The Mining Method of Small Coal Kiln Roadway Crossing Complicated Crossing at Working Face

A technology for working face and coal kiln, which is used in tunnels, ground mining, earth-moving drilling, etc., can solve problems such as restricting safety production, insufficient reinforcement of the front coal wall, and roof caving in the working face, so as to prevent roof caving accidents, improve roof conditions, The effect of enhancing coal wall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] The working face of the present invention crosses the complex small coal kiln roadway mining method, and its preferred specific implementation mode is:

[0014] Artificially adjust the layout direction of the working surface according to the following steps:

[0015] A. Start to adjust the layout direction at a distance of 30m from the small coal kiln, the tail of the machine is advanced, the tail is multi-top scraper conveyor, and the head does not top the scraper conveyor;

[0016] B. The nose and tail of the machine are pushed forward at the same time, but the nose of the machine is pushed forward, so that the layout direction of the working surface is changed again;

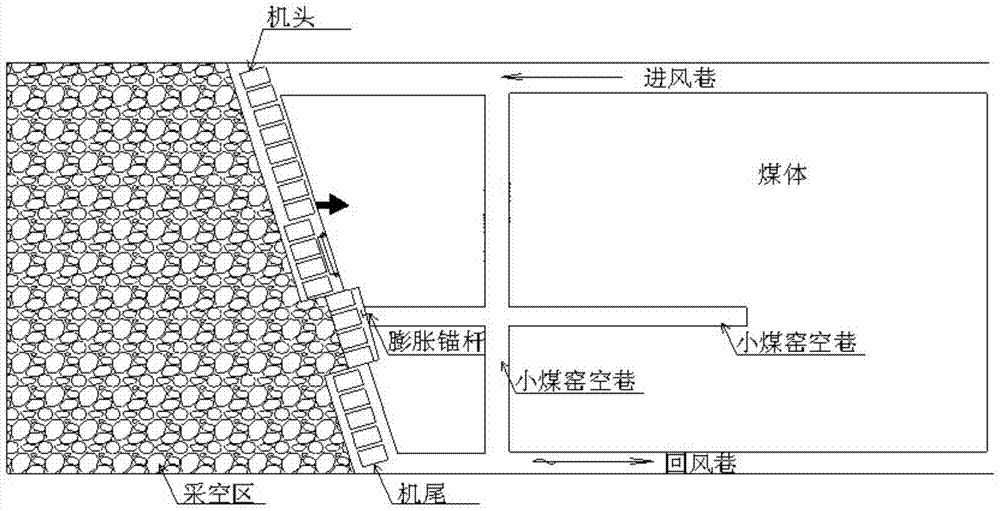

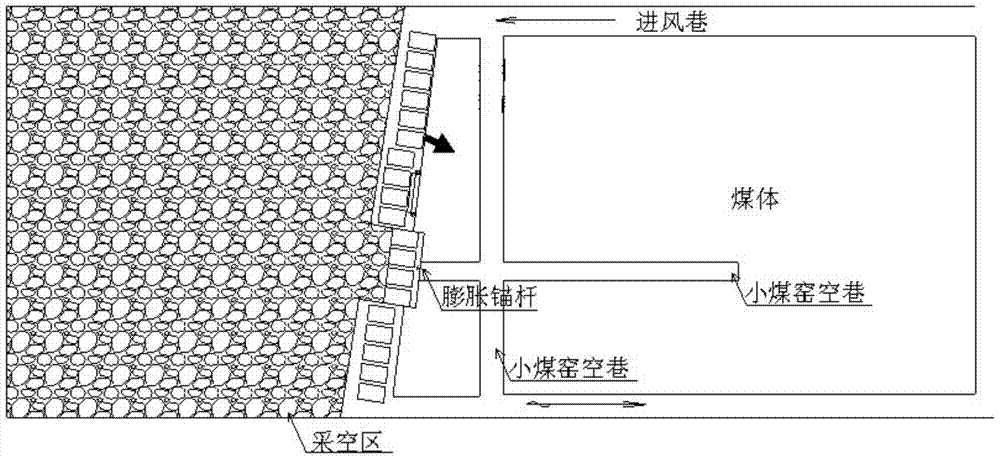

[0017] C. When the small coal kiln is about to be exposed, the working face is adjusted, and the expansion bolt is driven to the coal wall.

[0018] Lower the mining height near the small coal kiln, cut coal with the top, and insert the plate at the base if there is a separation layer at the base of t...

specific Embodiment

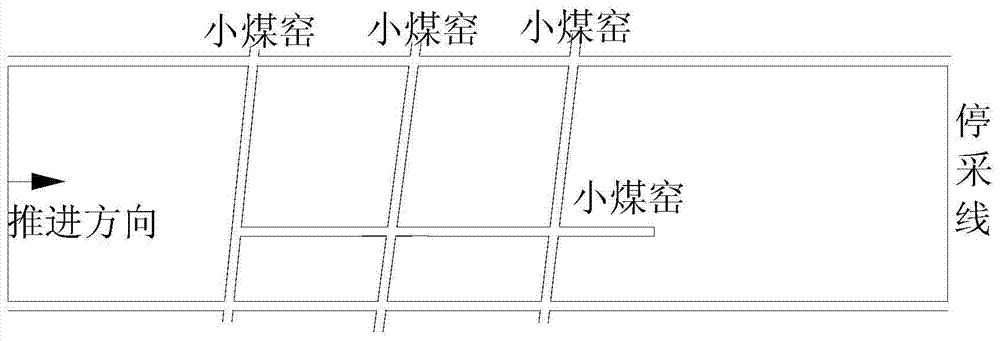

[0022] like Figure 1 to Figure 2c shown, including steps:

[0023] 1. Artificially adjust the layout direction of the working surface:

[0024] ① Adjust the layout direction at a distance of about 30m from the small coal kiln. The tail of the machine is advanced, and the tail of the machine is multi-topped with scraper conveyors, and the head of the machine is not topped with scraper conveyors.

[0025] ②Then the nose and tail of the machine are pushed forward at the same time, but the nose is pushed forward, so that the layout direction of the working surface is changed again.

[0026] ③Advance to the time when the small coal kiln is about to be exposed, and the working face is adjusted. And hit the expansion bolt to the coal wall.

[0027] 2. In the vicinity of small coal kilns, the mining height should be appropriately reduced, and the coal should be cut at the top. If there is a separation layer at the base of the support, you can insert a plate at the base.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com