Inorganic material for reinforcement

A technology of inorganic materials and raw materials, which is applied in the installation of bolts, mining equipment, and earth-moving drilling, etc., can solve the problems of easy sticking of the slurry at the pouring port, easy fire, and complicated construction, so as to ensure safe production and safety. The effect of roadway utilization, elimination of repeated maintenance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

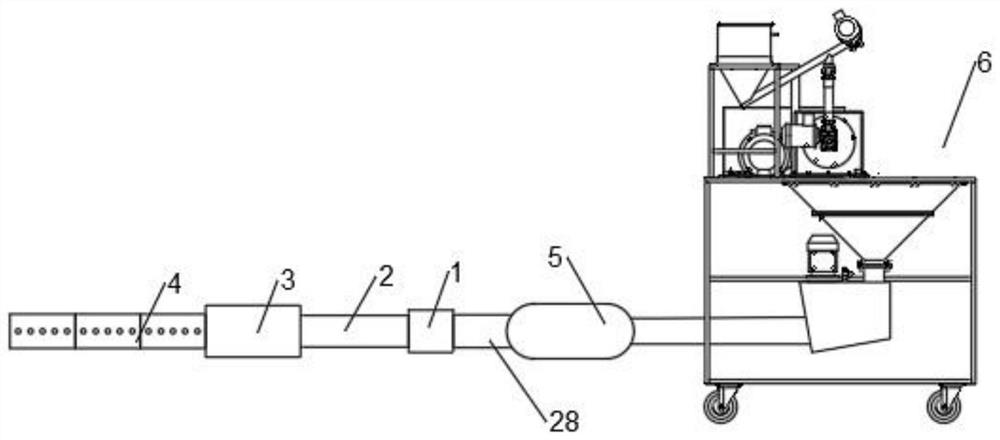

[0033] see Figure 1-6 As shown, an inorganic material for reinforcement is composed of the following raw materials in parts by weight: 30 parts of special cement, 0.1 part of quick-setting agent, 6 parts of stone powder, 0.4 part of bentonite, 0.2 part of sulfate, 0.1 part of superplasticizer, silicon 0.1 part of calcium powder, 0.1 part of early strength agent, 0 part of fine powder, 0 part of iron powder, 0.2 part of fly ash, 0.3 part of gypsum;

[0034] The strengthening process of the inorganic material includes the following steps:

[0035] S1. Use a bolter to drill a vertical anchor hole in the coal and rock mass, and insert the anchor cable into the anchor hole;

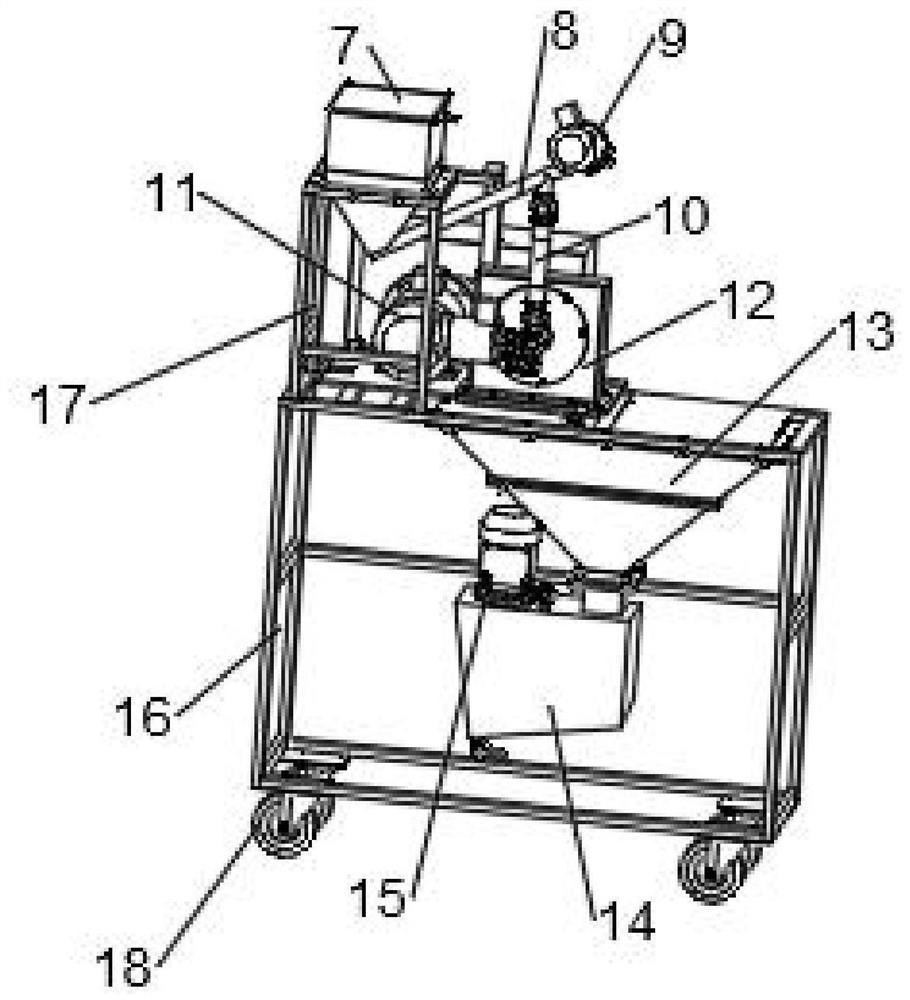

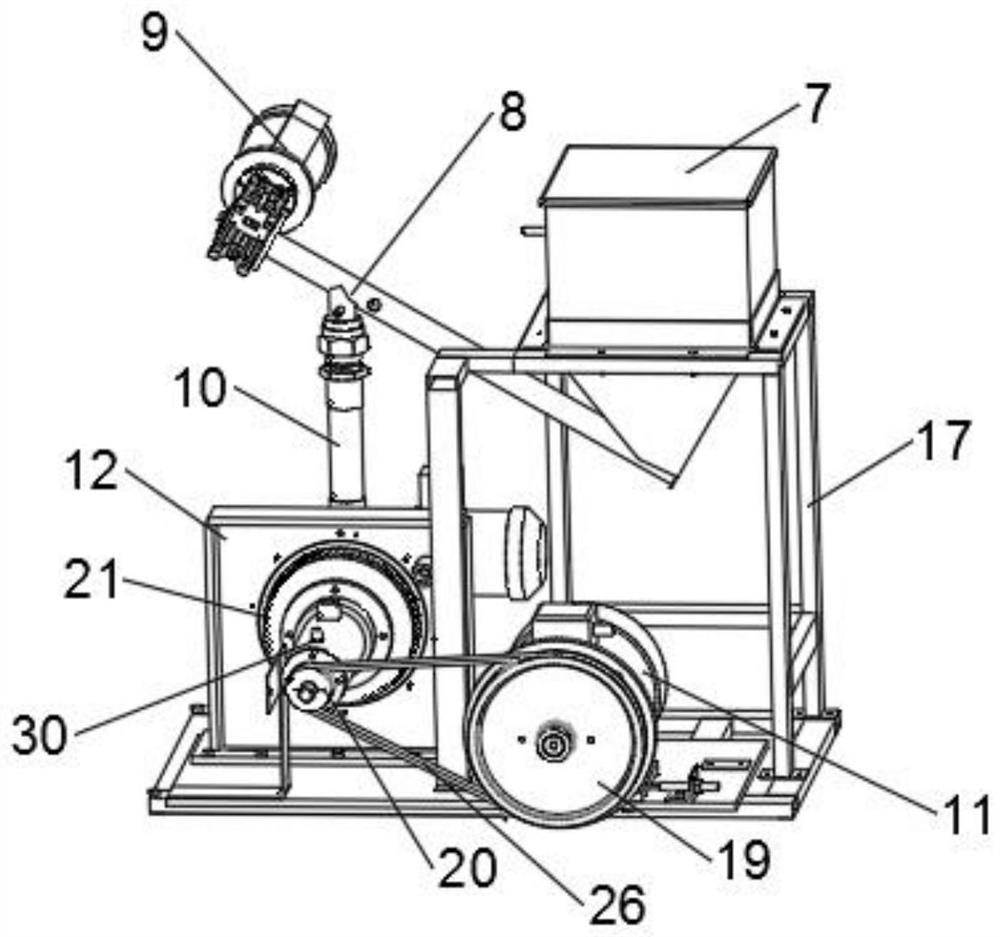

[0036] S2. First, add the inorganic materials into the feeding box 7 on the pulping device 6, then start the first drive motor 9 to drive the feeding screw to rotate, so that the inorganic materials follow the first feeding pipe 8 and the second feeding Pipe 10 enters in the pulverizing cavity in pulverizin...

Embodiment 2

[0039] An inorganic material for reinforcement, consisting of the following raw materials in parts by weight: 90 parts of special cement, 20 parts of quick-setting agent, 35 parts of stone powder, 26 parts of bentonite, 10 parts of sulfate, 15 parts of water reducing agent, and 18 parts of calcium silicate powder 17 parts of early strength agent, 10 parts of fine powder, 5 parts of iron powder, 20 parts of fly ash, 11 parts of gypsum;

[0040] The strengthening process of the inorganic material includes the following steps:

[0041] S1. Use a bolter to drill a vertical anchor hole in the coal and rock mass, and insert the anchor cable into the anchor hole;

[0042] S2. First, add the inorganic materials into the feeding box 7 on the pulping device 6, then start the first drive motor 9 to drive the feeding screw to rotate, so that the inorganic materials follow the first feeding pipe 8 and the second feeding Pipe 10 enters in the pulverizing cavity in pulverizing box 12, then,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com