A mine fiber grating roof detachment monitoring device and monitoring method

A fiber grating and roof separation technology, which is applied in the direction of using optical devices, measuring devices, mining devices, etc., can solve the problem that the automatic continuous monitoring and data transmission of roof separation cannot be realized, the safety and reliability of roadways and mining projects. It can solve problems such as early warning of abscission data, and achieve the effect of good monitoring effect, strong anti-electromagnetic interference ability, and avoidance of roof collapse accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

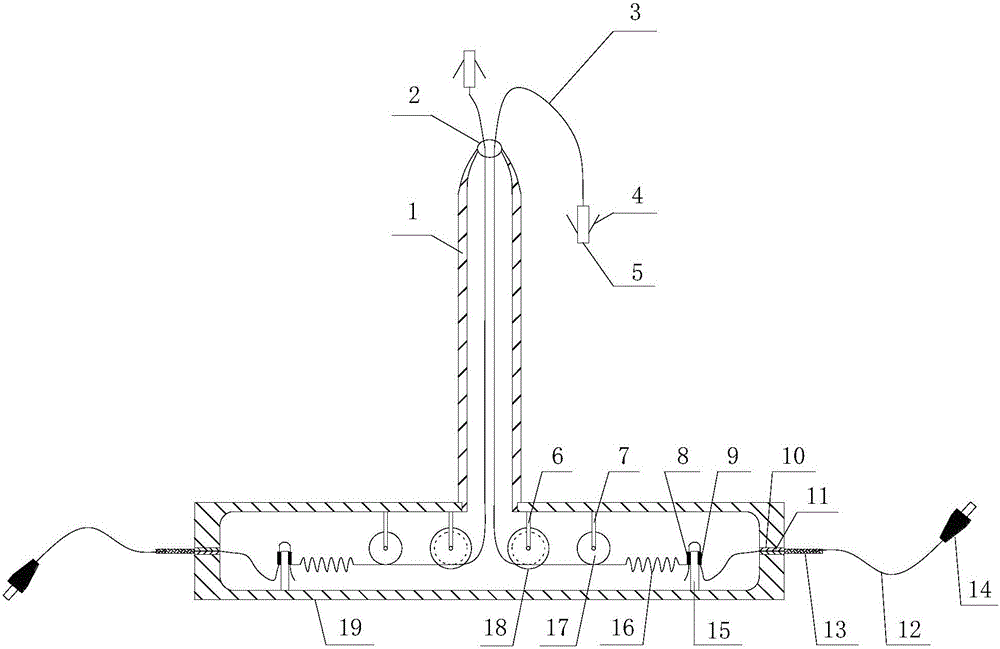

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

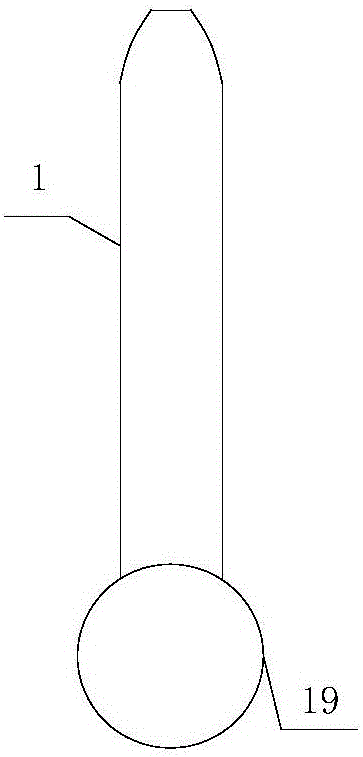

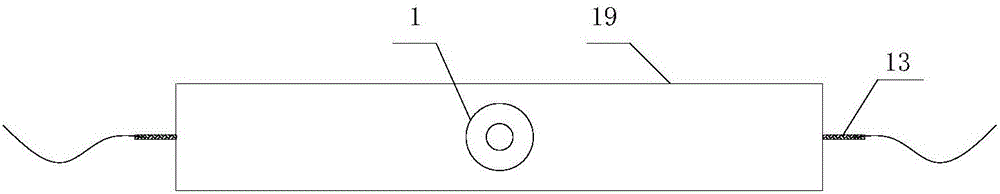

[0035] As shown in the figure, the fiber grating roof detachment monitoring device for mining of the present invention includes a vertical measuring cylinder 1 arranged in the drilling hole of the roof, the diameter of the vertical measuring cylinder 1 is 30-35mm, and the length is 250-350mm. The casing 19 is connected to the lower end of the vertical measuring cylinder 1, and the fixed pulley fixing frame 6 and the steel pulley fixing frame 7 are symmetrically arranged on the upper part of the packaging casing 19, and the equal strength cantilever beam 15 is symmetrically arranged on the lower part, and the left and right sides of the packaging casing 19 Optical fiber export holes 10 are opened symmetrically on the side, a fixed pulley 18 is provided on the pulley fixed frame 6, a steel belt pulley 17 is provided on the steel belt wheel fixed frame 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com