Method for determining basic rotating speed of roller of ultra-large-diameter sizing and reducing mill

A technology with a super-large diameter and a certain method, which is applied in the field of seamless steel pipe rolling, can solve problems such as the large deviation between the wall thickness of the finished pipe and the calculation, the deviation of the theoretical calculation value, and the failure of the traditional algorithm, so as to reduce the number of repetitions and save time , the effect of improving the calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: The method for determining the basic rotational speed of rolls of super-large caliber sizing and reducing mills of the present invention comprises the following steps:

[0037] Formula 1:

[0038] in: are the cross-sectional areas of pipes in Zone I and Zone II, respectively. Since the θ-direction force of the metal in the zone Ⅰ and zone Ⅱ is balanced, the average circumferential stress Satisfies the following formula:

[0039] Formula 2:

[0040] in: are the average wall thickness of pipes in Zone I and Zone II, respectively. Average radial stress of metal in zone Ⅰ and zone Ⅱ mean hoop stress mean axial stress The expressions are:

[0041] Formula 3:

[0042] Formula 4:

[0043] Formula 5:

[0044] Formula 6:

[0045] Formula 7:

[0046] Formula 8:

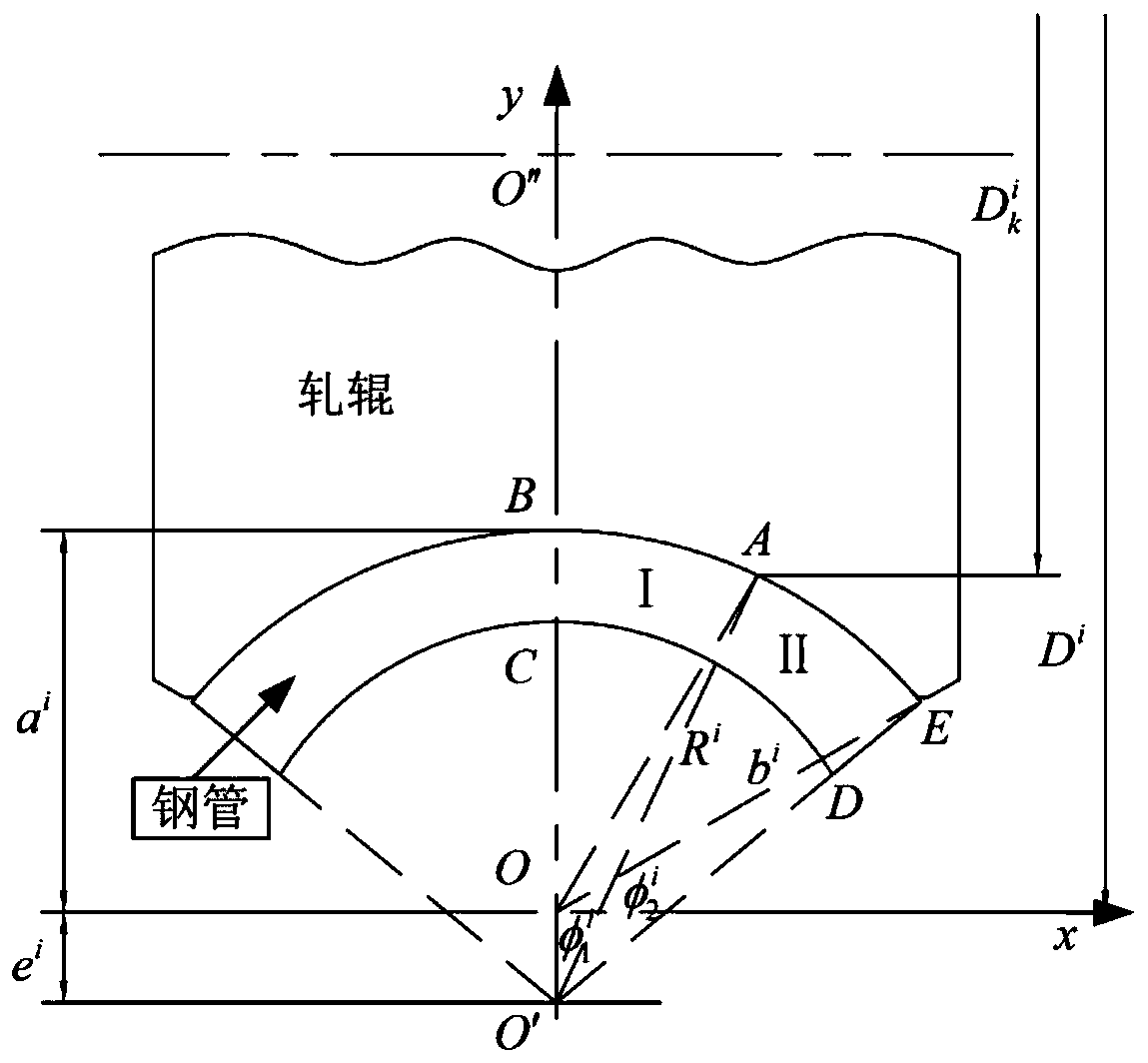

[0047] In formula 3 to formula 8: kf is the material deformation resistance, R i to attach figure 1 Indicates the radius of the arc BAE, that is, the arc radius of the...

Embodiment 2

[0070] The above method is used to calculate the basic speed of the roll of a φ920 seamless steel pipe sizing and reducing mill unit. The calculation process and results are as follows.

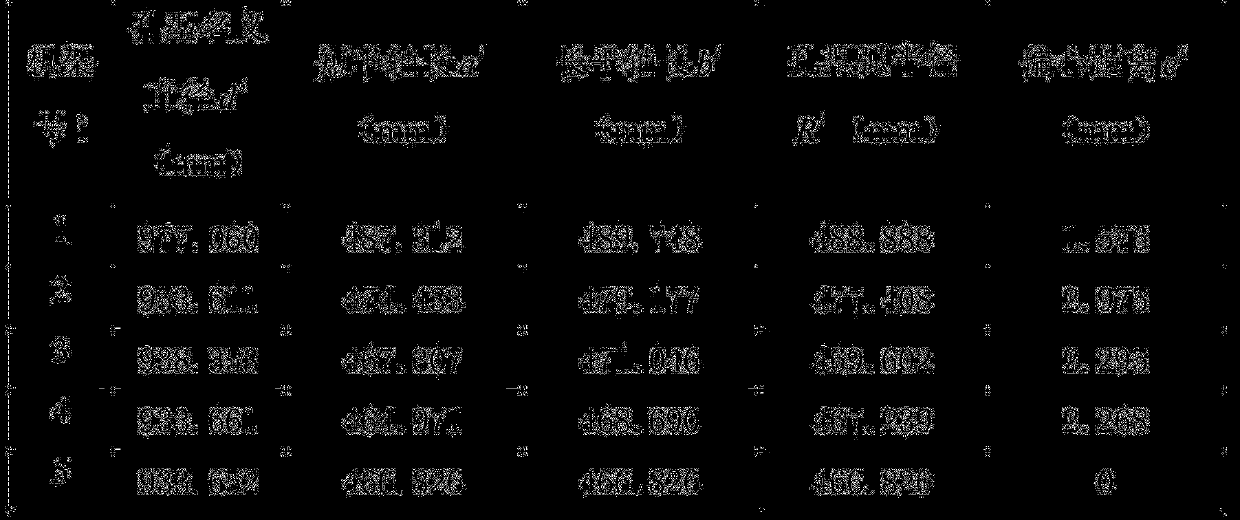

[0071] (1) Calculating the known pass parameters with the number of total racks of the fixed reducing machine m=5, the center distance of the rolls D i =1500mm, entrance speed V 0 =0.3m / s, the outer diameter of the inlet pipe of the first frame d 0 =980mm and wall thickness δ 0 = 50mm (hot state), other parameters such as: hole nominal diameter d i , long semi-minor axis a i , long semi-major axis b i , hole arc radius R i , the eccentric distance e between the hole arc center O' and the hole center O i See Table 1.

[0072] Table 1 Geometric parameter table of pass type of a φ920 seamless steel pipe sizing and reducing machine unit

[0073]

[0074] (2) Substituting the known data of each frame into formula 1 to formula 19 and simultaneously solving the average wall thickness δ of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com