Fully mechanized caving face along-track end bracket

A technology of fully mechanized caving face and end bracket, applied in the field of end bracket of fully mechanized caving face, can solve the problems of difficult column replacement, inability to adjust spacing, inability to bear eccentric load, etc., so as to improve supporting capacity and supporting area, Simple structure and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

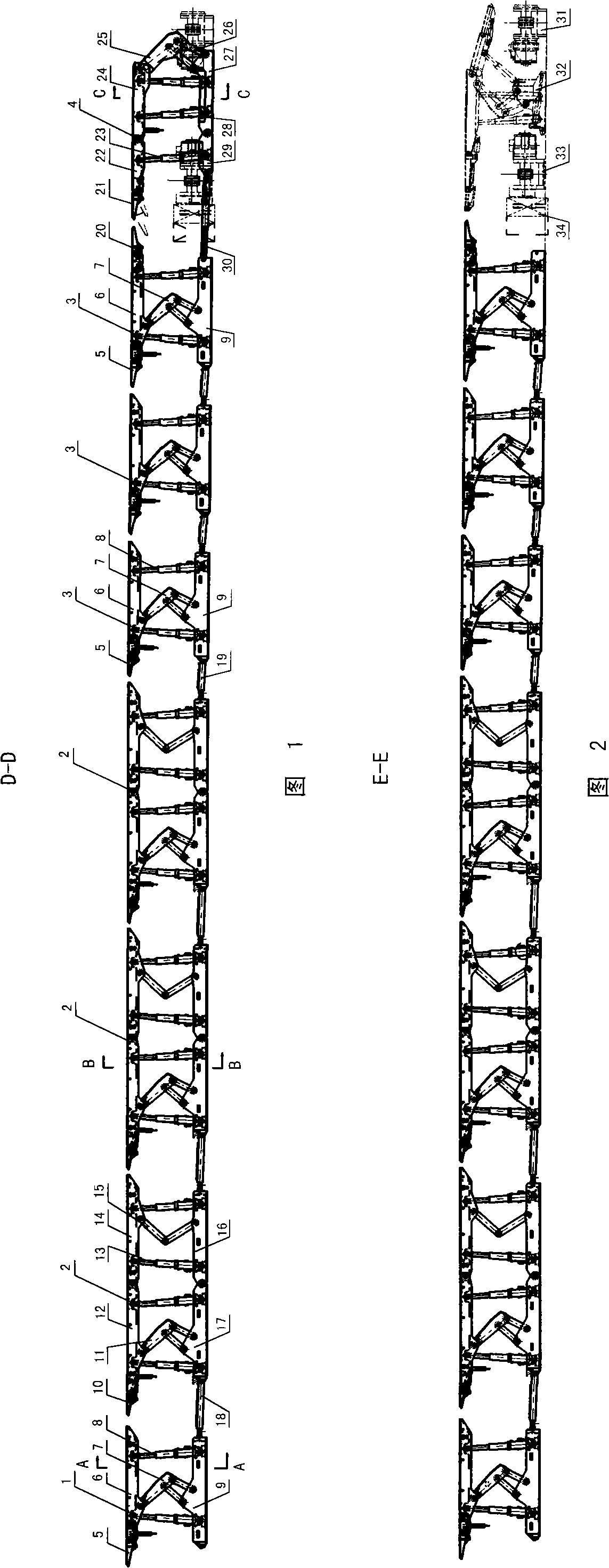

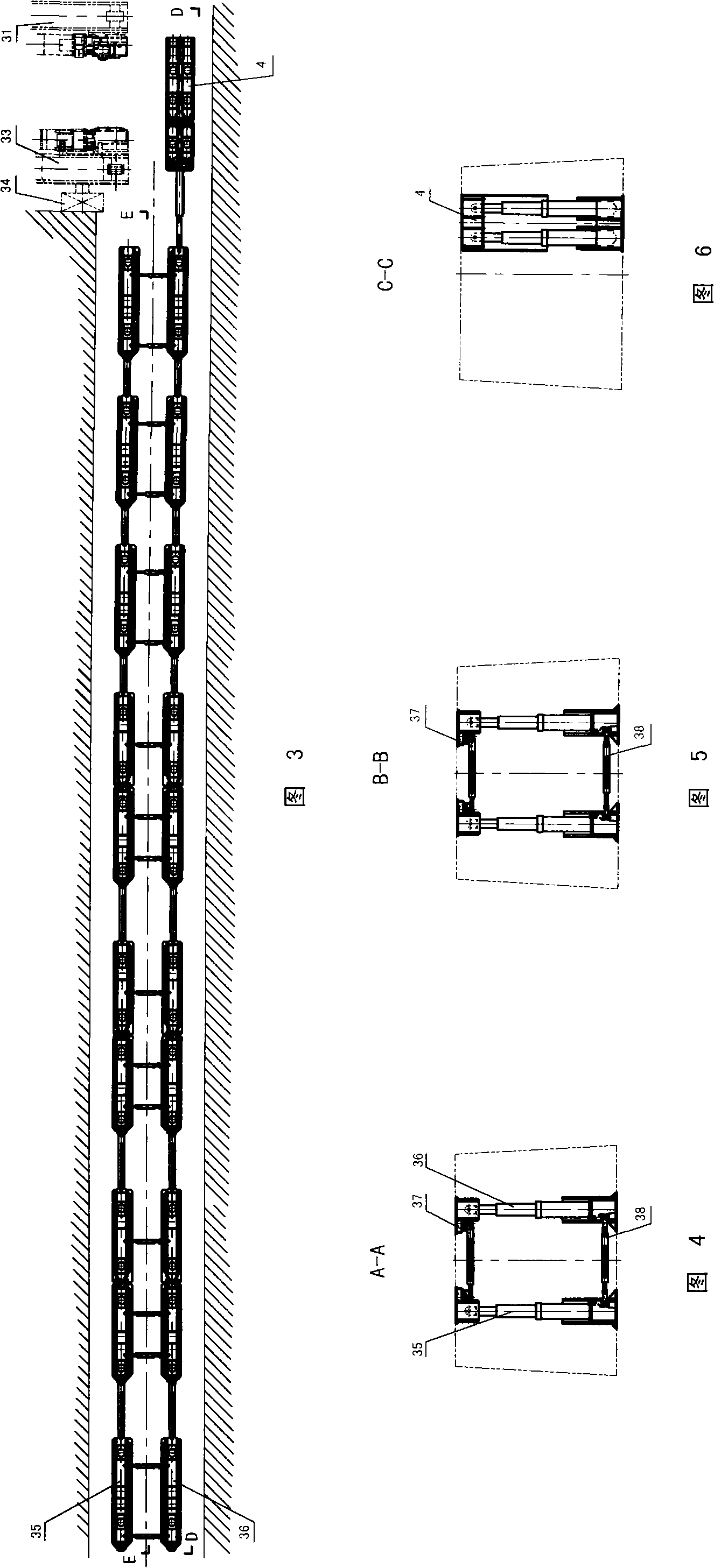

[0027] Figures 1 to 3 show the composition of the rail alignment end bracket of the fully mechanized caving face of the present invention. Its support structure is a four-frame eight-combination type; along the advancing direction of the working face, it is composed of anchor brackets 1, three sets of advanced brackets 2, three sets of end brackets 3, and tail brackets 4. The eight sets of brackets are sequentially connected to the whole end bracket of the cost rail through the pulling jacks between the bases.

[0028] ①Anchor bracket 1: It is a four-column and four-link structure with two inner and outer frames; that is, the anchor bracket 1 is composed of an inner frame 35 and an outer frame 36, that is, the top beam and the base are both inner and outer parts. All between the top beam 6 and the base 9 of the inner and outer frames are formed by two front and rear co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com