Subcooler for low-temperature liquid oxygen

A subcooler and liquid oxygen technology, applied in liquefaction, indirect heat exchanger, cold treatment separation, etc., to avoid potential safety hazards, prevent sudden temperature drop, prevent liquid nitrogen shortage or roof fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

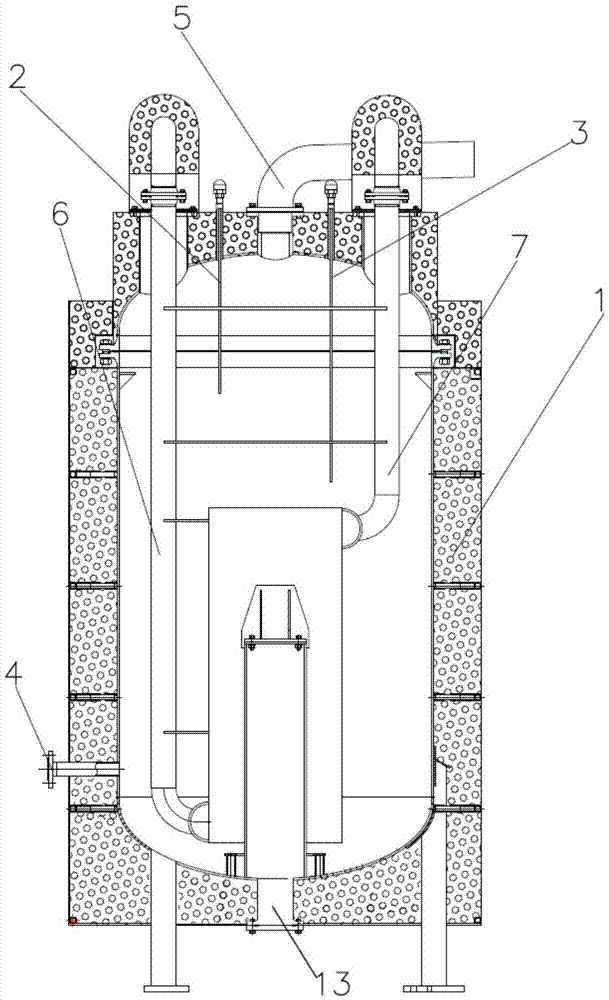

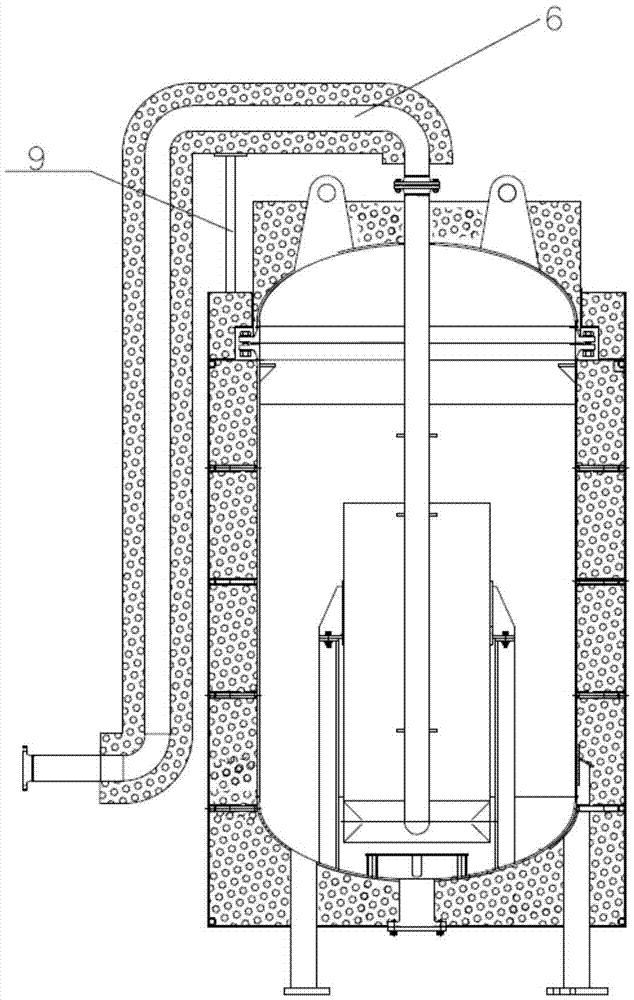

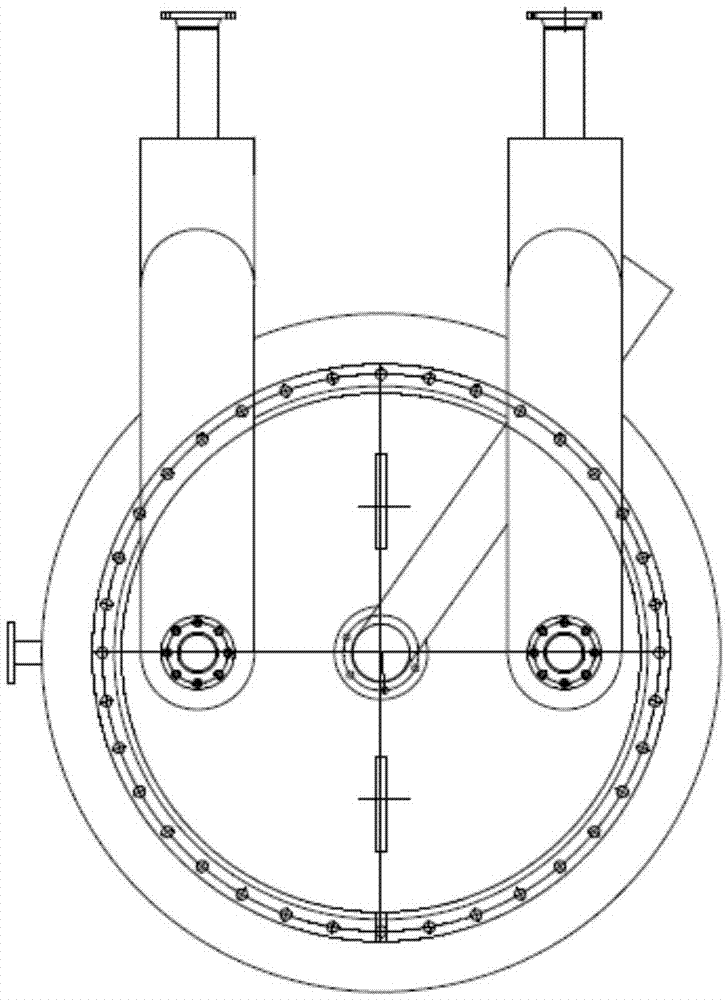

[0023] Such as figure 1 , figure 2 , image 3 As shown, a low-temperature liquid oxygen subcooler includes a liquid nitrogen storage tank 1, a cooling assembly, a high liquid level detection sensor 2 and a low liquid level detection sensor 3, and the cooling assembly is fixed on the liquid nitrogen through the cooling core support assembly. In the storage tank, the liquid nitrogen storage tank is provided with a liquid nitrogen inlet 4, a liquid nitrogen outlet and a nitrogen discharge port 5. The cooling unit includes a cooling core, a liquid oxygen input pipe and a liquid oxygen output pipe. Both the liquid oxygen input pipe 7 and the liquid oxygen 6 output pipe are connected to the cooling core; the high liquid level detection sensor is fixed on the high liquid level of the liquid nitrogen storage tank. position, the low liquid level detection sensor is fixed at the low liquid level of the liquid nitrogen storage tank. There is a filling valve at the inlet of liquid nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com