Stepping self-moving anchoring device for equipment train

A technology for equipment trains and anchoring devices, applied in mining equipment, earth-moving drilling, mine roof support, etc., can solve the problems of high risk, heavy workload, poor stability, etc., and achieve reliable anchoring, reduce damage, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

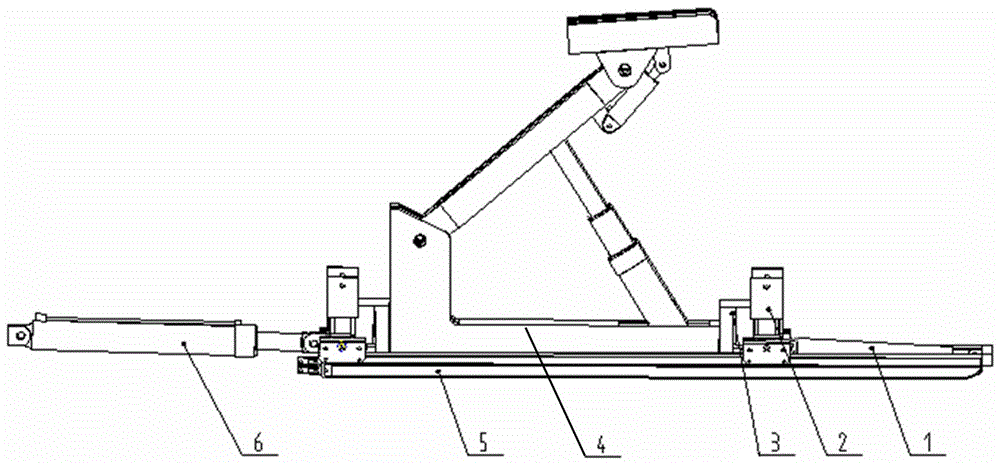

[0025] Such as figure 1 As shown, a stepping self-moving anchoring device for equipment trains includes a forward push jack 1, a lifting device 2, a deviation adjustment device 3, an anchor frame 4, a track 5 and a rear push jack 6, and the front and rear sides of the anchor frame 4 are respectively provided with There is a lifting device 2, the lower part of the lifting device 2 is provided with a track 5, and the front part of the track 5 is provided with a connecting rod. 5, the front and rear ends of the anchor frame 4 are respectively hinged with a deflection adjustment device 3, and the forward moving jack 1 is arranged on the front part of the anchor frame 4, and one end is hinged with the connecting rod of the track 5, and the other end is hinged with the anchor frame. Push jack 6 is arranged on the rear portion of anchor frame 4, and one end links to each other with anchor frame 4, and the other end is a free end, is used for being connected with equipment train.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com