Method for preparing graphene

A technology of graphene and graphite powder, which is applied in the field of graphene preparation by steam explosion, can solve the problems of difficulty in industrial scale preparation, limited graphite exfoliation, and many repeated steps in preparation, so as to achieve abundant raw materials, high exfoliation effect, Efficient peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

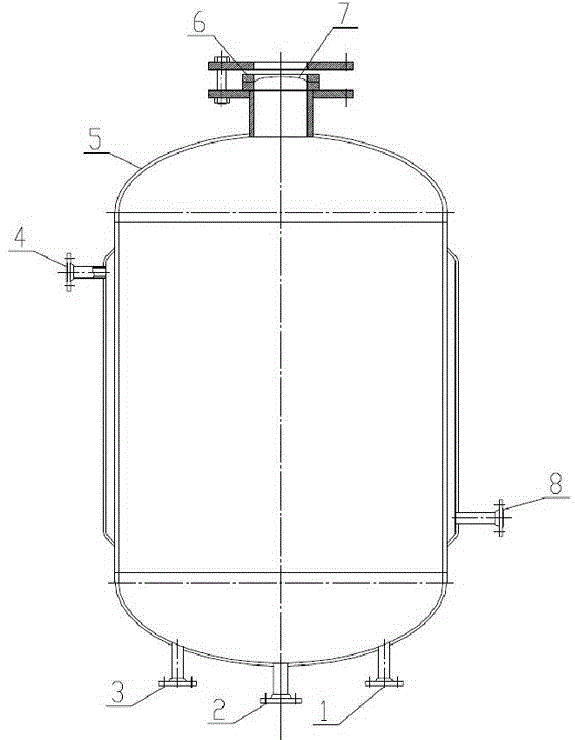

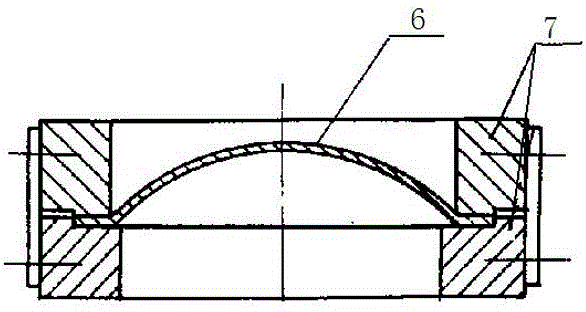

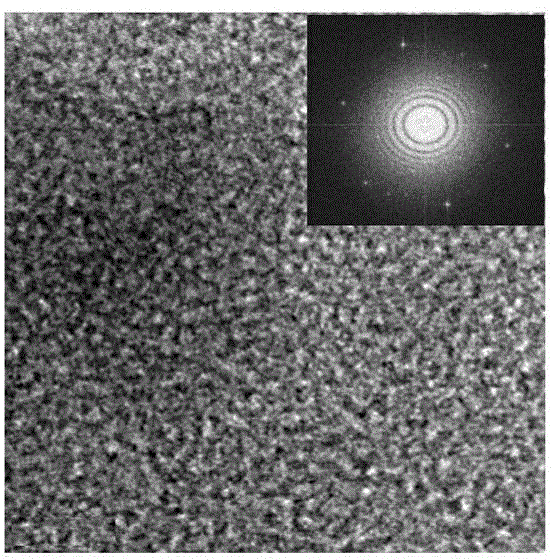

[0043] Inject 25g of graphite powder and 0.5g of n-butanol into the autoclave to mix the two evenly, select a positive arched rupture disc, seal the autoclave well, and pour 50g of propane into the autoclave after vacuuming; the mass ratio of graphite to propane 1:2, the mass ratio of n-butanol to propane is 1:100, control the temperature of the autoclave to 105°C, stay at this temperature for 15 minutes, then slightly increase the temperature and pressure (you can also maintain the same temperature, use compressor to increase the pressure), when the pressure in the autoclave exceeds the pressure 5MPa that the bursting disc can withstand, the bursting disc bursts, and all the materials rush out instantly, and a long cylindrical stainless steel collector with a port at the end is used to collect the materials. The interface is connected to the solvent recovery system, and the collected materials are put into NN-dimethylformamide, stirred for 5 minutes, and left to stand for 12 h...

Embodiment 2

[0045] Inject 60g of graphite powder and 4.8g of NN-dimethylformamide into the autoclave to mix the two evenly, select a reverse arched rupture disc, seal the autoclave well, and pour 240g of propane into the autoclave after vacuuming, graphite and The mass ratio of propane is 1:4, and the mass ratio of dimethylformamide to propane is 2:100; the temperature of the autoclave is controlled at 120°C, and the temperature is kept at this temperature for 5 minutes, and then the temperature is increased slightly, and the pressure is increased (it can also be maintained Keep the temperature constant, use a compressor to increase the pressure), when the pressure in the autoclave exceeds the pressure 6MPa that the bursting disc can withstand, the bursting disc bursts, and all the materials rush out instantly, and are collected by a long cylindrical stainless steel collector with an interface at the end Materials, the tail port of the collector is connected to the solvent recovery system,...

Embodiment 3

[0047] Inject 60g of graphite powder and 5.4g of N-methylpyrrolidone into the autoclave and mix them evenly. Select a flat bursting disc and seal the autoclave well. After vacuuming, pour 180g of propane. The mass ratio of graphite to propane is 1:3 , the mass ratio of methylpyrrolidone to propane is 3:100, control the temperature of the autoclave to 110°C, stay at this temperature for 10 minutes, then slightly increase the temperature and pressure (you can also maintain the same temperature and increase the pressure with a compressor ), when the pressure in the autoclave exceeds the pressure 8 MPa that the rupture disc can withstand, the rupture disc bursts, and all the materials rush out instantly, and a long cylindrical stainless steel collector with a port at the end is used to collect the materials, and the tail port of the collector is connected to the solvent recovery The system is connected, the collected materials are put into the autoclave again, and the above operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com