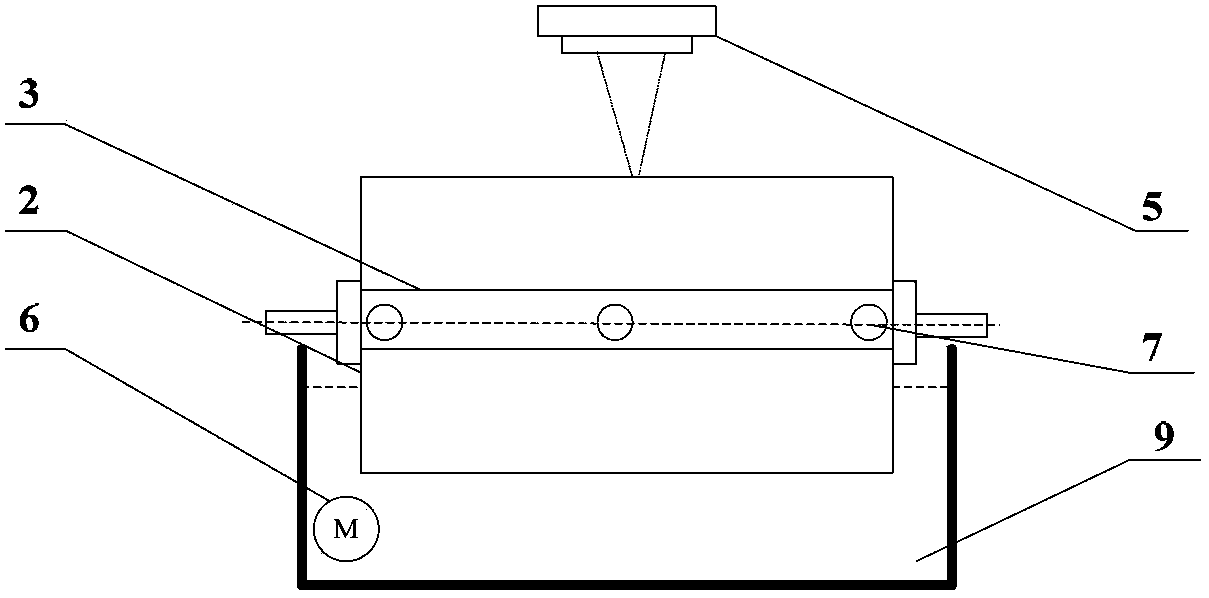

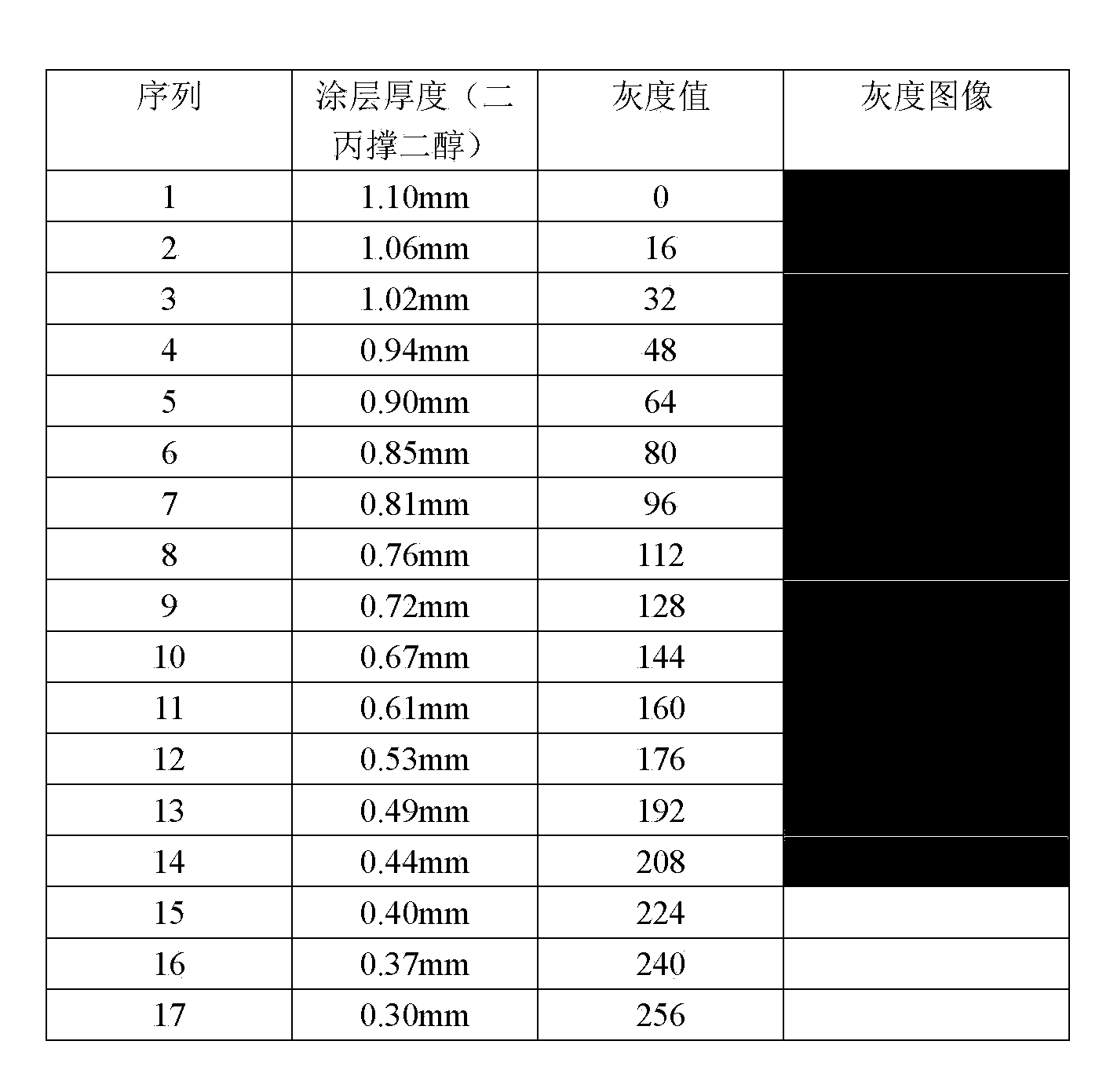

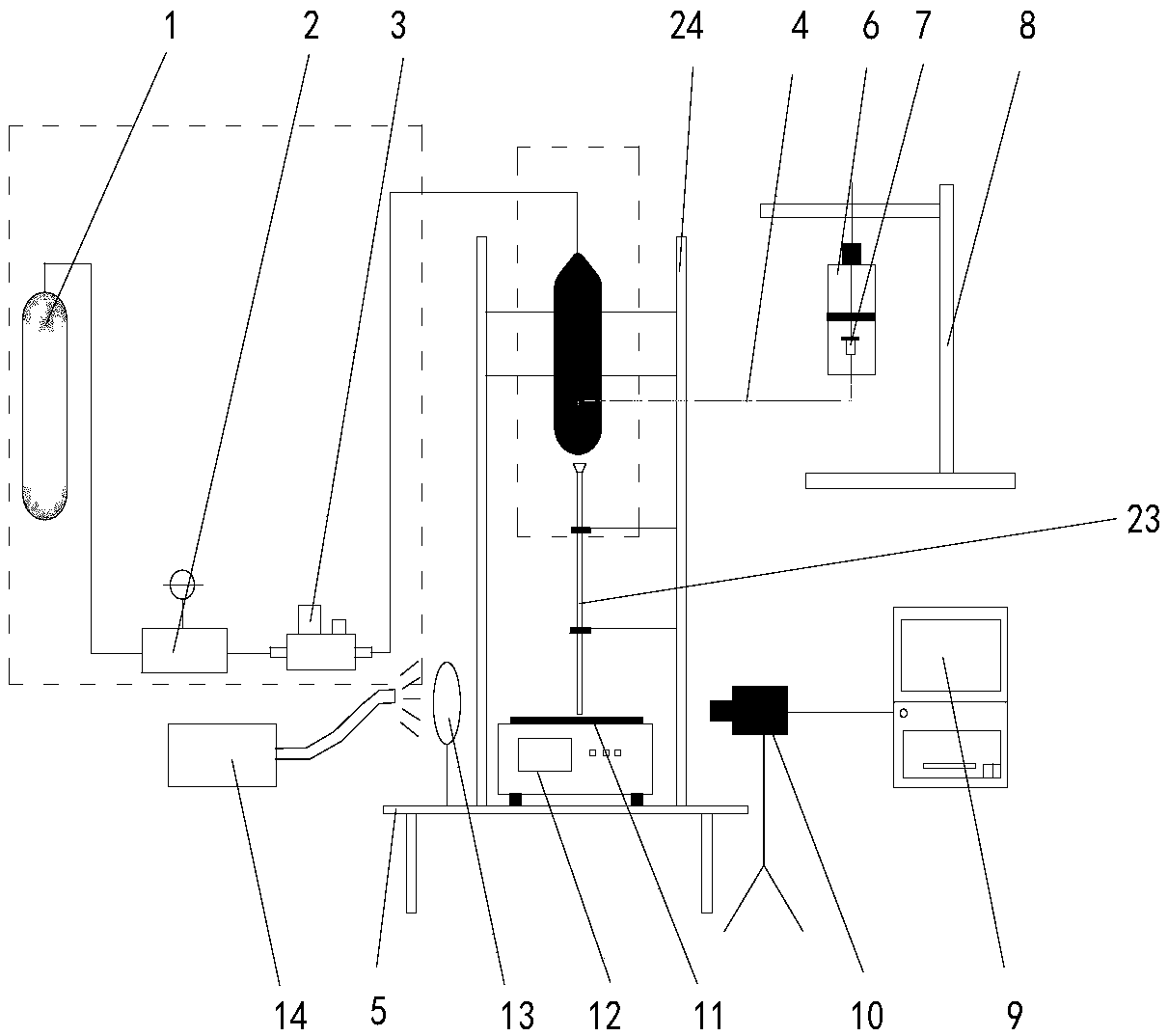

Simulation method and simulation device for controlling thickness of hot dip coating

ActiveCN103512722AGood reproducibilityImprove stabilityAerodynamic testingDiffuse reflectionEngineering

The invention discloses a simulation method for controlling the thickness of a hot dip coating and a simulation device for controlling the thickness of the hot dip coating. The simulation device includes a chemical reagent reservoir, a transparent roller, an air knife, a diffuse reflection light source, a high-speed camera, a motor, a pressure detection instrument, a baffle and a fan; the transparent roller is arranged at an upper portion inside the chemical reagent reservoir; the motor drives the transparent roller; the surface of the transparent roller is provided with the pressure detection instrument; the diffuse reflection light source is arranged inside the transparent roller; one side of the roller is provided with the air knife; and one side of the air knife is provided with the high-speed camera which is located above the transparent roller. The simulation method includes the following steps that: (1) a simulation plating solution is injected into the chemical reagent reservoir, and the pressure detection instrument, the air knife and the motor are started, and a dynamic hot galvanizing process is simulated; (2) the high-speed camera is started to acquire images and data, and the thickness of the coating of the simulation plating solution and an image gradation corresponding data table is contrasted, and data analysis is performed; and (3) the simulation plating solution is collected, and cyclic operation is performed. With the simulation method and the simulation device for controlling the thickness of the hot dip coating adopted, parameters can be optimized, the times of repeated experiments can be reduced, work efficiency can be improved, and the consumption of hot galvanizing experiment-used steel bars and raw materials can be decreased.

Owner:ANGANG STEEL CO LTD

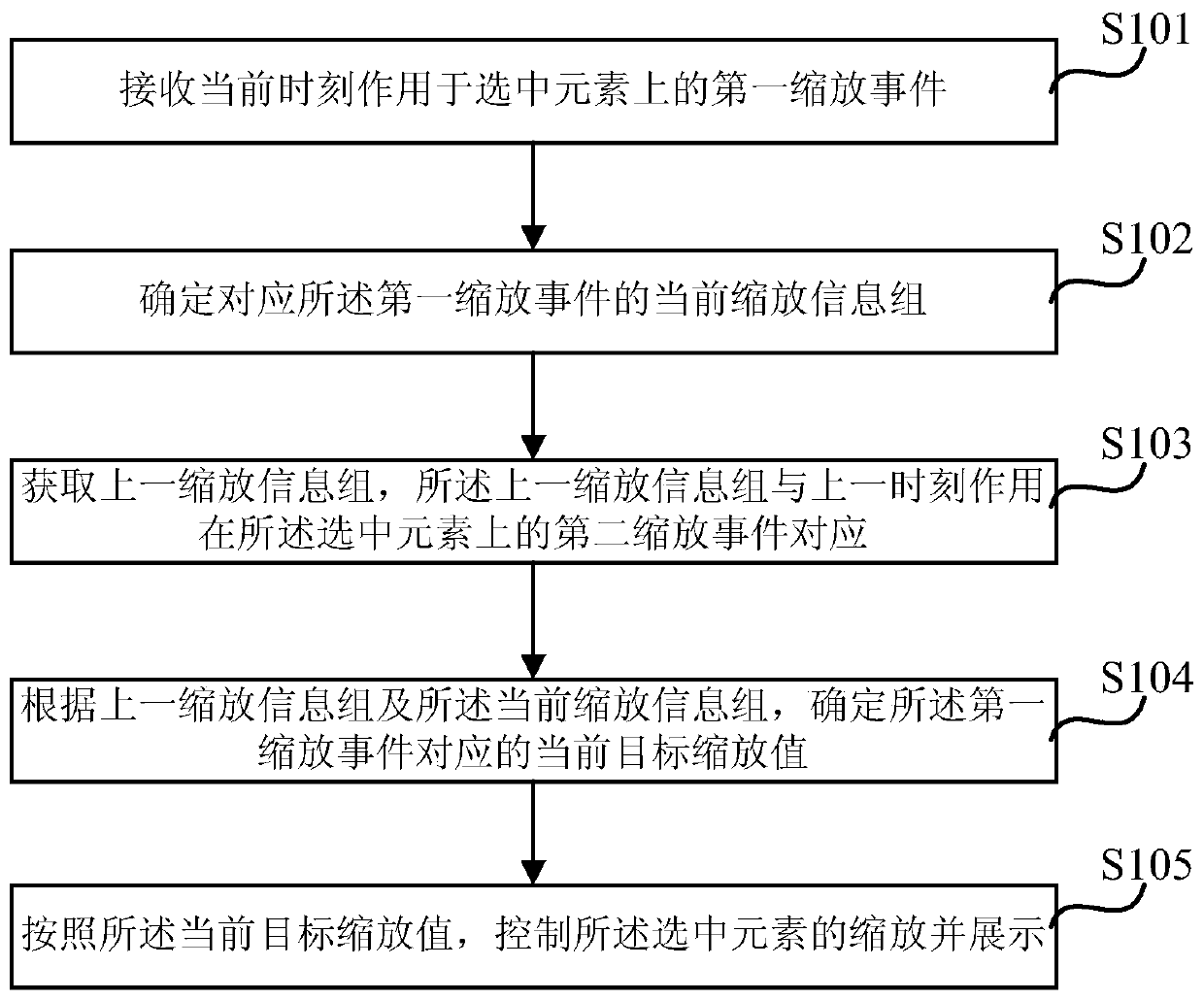

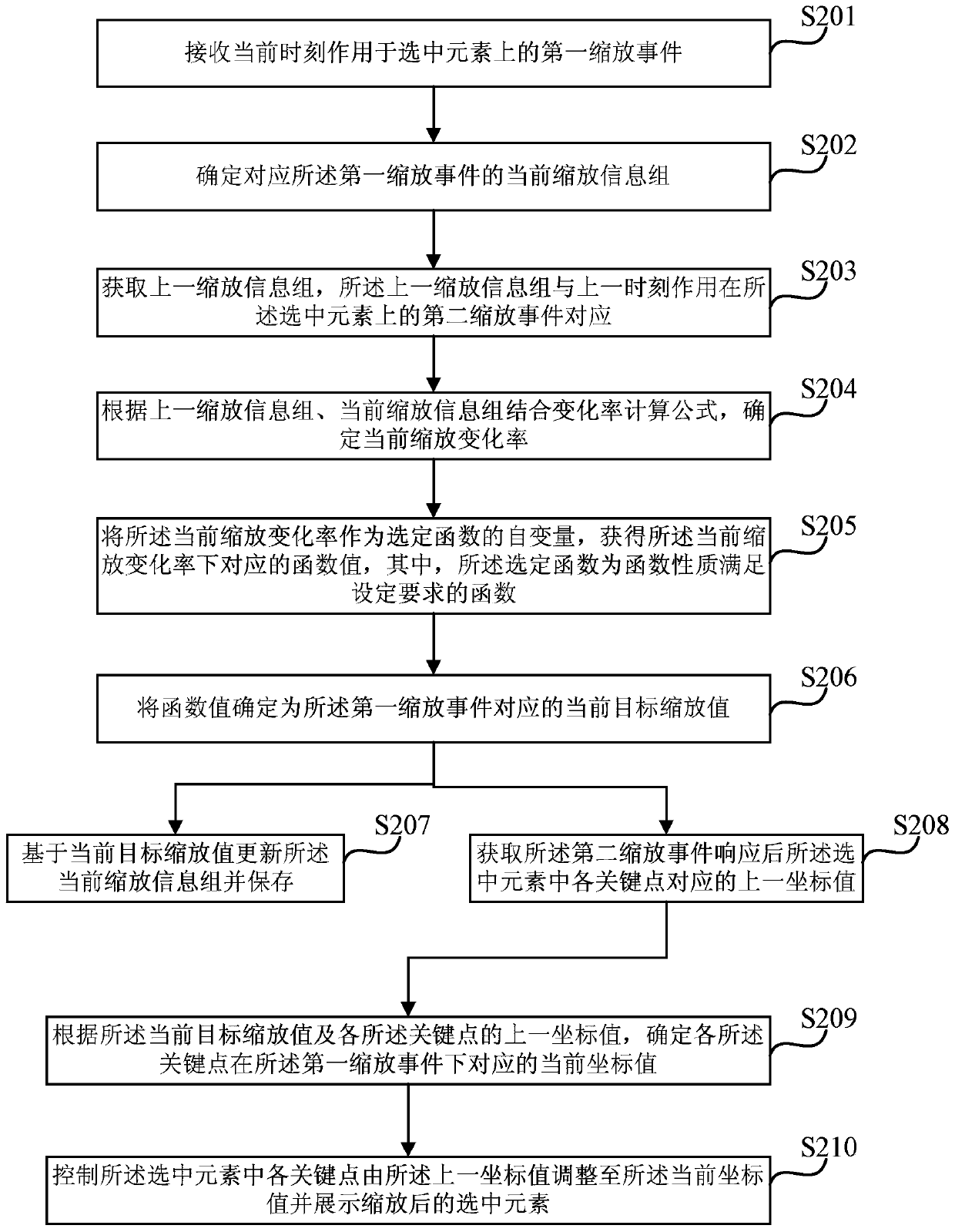

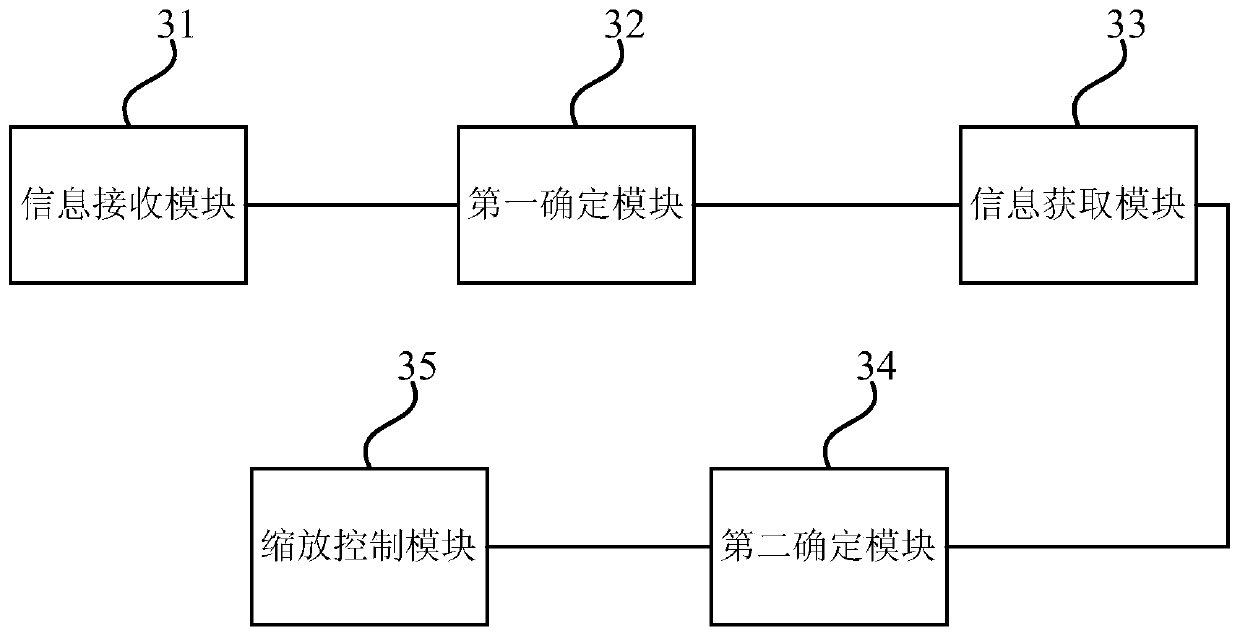

Element scaling control method, device and equipment and storage medium

ActiveCN110286827AReduce the number of repetitionsReduce zoom sensitivityInput/output processes for data processingSmall amplitudeComputer hardware

The embodiment of the invention discloses an element scaling control method and device, equipment and a storage medium. The method comprises the steps of receiving a first scaling event acting on a selected element at the current moment; determining a current scaling information group corresponding to the first scaling event; obtaining a previous zoom information group, wherein the previous zoom information group corresponds to a second zoom event acting on the selected element at the previous moment; determining a current target zoom value corresponding to the first zoom event according to a previous zoom information group and the current zoom information group; and according to the current target zoom value, controlling the zoom and display of the selected element. By utilizing the method, the change process of scaling can be controlled according to the moving speed of the user in the moving process of the scaling gesture, so that the scaling sensitivity during small-amplitude scaling can be better reduced, the effectiveness of scaling control is improved, the scaling speed during large-amplitude scaling is improved, and the repeated execution of the scaling gesture of the user is reduced.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

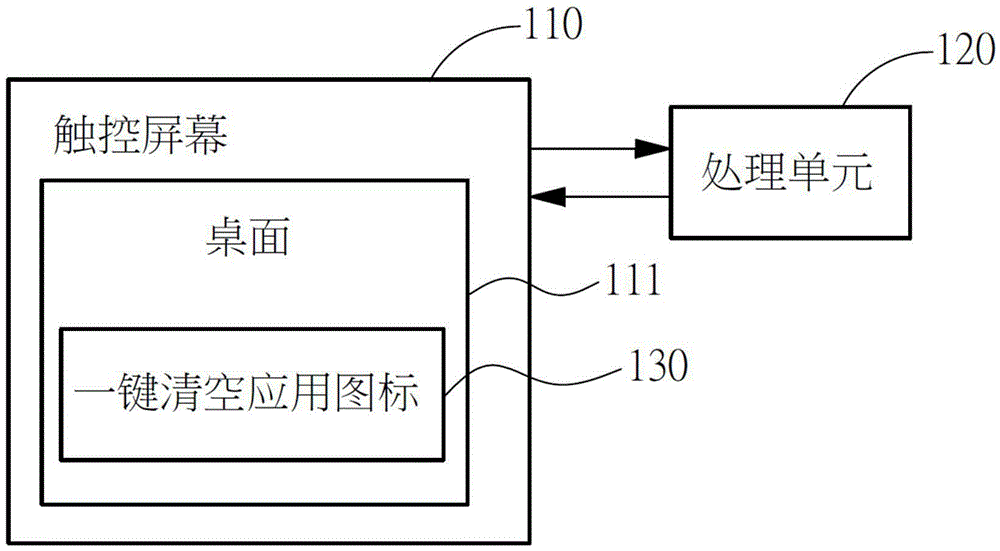

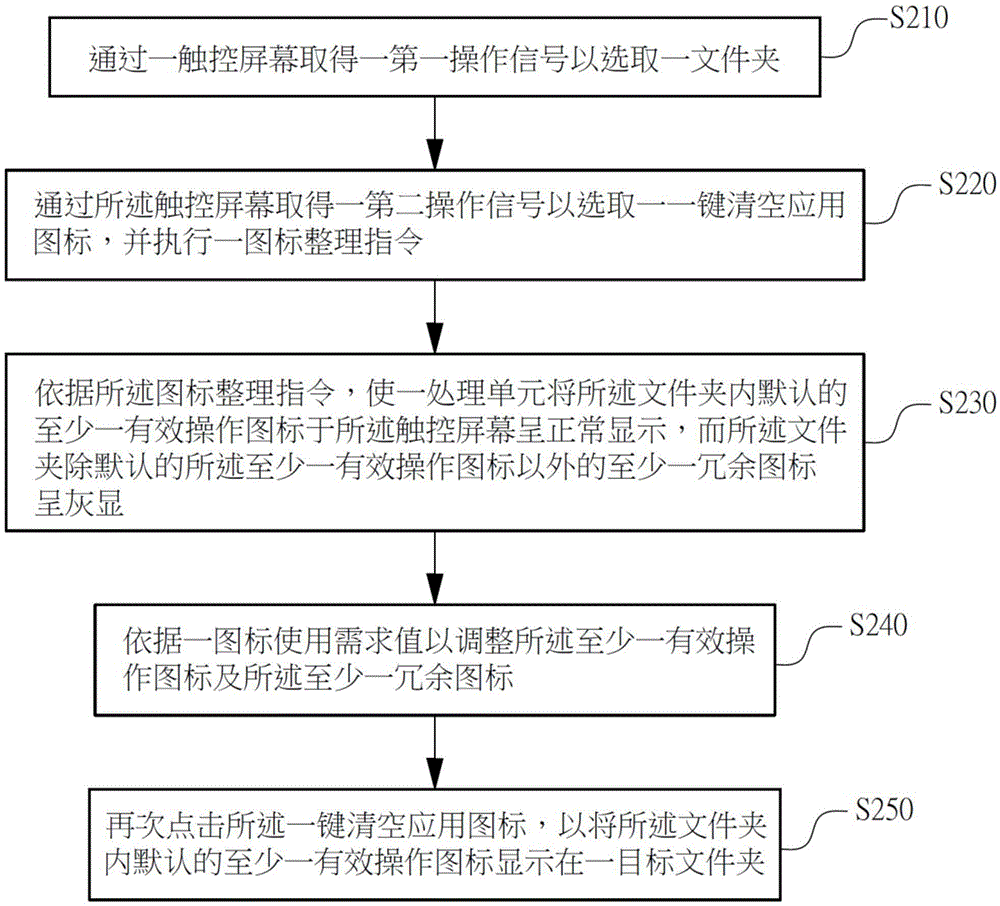

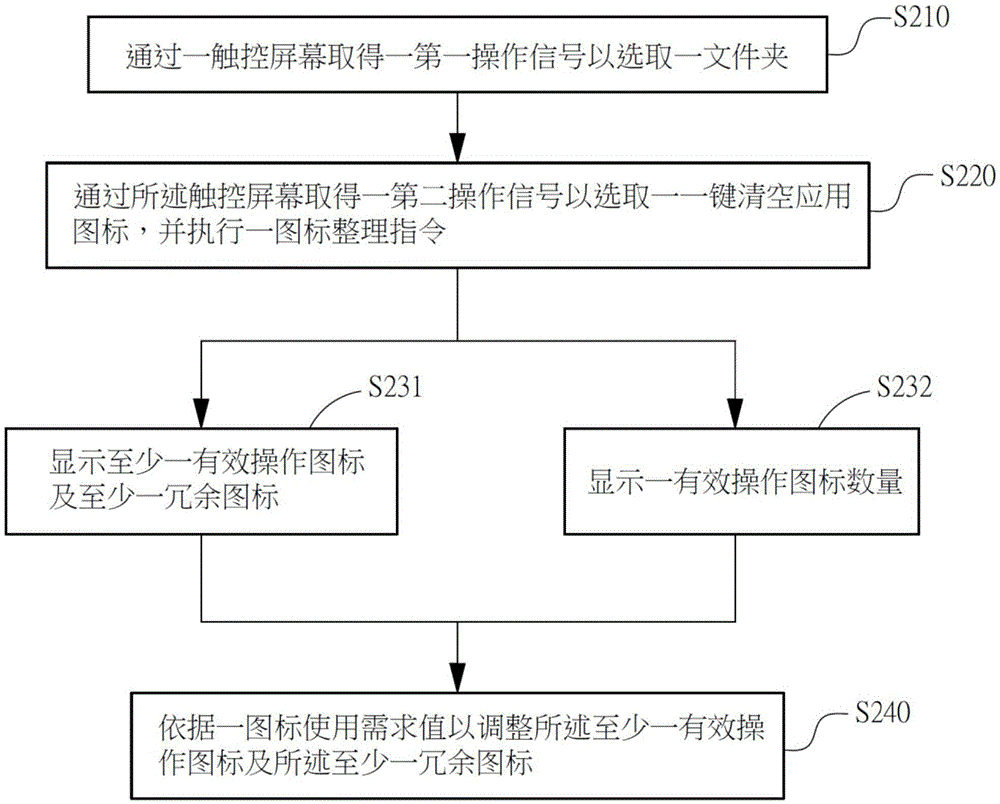

Method and system for merging to display application icons in folder

InactiveCN105630297AReduce stepsImprove efficiencyDigital output to display deviceHuman–computer interactionObject file

The invention relates to a method and a system for merging to display application icons in a folder. The method is characterized by comprising the following steps of obtaining a first operating signal through a touch screen so as to select a folder; obtaining a second operating signal through the touch screen so as to select a one-key empty application icon, and executing an icon arranging instruction; normally displaying at least one default effective operating icon in the folder on the touch screen by a processing unit according to the icon arranging instruction, and displaying at least one redundancy icon in the folder except the at least one default effective operating icon in a dimmed manner; regulating the effective operating icon and the redundancy icon by using the demand value according to an icon; clicking the one-key empty application icon again so as to display the at least one default effective operating icon in the folder in a destination folder.

Owner:SHENZHEN TINNO WIRELESS TECH

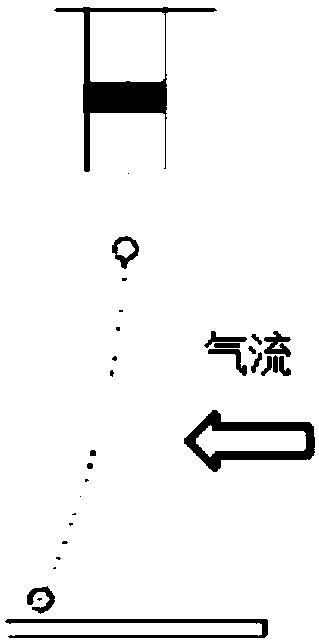

Liquid-drop wall-impingement experimental device capable of correcting drop point drift

ActiveCN109100149ATo achieve stable accelerationDoes not cause driftInternal-combustion engine testingEngineeringAcceleration Unit

The invention discloses a liquid-drop wall-impingement experimental device capable of correcting drop point drift, belongs to the technical field of liquid-drop wall-impingement experiment. The devicecomprises a gas path module, a gas flow acceleration control module, a windproof long pipe, a sliding guide rail, a supporting platform and a liquid-drop generation module; the gas path module is used for providing gas for driving the liquid-drop to accelerate and fall; the liquid-drop generation module is used for repeatedly generating a single liquid-drop; the gas flow acceleration control module is used for guiding gas flow of gas provided by the gas path module, eliminating turbulence, generating laminar flow and performing acceleration process on the liquid-drop through the laminar flow,so that the liquid-drop accelerates and fall and dripped on a testing plane; and the windproof long pipe is mounted on the sliding guide rail and is in a vertical state, wherein a gap is reserved between the bottom portion thereof and the testing plane and the top portion thereof is directly opposite to the liquid-drop outlet end of the gas flow acceleration control module. According to the liquid-drop wall-impingement experimental device, the drop point of the liquid-drop can be completely locked by adding a windproof long pipe with the inner diameter larger than the liquid-drop, thereby effectively solving the problem of drift of the liquid-drop caused by external air.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

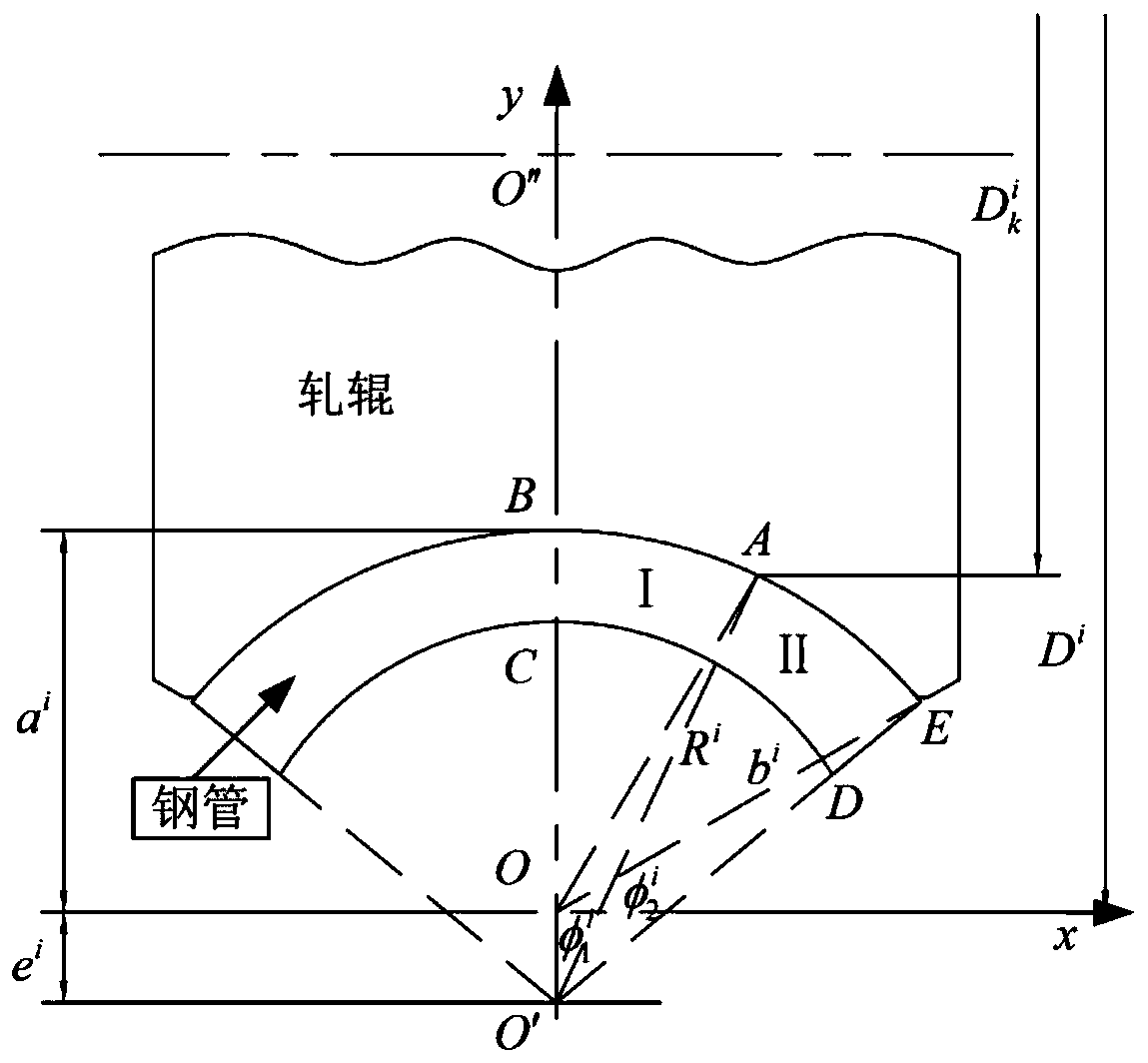

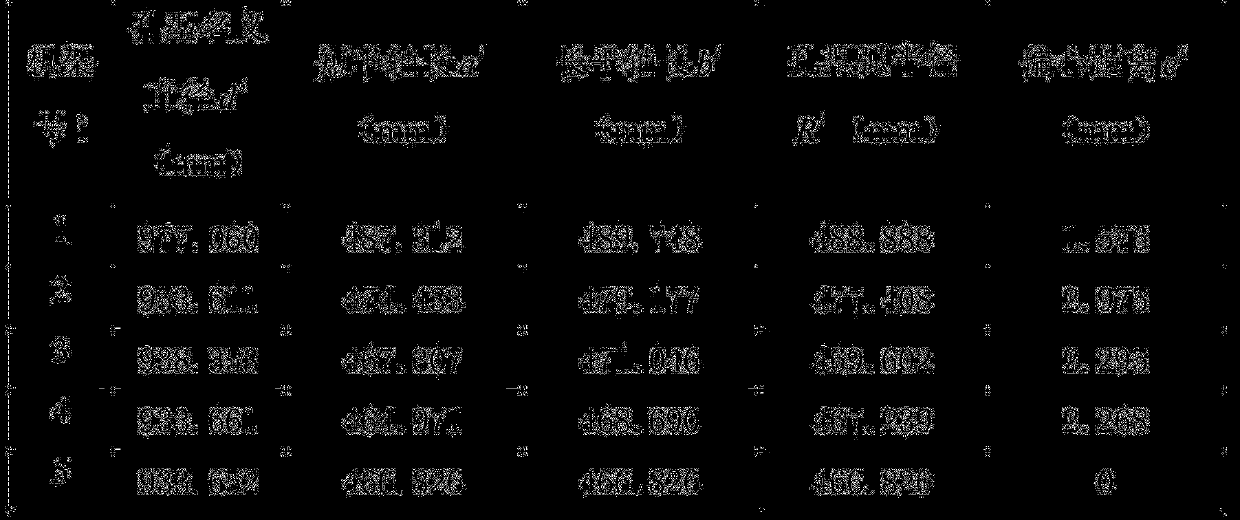

Method for determining basic rotating speed of roller of ultra-large-diameter sizing and reducing mill

ActiveCN110968831AImprove calculation accuracyReduce the number of repetitionsComplex mathematical operationsManufacturing computing systemsEngineeringAxial force

The invention provides a method for determining the basic rotating speed of a roller of an ultra-large-diameter sizing and reducing mill. Aiming at given hole pattern geometrical parameters and inletpipe geometrical parameters, the method utilizes a metal axial force balance equation, a circumferential force balance equation, a metal internal average stress equation and the like in a hole patternto simultaneously solve stress and strain states of metal in the hole pattern, and finally determines basic rotating speed values required to be set by each roller. According to the method, the calculation precision of subsequent force energy parameter calculation can be improved, and the repeated times of new process production experiments can be reduced, and basic rotating speed guidance is provided for further controlling the wall thickness distribution of the pipe by adjusting the rotating speed difference of all the racks, and the design and experiment time is saved, and the requirementsof users with higher requirements are met.

Owner:太原恒信科达重工成套设备有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com