Support method used in passing water guide fracture structure in mine exploration

A technology of fracture structure and water conduction, applied in mining equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of insecure safety, roadway collapse, personal safety threats, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

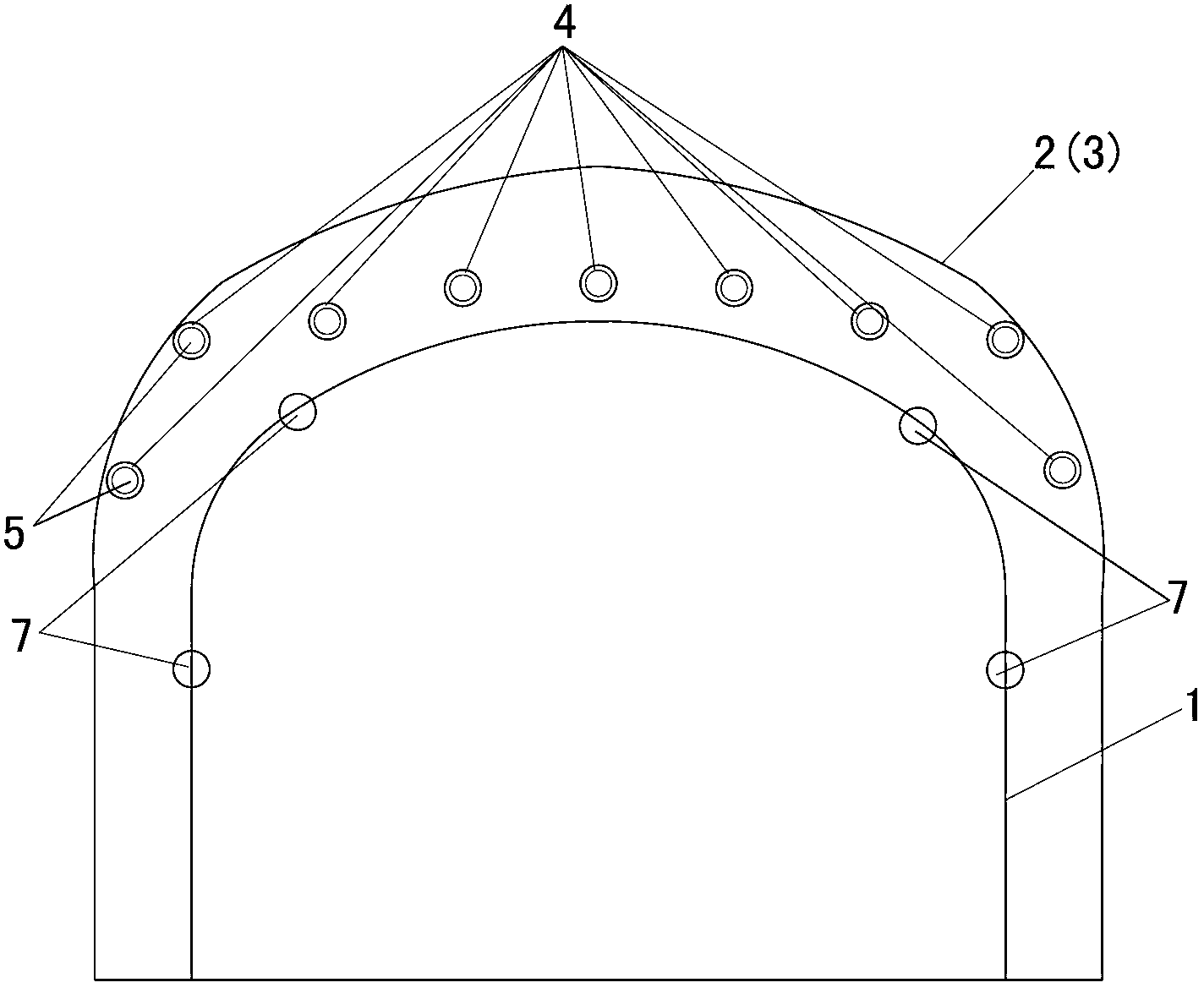

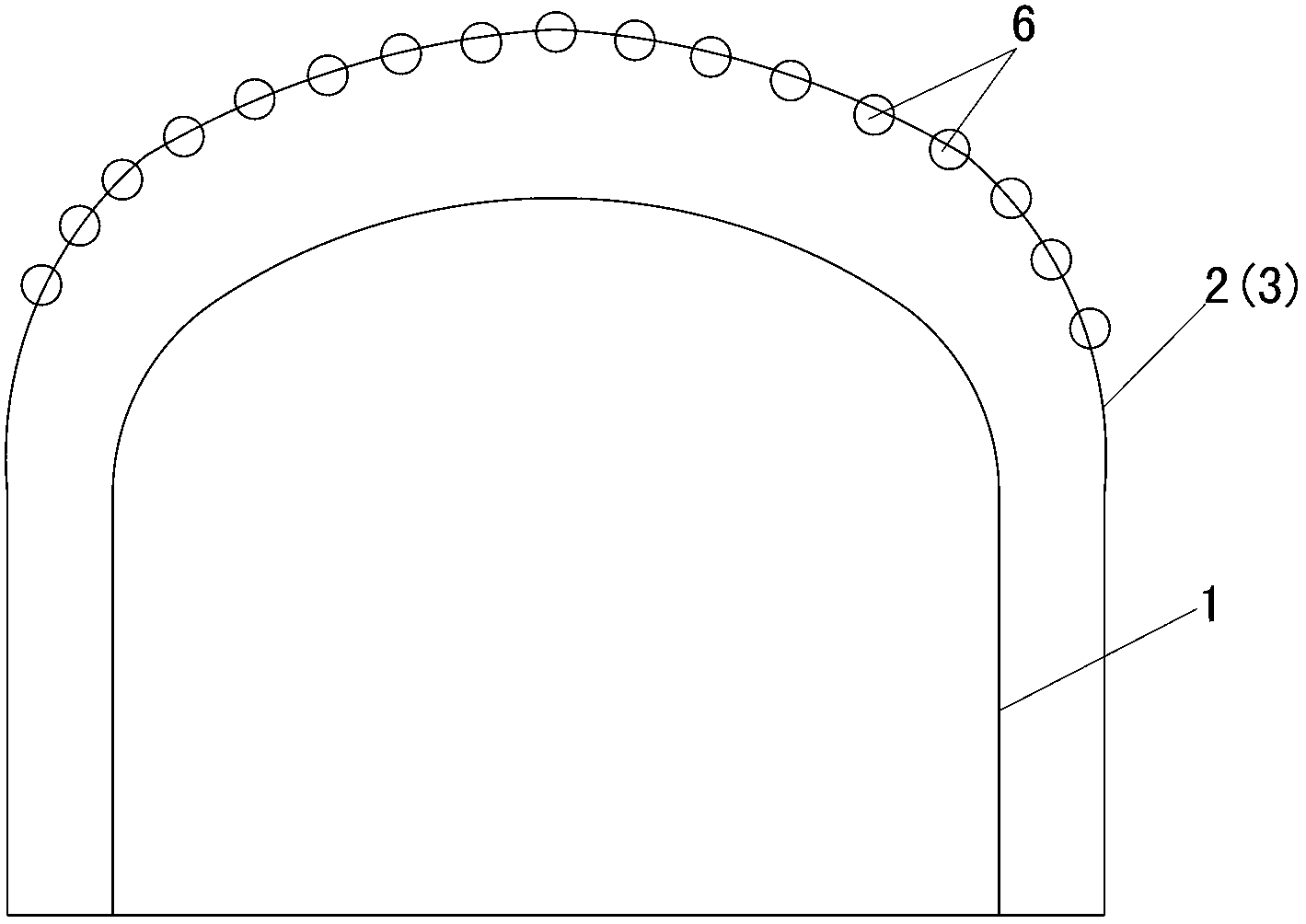

[0017] The supporting method of the water-conducting fracture structure in mine mining of the present invention comprises the following steps:

[0018] (1) Excavate an arched working roadway 1 with a cross-section of 4.2m in height and 3.4m in width along the direction perpendicular to the fault surface, and excavate a cross-section with a height of 5.2m in the circumferential direction of the wall of the working roadway 1 every 1.5m forward. m × 4.2m wide arched groove 2, in which a U-shaped steel bracket with a height of 5.2m × a width of 4.2m is placed. When the front excavation working roadway 1 is 5-10m away from the fault surface, stop the forward excavation;

[0019] (2) Afterwards, the end of the working roadway 1 is expanded, and the grouting equipment roadway 3 with a length of 3 meters is expanded forward. Grouting equipment is placed in the roadway 3 of the grouting equipment for injecting cement mortar, combined with figure 1 As shown, then the end of the roadwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com