A liquid pressure monitoring device and monitoring method

A technology of liquid pressure and monitoring device, applied in the field of sensing, can solve problems such as large blind area of reading, difficulty in meeting explosion-proof requirements in coal mines, and difficulty in reading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

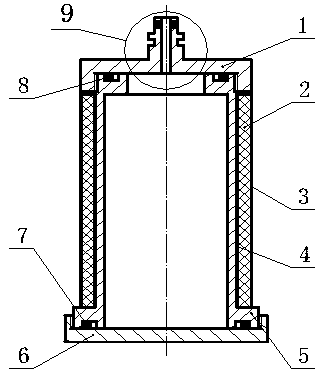

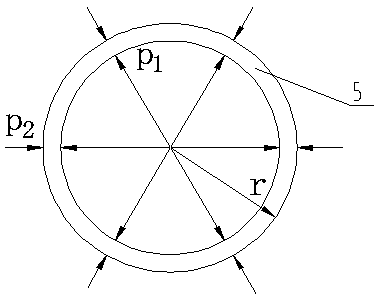

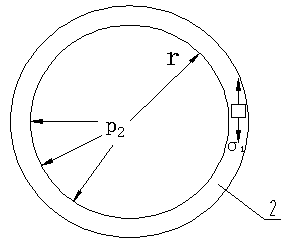

[0065] Such as figure 1 As shown, a liquid pressure monitoring device has a cylindrical structure as a whole. The upper and lower sides of the cylinder are respectively an upper end cover 1 and a lower end cover 6. The upper end cover 1 and the lower end cover 6 are respectively in contact with the middle bearing tube 5. 6 and the inner space formed by the bearing tube 5 is the bearing chamber, and the upper end cover 1, the lower end cover 6 and the bearing tube 5 are respectively connected by threads; the cross sections of the upper end cover 1 and the lower end cover 6 are U-shaped structures, and the bearing tube 5 is a The upper end of the carrying pipe 5 is provided with a concave connector, and the lower end is provided with a convex connector; the top center of the upper end cover 1 is provided with a male direct connector, which is connected with the hydraulic support; the outer side of the bearing pipe 5 is provided with a circular display The color material 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com