A kind of adjustable self-moving equipment train

A self-moving equipment train and leveling technology, which is applied in earth-moving drilling, transportation and packaging, underground transportation, etc., can solve the problems of inconvenient equipment movement and assembly, large maintenance volume, easy sports car, etc. risk, ensure work safety, and ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

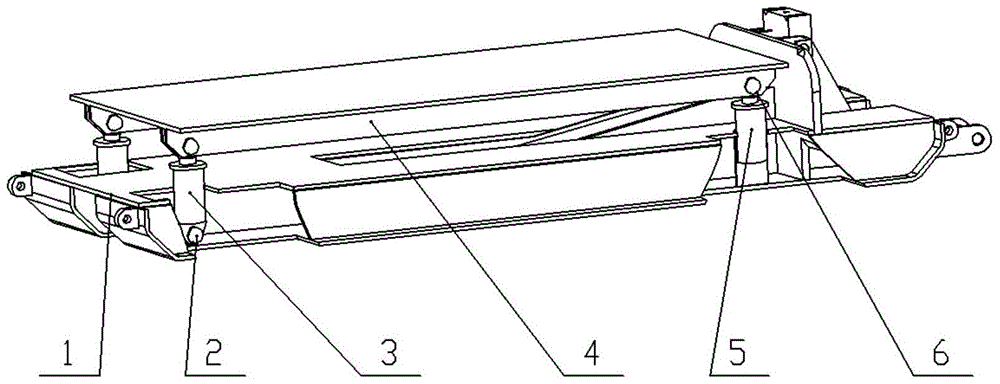

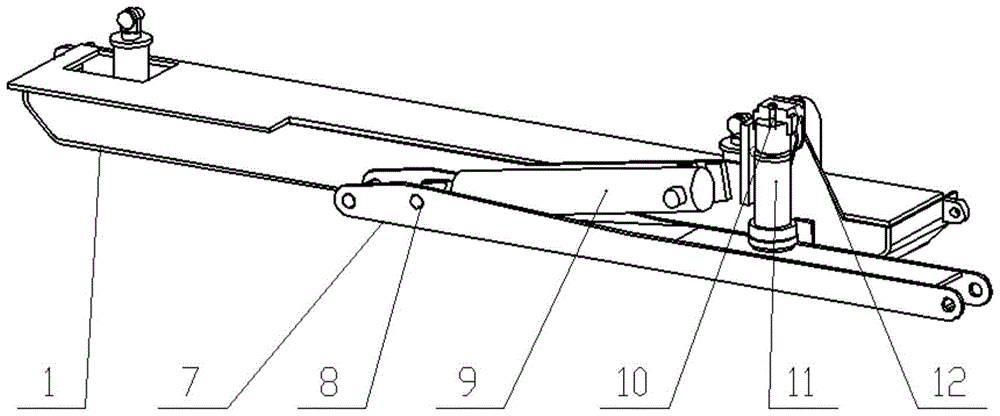

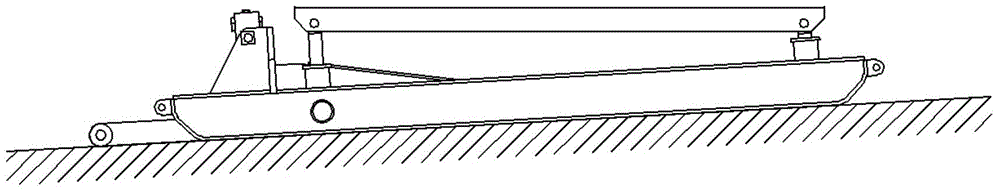

[0014] The following combined with the accompanying drawings ( Figure 1-Figure 4 ) describe the present invention in detail:

[0015] The equipment train is the key equipment to ensure the normal and continuous production in the coal mine. It mainly installs some power supplies, control devices or hydraulic power devices to provide the basis for the equipment control of the coal mine fully mechanized mining face. The existing equipment train basically adopts winch traction. Rail-type equipment trains, but this method occupies a large amount of equipment and materials, and the cost is high, and the risk of falling off the road or running a car is prone to occur during the pulling process of the winch. At the same time, when the equipment train passes the slope, it will cause some The failure of equipment that requires high levelness will directly affect the normal production of fully mechanized mining faces. Therefore, the present invention provides a train with adjustable sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com