Detection device and detection method for axial force of anchor rod

A detection device and a technology of an anchor rod, applied in the field of sensors, can solve the problems of affecting the measurement accuracy, low sensitivity of the detection coil, poor air gap consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

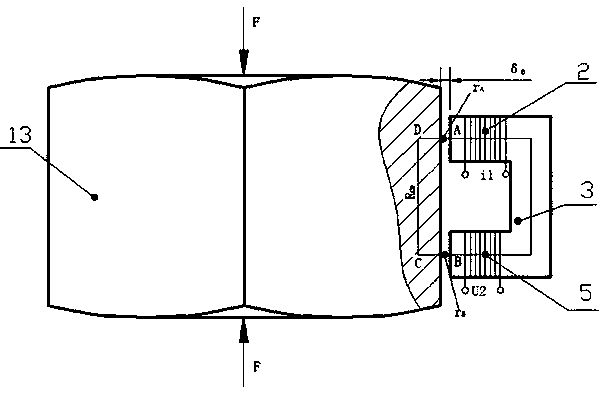

[0093] Such as figure 1 Shown is a bolt axial force detection device composed of a control circuit and a two-pole U-shaped magnetic core 3 wound with an excitation coil 2 and a detection coil 5 . When the detection device is placed on the surface of the fastening nut 13 of the tested anchor rod or at a certain air gap, and the excitation coil 2 is passed through a high-frequency alternating current, an alternating magnetic flux is generated on the excitation pole, which passes through the air. Gap and the measured bolt fastening nut 13 and the detection device constitute a closed magnetic circuit. When the bolt fastening nut 13 is subjected to the axial force F of the bolt, its magnetic permeability μ will change and the reluctance R will change, which will cause a change in the magnetic flux, and then the output voltage U2 in the detection coil 5 will change, through Measuring the magnitude of the voltage U2 can measure the magnitude of the axial force of the bolt.

[0094]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com