Application method of composite sodium-based bentonite on construction of underground continuous wall

A technology of underground diaphragm wall and sodium bentonite, which is applied in the direction of foundation structure engineering, sheet pile wall, construction, etc., to achieve effective adsorption and suspension, reduce thickness, and have significant adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

[0026] Certain underground diaphragm wall project, underground wall depth 62 meters, adopt the method for the present invention to carry out the retaining wall construction of underground diaphragm wall, promptly adopt composite sodium-based bentonite as the material of preparation retaining wall mud, and this composite sodium-based bentonite is purchased from the market , A new type of composite sodium-based bentonite produced in Northeast Liaoning, its model is "Youzuan 100".

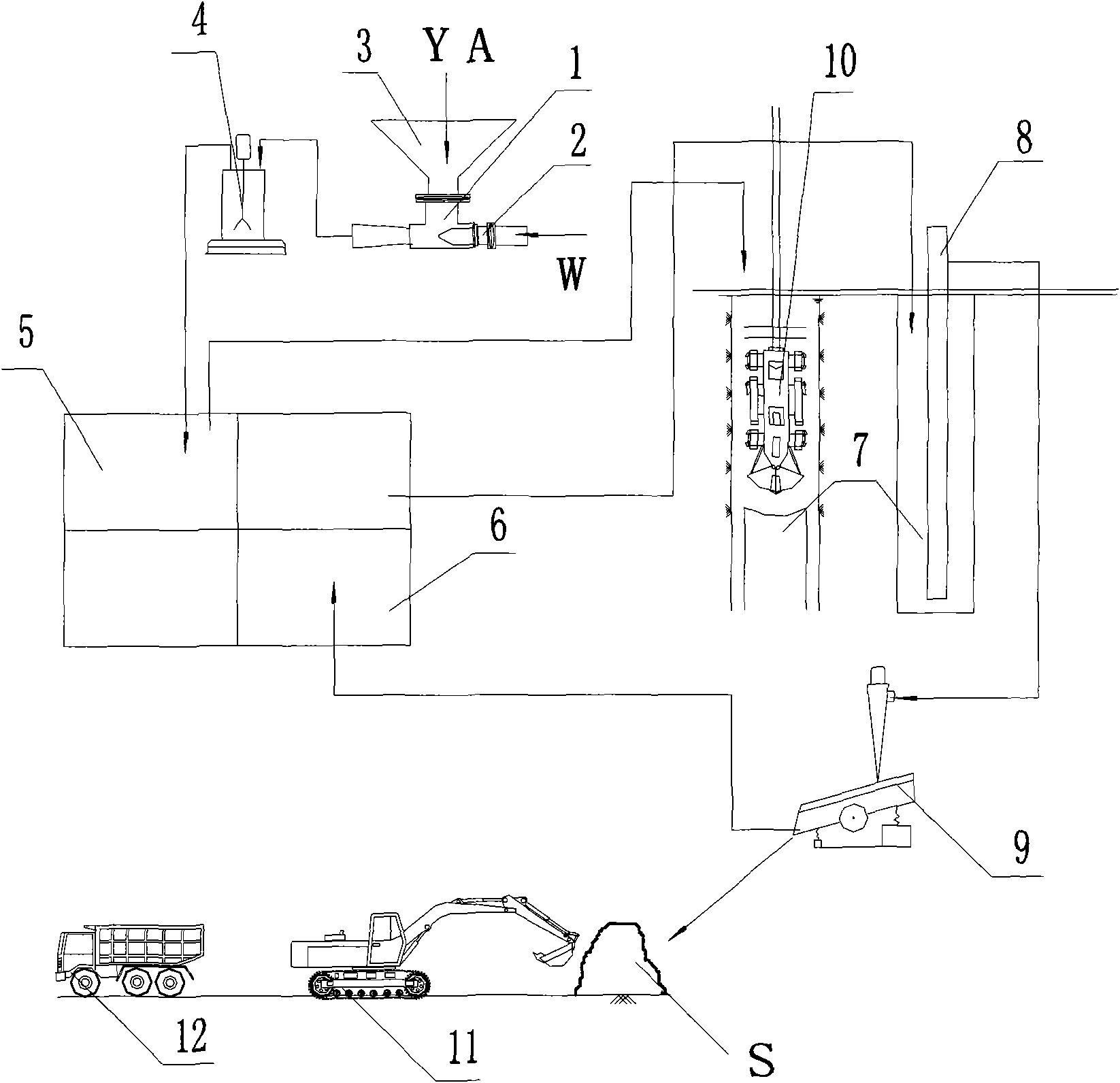

[0027] First arrange and install the mud system before construction, please refer to figure 1 , the mud system includes a mixer 1, a mud mixing tank 4, a mud storage box 5, a mud storage box 6 and a mud separation system 9, and the mud capacity of the mud storage box 6 must not be less than 3 times the volume of a single underground continuous wall .

[0028] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com