Deep sludge continuous fishpond pipe laying construction method

A technology of pipeline installation and construction method, which is applied in the direction of pipeline laying and maintenance, pipes/pipe joints/pipe fittings, mechanical equipment, etc. The effect of reducing the amount of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

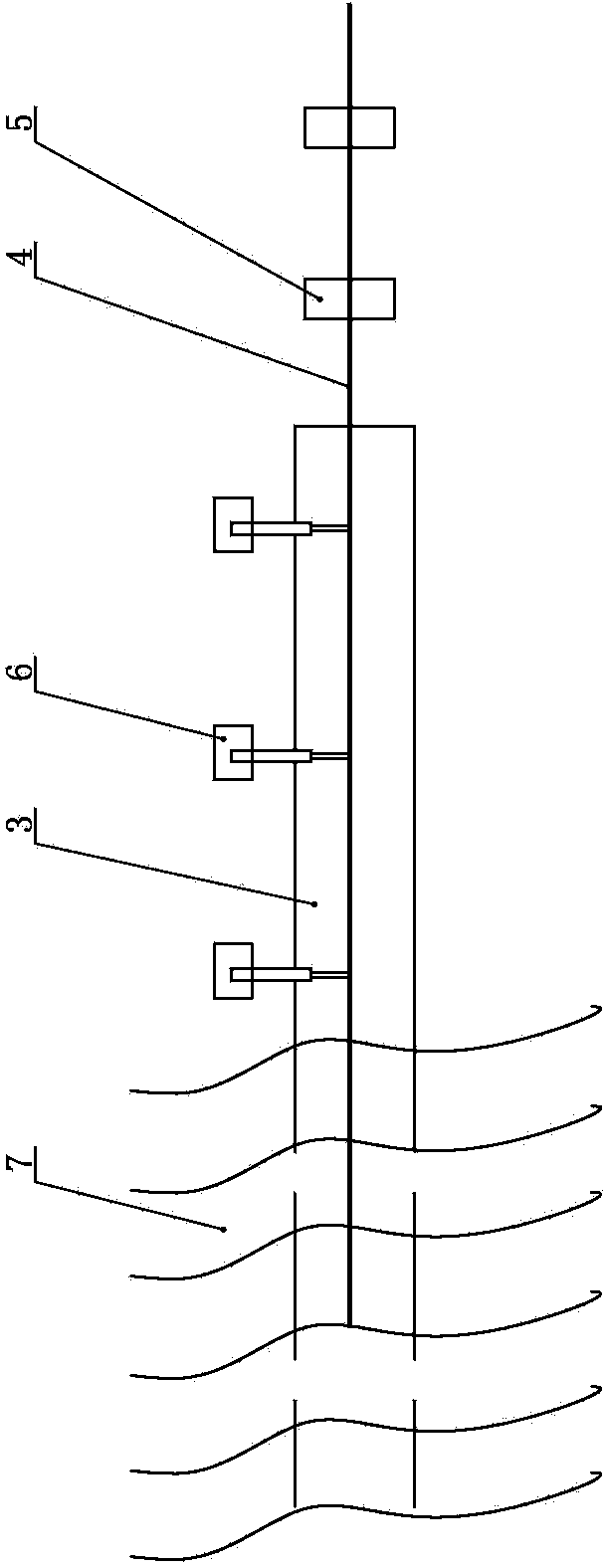

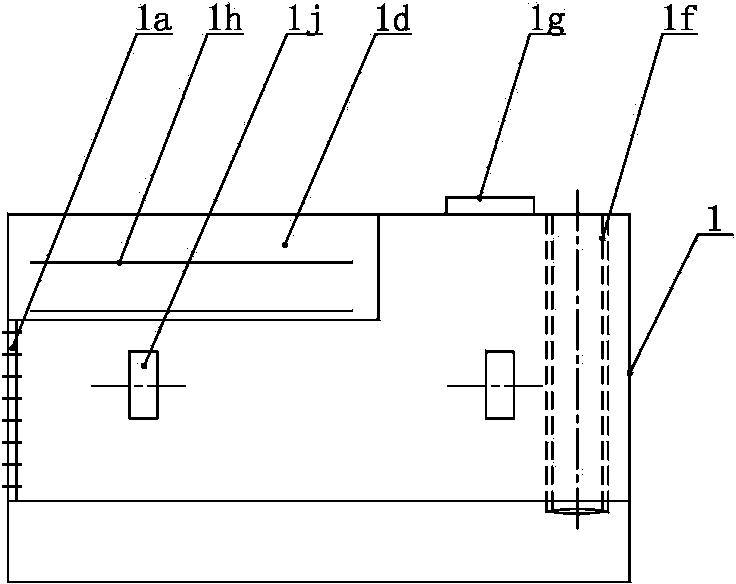

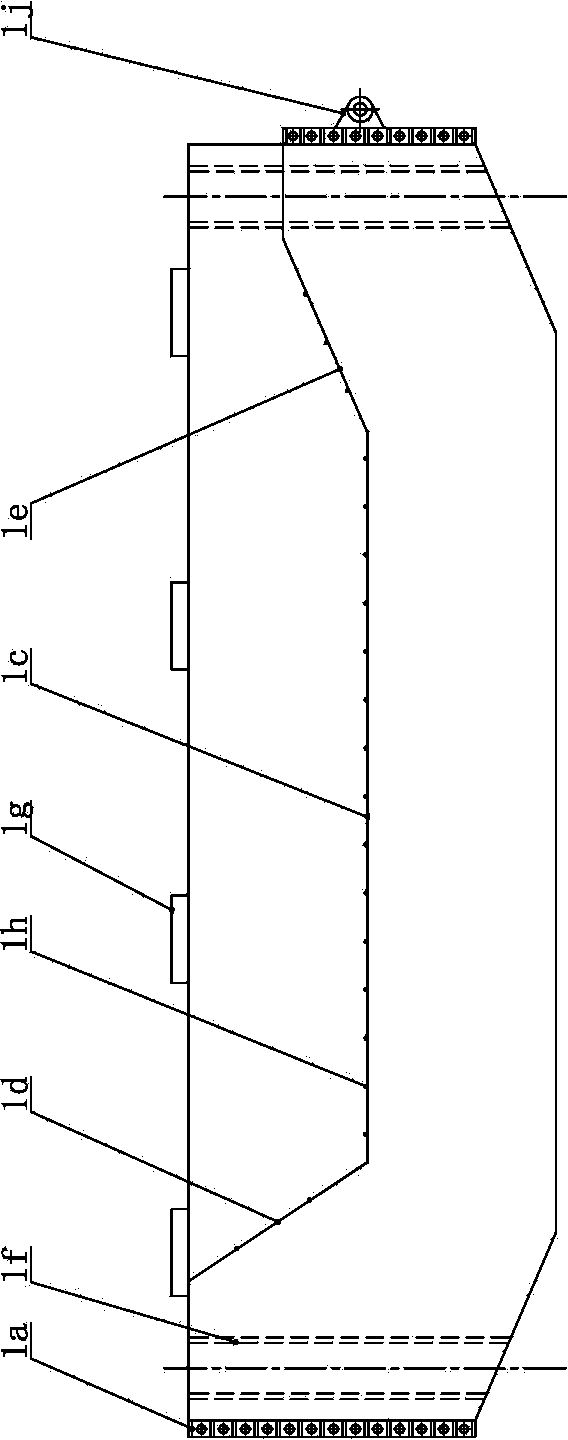

[0027] like figure 1 Shown, the deep silt continuous fishpond pipeline installation construction method of the present invention, comprises the following steps successively:

[0028] (1) Preparations before construction, including technical preparations, material preparations and equipment preparations;

[0029] (2) Measure and set out the fish pond 7 where the pipeline needs to be laid, insert a flagpole in the center of the pipeline, and clear the obstacles within 5m on both sides of the pipeline centerline. The bending radius of the pipeline is larger than the natural elastic bending radius of the pipeline, usually More than 1000 times the pipe diameter;

[0030] ⑶ Hoist the floating cabin into the water, approach the shore first, drive the excavator onto the floating cabin, check and debug the performance of the excavator, and after the safety and reliability of the walking and positioning, excavate the trench along the center line of the trench to connect the fish ponds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com