Fully mechanized working faces track along end head bracket

A technology of fully mechanized caving face and end support, which is applied in the field of end support of fully mechanized caving face, which can solve the problems of large deformation along the track, large roof sinking, and small roof sinking, etc., to achieve empty roof The effect of small area, small roof sinking, and reduced labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

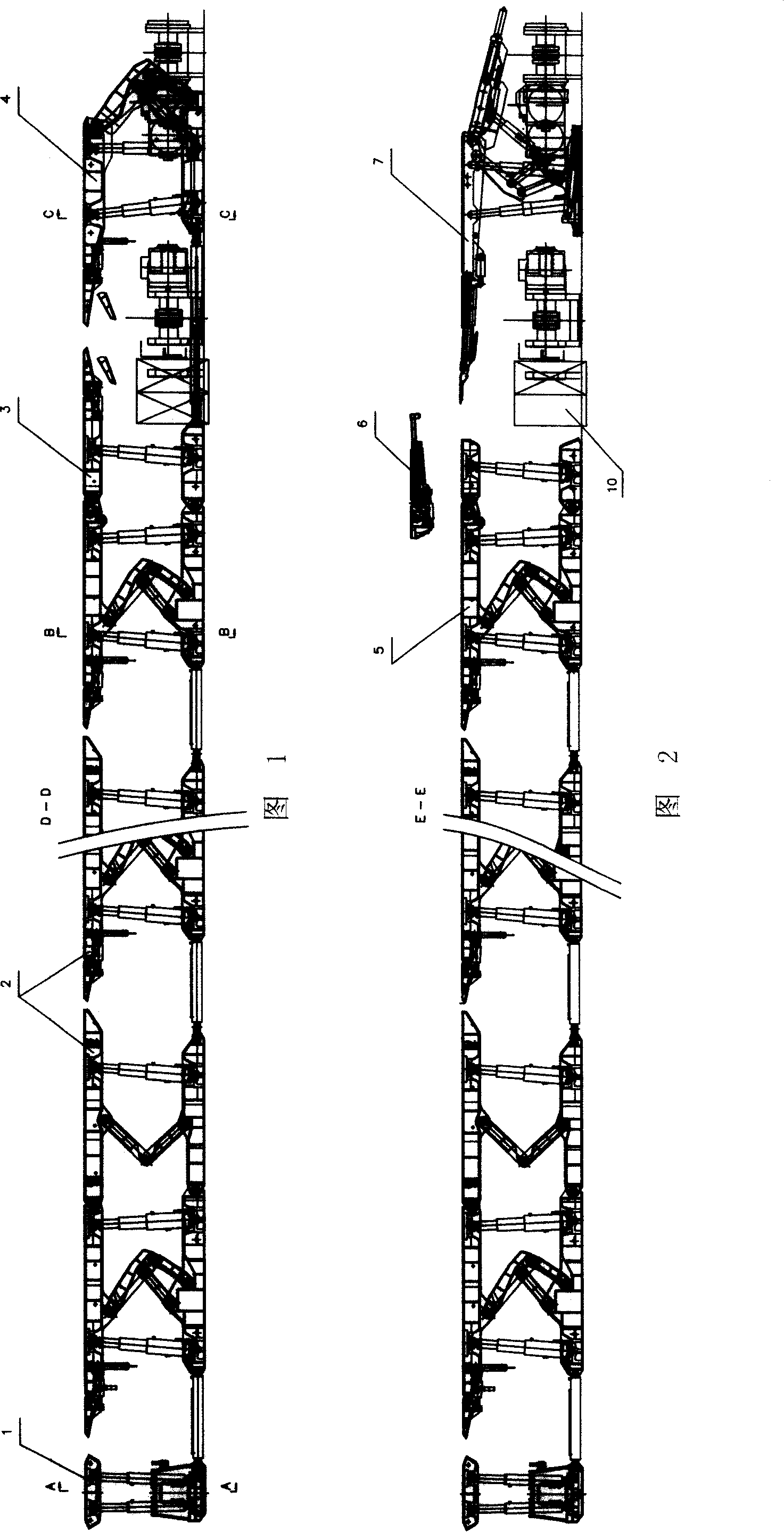

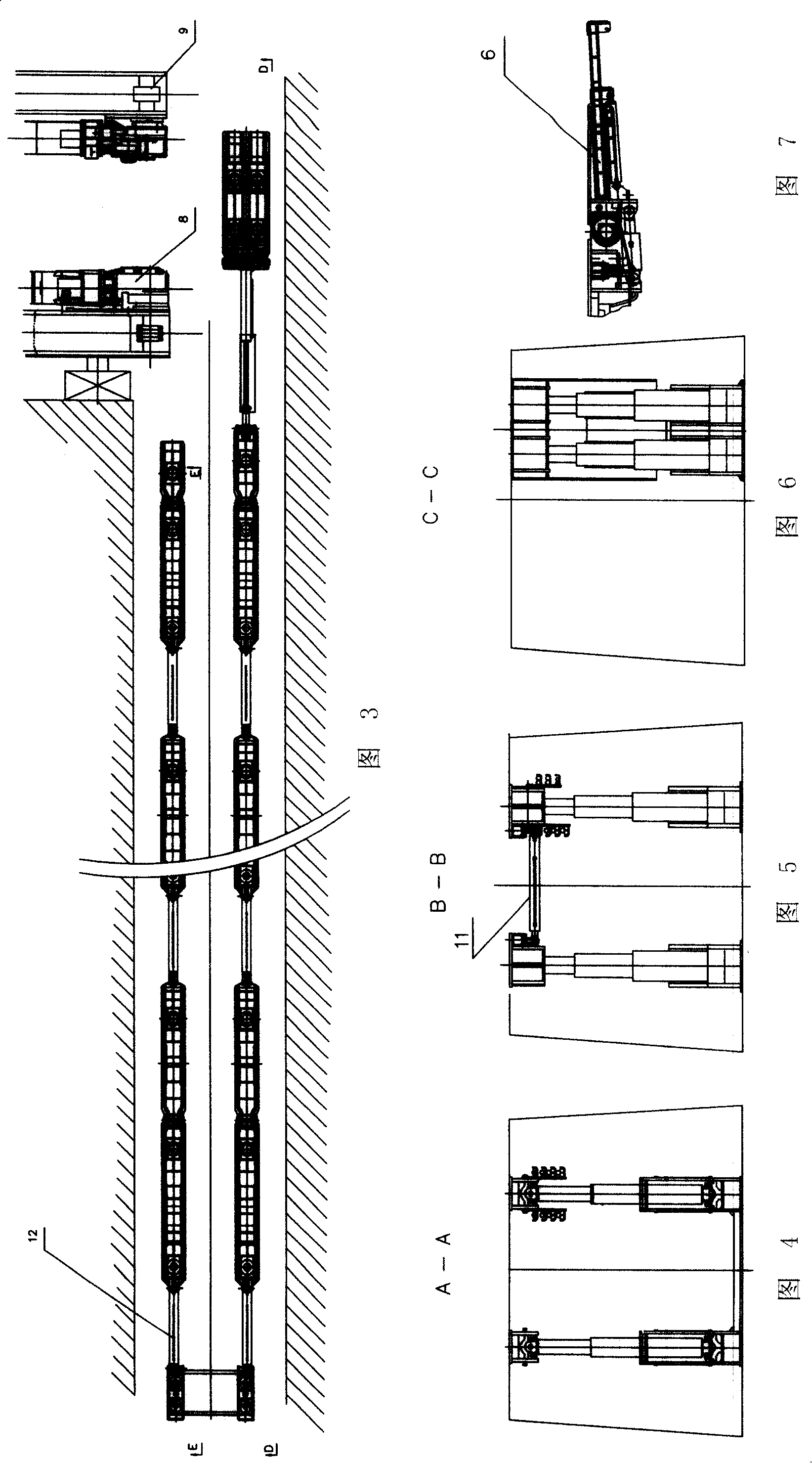

[0026] Figures 1 to 3 show the composition of the rail alignment end bracket of the fully mechanized caving face of the present invention. It is mainly composed of an anchor bracket 1, a plurality of sets of advanced brackets, and a terminal bracket 4. Anchor bracket 1, each leading bracket and end bracket 4 are connected to the whole of the cost sleeve rail along the end bracket in sequence by the pulling jack 12 between their bases.

[0027] ① The terminal bracket 4 adopts a narrow support shielding bracket with a width of 1300mm. Its structure is the same as that of general support and protection hydraulic support, consisting of top beam, base, cover beam, front beam, front probe beam, four columns, four-bar linkage mechanism, pulling jack, hydraulic control valve, hydraulic pipeline, etc.

[0028] The end support 4 adopts a narrow support shielding support to meet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com